In the realm of lawn maintenance, comprehending the intricate layout of machinery is essential for both enthusiasts and professionals. A thorough understanding of the individual elements that comprise such equipment can significantly enhance performance and longevity. This section aims to provide a comprehensive overview of these essential components, facilitating better maintenance practices.

Each machine consists of various components, each serving a specific purpose. By familiarizing oneself with these parts, users can effectively troubleshoot issues and optimize their equipment’s functionality. This knowledge empowers operators to carry out repairs and replacements with confidence, ensuring their machinery operates smoothly and efficiently.

Furthermore, recognizing the significance of each element promotes informed decision-making when it comes to upgrades or replacements. A detailed exploration of the various sections within the equipment will aid users in identifying the best practices for upkeep and enhance overall user experience. Understanding these fundamentals is key to achieving optimal results in lawn care and maintenance.

This section will delve into the essential components of a well-known lawn maintenance machine, highlighting its key features and functionality. Understanding these elements is crucial for effective maintenance and operation, ensuring optimal performance for various landscaping tasks.

- Introduction to the Equipment

Overview of the machinery, its purpose, and significance in landscaping operations.

- Key Features and Specifications

A detailed description of the main features and technical specifications that define the model.

- Major Components Breakdown

An outline of the significant elements that comprise the unit, emphasizing their roles.

- Maintenance Essentials

Guidelines on routine upkeep practices necessary to maintain the machine’s efficiency.

- Common Issues and Troubleshooting

Insights into typical problems users might encounter and solutions for resolving them.

- Replacement Part Options

Discussion on available alternatives for components, including OEM and aftermarket options.

- Assembly and Disassembly Instructions

Step-by-step guidance on how to safely take apart and reassemble the machinery for repairs or maintenance.

- Conclusion and Final Thoughts

Summarizing the importance of understanding the various parts and their functions for effective usage.

Key Components of the Mower

Understanding the essential elements of a lawn care machine is crucial for effective maintenance and optimal performance. Each component plays a specific role in ensuring the equipment operates smoothly and efficiently, contributing to a well-manicured lawn. This section highlights the primary parts that comprise the mower and their significance in its functionality.

Essential Elements

The following table outlines the main components and their respective functions within the mowing equipment:

| Component | Function |

|---|---|

| Engine | Powers the mower, enabling movement and blade rotation. |

| Deck | Houses the blades and directs grass clippings. |

| Blades | Cuts the grass to the desired height. |

| Wheels | Facilitates mobility and maneuverability across various terrains. |

| Handle | Provides control and direction during operation. |

Importance of Regular Maintenance

Regular upkeep of these crucial parts ensures longevity and reliability. By keeping each component in optimal condition, users can achieve better mowing results and extend the lifespan of their equipment.

