When it comes to maintaining high-performance watercraft, a thorough comprehension of engine components is essential. Each element plays a critical role in ensuring optimal functionality and reliability. Knowing how these parts interact can significantly enhance your boating experience.

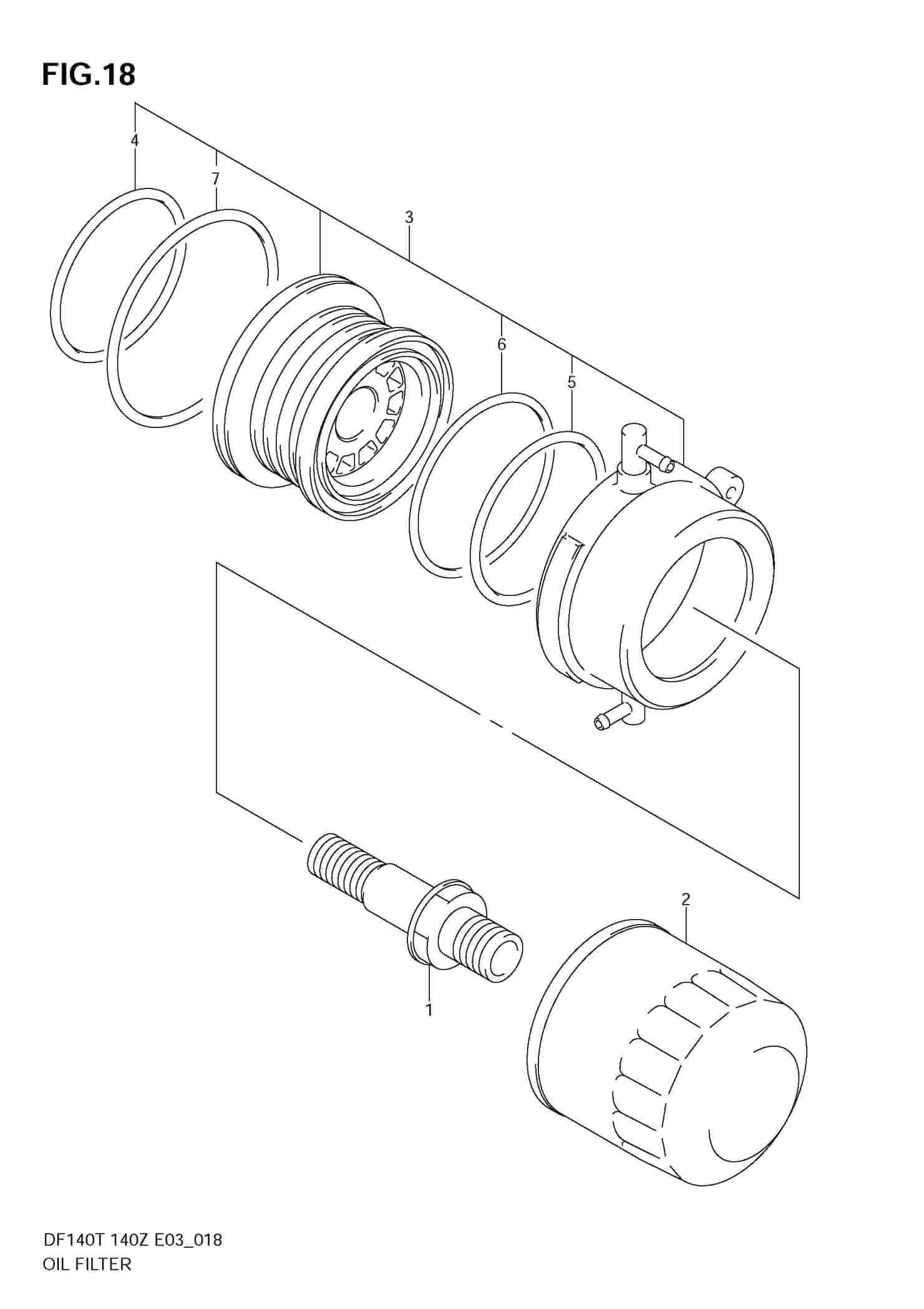

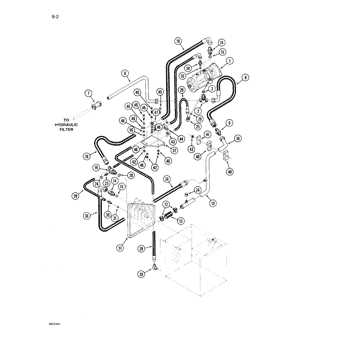

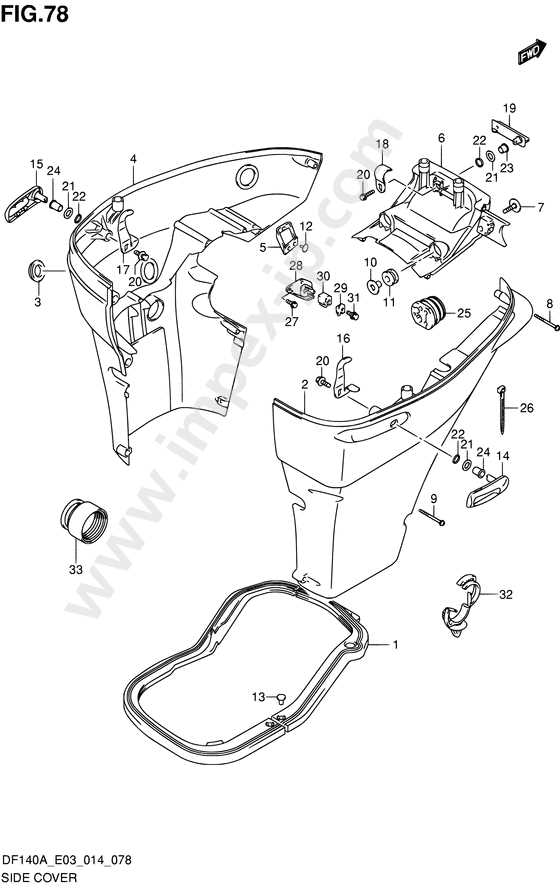

Visual representations of engine assemblies provide invaluable insights into their construction and operation. By exploring these illustrations, enthusiasts can pinpoint specific components, facilitating easier troubleshooting and repairs. This approach allows for a more in-depth understanding of how everything fits together.

Whether you are a seasoned technician or a passionate hobbyist, diving into the intricate details of engine assemblies is the ultimate way to ensure your vessel operates smoothly. Engaging with comprehensive guides not only aids in repairs but also fosters a deeper appreciation for marine technology.

Understanding the Suzuki DF140 Components

Exploring the intricate details of an outboard motor reveals a complex interplay of various elements, each playing a crucial role in overall functionality. A comprehensive grasp of these components can enhance maintenance practices and boost performance, ensuring reliability on the water.

Key Elements of the Engine

At the heart of the system lies the engine assembly, which serves as the powerhouse. It consists of a variety of subassemblies, including the cylinder block, crankshaft, and camshaft. These components work harmoniously to convert fuel into mechanical energy, driving the vessel forward. Understanding their positions and functions can aid in troubleshooting and repairs.

Auxiliary Systems and Their Functions

In addition to the primary engine components, auxiliary systems such as the cooling mechanism, fuel delivery system, and electrical circuit are vital. The cooling system prevents overheating, while the fuel delivery apparatus ensures optimal combustion. The electrical circuit powers various functionalities, from ignition to instrumentation. Each system requires careful attention to detail for efficient operation.

Recognizing how these components interconnect allows for informed decisions during maintenance and upgrades. By familiarizing oneself with the various assemblies and their purposes, one can enhance both the longevity and performance of the motor.

Importance of Parts Diagrams

