In any structure, ensuring safety through effective prevention measures is crucial. A well-designed water delivery network can play a significant role in minimizing damage during emergency situations. By comprehending the various components involved in these systems, one can appreciate how they function together to safeguard occupants and property.

Each element within this framework serves a distinct purpose, working in unison to provide an efficient response to potential hazards. From the storage units to the activation devices, understanding their arrangement and operation enhances the overall effectiveness of these protective measures. Exploring the intricacies of these assemblies allows for a deeper insight into their reliability and maintenance requirements.

By familiarizing oneself with these crucial components, stakeholders can make informed decisions regarding installation and upkeep. This knowledge not only contributes to enhanced safety protocols but also fosters a culture of preparedness within any environment.

This section aims to provide a comprehensive overview of the essential elements involved in a specific protective setup. Understanding these components is crucial for effective installation and maintenance. Below are the distinct headings that will guide the exploration of each key element.

- Key Elements of Protection

- Common Types of Devices

- Functionality and Operation Overview

- Installation Considerations and Best Practices

- Maintenance Tips for Longevity

Each heading will address significant aspects of the equipment, ensuring a thorough understanding for readers interested in safety measures.

Key Elements of Sprinkler Systems

Effective water distribution mechanisms play a vital role in maintaining safety within various environments. Understanding the fundamental components that contribute to their functionality is essential for ensuring optimal performance and reliability.

