In the realm of outdoor equipment, having a clear visual representation of individual elements is essential for effective maintenance and repair. Such illustrations serve as invaluable resources, guiding users through the intricate assembly of various machinery. By studying these visuals, one can enhance their comprehension of the overall functionality.

Moreover, these representations provide insights into the relationship between components, ensuring that every piece operates harmoniously. They are particularly useful for those seeking to optimize performance or address specific issues that may arise during usage. Ultimately, a detailed view fosters confidence in tackling repairs and modifications.

Whether you are a seasoned professional or a novice enthusiast, familiarizing yourself with these schematics is a crucial step toward achieving efficiency and longevity in your equipment. This knowledge empowers individuals to take proactive measures, ensuring their tools remain in top condition.

Overview and Features

This section provides a comprehensive look at a specific outdoor equipment model, highlighting its essential attributes and advantages. Designed for efficiency and user-friendliness, this machine caters to various landscaping needs, ensuring optimal performance in diverse conditions.

Key Attributes

- Robust construction for durability

- Powerful engine for enhanced performance

- Ergonomic design for comfortable handling

Benefits

- Improves productivity and efficiency

- Versatile usage for different tasks

- Easy maintenance for long-lasting operation

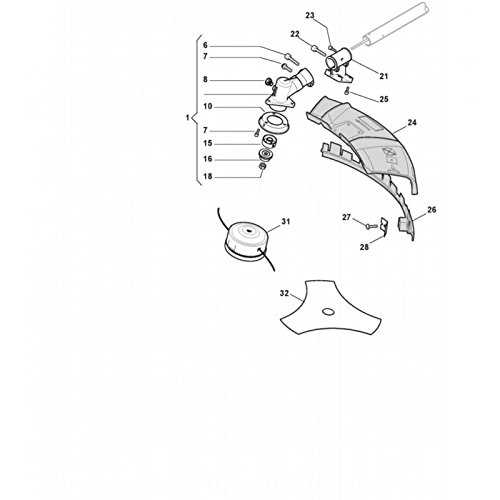

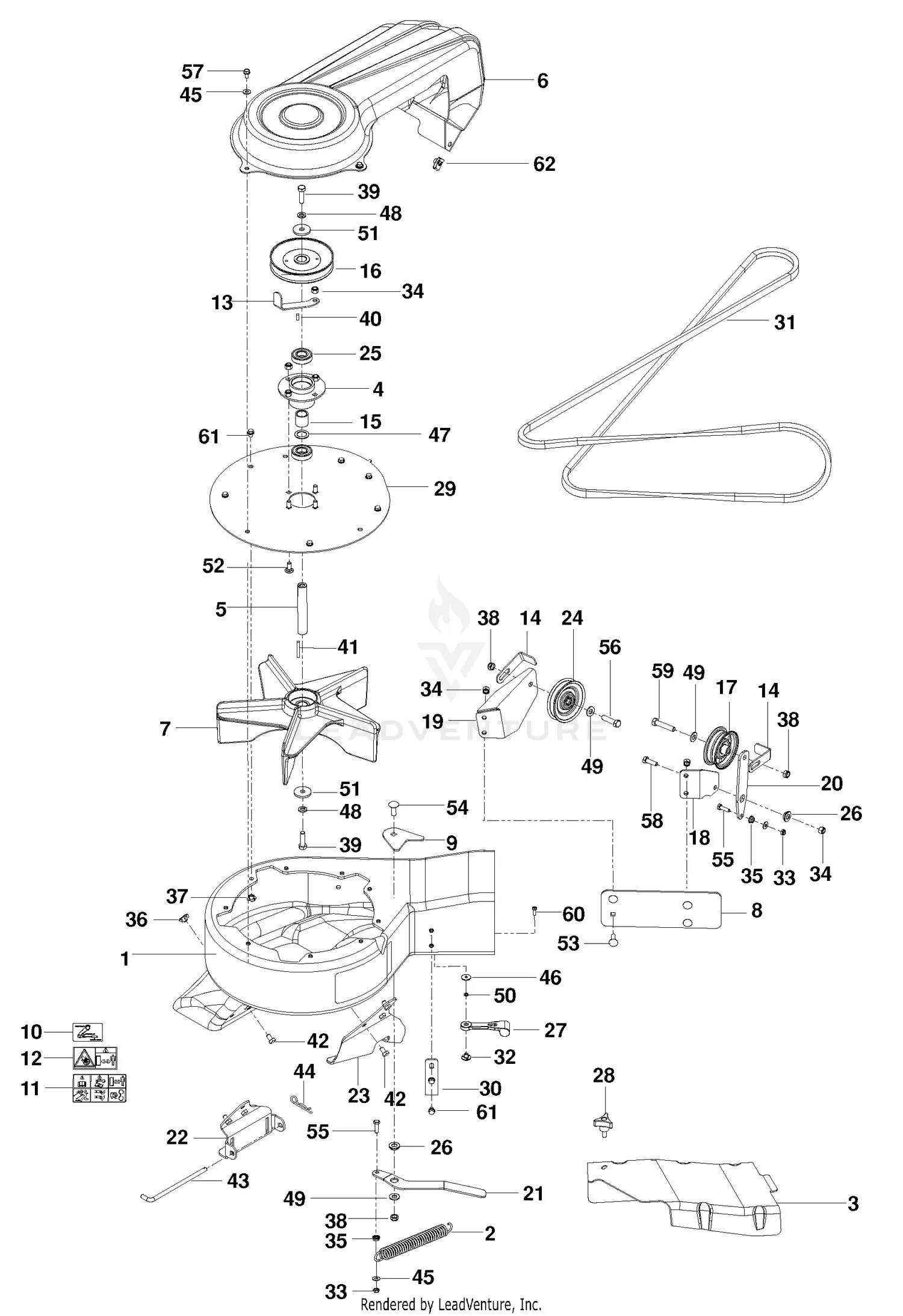

Understanding the Parts Diagram

Comprehending the layout of components is essential for effective maintenance and repair of equipment. Such visual representations offer a clear overview of how various elements interact, facilitating a deeper understanding of functionality. By breaking down complex machinery into identifiable sections, users can pinpoint specific areas for attention or replacement.

These schematics serve as invaluable references, particularly when troubleshooting issues or conducting routine inspections. They illustrate the arrangement and connections of each piece, enabling operators to visualize the entire system’s operation. Recognizing the role of each component can significantly enhance efficiency and prolong the lifespan of the equipment.

