In the following section, we delve into a detailed analysis of essential components and their arrangements for various models. This guide is designed to help enthusiasts and technicians understand the intricate configurations, allowing for efficient maintenance and repair. By exploring each aspect, we aim to provide clarity on how different elements are interconnected.

The layout of these assemblies is vital for understanding how various elements work together to ensure optimal performance. Knowing the positioning and function of each segment helps in troubleshooting and identifying areas that may require attention. This guide offers a comprehensive look at these systems, focusing on ease of navigation and clarity.

Detailed schematics are essential tools for those looking to maintain or enhance their equipment. These visual aids, combined with in-depth explanations, make it simpler to grasp the intricate details of each section. Whether you are performing routine checks or in-depth repairs, having access to accurate information ensures a smooth and efficient process.

Understanding the specific arrangement of these systems not only enhances one’s ability to work with them but also extends the longevity of the machinery. By utilizing these insights, users can better manage their equipment, ensuring it remains in peak condition for

Overview of Essential Components

This section provides a comprehensive understanding of the fundamental elements that comprise an all-terrain vehicle. Recognizing the significance of each component is vital for maintenance and enhancement of performance. Each part plays a crucial role in the overall functionality, ensuring a smooth and efficient riding experience.

Key Components

- Engine Assembly

- Transmission System

- Suspension System

- Braking Mechanism

- Fuel Delivery System

Maintenance Tips

- Regularly inspect fluid levels to ensure optimal performance.

- Check for wear and tear on belts and hoses.

- Maintain tire pressure and tread depth for safety.

- Clean air filters to improve engine efficiency.

- Follow the manufacturer’s recommendations for servicing intervals.

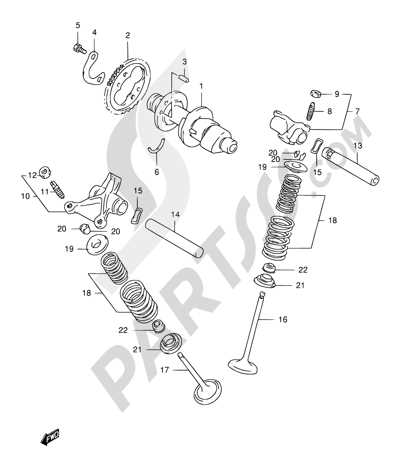

Engine Components and Configuration

The engine is the heart of any vehicle, responsible for converting fuel into mechanical energy. Understanding its components and their arrangement is crucial for efficient performance and maintenance. This section provides an overview of essential elements that make up a typical engine assembly and their functions within the system.

Key Components

- Cylinder Block: The main structure housing the cylinders and various internal components.

- Pistons: Move up and down within the cylinders, converting combustion energy into mechanical power.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, enabling power transfer to the drivetrain.

- Camshaft: Controls the opening and closing of the engine’s valves, ensuring optimal airflow during the combustion cycle.

- Valves: Regulate the intake of air and fuel and the exhaust of combustion gases.

- Timing Chain or Belt: Ensures synchronized movement between the crankshaft and camshaft, crucial for engine timing.

Configuration Overview

The arrangement of these components varies depending on the engine design. Common configurations include inline, V-type, and flat engines, each offering distinct advantages in terms of power output, efficiency, and compactness.

- Inline Engines: Have cylinders arranged in a straight line, providing simplicity and ease of maintenance.

- V-Type Engines: Feature cylinders arranged in a V shape, allowing for more power in a compact design.

- Flat Engines: Position cylinders horizontally, resulting in a lower center of gravity and improved handling characteristics.

Transmission and Gear Assembly Details

The transmission and gear assembly plays a crucial role in the overall performance and efficiency of an all-terrain vehicle. This intricate system is responsible for transferring power from the engine to the wheels, allowing for smooth acceleration and deceleration while navigating various terrains.

Understanding the components involved in this assembly is essential for proper maintenance and repairs. Key elements include the gears, shafts, and various connectors that work together to ensure seamless operation. Each component must be in optimal condition to maintain the vehicle’s reliability and longevity.

Regular inspection of the transmission system can prevent potential issues, such as slipping gears or unexpected noises. Routine maintenance involves checking fluid levels, replacing worn-out parts, and ensuring that all connections are secure. By prioritizing these practices, owners can enhance their vehicle’s performance and extend its lifespan.

