Maintaining a well-kept garden requires reliable equipment, and comprehending the various components of your gardening apparatus is essential for optimal performance. This section provides insight into the intricate elements that contribute to the overall functionality of your device.

Exploring the various components can help you identify potential issues and enhance the efficiency of your machine. By examining the intricate layout, users can delve into the relationships between different sections and how they work together to deliver the ultimate results.

Whether you’re a novice or an experienced gardener, understanding these elements can greatly improve your experience. A clear visual representation allows for better troubleshooting and maintenance, ensuring that your tool remains in peak condition for years to come.

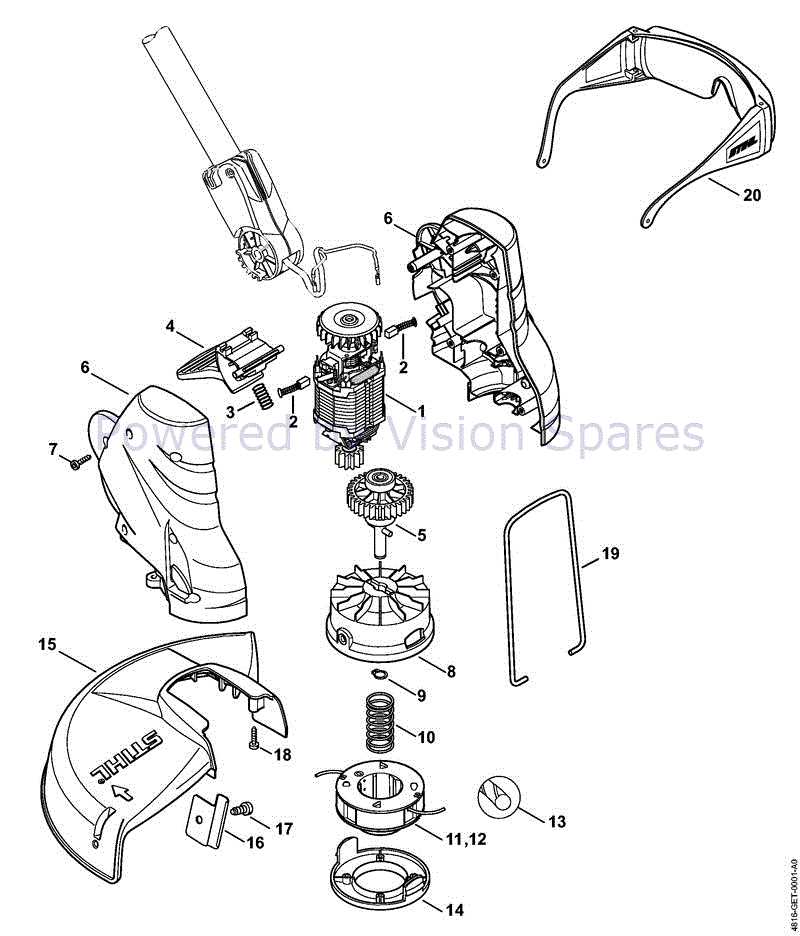

Understanding Stihl String Trimmers

These versatile gardening tools are essential for maintaining a neat and tidy outdoor space. They allow users to efficiently manage overgrown vegetation, ensuring that lawns and gardens look their best. With a variety of components working in harmony, these devices provide both power and precision, making them a favorite among homeowners and professionals alike.

Key Components and Their Functions

The main elements of these machines include the motor, cutting head, and shaft. Each part plays a crucial role in the overall functionality. The motor generates the necessary power, while the cutting head is designed to handle various types of vegetation. The shaft connects these components, allowing for maneuverability and ease of use.

Maintenance for Longevity

Key Components of String Trimmers

The effectiveness of a grass-cutting tool relies on several essential elements that work harmoniously to deliver optimal performance. Understanding these crucial components enhances the user experience and maintenance practices.

Cutting Mechanism

The cutting mechanism is fundamental, often utilizing a rotating line or blade to efficiently sever grass and weeds. This element’s design can significantly affect the speed and quality of the cut, ensuring a clean finish in various conditions.

Power Source

The power source, whether electric or gas-powered, drives the entire unit. It determines the tool’s mobility, duration of use, and overall strength, making it a pivotal aspect for users to consider based on their specific needs.