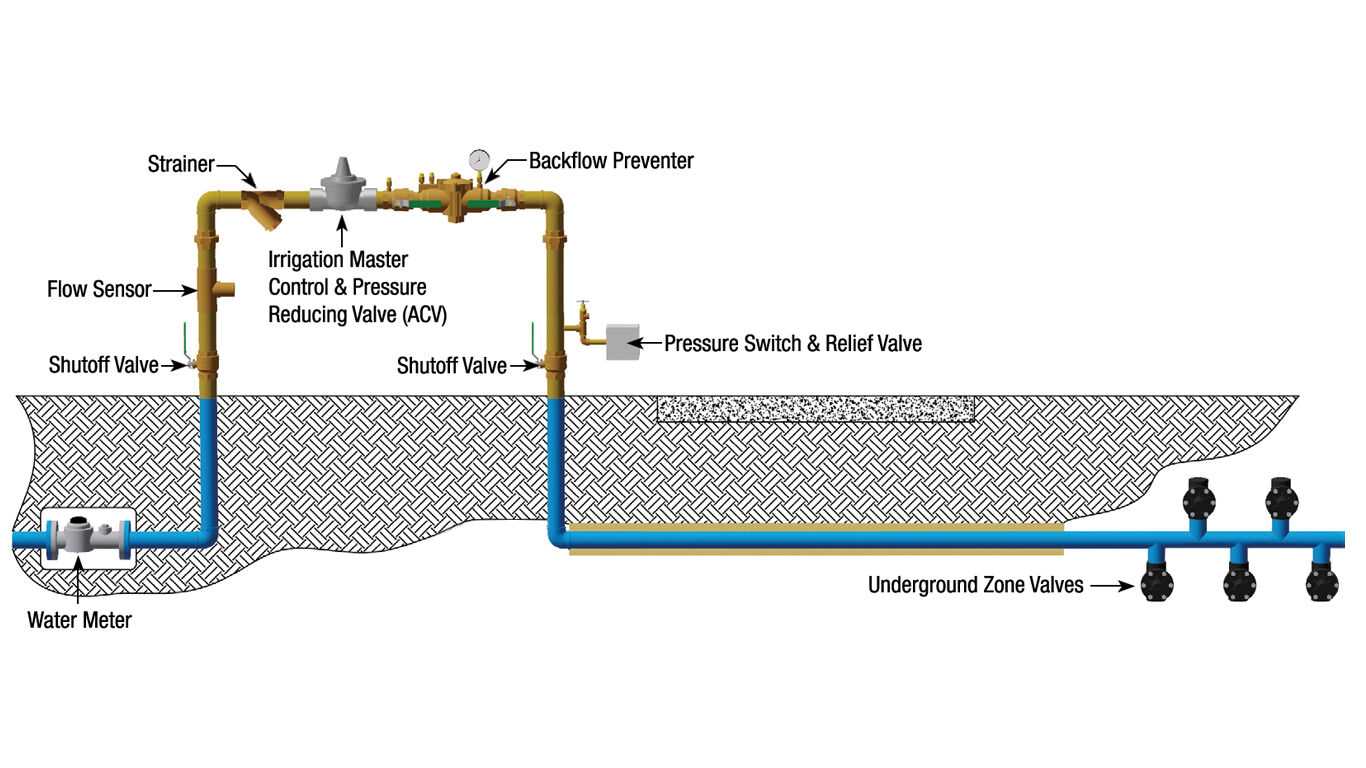

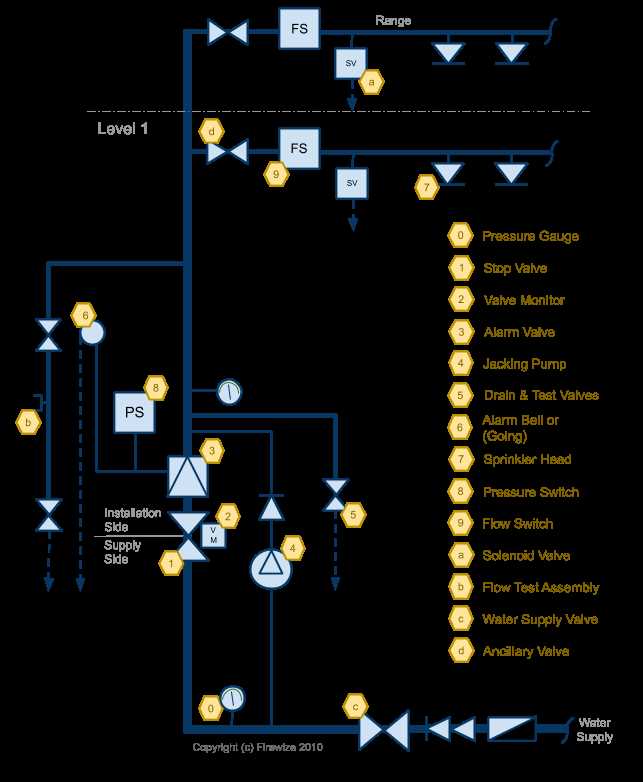

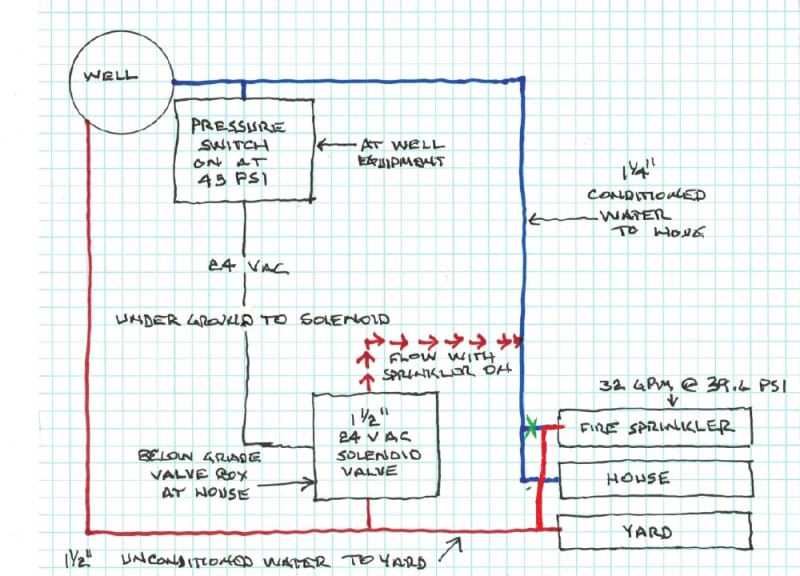

1. Distribution Network: This element is crucial for delivering water throughout the designated area. It consists of pipes and fittings that transport liquid from the source to specific locations, ensuring adequate coverage.

2. Activation Devices: These components are designed to trigger the flow of water when specific conditions are met. They often rely on temperature sensors that detect changes in the environment, signaling the need for activation.

3. Water Supply Source: A dependable supply of water is fundamental for the operation of these mechanisms. It can come from various sources, such as municipal water lines or dedicated storage tanks, ensuring consistent availability during emergencies.

4. Nozzles: These components disperse water in a controlled manner, creating patterns that maximize coverage while minimizing waste. Their design is critical for effective distribution across different areas.

5. Control Valves: These elements regulate the flow of water within the distribution network. They are essential for isolating sections of the system during maintenance or in the event of a malfunction, ensuring safety and functionality.

By understanding these critical components, individuals can appreciate the complexity and importance of water distribution mechanisms in protecting lives and property.

Functionality of Each Component

This section explores the roles and operations of various elements within a water distribution network designed for fire protection. Understanding how each component interacts helps ensure effective response during emergencies.

Each element in this network has a specific function that contributes to its overall efficacy:

- Control Valve: Regulates water flow, allowing for precise management of pressure and distribution.

- Water Source: Provides the necessary fluid, typically sourced from municipal supplies or dedicated tanks.

- Piping: Connects all elements, ensuring seamless water movement throughout the infrastructure.

- Delivery Device: Dispenses water to the area needing protection, effectively targeting the affected zones.

- Alarm System: Alerts personnel to activate the network and monitor its functionality during an incident.

- Control Panel: Central hub for monitoring and managing the entire setup, providing essential feedback and alerts.

Each component’s reliability is crucial for the efficient operation of the entire network, ultimately enhancing safety measures.