In summary, familiarity with the transmission and gear assembly is vital for any vehicle owner. Knowledge of the individual components and their functions aids in troubleshooting and ensures a smoother driving experience, regardless of the conditions encountered on the road.

Suspension System Breakdown

The suspension system is a critical component of any all-terrain vehicle, designed to enhance ride quality and handling by absorbing shocks from uneven surfaces. This system plays a vital role in maintaining traction and stability, ensuring a smooth and controlled experience, even in challenging conditions.

Key Components of the Suspension System

Understanding the various elements of the suspension mechanism is essential for effective maintenance and performance optimization. Key parts include:

- Shocks and Struts: These components dampen the energy from bumps and dips, providing a smoother ride.

- Springs: Springs support the weight of the vehicle and help absorb shocks, maintaining ground contact.

- Control Arms: These connect the suspension to the frame, allowing for controlled movement and alignment.

Maintenance Tips

Regular maintenance of the suspension system ensures longevity and optimal performance. Check for wear and tear on shocks and springs, and ensure all connections are secure. Replace worn components promptly to avoid further damage and maintain safe handling characteristics.

Electrical System and Wiring Layout

The electrical system is a crucial component of any all-terrain vehicle, ensuring proper functionality and safety. This section delves into the arrangement of wiring and electrical connections, providing insights into how various elements interact to support the vehicle’s operation.

Key Components

- Battery: Supplies power to the electrical system.

- Starter Motor: Engages the engine upon ignition.

- Alternator: Recharges the battery while the engine runs.

- Wiring Harness: Connects various electrical components.

- Fuses: Protect circuits from overload.

Wiring Layout Overview

The wiring layout facilitates the connection between essential components, allowing for efficient power distribution. A well-organized wiring system is crucial for preventing shorts and ensuring reliable performance.

- Power distribution begins at the battery, branching out to various components.

- The alternator connects to the battery to maintain charge during operation.

- Fuses are strategically placed to safeguard sensitive electronics from electrical surges.

- Connections to switches and relays allow for controlled operation of lights and other accessories.

Understanding the electrical system and its layout is essential for troubleshooting and maintenance, ensuring optimal performance of the vehicle.

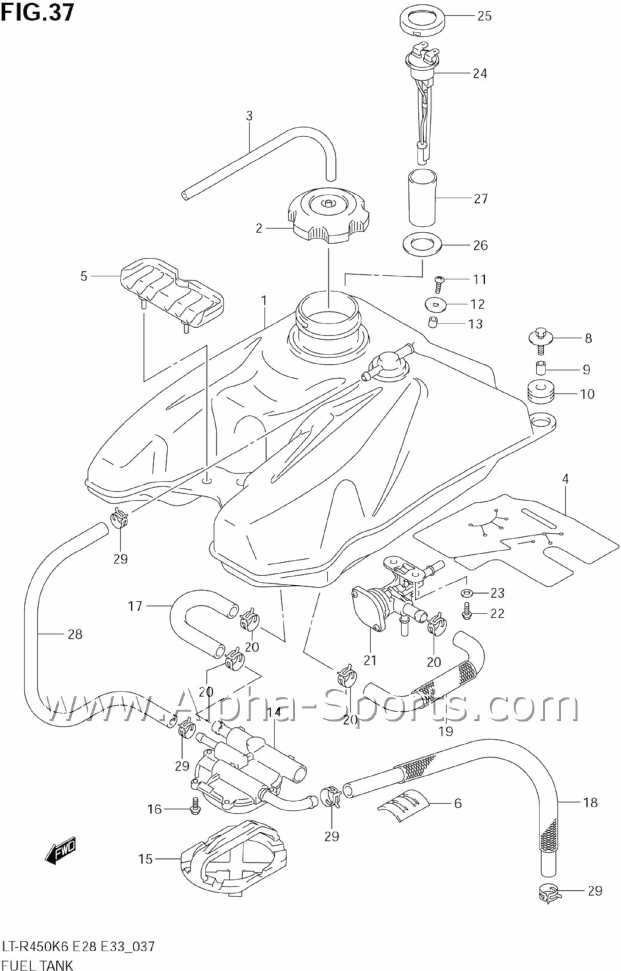

Fuel System and Carburetor Parts

The fuel system plays a crucial role in ensuring optimal engine performance by effectively delivering the necessary fuel mixture for combustion. Understanding its components is essential for maintaining and troubleshooting the system. This section delves into the various elements that make up the fuel delivery mechanism, with a particular focus on the carburetor and its associated parts.