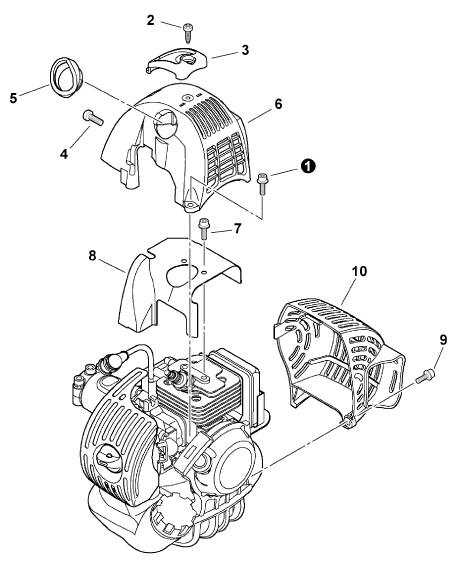

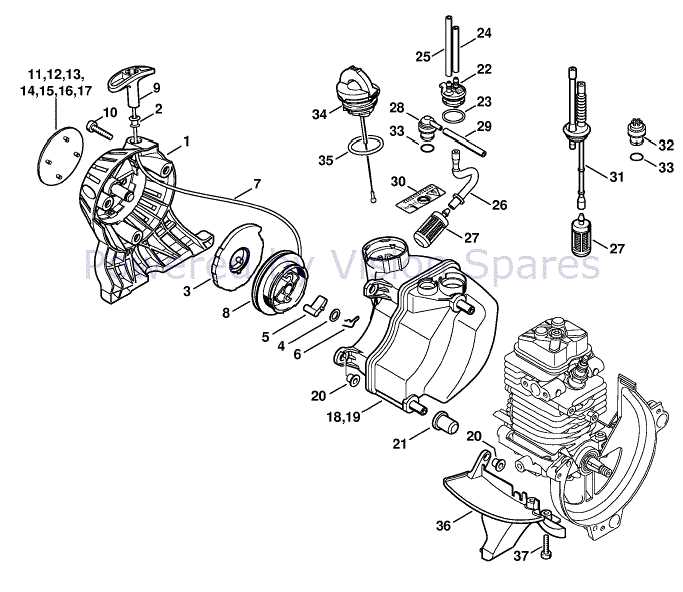

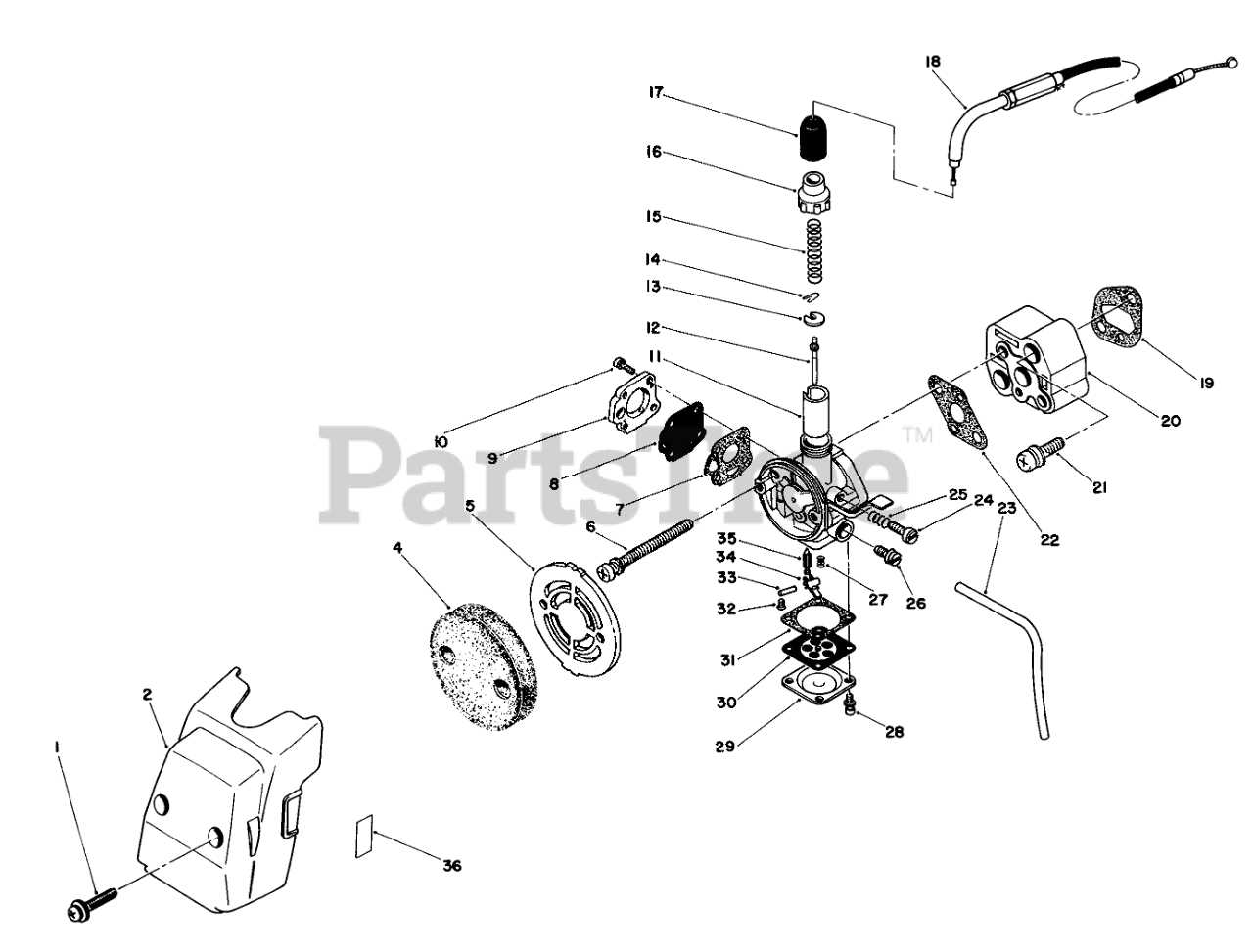

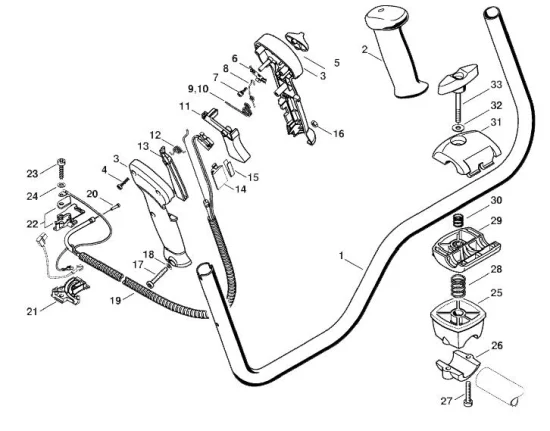

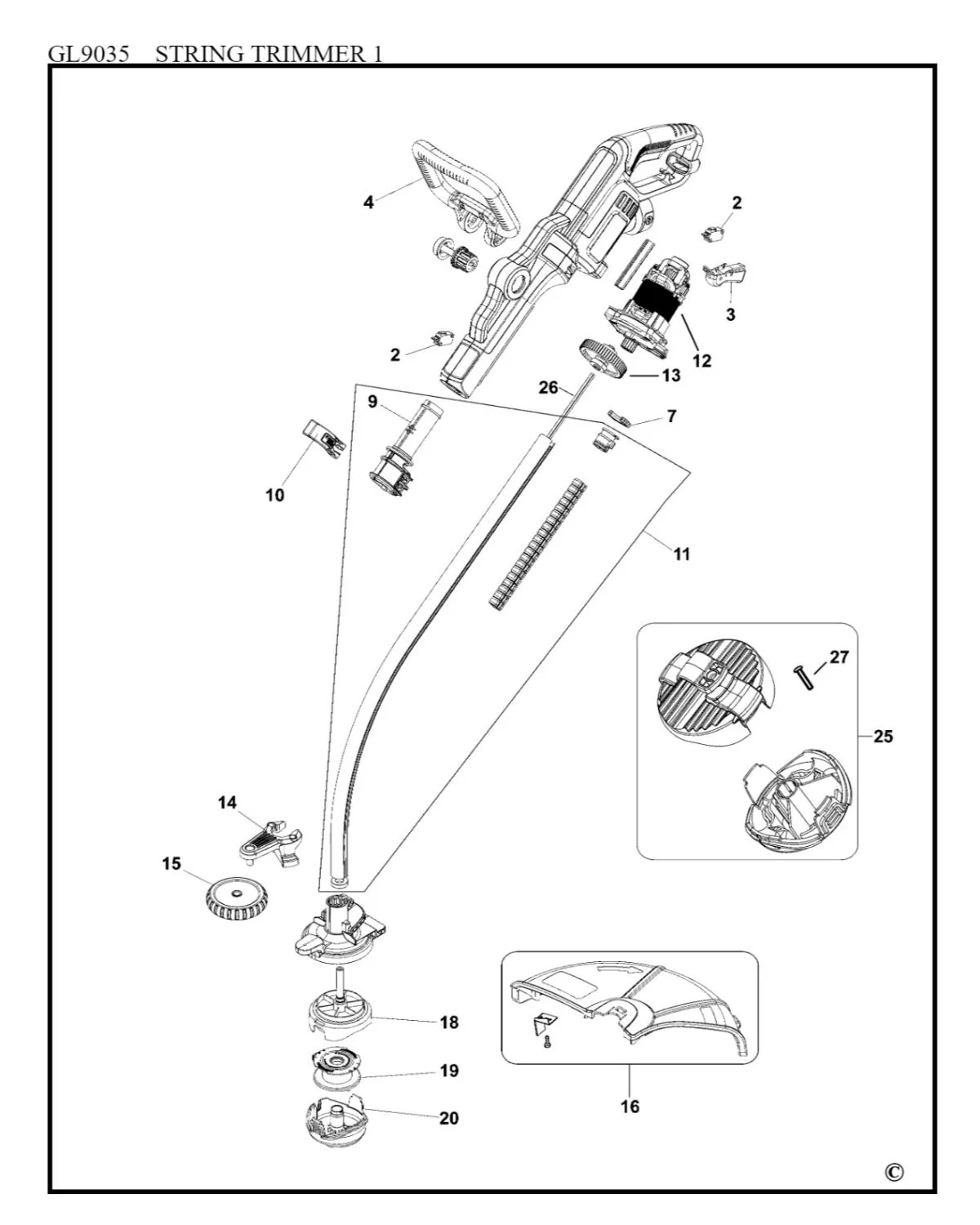

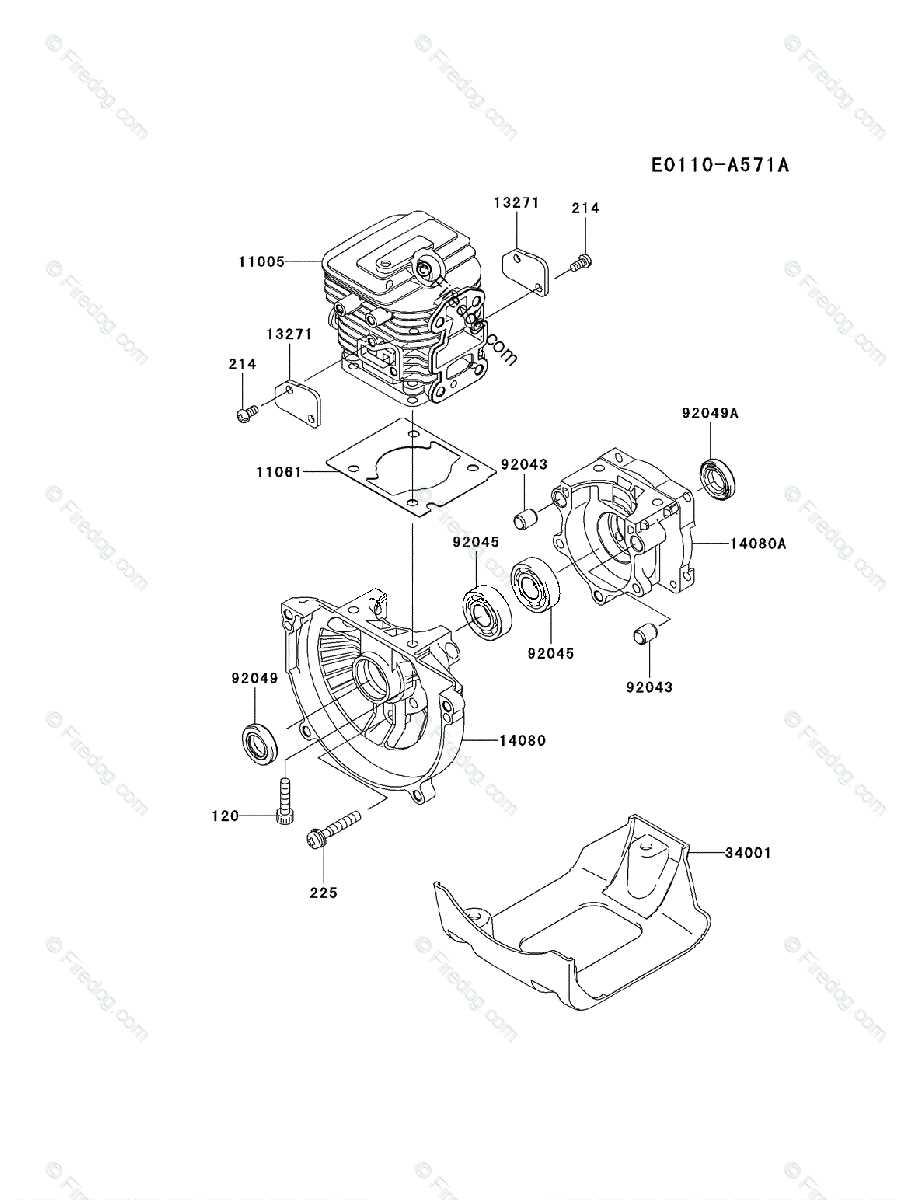

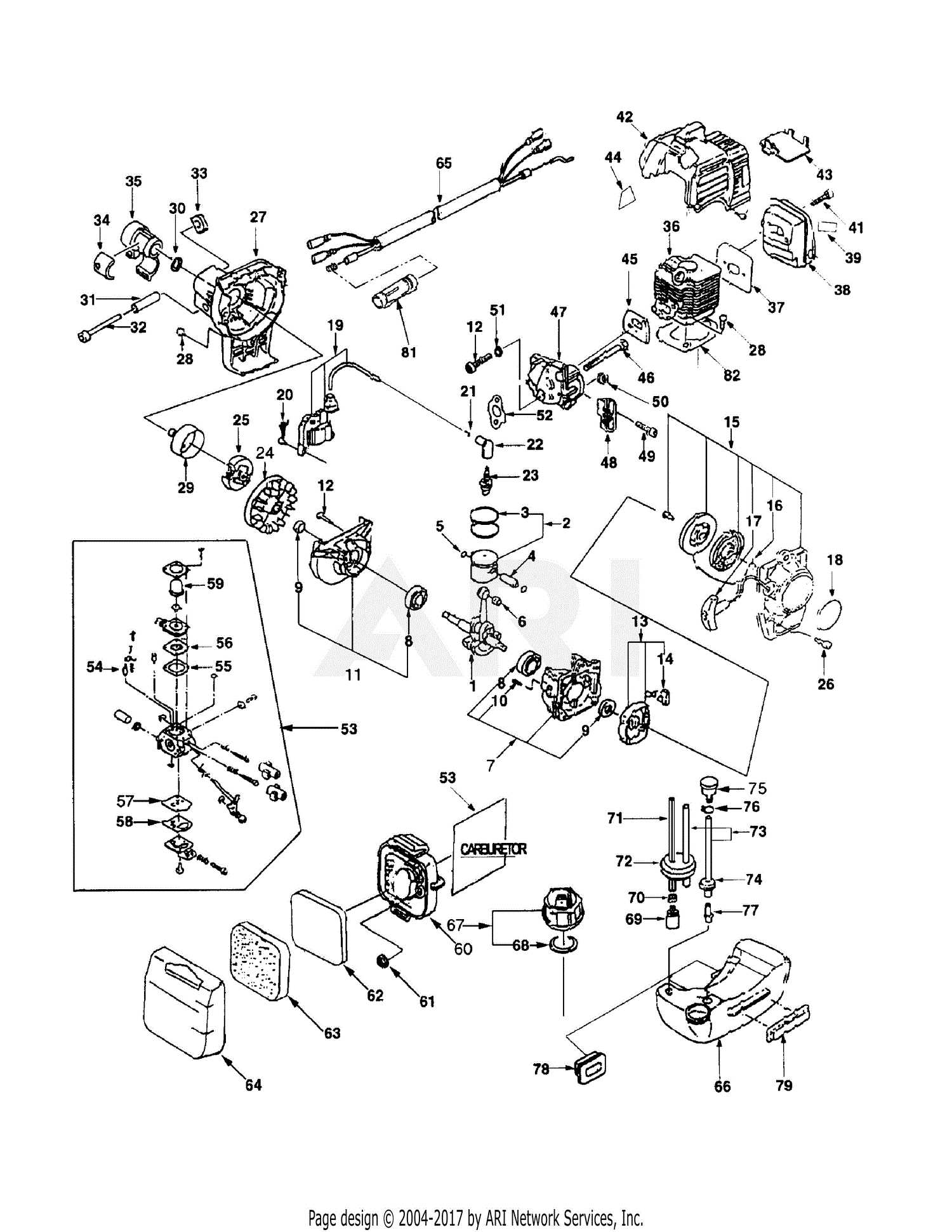

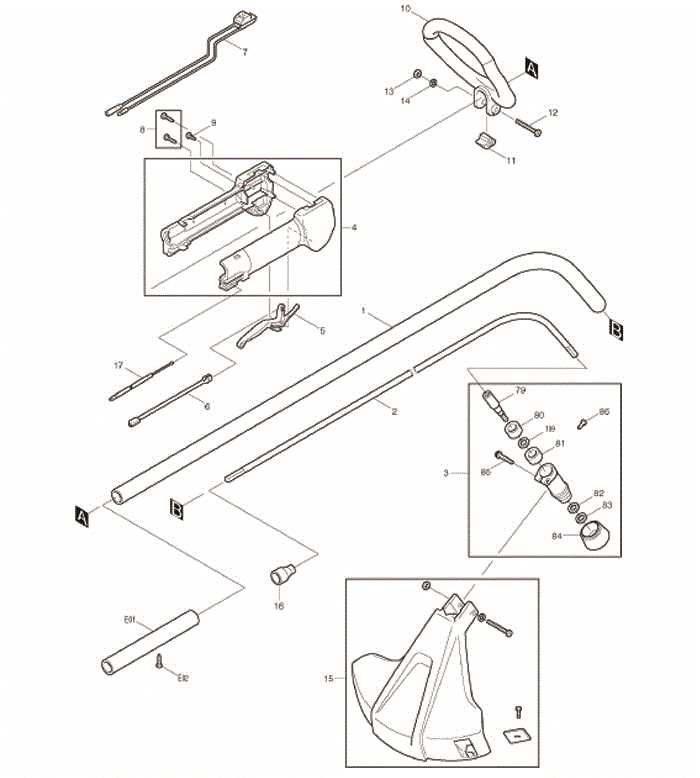

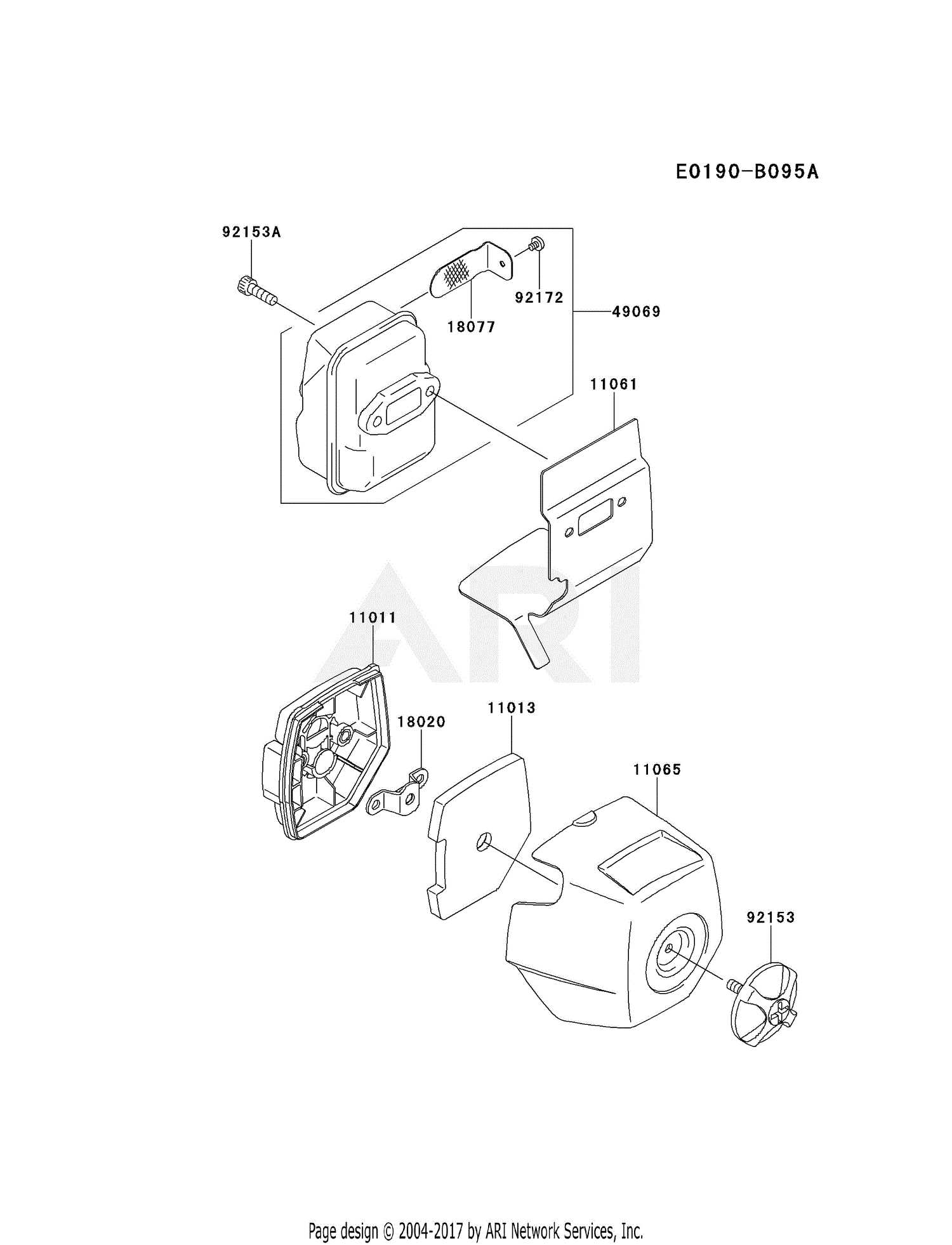

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair. These illustrations provide a clear representation of components and their relationships, enabling users to identify what is needed for upkeep or replacement.