Common Types of Sprinkler Systems

In the realm of safety measures, various methods exist to ensure effective coverage and protection against hazards. Each approach serves distinct environments and requirements, providing tailored solutions for different applications. Understanding these methods can help in selecting the most suitable option for specific needs.

| Type | Description |

|---|---|

| Wet Pipe | This design features pipes filled with water at all times, allowing for immediate response when activated. It is the most common type used in many settings. |

| Dry Pipe | Pipes remain empty until activation occurs, where a valve opens to allow water flow. This type is ideal for environments where freezing is a concern. |

| Pre-Action | Combining elements of both wet and dry systems, this option requires two triggers to activate, enhancing safety in sensitive areas. |

| Deluge | This approach features open heads that release a large volume of water simultaneously upon activation, suitable for high-risk environments. |

Installation Guidelines for Sprinklers

When implementing an effective suppression mechanism, it is essential to follow proper installation procedures to ensure optimal functionality and reliability. Understanding the fundamental principles can significantly impact the overall performance of the safety features.

Preparation and Planning: Prior to installation, thorough planning is crucial. Assess the area to determine the appropriate locations for placement, ensuring that coverage is comprehensive. Consider factors such as ceiling height, potential obstructions, and the specific requirements of the environment.

Tools and Materials: Gather all necessary tools and materials before beginning the installation. This includes mounting hardware, connecting pipes, and any additional equipment needed for proper integration. Ensuring that everything is readily available will streamline the process.

Installation Steps: Begin by securely mounting the units according to the manufacturer’s instructions. Ensure that connections are tight and leak-free. Follow the recommended spacing guidelines to maintain efficiency and effectiveness in coverage.

Testing and Maintenance: After installation, it is vital to conduct thorough testing to confirm that all components function as intended. Schedule regular maintenance checks to ensure ongoing performance and address any potential issues promptly.

Maintenance Requirements for Sprinkler Parts

Regular upkeep is essential to ensure optimal performance and longevity of these critical components. Proper maintenance helps to identify potential issues before they escalate, ensuring that the protective measures in place function effectively when needed. This proactive approach can significantly reduce the likelihood of unexpected failures and enhance overall safety.

To maintain these crucial elements, it is recommended to conduct routine inspections at least once a year. During these inspections, check for signs of wear and corrosion, as well as any obstructions that may impede functionality. Cleaning should be performed to remove dust, debris, and other contaminants that could affect performance.

Additionally, testing the functionality of each component is vital. This includes verifying that the activation mechanisms respond correctly and that any sensors or alarms are operational. In case of any detected anomalies, immediate repairs or replacements should be carried out to ensure the integrity of the entire setup.

Documenting maintenance activities and findings is also important. Keeping detailed records assists in tracking the condition of the components over time and aids in planning future inspections and replacements. This systematic approach not only promotes safety but also ensures compliance with regulatory standards.

Identifying System Malfunctions

Recognizing issues within a suppression mechanism is essential for ensuring its effective operation. Timely detection of anomalies can prevent potential failures and enhance safety measures. This section outlines the common signs that may indicate a malfunction in the suppression network.

Unusual Noises: If you hear strange sounds such as hissing or clanking, it may signal an underlying problem. These noises can stem from pressure irregularities or component wear.

Unresponsive Activation: A failure to activate when needed is a critical concern. Testing the mechanism regularly can help identify any issues before they escalate.

Visible Leaks: Any signs of moisture or water accumulation around the installation should be examined closely. Leaks can compromise the integrity of the system and lead to further complications.

Discoloration or Corrosion: Components showing signs of rust or discoloration may indicate degradation, which could affect performance. Regular inspections are necessary to maintain optimal functionality.

Inconsistent Pressure: Fluctuations in pressure readings can suggest issues with the supply or internal components. Monitoring these levels is vital for overall efficiency.

By being vigilant about these indicators, users can ensure that the suppression network remains reliable and effective in its protective role.

Upgrades for Fire Safety Systems

Enhancing safety measures is crucial for protecting lives and property from unforeseen incidents. Modern upgrades can significantly improve the effectiveness and reliability of protective installations. Implementing these advancements ensures a proactive approach to safety management.

Key enhancements include:

- Integration of advanced detection technologies for quicker response times.

- Installation of more efficient delivery mechanisms for increased coverage.

- Utilization of smart monitoring systems for real-time assessments.

- Regular maintenance schedules to ensure optimal functionality.

Investing in these improvements not only enhances safety but also ensures compliance with current regulations and standards.

Regulatory Standards for Installation

The establishment of specific guidelines is crucial for the proper assembly and functionality of these essential safety measures. Adhering to regulations ensures that installations meet the required performance levels and contribute to overall safety.

Various authorities set standards that govern the installation process. These guidelines typically cover aspects such as:

- Design specifications and calculations

- Material requirements and quality control

- Installation techniques and methodologies

- Maintenance and testing protocols

Compliance with these standards is often mandatory and is enforced through regular inspections and assessments. The following organizations play key roles in establishing these regulations:

- National Fire Protection Association (NFPA)

- International Organization for Standardization (ISO)

- Local building codes and regulations

Understanding and following these guidelines not only enhances the reliability of the safety equipment but also protects lives and property from potential hazards.