When it comes to maintaining outdoor machinery, comprehending the various components and their functions is crucial for ensuring optimal performance. This section delves into the intricate relationships between different elements that contribute to efficient cleaning tasks. By familiarizing oneself with these parts, users can enhance their experience and prolong the lifespan of their equipment.

Identifying each element within the assembly allows operators to troubleshoot issues effectively and execute repairs when necessary. Visual aids serve as valuable tools, providing a clear overview of how these components interact. Recognizing the significance of each piece not only streamlines the maintenance process but also empowers users to tackle potential challenges confidently.

Moreover, understanding the design and layout of these systems can lead to improved cleaning results. Whether it’s enhancing water flow or optimizing pressure, a thorough knowledge of the components involved can make a noticeable difference. This exploration offers insights that cater to both novices and seasoned users, ensuring that everyone can benefit from the information presented.

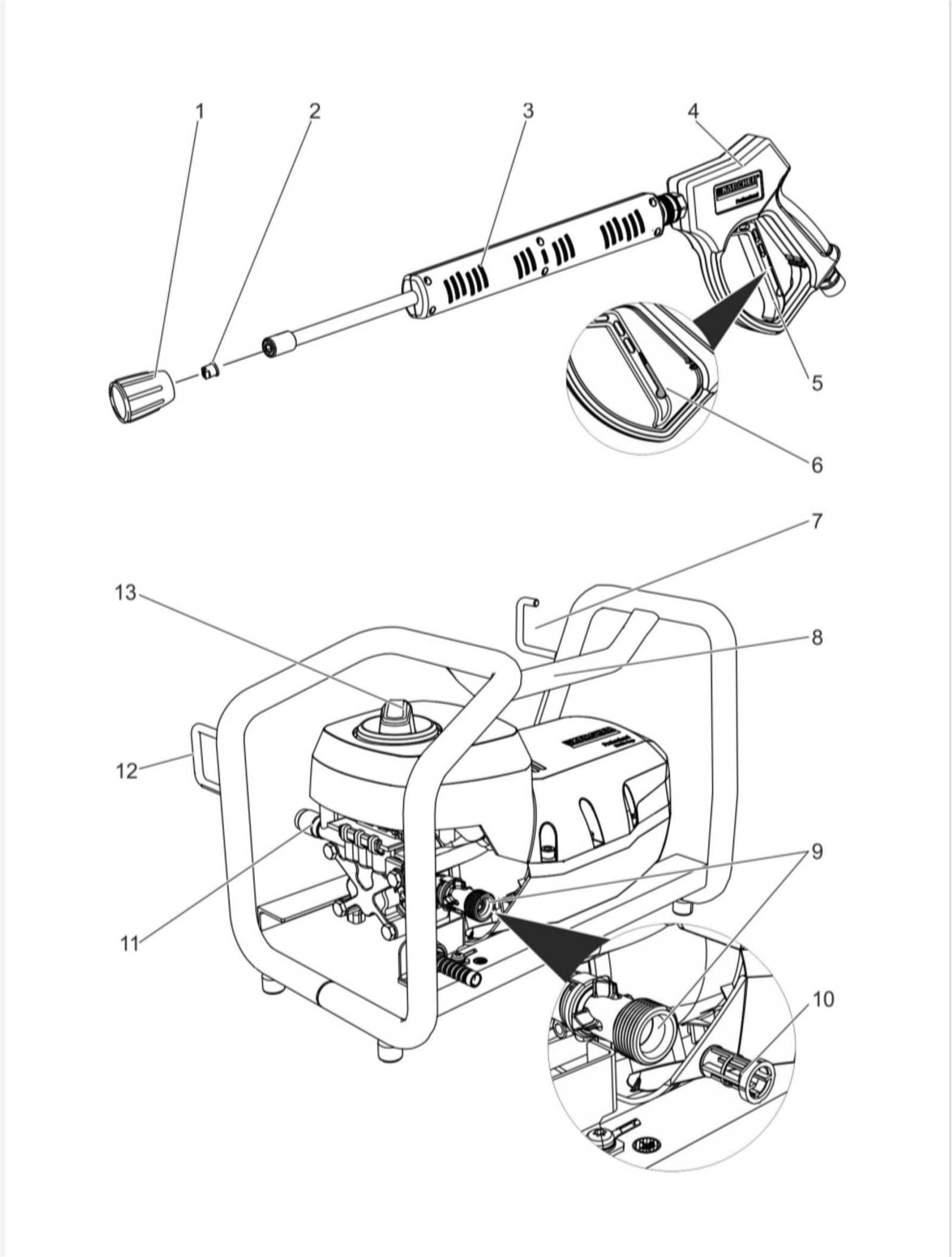

Understanding Surface Cleaner Components

Exploring the various elements that contribute to the efficiency of a cleaning device reveals their essential roles in enhancing performance. Each component is meticulously designed to work in harmony, ensuring optimal functionality and user satisfaction.