Key Components of the Fuel Delivery Mechanism

At the heart of the fuel system is the carburetor, which blends air and fuel to create the right mixture for engine operation. This assembly typically consists of several integral components, including the float chamber, needle valve, and jets. The float chamber regulates the fuel level, ensuring a consistent supply, while the needle valve controls the flow of fuel into the carburetor. Various jets are responsible for adjusting the fuel-air mixture based on the engine’s demand, optimizing performance across different operating conditions.

Maintenance and Troubleshooting

Regular maintenance of the fuel system is essential to prevent performance issues. Common tasks include cleaning the carburetor, inspecting for leaks, and ensuring that the fuel filters are free from debris. If the engine exhibits symptoms such as poor acceleration or rough idling, it may indicate a need to adjust or replace certain components within the carburetor. Proper understanding and care of these elements will help in sustaining the overall efficiency and reliability of the engine.

Exhaust and Cooling Mechanism

The exhaust and cooling system plays a critical role in maintaining the optimal performance and longevity of an engine. This mechanism efficiently expels gases produced during combustion while ensuring that the engine operates within safe temperature limits. Proper functioning of this system is essential for preventing overheating and ensuring the effective expulsion of exhaust fumes.

Exhaust System Components

The exhaust system is composed of several integral parts that work together to channel harmful gases away from the engine. These components are designed to minimize emissions and enhance engine efficiency.

| Component | Function |

|---|---|

| Exhaust Manifold | Collects exhaust gases from the engine cylinders. |

| Catalytic Converter | Reduces harmful emissions by converting them into less harmful substances. |

| Muffler | Reduces noise produced by the exhaust gases. |

| Exhaust Pipe | Channels gases away from the vehicle. |

Cooling System Essentials

The cooling system is designed to regulate the engine temperature by dissipating heat. It prevents overheating, which can lead to severe engine damage and decreased performance. The cooling system comprises several key elements that ensure effective heat management.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant to the air. |

| Thermostat | Regulates the flow of coolant based on temperature. |

| Water Pump | Circulates coolant throughout the engine. |

| Coolant Reservoir | Stores excess coolant for the system. |

Braking System and Controls

The braking system is a crucial component of any all-terrain vehicle, ensuring safe and reliable operation across diverse terrains. This section will explore the various elements that contribute to effective deceleration and control, highlighting the importance of maintenance and functionality.

Components of the Braking System include hydraulic discs, calipers, and brake pads, which work together to provide optimal stopping power. The hydraulic mechanism allows for smooth engagement and disengagement, reducing wear and tear on components.

Controls play a vital role in the braking process, encompassing levers and foot pedals that activate the system. Proper positioning and responsiveness of these controls are essential for achieving precise handling and maneuverability.

Regular maintenance of the braking system is necessary to ensure optimal performance. This includes checking fluid levels, inspecting pads for wear, and ensuring that all components function correctly. Any signs of malfunction should be addressed immediately to maintain safety.

Understanding the intricacies of the braking mechanism and its controls is essential for every operator. A well-maintained system not only enhances safety but also contributes to the overall performance and longevity of the vehicle.

Chassis and Frame Structure

The chassis and frame play a crucial role in providing stability and support for the entire vehicle. They serve as the foundation on which various components are mounted, ensuring that the structure can withstand various forces and stresses during operation. A well-designed chassis contributes not only to the durability of the vehicle but also to its performance and handling characteristics.

Frame Composition

The frame is typically constructed from high-strength materials, which offer a balance between weight and robustness. This composition is vital for enhancing the vehicle’s resilience against impacts and vibrations. Additionally, the frame design often incorporates specific geometries to optimize weight distribution and improve overall stability.

Importance of Structural Integrity

Maintaining the structural integrity of the chassis is essential for safe and efficient operation. Any weaknesses or damages can significantly affect the vehicle’s performance and handling. Regular inspections and maintenance are recommended to identify potential issues early, ensuring that the chassis remains in optimal condition. Effective maintenance can enhance the lifespan of the vehicle and improve its overall reliability.