In the realm of automotive engineering, comprehending the layout of various vehicle components is essential for effective maintenance and repairs. A well-structured visual representation can significantly aid both technicians and enthusiasts in navigating the intricate relationships between different elements within a vehicle. This understanding can enhance one’s ability to diagnose issues and facilitate seamless integration when replacing or upgrading components.

Detailed illustrations serve as valuable resources, providing insights into the arrangement and functionality of critical elements. By exploring these representations, individuals can gain a clearer perspective on how each component interacts with others, ensuring that any modifications or repairs are conducted with precision. Whether it’s for routine maintenance or performance enhancements, having a thorough grasp of these layouts is invaluable for anyone engaged in the care of their vehicle.

Furthermore, the availability of comprehensive schematics empowers users to make informed decisions about their automotive projects. Understanding the connections and configurations allows for better troubleshooting and optimization of performance. As we delve into this topic, we will explore the various aspects that contribute to a well-functioning vehicle and highlight the importance of a clear visual guide in achieving automotive excellence.

Overview of 2008 Toyota Tacoma Parts

This section provides a comprehensive look at the components that make up a particular model from a well-known automotive manufacturer. Understanding the various elements that contribute to the overall functionality and performance of the vehicle can enhance maintenance and repair efforts, ensuring longevity and reliability.

Essential Components

The vehicle is designed with numerous critical components that work together to deliver a smooth driving experience. From the engine and transmission to the suspension and braking system, each element plays a vital role. Familiarity with these components is crucial for anyone looking to perform repairs or upgrades effectively.

Maintenance Considerations

Regular upkeep of these various elements is essential for optimal operation. Ensuring that each component is functioning correctly not only improves performance but also contributes to safety on the road. Identifying wear and tear early can prevent more significant issues down the line, making proactive maintenance a priority for vehicle owners.

Understanding Engine Components Layout

The arrangement of various mechanical elements within an engine plays a crucial role in its overall functionality and efficiency. Each component serves a specific purpose, contributing to the effective operation of the entire system. Gaining insight into this layout allows enthusiasts and technicians to comprehend how different parts interact and influence performance.

Main Components Overview

Engine assembly consists of several key elements that work together harmoniously. Below are the primary components involved:

- Cylinder block

- Pistons

- Crankshaft

- Camshaft

- Valves

- Timing belt or chain

Functional Relationships

Understanding the interrelations among these components is essential for diagnosing issues and enhancing performance. Key interactions include:

- The crankshaft converts linear motion from pistons into rotational motion.

- Camshaft controls the timing of valve openings and closings.

- Pistons compress air-fuel mixtures, facilitating combustion.

Familiarity with these layouts and functions enables individuals to maintain and optimize engine performance effectively.

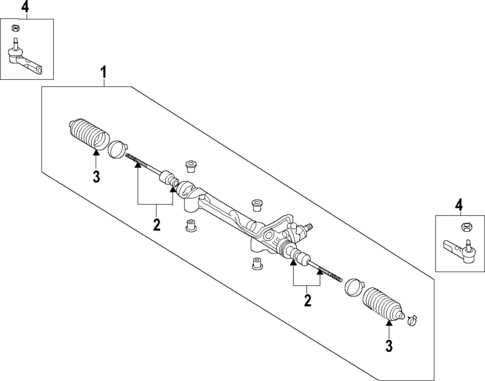

Suspension System Overview and Parts

The suspension mechanism is a critical component of any vehicle, providing stability, comfort, and handling during travel. It plays a vital role in ensuring that the wheels maintain contact with the road, thus enhancing traction and reducing wear on other systems. Understanding the various elements of this mechanism can help in appreciating how vehicles manage dynamic forces and maintain balance on uneven surfaces.

Key Components of the Suspension Mechanism

The main constituents of the suspension mechanism include various links, springs, and dampers. Links connect different parts and allow for relative movement, while springs absorb energy from impacts, ensuring a smooth ride. Dampers, or shock absorbers, control the oscillations caused by the springs, providing better stability during operation.

Functionality and Benefits

The effective operation of this mechanism not only improves ride quality but also enhances overall safety. By absorbing bumps and shocks from the road, the suspension system minimizes the impact on passengers and cargo. Furthermore, a well-designed suspension can improve handling characteristics, allowing drivers to navigate turns and obstacles more confidently.

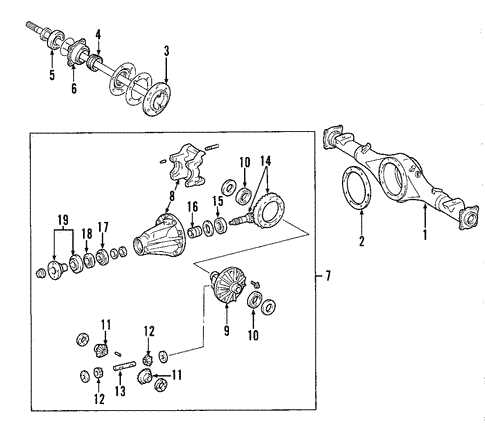

Transmission Assembly and Related Parts

The transmission assembly is a critical component of any vehicle’s drivetrain, responsible for managing the power generated by the engine and ensuring smooth transitions between various speeds. Understanding the various elements that comprise this system is essential for maintenance and repair, as well as for enhancing overall vehicle performance.