Central Hub: This vital section serves as the core of the apparatus, linking different functionalities and facilitating smooth operation. It often houses the motor and gearing systems, which are crucial for movement and power delivery.

Rotating Nozzles: These dynamic elements generate powerful jets of liquid that effectively dislodge dirt and grime. Their design allows for adjustable angles and patterns, maximizing coverage and efficiency during use.

Cleaning Deck: The broad surface area of this component ensures that a substantial expanse can be treated in a single pass. Its construction is often robust, designed to withstand pressure and repeated use while delivering consistent results.

Wheels: Mobility is key for any cleaning apparatus, and the wheels play a significant role in providing ease of movement across various terrains. Their size and tread patterns can affect both maneuverability and stability.

Water Connection: A secure and efficient interface for connecting the cleaning solution is crucial. This component must ensure a steady flow while preventing leaks, contributing to the overall effectiveness of the system.

Each of these elements contributes uniquely to the performance of the device, and understanding their functions can enhance user experience and maintenance practices.

Essential Parts of Briggs and Stratton Models

Understanding the fundamental components of outdoor power equipment is crucial for maintenance and efficient operation. Each model features specific elements that contribute to its performance, durability, and ease of use. Familiarity with these key components enables users to ensure proper care and enhance the longevity of their machines.

| Component | Description |

|---|---|

| Engine | The heart of the equipment, providing the necessary power for operation. |

| Spray Bar | Distributes water evenly across the cleaning surface for effective results. |

| Wheels | Facilitate mobility, allowing the user to maneuver the unit with ease. |

| Housing | Protects internal mechanisms while contributing to overall durability. |

| Nozzles | Regulate the flow of liquid, providing different spray patterns for various tasks. |

| Handle | Offers grip and control, ensuring comfortable operation during use. |

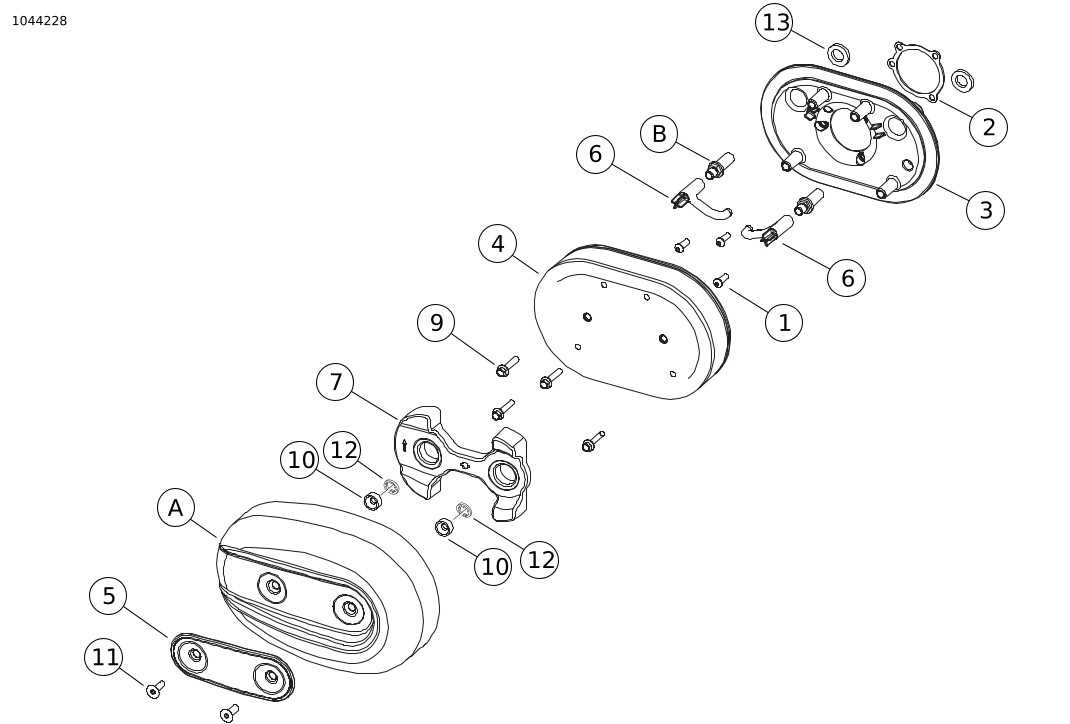

How to Read Parts Diagrams

Understanding schematic representations of components is essential for effective maintenance and repair. These illustrations serve as visual guides, helping users identify individual elements, their arrangement, and how they interact within the overall assembly. Familiarity with these visuals enhances troubleshooting efficiency and promotes a smoother repair process.

Identifying Components

Begin by examining the symbols and labels associated with each element. Each part is typically represented by a unique identifier, which corresponds to a list or catalog. Take note of the specific shapes and connections; this information is vital for understanding how each piece fits within the larger system.

