Maintaining and servicing machinery requires a clear understanding of its internal mechanisms and structure. A comprehensive visual representation of all elements can significantly enhance your ability to identify, replace, or upgrade specific sections. Such resources are invaluable for both novices and seasoned technicians, ensuring a smooth operation and longevity of the equipment.

Effective maintenance hinges on access to detailed visual aids that outline each part’s placement and function. By familiarizing yourself with these illustrations, you can easily pinpoint areas requiring attention. This not only streamlines repair processes but also promotes a proactive approach to equipment care.

Moreover, having a reliable reference can empower users to undertake repairs with confidence, reducing reliance on external help. Such guides foster a deeper connection with your tool, transforming routine upkeep into an engaging and educational experience. Embracing this knowledge can ultimately lead to improved performance and satisfaction in your projects.

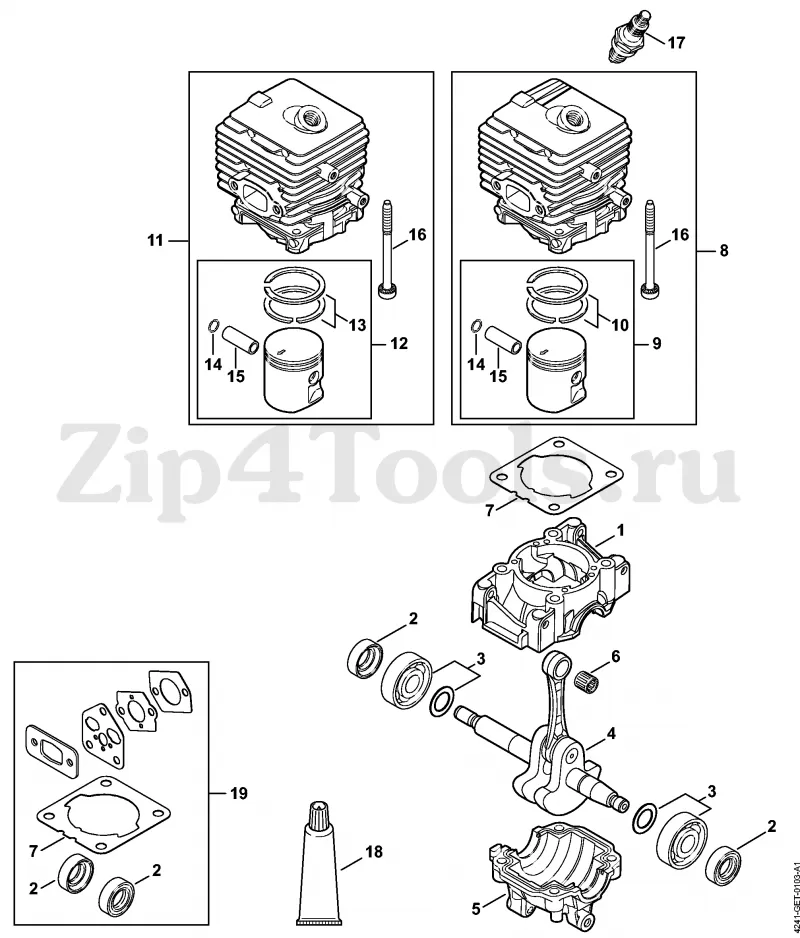

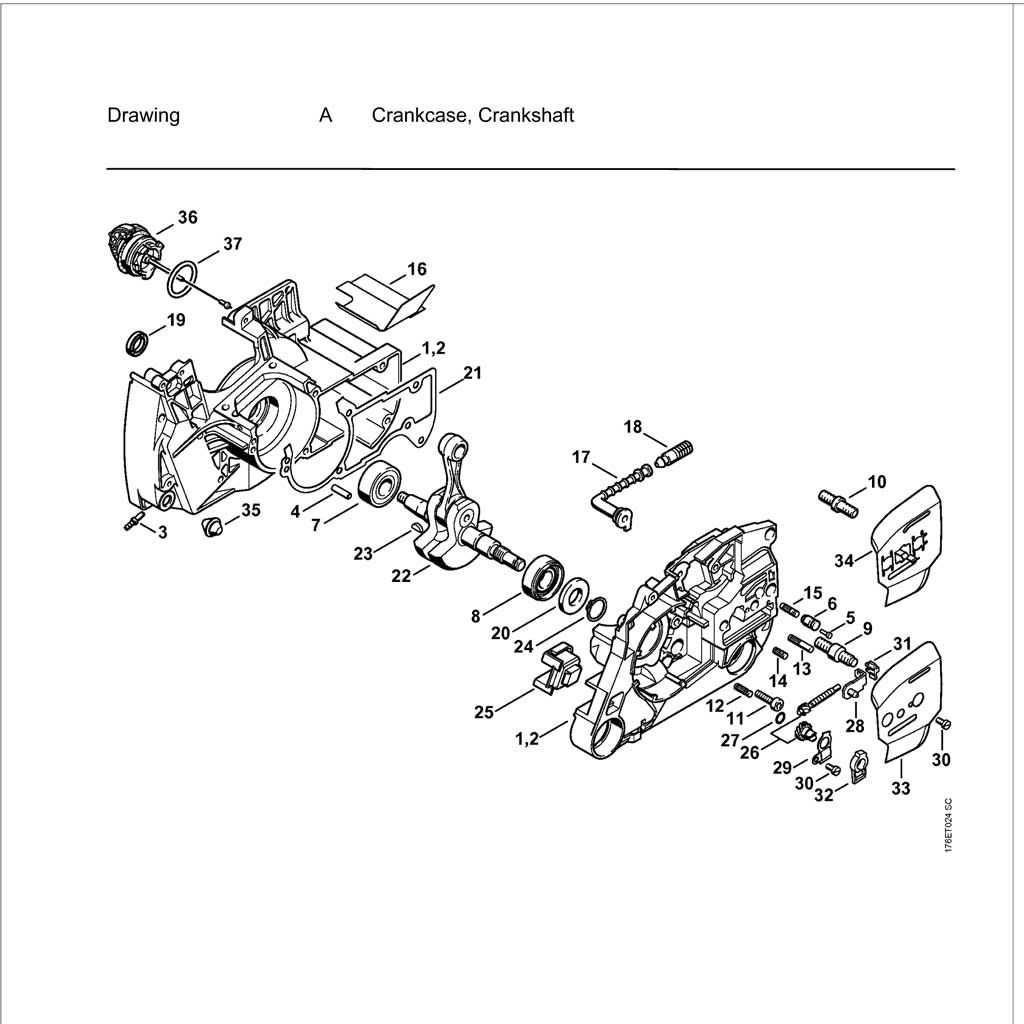

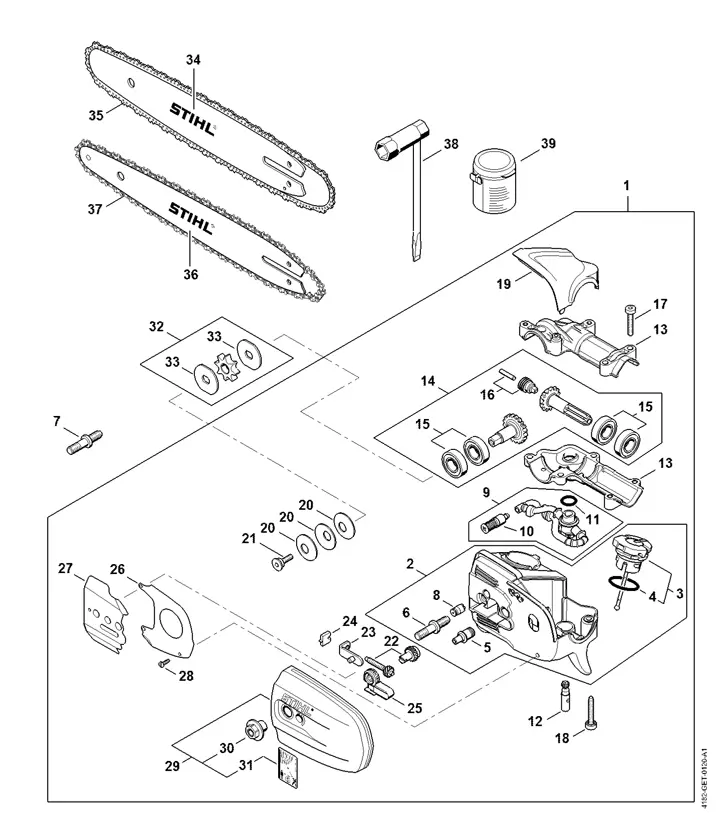

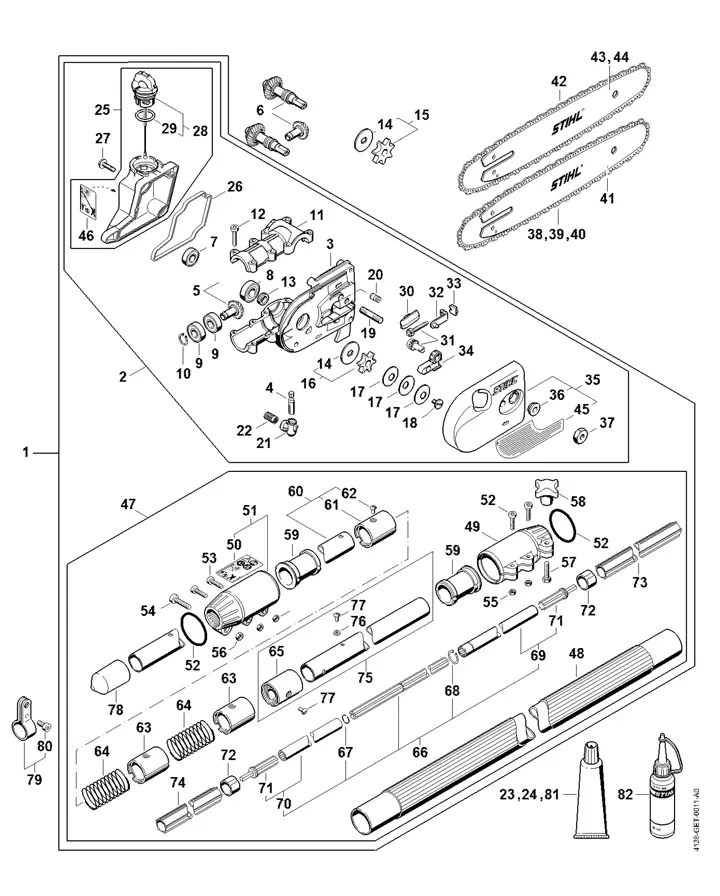

Understanding Stihl TS400 Components

The intricate machinery of a cutting tool is composed of various elements, each serving a unique function that contributes to the overall performance and efficiency. A thorough comprehension of these components is essential for effective maintenance and optimal usage. By exploring the roles and interrelationships of these parts, operators can enhance their understanding and ensure the longevity of their equipment.

Key Elements of the Cutting Tool

At the heart of any high-performance tool lies its engine, which powers the entire system. This engine relies on a carefully calibrated fuel delivery system, enabling precise combustion and optimal power output. Additionally, the cutting mechanism is engineered to provide durability and efficiency, utilizing high-quality materials to withstand the rigors of frequent use.

