For anyone who owns a high-performance cutting tool, having a thorough understanding of its internal components is crucial. This knowledge not only aids in effective maintenance but also enhances the overall longevity of the equipment. A well-documented visual representation can serve as an invaluable resource, simplifying the complex task of identification and replacement.

When faced with repairs or upgrades, it’s essential to navigate the intricate network of parts efficiently. Each component plays a pivotal role in the functionality of the tool, and recognizing their positions and connections can save both time and effort. By familiarizing oneself with the layout, users can confidently address issues and perform necessary adjustments.

In this section, we will explore a detailed illustration that highlights the essential elements of your cutting equipment. Whether you are a seasoned professional or a novice, this guide will equip you with the insights needed to tackle maintenance tasks and ensure your tool operates at peak performance.

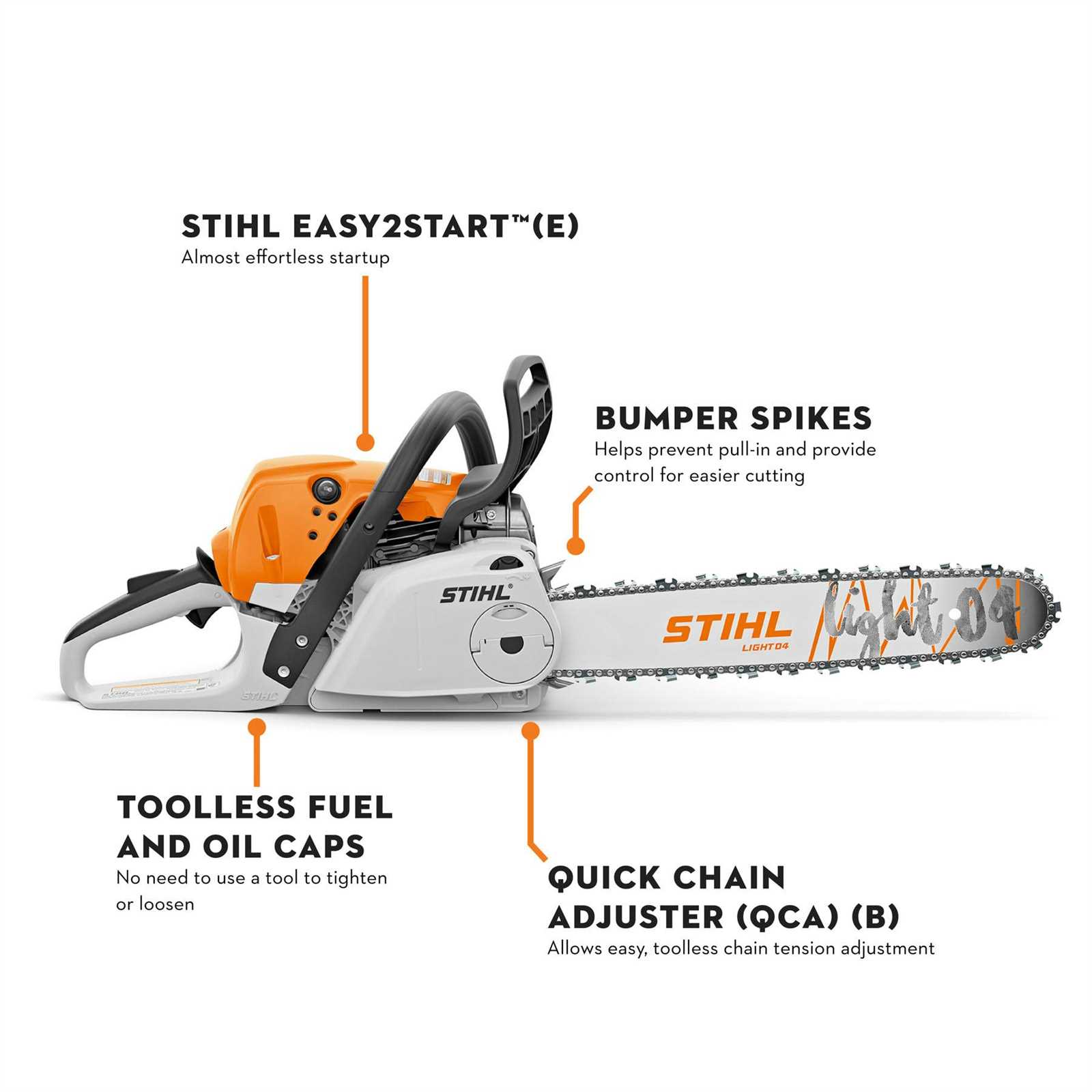

Understanding the Stihl MS 251

This section delves into the intricate workings of a popular power tool designed for efficient cutting tasks. Recognizing the essential components is crucial for optimal performance and maintenance.