Understanding Relationships

Pay attention to the lines and arrows that connect various elements. These lines indicate how components relate to one another, whether they are directly linked or depend on another part for functionality. Grasping these relationships will aid in visualizing the workflow of the assembly and anticipating how changes might affect overall performance.

Common Issues with Surface Cleaners

When it comes to outdoor maintenance tools, users often encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems can help in troubleshooting and maintaining optimal functionality.

- Uneven Cleaning Results:

- Debris build-up on the cleaning head.

- Inconsistent pressure distribution.

- Difficulty Starting:

- Fuel-related issues.

- Clogged air filters or spark plugs.

- Noise and Vibration:

- Loose components or damaged parts.

- Improper assembly or alignment.

- Water Leakage:

- Worn or damaged seals.

- Improper connections in hoses.

- Power Loss:

- Blocked nozzles or hoses.

- Engine performance issues.

Addressing these issues promptly can ensure that your outdoor equipment remains efficient and effective, providing a reliable solution for cleaning tasks.

Replacement Parts for Optimal Performance

Ensuring the efficiency and longevity of your equipment often hinges on the quality of its components. Utilizing the correct replacements not only enhances functionality but also prolongs the lifespan of the machine. This section delves into essential components that can significantly improve performance and reliability.

Key Components for Enhancement

- Rotary Brushes: These are vital for effective cleaning. Regularly inspecting and replacing worn brushes can prevent damage and maintain optimal performance.

- Hoses: Durable and flexible hoses are crucial for consistent water flow. Check for kinks or leaks that may hinder operation.

- Connectors: Quality connectors ensure a secure fit between hoses and the main unit, reducing the risk of water loss.

- Nozzles: Various nozzle types provide different spray patterns. Replacing clogged or damaged nozzles can enhance cleaning efficiency.

Benefits of Using Quality Replacements

- Improved Efficiency: High-quality replacements maximize performance, ensuring tasks are completed more effectively.

- Cost Savings: Investing in durable components reduces the frequency of replacements and repairs.

- Safety: Reliable parts minimize the risk of malfunctions, protecting both the user and the equipment.

Regular maintenance and timely replacement of components are essential practices for anyone looking to maintain peak performance in their equipment. Prioritizing quality in replacements pays off in the long run, both in performance and durability.

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves regular upkeep and attention to detail. By following specific practices, you can enhance performance and extend the life of your machinery. Here are essential tips to maintain optimal functionality.

- Regular Cleaning: Remove debris and dirt after each use to prevent buildup that can impair performance.

- Inspect Components: Frequently check parts for wear and tear, replacing any damaged elements promptly.

- Change Fluids: Ensure that oils and lubricants are fresh and at the correct levels to facilitate smooth operation.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule for servicing and part replacements.

By incorporating these practices into your routine, you will not only improve the efficiency of your equipment but also significantly enhance its lifespan.

Where to Find Parts Diagrams

Locating visual schematics for machinery components can significantly simplify the repair and maintenance process. These illustrations provide essential details on each element’s arrangement, helping users identify necessary replacements and ensure proper assembly. Understanding where to find these resources is crucial for effective troubleshooting and efficient repairs.

Official Manufacturer Websites

One of the most reliable sources for schematics is the official website of the manufacturer. Many brands offer downloadable resources that include comprehensive visual aids. By navigating to the support or resources section, users can often find detailed guides tailored to specific models, allowing for easy access to necessary information.

Online Retailers and Forums

Numerous online retailers and community forums also serve as valuable repositories for schematics. Sites dedicated to equipment and tool sales frequently provide downloadable manuals, while user forums may feature discussions where members share links to useful resources. Engaging with these communities can enhance knowledge and offer insights into common issues and solutions.

Upgrading Your Surface Cleaning Equipment

Enhancing your cleaning apparatus can significantly boost efficiency and performance. By incorporating advanced components and technology, you can achieve superior results in various cleaning tasks. This upgrade not only improves the functionality but also extends the lifespan of your equipment.

When considering improvements, it’s essential to evaluate the key elements of your apparatus. The right combination of tools and accessories can make a notable difference in effectiveness and ease of use. Here’s a breakdown of crucial upgrades to consider:

| Component | Benefits |

|---|---|

| High-Pressure Nozzles | Increases water flow and cleaning power, reducing time spent on tasks. |

| Rotary Attachments | Provides a wider cleaning path and removes stubborn dirt effortlessly. |

| Replacement Hoses | Ensures durability and flexibility, reducing wear and tear during operation. |

| Additional Brushes | Allows for tailored cleaning on various surfaces, enhancing versatility. |

By investing in these enhancements, you can transform your cleaning experience, making it more efficient and effective. Proper maintenance and timely upgrades ensure that your equipment remains reliable for years to come.