Visual representations of component arrangements play a crucial role in maintenance and repair processes. They provide a clear overview of how individual elements fit together and function, facilitating a better understanding of complex machinery. This clarity is essential for both novice and experienced technicians, enabling them to troubleshoot issues more efficiently.

Enhanced Understanding

Having access to detailed visuals allows users to identify specific components easily. This understanding aids in recognizing wear and tear, as well as potential failure points. With a comprehensive view, technicians can approach repairs with greater confidence and accuracy.

Streamlined Maintenance

Utilizing visual aids significantly streamlines the maintenance workflow. When components are illustrated clearly, it reduces the chances of errors during reassembly. Technicians can refer to these resources to ensure every part is correctly installed, leading to improved performance and longevity of the equipment.

| Benefit | Description |

|---|---|

| Clarity | Helps in visualizing the arrangement of elements. |

| Efficiency | Reduces time spent on identifying and replacing components. |

| Accuracy | Minimizes the risk of incorrect assembly. |

| Knowledge Sharing | Facilitates better communication among technicians. |

Key Features of DF140 Engine

This engine is designed to deliver exceptional performance and reliability, making it a popular choice among boating enthusiasts. With advanced engineering and innovative technology, it ensures smooth operation and efficient fuel consumption.

- Power Output: The engine provides robust horsepower, enabling quick acceleration and optimal speed on the water.

- Fuel Efficiency: Engineered for reduced fuel consumption, it allows for longer journeys without frequent refueling.

- Lightweight Design: Its compact and lightweight structure enhances overall vessel performance and handling.

- Corrosion Resistance: Built with materials that resist saltwater corrosion, it ensures durability in harsh marine environments.

- Low Emissions: Designed with eco-friendly technology, it minimizes environmental impact while maintaining high performance.

Overall, this engine combines power, efficiency, and durability, making it an excellent option for a variety of boating activities.

Common Repairs for Suzuki Outboards

Maintaining the longevity and performance of marine engines often requires addressing specific issues that arise during usage. Understanding typical repairs can significantly enhance the reliability of your vessel. This section delves into frequent maintenance tasks that owners may encounter, ensuring smooth operation on the water.