Furthermore, utilizing these visuals helps in ensuring that replacements are accurate and compatible. When parts need to be sourced, having a detailed illustration simplifies the process, reducing the risk of errors. Engaging with these layouts not only improves technical skills but also fosters a more informed approach to equipment care.

Common Issues and Solutions

In any mechanical system, users often encounter recurring challenges that can impede performance. Understanding these common obstacles and their remedies is essential for maintaining efficiency and longevity. This section aims to highlight frequent problems along with effective strategies for resolution.

One prevalent issue is difficulty in starting the device. This can often be attributed to fuel blockages or a drained battery. Ensuring that fuel lines are clear and the battery is fully charged can resolve this problem.

Another frequent concern is uneven operation. This may arise from worn components or misalignment. Regular inspections and timely replacements can help restore smooth functionality.

Overheating is also a common complaint. It typically results from inadequate cooling or excessive strain on the system. Ensuring proper ventilation and monitoring usage can prevent this issue from escalating.

Lastly, abnormal noise can indicate underlying problems. Loose parts or improper assembly are often the culprits. Conducting routine checks and tightening connections can mitigate these sounds and enhance overall performance.

Where to Find Replacement Parts

When it comes to maintaining your equipment, locating the right components is crucial for optimal performance. Whether you’re looking for specific pieces or general supplies, there are various avenues to explore.

- Authorized Dealers: Start by visiting certified retailers that specialize in your equipment brand. They often carry a comprehensive range of genuine components.

- Online Marketplaces: Websites such as Amazon, eBay, and specialized online stores provide a wide selection. Make sure to read reviews and check seller ratings to ensure quality.

- Local Repair Shops: Many repair facilities offer spare components or can order them for you. Consulting with professionals can also provide insights into which parts are most reliable.

- Manufacturer’s Website: The official website usually has a dedicated section for replacements, including detailed descriptions and compatibility information.

- Forums and Community Groups: Engaging with online communities can yield valuable advice and even sources for hard-to-find items.

By exploring these options, you can efficiently source the necessary components to keep your equipment running smoothly.