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Each illustration uses specific icons to represent different components. Knowing these symbols helps in quicker identification.

- Refer to the Legend: Diagrams usually come with a legend that explains the symbols and their meanings. Always consult it for clarity.

- Follow the Flow: Look for arrows or lines that indicate connections or assembly order. This will guide you through the construction process.

- Note the Labels: Each component is typically labeled with a reference number. Use these numbers to cross-reference with parts lists.

- Check for Multiple Views: Some diagrams offer different angles or exploded views. These can provide additional context on assembly and fitting.

By mastering these techniques, you will enhance your ability to engage with these valuable resources, leading to more efficient maintenance and repairs.

Common Issues with String Trimmer Parts

Garden maintenance tools often encounter various challenges that can hinder their performance. Understanding these issues is essential for effective upkeep and repair. This section outlines typical problems that may arise, along with their potential solutions, to ensure optimal functionality.

Frequent Problems

Several common malfunctions can occur with garden maintenance equipment. These issues may stem from wear and tear, improper use, or lack of maintenance. Below are some prevalent concerns:

| Issue | Description | Solution |

|---|---|---|

| Line Breakage | Frequent snapping of the cutting line can occur, affecting efficiency. | Use a higher-quality line or adjust the spool tension. |

| Engine Stalling | The motor may unexpectedly stop, disrupting operation. | Check fuel levels and clean the air filter. |

| Vibration | Excessive shaking can make handling difficult and uncomfortable. | Inspect for loose screws or damaged components. |

| Overheating | Excessive heat can damage internal parts. | Allow the machine to cool down and clean cooling vents. |

Prevention Tips

Regular maintenance is key to preventing many of these issues. Performing routine checks and following manufacturer guidelines can prolong the lifespan of your equipment and enhance its efficiency. Keeping the device clean and ensuring proper storage will also mitigate potential problems.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your gardening equipment. By following a few simple practices, you can enhance performance, prevent breakdowns, and maintain a smooth operation throughout the seasons.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean Air Filter | Every 10 hours of use | Improves airflow and engine efficiency |

| Inspect Spark Plug | Every 25 hours of use | Ensures reliable ignition and optimal combustion |

| Check Cutting Line | Before each use | Maintains effective cutting performance |

| Sharpen Blades | Every 10 hours of use | Enhances cutting efficiency and reduces strain |

| Examine Fuel System | Monthly | Prevents fuel-related issues and improves engine operation |

Implementing these maintenance tasks will not only keep your equipment in peak condition but also contribute to a more enjoyable gardening experience. Regular attention to these details can save you time and money in the long run.