Fuel System Issues: Over time, fuel lines can degrade or become clogged. Regular inspection and replacement of these components are essential for optimal engine performance.

Cooling System Maintenance: The cooling system is vital for preventing overheating. Checking the water pump and thermostat should be a routine task to ensure proper temperature regulation.

Electrical Failures: Battery connections and wiring can deteriorate, leading to starting issues. Regularly inspecting and cleaning these parts can prevent electrical malfunctions.

Propeller Repairs: Damage to the propeller can impact efficiency. Monitoring for dents or bends and addressing these promptly is crucial for performance.

Regular Maintenance: Routine tasks such as oil changes and filter replacements can prevent larger issues and prolong the lifespan of your engine. Always consult the manual for specific maintenance schedules.

Identifying Parts by Diagram

Understanding components through visual representations is essential for effective maintenance and repair. A well-organized illustration serves as a valuable tool, allowing users to quickly locate and identify various elements within a system. This section will explore how to navigate these visuals efficiently.

Here are some key steps to consider when interpreting such illustrations:

- Familiarize Yourself with the Layout: Begin by recognizing the overall structure of the illustration. Look for sections that categorize different groups of components.

- Focus on Labels: Pay close attention to any annotations or labels. These can provide crucial information about the function and position of each element.

- Use a Reference List: Often, a list accompanies the visual. This reference can clarify terminology and assist in understanding what each part does.

Additionally, here are some tips to enhance your identification process:

- Zoom In: If available, use digital tools to zoom in on specific areas for a clearer view of smaller components.

- Color Coding: Notice any use of colors; these can indicate categories or types of parts, making it easier to distinguish between them.

- Cross-Reference: Whenever possible, cross-reference with a manual or guide to confirm details about particular elements.

By following these strategies, users can effectively navigate and utilize visual aids to streamline their understanding and maintenance tasks.

Maintenance Tips for DF140 Owners

Proper upkeep is essential for ensuring the longevity and performance of your outboard motor. Regular attention to key components can prevent issues and enhance efficiency, allowing for a smoother experience on the water.

Start by checking the oil levels frequently, as maintaining the right lubrication is crucial for optimal function. Replace the oil and filter according to the recommended intervals to ensure the engine runs smoothly.

Examine the fuel system regularly, looking for any signs of leaks or contamination. Use high-quality fuel and consider adding a fuel stabilizer, especially during periods of inactivity.

Inspect the cooling system to avoid overheating. Ensure that the water intake is free of debris and that the thermostat is functioning properly.

Pay attention to the propeller; any dents or damage can affect performance. Regularly clean and inspect it for wear and tear, replacing it if necessary.

Finally, adhere to the manufacturer’s service schedule, as this can guide you in addressing any specific maintenance needs and prolonging the lifespan of your equipment.

Where to Find Replacement Parts

Locating suitable components for your marine engine can be straightforward if you know where to look. Several resources are available to ensure you can find what you need to keep your vessel running smoothly.

- Authorized Dealers: Visit local dealers who specialize in marine equipment. They often have a wide range of original components.

- Online Retailers: Explore e-commerce platforms that focus on marine supplies. Websites often have extensive catalogs with user-friendly search features.

- Marine Supply Stores: Check nearby shops that cater to boat owners. These stores may carry a selection of essential items and can provide advice.

- Forums and Communities: Join online boating communities. Members often share recommendations on where to purchase quality components.

- Salvage Yards: Look into salvage yards for used parts that are still in good condition, offering a budget-friendly alternative.

Using these resources can help you delve into the best options for your needs and ultimately ensure your equipment remains in peak condition.

Comparing DF140 with Other Models

This section explores the differences and similarities between a specific outboard motor and its contemporaries, focusing on performance, efficiency, and design features.

When evaluating various models, several key aspects should be considered:

- Power Output: How does the horsepower compare across different engines?

- Fuel Efficiency: What are the consumption rates under similar conditions?

- Weight: How does the overall weight impact handling and installation?

- Durability: Which models offer better resistance to corrosion and wear?

By examining these factors, potential buyers can make informed decisions that align with their specific needs and preferences.

- Assess individual performance metrics.

- Analyze user feedback and reviews.

- Consider service availability and maintenance costs.

Resources for DIY Repairs

Engaging in self-repair tasks can be both rewarding and cost-effective. Accessing the right resources is crucial for successfully tackling maintenance projects on various equipment. With the right information and tools, enthusiasts can gain confidence and enhance their skills.

Online Forums and Communities

Participating in online discussions allows individuals to share experiences, troubleshoot problems, and gather valuable tips from fellow enthusiasts. These platforms often host a wealth of knowledge, enabling users to delve deeper into specific issues they might encounter.

Instructional Videos and Guides

Video tutorials and written manuals provide step-by-step instructions that are essential for understanding complex repairs. Utilizing these resources can significantly ease the learning curve, offering visual aids and detailed explanations that simplify even the most challenging tasks.