Key Features

This tool offers a blend of power and convenience, making it suitable for both professional and amateur use. Its lightweight design and ergonomic features enhance user comfort, allowing for extended operation without fatigue.

Maintenance Essentials

Regular upkeep is vital for longevity. Familiarizing oneself with the internal assembly can prevent common issues and ensure reliable performance throughout its lifespan.

| Component | Function |

|---|---|

| Engine | Powers the tool for cutting |

| Bar | Guides the chain during operation |

| Chain | Conducts the cutting action |

| Air Filter | Prevents debris from entering the engine |

Key Components of the Chainsaw

The efficiency and performance of a cutting tool are largely determined by its fundamental elements. Understanding these vital parts can enhance both the usage and maintenance of the machine. Each component plays a specific role in ensuring optimal functionality and safety during operation.

The engine serves as the powerhouse, converting fuel into mechanical energy. This energy is then transmitted to the cutting mechanism, enabling effective wood slicing. The bar, a crucial element, guides the chain while providing a stable surface for cutting. The chain itself, equipped with sharp teeth, is responsible for the actual cutting action, allowing for smooth and efficient performance.

The handle offers control and maneuverability, ensuring the user can operate the tool with precision. Additionally, safety features, such as the brake and throttle lock, protect the operator from potential hazards. Regular inspection and maintenance of these components are essential for extending the tool’s lifespan and maintaining its cutting capabilities.