This section will outline the key components found within the transmission assembly and their functions, providing insight into how they work together to facilitate effective operation.

| Component | Description |

|---|---|

| Transmission Housing | The outer casing that encases all internal components, protecting them from external elements. |

| Input Shaft | Transmits engine power to the transmission, allowing for gear engagement. |

| Output Shaft | Delivers power from the transmission to the driveshaft, enabling wheel movement. |

| Gear Set | A series of gears that regulate torque and speed, allowing for various driving conditions. |

| Torque Converter | Facilitates smooth power transfer from the engine to the transmission, especially during starts and low-speed driving. |

| Shift Forks | Assist in the movement of gears within the transmission, enabling gear changes. |

| Fluid Pump | Maintains fluid pressure within the transmission, ensuring effective lubrication and cooling of components. |

Electrical System Components Explained

The electrical framework of a vehicle is vital for its operation, facilitating communication between various elements and ensuring functionality. Understanding these components is essential for diagnosing issues and performing maintenance effectively.

At the core of this framework lies the battery, which serves as the primary energy source, supplying power to all electrical systems. A robust alternator is also crucial, as it recharges the battery and powers the vehicle’s electrical components while the engine is running.

Additionally, wiring harnesses connect different systems, enabling the flow of electricity and data. Fuses play a protective role, safeguarding circuits from overloads and preventing potential damage. Switches and relays further control electrical flow, allowing for user input to engage various functions, such as lighting and ignition.

Finally, sensors are integral, providing feedback to the vehicle’s computer systems, which monitor and adjust operations for optimal performance. A thorough understanding of these elements contributes significantly to the overall efficiency and reliability of the vehicle.

Brake System Breakdown and Parts

The braking mechanism of a vehicle is essential for ensuring safety and control during operation. Understanding the components involved in this system can help in maintaining optimal performance and identifying potential issues before they become serious. This section provides an overview of the various elements that contribute to effective braking, enabling drivers to appreciate the importance of each part.

Main Components of the Braking Mechanism

The braking mechanism typically includes a variety of crucial elements such as calipers, rotors, pads, and hydraulic systems. Each component plays a specific role in the overall functionality, from generating friction to transferring force. Regular inspection and maintenance of these components are vital to prevent wear and ensure reliable stopping power.

Recognizing the signs of wear in the braking system is critical for vehicle safety. Common indicators include squeaking noises, reduced responsiveness, and vibrations during braking. Regular checks of the brake fluid level and replacing worn pads can significantly enhance performance and extend the lifespan of the entire system.

Interior Features and Associated Parts

The cabin of a vehicle is designed to provide comfort, convenience, and functionality. Various elements contribute to a well-rounded experience, ensuring that every journey is enjoyable. This section highlights the essential components that enhance the interior environment, focusing on their roles and how they interact to create a cohesive user experience.

Comfort and Convenience

Key components such as seating arrangements, climate control systems, and storage solutions play a vital role in passenger comfort. Ergonomic seating ensures optimal support during travels, while advanced climate control maintains a pleasant atmosphere regardless of external conditions. Additionally, thoughtful storage options offer practicality, allowing occupants to keep their belongings organized and accessible.

Entertainment and Connectivity

Modern vehicles integrate advanced technology to enhance the driving experience. Infotainment systems serve as the hub for entertainment and communication, connecting occupants to their favorite media and navigation tools. Bluetooth and USB connectivity facilitate seamless integration with personal devices, ensuring that passengers remain engaged throughout their journeys.

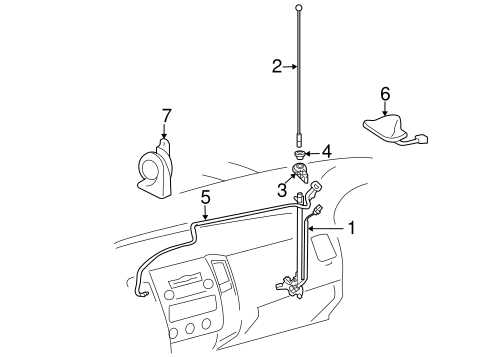

Exterior Parts and Accessories Guide

This section offers a comprehensive overview of various components and enhancements available for enhancing the outer appearance and functionality of your vehicle. Understanding these elements can significantly improve both aesthetic appeal and performance, allowing owners to customize their rides to meet personal preferences and needs.

Among the essential exterior elements are bumpers, which not only protect the vehicle but also provide an opportunity for styling upgrades. Grilles can be swapped to achieve a more aggressive or refined look, while fenders serve a dual purpose of protection and visual enhancement. Headlights and taillights are crucial for safety and can be upgraded to modern designs that improve visibility and style.

Additionally, roof racks and side steps offer practical benefits, providing extra storage options and making entry and exit more convenient. Each accessory is designed to improve functionality while reflecting the owner’s taste, creating a vehicle that stands out on the road.

Investing in high-quality exterior elements ensures durability and longevity, making it essential to choose reliable sources for these enhancements. Customization not only boosts the vehicle’s performance but also elevates its overall presence, making it uniquely yours.

Maintenance Parts for Long-Term Care

Ensuring the longevity of a vehicle requires regular attention to various components that play a crucial role in its overall performance and reliability. By focusing on essential items, owners can effectively prolong the lifespan of their vehicles while enhancing functionality. Implementing a systematic maintenance routine not only safeguards against unexpected issues but also improves driving experiences.

Essential Components for Regular Upkeep

Key elements that require routine inspection and replacement include filters, fluids, and belts. Regularly changing oil filters and air filters ensures optimal engine performance and efficiency. Additionally, monitoring coolant and transmission fluid levels is vital for preventing overheating and maintaining smooth operation. Inspecting and replacing worn belts can also prevent breakdowns and costly repairs.

Importance of Quality Replacement Items

Selecting high-quality replacement items is critical for effective maintenance. Utilizing genuine or reputable aftermarket components ensures compatibility and reliability. Investing in durable materials not only enhances performance but also minimizes the frequency of replacements, providing peace of mind for vehicle owners. Consistent maintenance using quality items ultimately leads to a dependable driving experience.