Maintenance Tips for Longevity

Ensuring the long-term functionality of your equipment requires regular care and attention. By implementing effective maintenance practices, you can significantly extend the lifespan of your tools and devices. Consistent upkeep not only enhances performance but also minimizes the likelihood of unexpected failures.

Start with a routine inspection, checking for any signs of wear or damage. Look for loose components, frayed wires, or accumulated debris that could hinder operation. Keeping the working area clean and free from obstructions is also essential to prevent unnecessary strain on moving parts.

Lubrication is a key factor in maintaining smooth operation. Regularly apply appropriate lubricants to moving components to reduce friction and prevent rust. Be sure to follow manufacturer recommendations for specific products and intervals.

Another crucial aspect is ensuring that filters and other essential parts are regularly replaced or cleaned. This helps maintain optimal performance and efficiency. Keeping a maintenance log can also be beneficial, allowing you to track service dates and any repairs made.

Finally, store your equipment in a dry, temperature-controlled environment to prevent damage from moisture or extreme temperatures. Proper storage practices contribute significantly to the longevity and reliability of your tools.

Comparing Toro Models

When selecting a piece of outdoor equipment, it’s crucial to understand the differences between various models available on the market. Each variant comes with unique features that cater to different needs, making it important to analyze their specifications and performance.

Here are some key factors to consider when comparing different models:

- Performance: Look at engine power, cutting efficiency, and operational speed.

- Durability: Assess the materials used in construction and overall build quality.

- Ease of Use: Evaluate user-friendly features such as controls, weight, and maneuverability.

- Maintenance: Consider how easy it is to perform routine maintenance and access components.

- Price Range: Compare costs and value for money based on features offered.

By thoroughly examining these elements, you can make a more informed decision that aligns with your specific requirements and preferences.

Here’s a brief comparison of popular models:

- Model A: Known for its robust engine and high cutting capacity, ideal for larger lawns.

- Model B: Offers advanced features and a lightweight design, perfect for small to medium-sized areas.

- Model C: Emphasizes durability and long-term reliability, suitable for commercial use.

Choosing the right equipment requires careful consideration of these various aspects to ensure optimal performance for your outdoor tasks.

User Reviews and Experiences

This section aims to provide insights into the experiences and feedback from users regarding a specific product. Understanding real-life applications and user satisfaction can greatly influence potential buyers. Below are some common themes highlighted in user reviews.

- Performance: Many users have praised the effectiveness of the equipment, noting its ability to handle various tasks with ease.

- Durability: Several reviewers emphasized the robust construction, stating that it withstands regular use and harsh conditions.

- Ease of Use: Many users appreciated the intuitive design, making operation straightforward even for beginners.

- Maintenance: Some feedback focused on the simplicity of upkeep, with users noting that parts are easy to access and replace when necessary.

Moreover, specific anecdotes highlight the versatility of the product. Users have shared experiences about using it in diverse environments, ranging from residential to commercial settings, showcasing its adaptability.

- Customer Service: Reviewers have mentioned their interactions with support teams, often reflecting positively on the responsiveness and helpfulness.

- Value for Money: Many users feel that the investment is justified, considering the long-term performance and reliability.

- Comparative Analysis: Some users compared it with similar products, often concluding that it offers superior functionality and features.

In conclusion, the collective feedback provides a well-rounded perspective, helping prospective buyers make informed decisions based on the experiences of others.

Assembly and Disassembly Instructions

This section provides a comprehensive guide for the proper assembly and disassembly of your equipment, ensuring optimal performance and longevity. Understanding these procedures is essential for maintenance and repair tasks, allowing users to handle components safely and efficiently.

Before beginning, ensure that you have all necessary tools and components on hand. Familiarize yourself with the layout and functionality of each part, as this knowledge will facilitate a smoother process. Always refer to the provided specifications for torque settings and alignment guidelines to achieve a secure fit.

To disassemble, start by removing any fasteners or connectors that secure the parts together. Carefully take apart the sections, noting the order and orientation of each piece. It may be helpful to take pictures or label components to avoid confusion during reassembly.

When assembling, follow the reverse order of disassembly. Ensure that each part is clean and free from debris before installation. Secure each component tightly, but avoid overtightening, which could damage the materials. After reassembly, perform a thorough inspection to verify that everything is properly aligned and secured.

Following these instructions will help maintain the integrity of your equipment, enhancing its efficiency and lifespan. Regular maintenance checks will also ensure that all components remain in good condition, preventing potential issues down the line.