Maintenance and Care

Proper upkeep of each component is vital for sustained performance. Regular checks on the air filter and spark plug can prevent potential issues, while timely replacement of worn-out parts ensures that the machine operates at its peak. Understanding the individual roles of these elements not only aids in troubleshooting but also enhances the overall operational lifespan of the equipment.

Importance of Parts Diagrams

Understanding the intricacies of machinery and equipment often requires a visual representation of its components. Such illustrations serve as essential tools for maintenance and repair, enabling users to identify each piece and comprehend how they interconnect. This clarity not only enhances troubleshooting but also fosters a greater appreciation for the engineering behind the equipment.

Facilitating Maintenance and Repair

Visual aids simplify the process of upkeep by breaking down complex assemblies into manageable sections. With a clear layout, technicians can quickly locate the necessary elements and assess their condition. This efficiency reduces downtime, allowing for timely interventions that keep the machinery operational. Moreover, having a reference for component arrangement minimizes the risk of misplacement during reassembly.

Enhancing Learning and Training

For those new to a particular type of equipment, visual representations are invaluable educational resources. They provide a concrete way to learn about different elements and their functions, making the learning process more intuitive. Additionally, these resources can support training sessions, enabling instructors to convey information effectively and ensure that trainees grasp the essential aspects of machine operation.

How to Read a Parts Diagram

Understanding an illustration of components is essential for effective maintenance and repair of machinery. Such illustrations provide a visual representation of various elements and their relationships, enabling users to identify parts accurately and facilitating the reassembly process. Familiarity with the symbols and layout will enhance your ability to utilize these resources efficiently.

To interpret an illustration effectively, follow these key steps:

| Step | Description |

|---|---|

| 1 | Examine the overall layout to get a sense of the entire assembly. |

| 2 | Identify individual elements by locating reference numbers or codes that correspond to a list. |

| 3 | Pay attention to notes or legends that explain symbols and color codes used in the illustration. |

| 4 | Refer to the accompanying list to find detailed information about each component, including specifications and part numbers. |

| 5 | Cross-reference with other resources, such as service manuals, to gain a deeper understanding of assembly and disassembly procedures. |

By following these steps, you can navigate through illustrations of components with confidence, ensuring accurate identification and effective repair processes.

Common TS400 Replacement Parts

In the realm of power tools, regular maintenance and timely replacement of worn components are essential for optimal performance. Identifying the most frequently needed components can enhance the longevity of the equipment, ensuring reliable operation and efficiency. Here, we will explore the vital elements often required for upkeep, focusing on their significance and function.

Engine Components

The heart of any cutting tool lies in its engine. Essential items such as spark plugs, air filters, and fuel filters play a crucial role in maintaining engine health. Spark plugs ignite the fuel mixture, while air and fuel filters ensure that only clean elements enter the combustion chamber. Regular replacement of these items can lead to improved fuel efficiency and smoother operation.

Cutting implements are another critical aspect to monitor. Blades and disks experience wear and tear over time, affecting performance and precision. Regularly changing these accessories not only maintains cutting efficiency but also enhances safety during operation. Keeping a stock of high-quality cutting tools can significantly reduce downtime and improve productivity.

Where to Find PDF Diagrams

Locating technical illustrations and manuals can significantly enhance your understanding and maintenance of equipment. Whether you are seeking assembly instructions, schematics, or component listings, various resources are available to assist you in obtaining these valuable documents.

Here are some effective methods to find these resources:

- Manufacturer Websites: Many producers offer downloadable resources directly on their official sites. Navigate to the support or downloads section for access to detailed guides.

- Online Forums: Communities dedicated to specific tools often share valuable documents. Engaging in discussions can lead to recommendations and shared resources.

- Retailer Resources: Some retailers provide manuals for the products they sell. Check the product page or customer support sections for downloadable content.

- Specialized Websites: Numerous platforms are dedicated to technical documents. A quick search can yield a wealth of illustrations relevant to your needs.

- Local Dealers: Authorized dealers often have access to technical resources. Contacting them can provide direct assistance in finding the right materials.