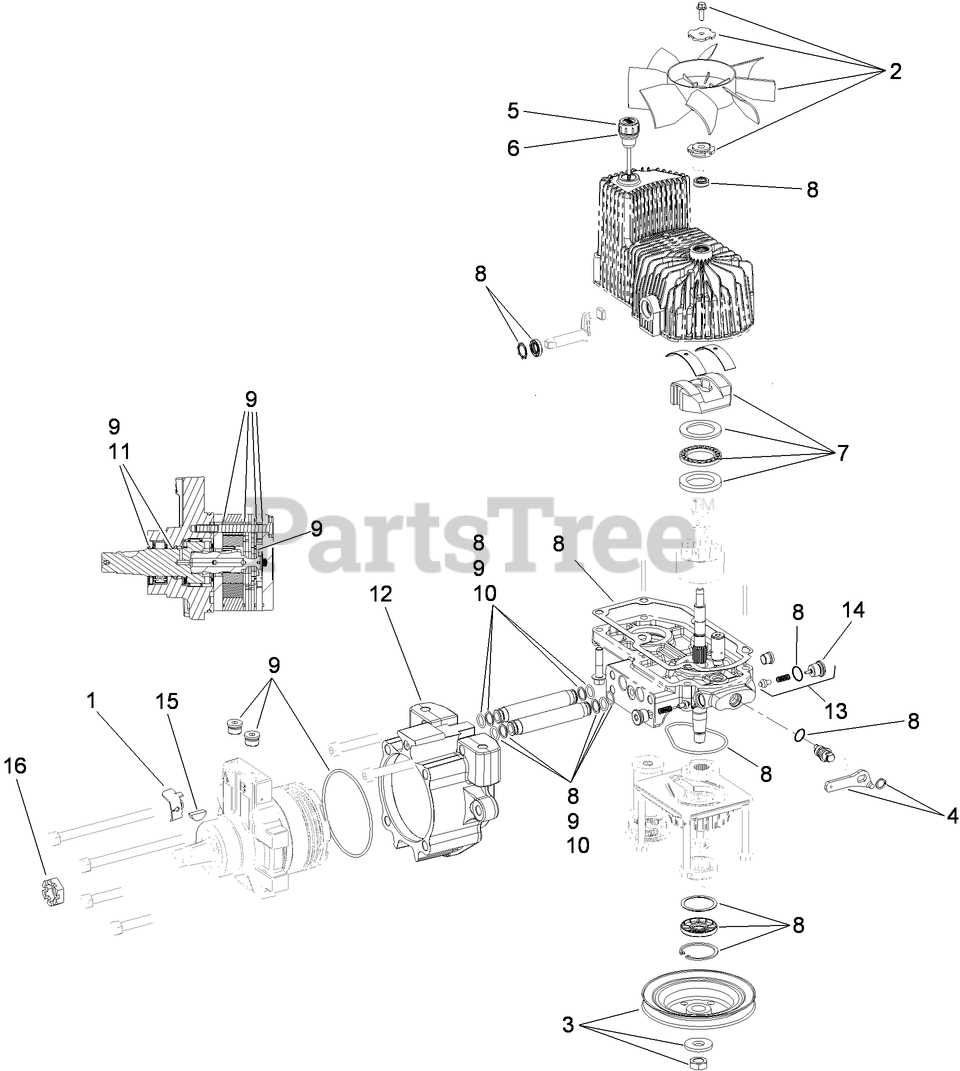

Understanding the Parts Layout

This section provides an overview of the arrangement of components within the equipment, offering insights into how they function together to achieve optimal performance. Grasping this layout is essential for effective maintenance and troubleshooting.

Each component plays a vital role in the overall operation, and recognizing their locations and connections can significantly enhance the understanding of the machinery’s functionality. The layout is typically organized in a systematic manner, allowing for efficient access and replacement of each element.

- Engine: Central to the machinery’s operation, providing the necessary power.

- Transmission: Responsible for transferring power from the engine to the wheels.

- Fuel System: Ensures a steady supply of fuel to the engine for combustion.

- Electrical Components: Control various functions and provide ignition.

- Hydraulic System: Powers movement and operation of attachments.

- Chassis: The framework that supports all other components.

Familiarizing oneself with these elements can lead to improved operational efficiency and longevity of the machinery. Regular inspections and a clear understanding of the layout will facilitate prompt identification of issues, ensuring smooth performance.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for enhancing the lifespan of your equipment. By following a few straightforward practices, you can ensure optimal performance and prevent costly repairs down the line. Routine maintenance not only prolongs functionality but also enhances safety during operation.

Routine Checks

Conducting regular inspections helps identify potential issues early. Here are some key areas to focus on during your checks:

| Component | Inspection Frequency | Key Considerations |

|---|---|---|

| Oil Level | Before each use | Ensure the oil is clean and at the correct level. |

| Blades | After every 10 hours of use | Check for sharpness and damage; sharpen as needed. |

| Filters | Monthly | Clean or replace to maintain airflow and efficiency. |

| Tires | Weekly | Inspect for wear and proper inflation. |

Seasonal Maintenance

Adapting your maintenance routine to the changing seasons can greatly benefit your equipment’s durability. Prioritize specific tasks based on usage patterns and environmental factors.

Common Issues and Solutions

When operating complex machinery, users often encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their corresponding fixes is essential for maintaining optimal functionality.

Frequent Challenges

- Difficulty in starting the engine

- Unusual noises during operation

- Inconsistent cutting performance

- Vibrations that affect stability

- Fluid leaks from the system

Proposed Solutions

- Check the fuel level and ensure the fuel is fresh.

- Inspect the spark plug for wear and replace it if necessary.

- Examine the blades for sharpness and damage, sharpening or replacing them as needed.

- Tighten any loose bolts or screws that may contribute to vibrations.

- Identify the source of leaks and replace worn seals or hoses.

Regular maintenance and attention to these issues can significantly enhance the longevity and performance of the equipment.