Replacement Parts: When to Buy

Understanding the right time to acquire components for your gardening tools is crucial for maintaining their performance and longevity. Regular inspections can help identify wear and tear, ensuring you address issues before they affect functionality.

| Signs to Replace | Recommended Action |

|---|---|

| Reduced Cutting Efficiency | Check blades or cutting lines; consider replacement if damaged. |

| Increased Vibration | Inspect motor mounts and other support parts; replace as needed. |

| Excessive Noise | Evaluate bearings and housing; faulty components should be replaced. |

| Physical Damage | Replace visibly damaged or broken elements immediately. |

Upgrading Your Stihl Trimmer

Enhancing your gardening tool can significantly improve its performance and efficiency. Upgrades not only help in maintaining the longevity of your equipment but also provide a more enjoyable experience while working on your outdoor projects. Whether you’re looking to boost power, reduce weight, or enhance precision, there are numerous options available to elevate your tool’s capabilities.

Choosing the Right Accessories

When considering enhancements, selecting the appropriate accessories is crucial. Upgrading the cutting head can lead to more efficient mowing, allowing you to tackle tougher weeds with ease. Additionally, opting for high-quality line can improve durability and reduce the frequency of replacements. Always refer to compatibility guides to ensure the chosen components fit seamlessly with your equipment.

Maintenance and Performance Boosts

Regular maintenance is essential for optimal functionality. Investing in new filters or spark plugs can dramatically affect the power output and overall efficiency of your tool. Furthermore, adjusting the engine settings or incorporating performance-enhancing fuel can lead to noticeable improvements. Remember to consult your user manual for specific recommendations on upgrades to achieve the best results.

Finding Authorized Stihl Dealers

Locating certified vendors for your outdoor equipment is essential for ensuring you receive quality service and genuine products. Authorized dealers not only offer a comprehensive selection of tools but also provide expert advice and support. Their knowledge can help you make informed decisions about maintenance and upgrades for your machines.

Benefits of Choosing Authorized Vendors

Opting for certified distributors ensures that you gain access to authentic components and specialized services. These establishments often have trained professionals who can assist with repairs, maintenance, and advice tailored to your specific needs. Additionally, authorized sellers may provide warranties and guarantees that unauthorized vendors cannot match, ensuring peace of mind with every purchase.

How to Identify Authorized Dealers

To find certified distributors, visit the manufacturer’s official website, where you can use their dealer locator tool. This resource typically allows you to input your location to discover the nearest authorized sellers. Alternatively, checking local business directories or seeking recommendations from fellow enthusiasts can lead you to reputable sources. Remember to verify the dealer’s credentials before making a purchase to ensure you are dealing with a legitimate establishment.

DIY Repairs for String Trimmers

Maintaining garden equipment can save time and money while ensuring optimal performance. Many enthusiasts find that performing repairs themselves not only fosters a deeper understanding of their tools but also enhances their gardening experience. With a little know-how and the right approach, anyone can tackle common issues and extend the life of their machinery.

Identifying Common Issues

Before diving into repairs, it’s crucial to recognize frequent problems that may arise. Issues such as improper cutting, unusual noises, or difficulty starting are common indicators that something may be amiss. Regular maintenance can often prevent these challenges, but when they do occur, understanding the root cause is essential.

Essential Repair Tips

For those willing to get their hands dirty, here are some helpful suggestions:

- Inspect Components: Regularly check for wear and tear on essential components, such as the ignition system and fuel lines.

- Replace Worn Parts: If any elements appear damaged, replacing them promptly can prevent further complications.

- Keep Clean: Ensure that the equipment is free from debris and dirt, which can hinder performance.

With these tips and a bit of patience, anyone can confidently perform their own repairs and keep their gardening tools in top shape.