Utilizing these avenues will facilitate your search for the necessary documentation, ensuring you have the information required for effective maintenance and repair tasks.

Tips for Proper Maintenance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. By adhering to a structured maintenance routine, you can enhance performance and reduce the likelihood of unexpected breakdowns. This section outlines essential practices that contribute to the reliable operation of your machinery.

Regular Cleaning

Keeping your tools clean is vital for optimal performance. Dirt and debris can accumulate, affecting functionality and leading to premature wear. Regularly inspect and clean components to maintain their condition.

Routine Inspections

Conducting periodic checks is crucial for identifying potential issues before they escalate. Look for signs of wear or damage, such as frayed wires or cracked parts. Addressing these concerns early can save time and money in the long run.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean filters | Every month | Ensure airflow is not restricted. |

| Check spark plug | Every three months | Replace if worn or dirty. |

| Inspect fuel lines | Every six months | Look for leaks or cracks. |

| Lubricate moving parts | Monthly | Use appropriate lubricant to reduce friction. |

Identifying TS400 Part Numbers

Understanding the components of your equipment is crucial for effective maintenance and repair. Each individual element plays a specific role in the overall functionality, and knowing how to identify them can significantly enhance your repair experience. This section will guide you through the process of recognizing the unique identifiers associated with each component, ensuring that you can source the correct replacements when needed.

Components are typically labeled with unique identification numbers, which facilitate easy ordering and inventory management. These identifiers are often found on the parts themselves or in technical documentation related to the equipment. Familiarizing yourself with these numbers not only aids in identifying components but also helps you navigate the ordering process more efficiently. Additionally, many manufacturers provide reference guides or catalogs that list these identifiers alongside detailed descriptions, allowing you to cross-reference and confirm your selections.

When seeking replacements, it’s beneficial to cross-check the identification numbers with reliable resources. Various online platforms and dealerships provide searchable databases that can expedite your search. Using these tools, you can quickly locate the components you need and verify their compatibility with your equipment.

Maintaining an organized approach to part identification will save you time and reduce the risk of errors. As you gain experience in recognizing these identifiers, you’ll find that managing your equipment becomes a more straightforward and efficient process.

Repairing vs. Replacing Components

When faced with malfunctioning machinery, one must decide between mending existing parts or opting for new replacements. This choice can significantly impact both functionality and cost. Understanding the advantages and disadvantages of each approach is essential for making an informed decision.

Repairing components often offers several benefits:

- Cost-Effectiveness: Fixing parts can be less expensive than purchasing new ones, especially for minor issues.

- Preservation of Originality: Retaining original components may maintain the machine’s integrity and performance.

- Environmental Considerations: Repairing reduces waste and supports sustainability by extending the lifespan of existing materials.

However, there are situations where replacing parts is the more suitable option:

- Improved Performance: New components may provide enhanced functionality or efficiency that repairs cannot achieve.

- Long-Term Reliability: Investing in new parts can prevent future breakdowns and reduce ongoing maintenance costs.

- Time Efficiency: Replacements can sometimes be quicker than repairs, minimizing downtime in critical situations.

Ultimately, the decision to repair or replace should be based on a careful assessment of the specific situation, including the severity of the damage, budget constraints, and the overall importance of the equipment in question.

Frequently Asked Questions About TS400

This section aims to address common inquiries related to a specific model of handheld cutting equipment. Understanding these aspects can enhance user experience and ensure optimal performance for various tasks.

What maintenance is required for optimal performance?

Regular maintenance includes checking the fuel system, cleaning air filters, and ensuring sharp cutting blades. Scheduled inspections can prevent issues and prolong the lifespan of the equipment.

How do I troubleshoot common issues?

If the machine fails to start, check the spark plug and fuel supply. For performance drops, inspect the air filter and cutting elements. Regular troubleshooting can quickly resolve minor problems.