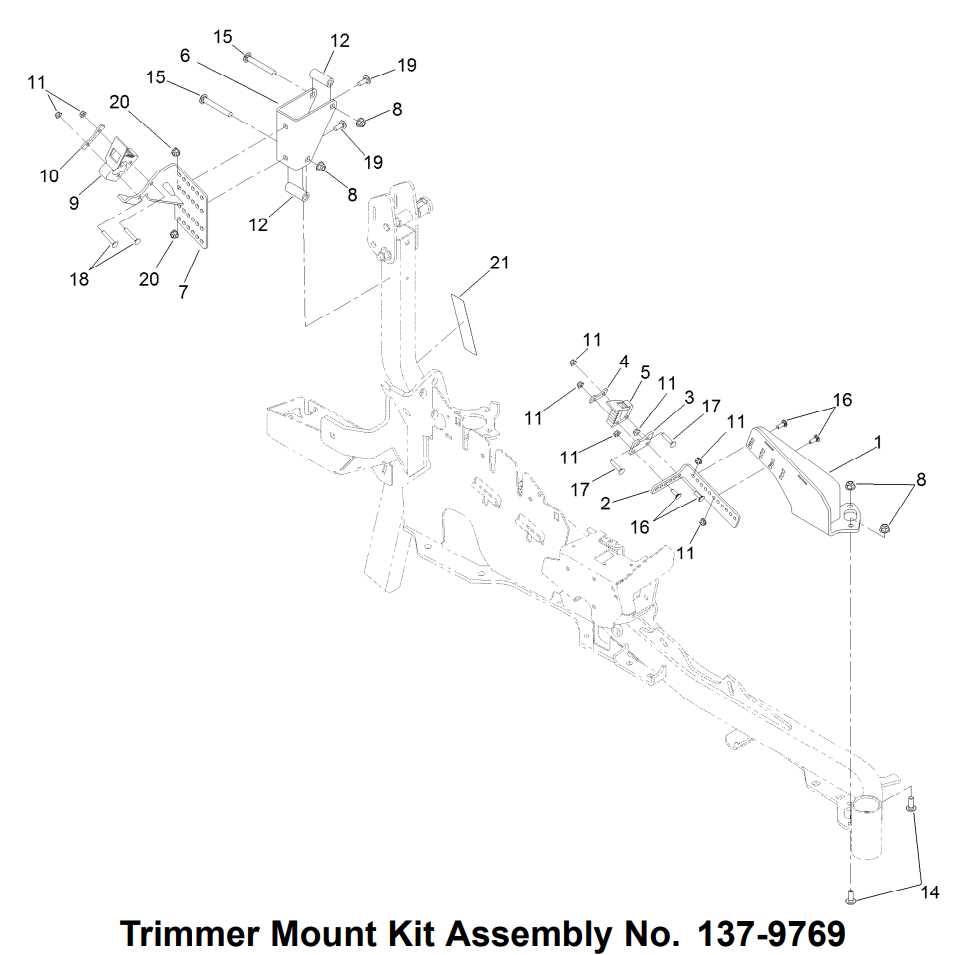

Parts Replacement Procedures

This section outlines essential steps for substituting components within your equipment, ensuring optimal performance and longevity. Understanding the proper methods for exchanging these elements can significantly enhance functionality and reduce the risk of malfunctions.

Preparation for Replacement

Before beginning the replacement process, ensure you have the necessary tools and replacement components at hand. Always refer to the user manual for specific guidance related to the model in question. It is advisable to wear safety gear and work in a clean, well-lit environment to prevent accidents.

Replacement Steps

Start by disconnecting the power source to ensure safety during the procedure. Carefully remove the existing component, taking note of its placement for easier installation of the new part. Follow the reverse order for installation, ensuring all connections are secure. Finally, conduct a thorough inspection to confirm everything is properly aligned and functional.

Finding Compatible Replacement Parts

When maintaining outdoor equipment, it is essential to ensure the components used are suitable for optimal functionality. Identifying appropriate alternatives can enhance performance and extend the lifespan of your machinery. This section will guide you through the process of selecting compatible replacements for your equipment.

Understanding Compatibility Criteria

To make informed decisions, it is crucial to understand the factors influencing compatibility. Key elements include specifications, dimensions, and material quality. Consulting the user manual or manufacturer’s guidelines can provide valuable insights into which features are necessary for a successful match.

Resources for Sourcing Alternatives

Several resources are available to assist in locating suitable replacements. Online retailers and specialized stores often have extensive catalogs of components that meet compatibility requirements. Additionally, forums and community groups can be excellent platforms for gathering recommendations from experienced users who have faced similar challenges.

Importance of Genuine Toro Parts

Using authentic components is essential for maintaining the performance and longevity of any machinery. Genuine replacements are designed to fit perfectly and work seamlessly with existing systems, ensuring optimal functionality. This compatibility helps prevent potential issues that can arise from using inferior alternatives.

Moreover, original components often come with warranties that offer peace of mind. These assurances reflect the manufacturer’s confidence in their products, providing assurance that the equipment will operate as intended. This investment in quality can save both time and money in the long run.

Choosing certified components also supports the efficiency of the machine. Authentic items undergo rigorous testing to meet specific standards, leading to improved reliability and reduced risk of failure. By prioritizing these high-quality options, operators can maximize productivity and minimize downtime.