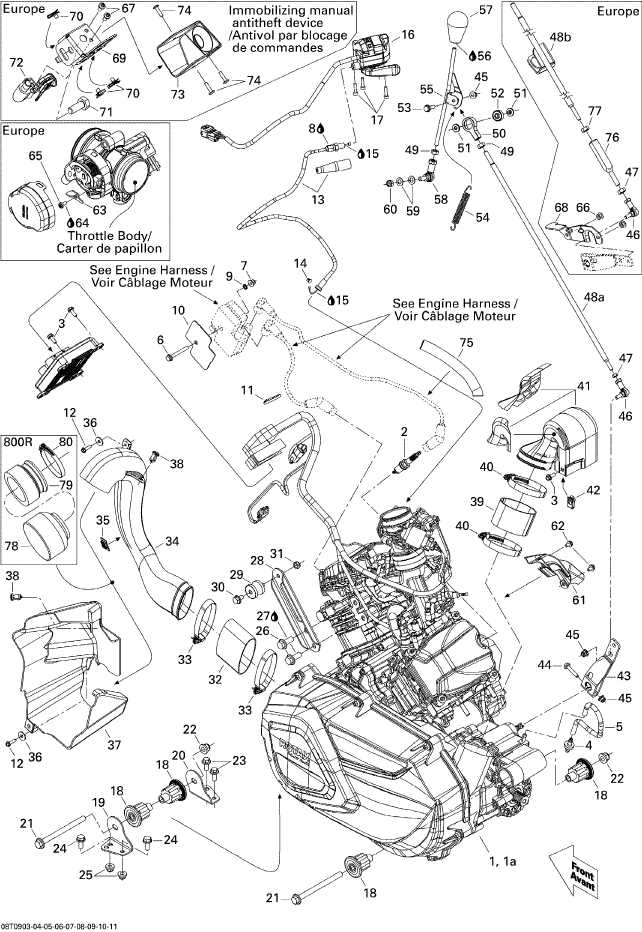

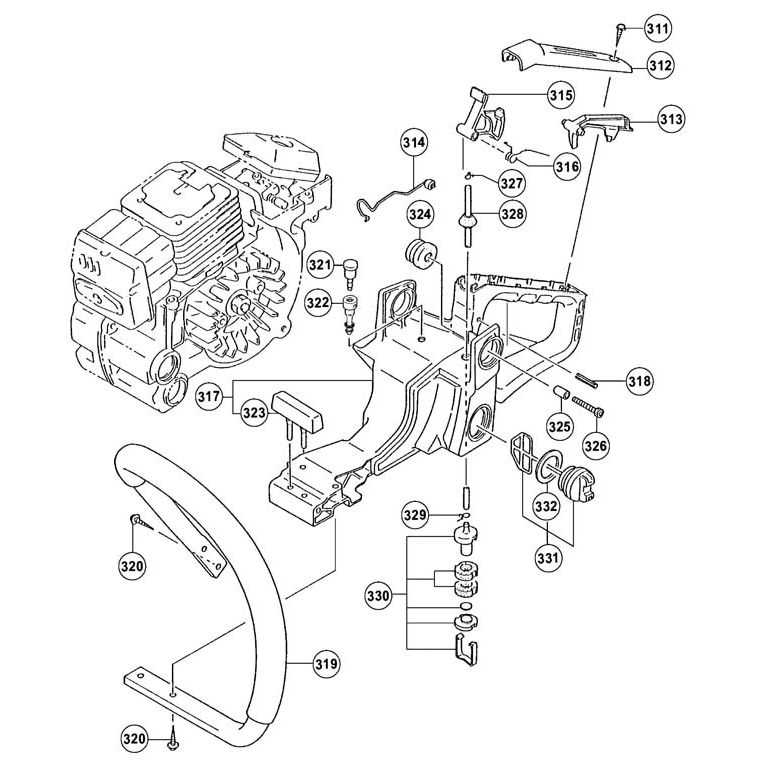

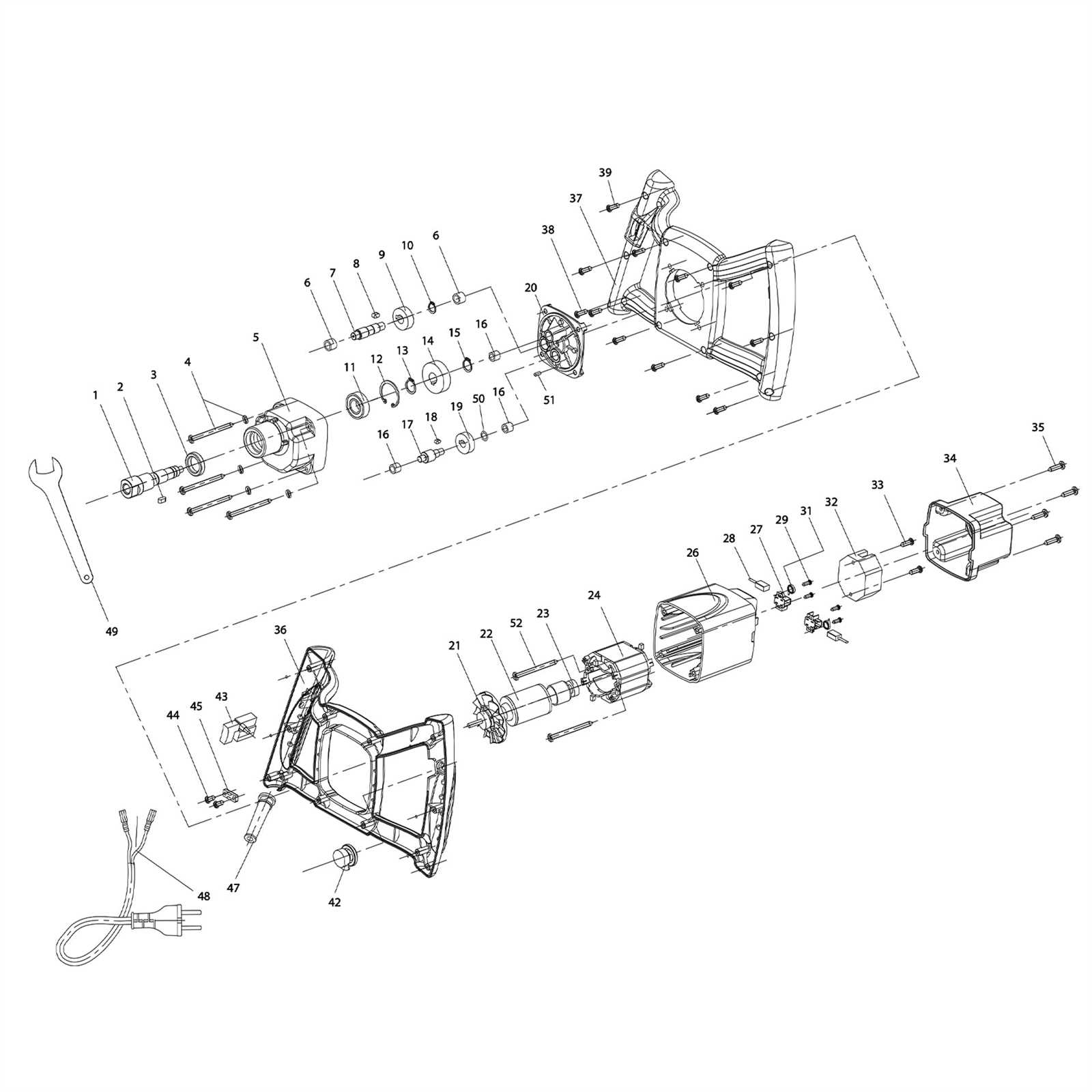

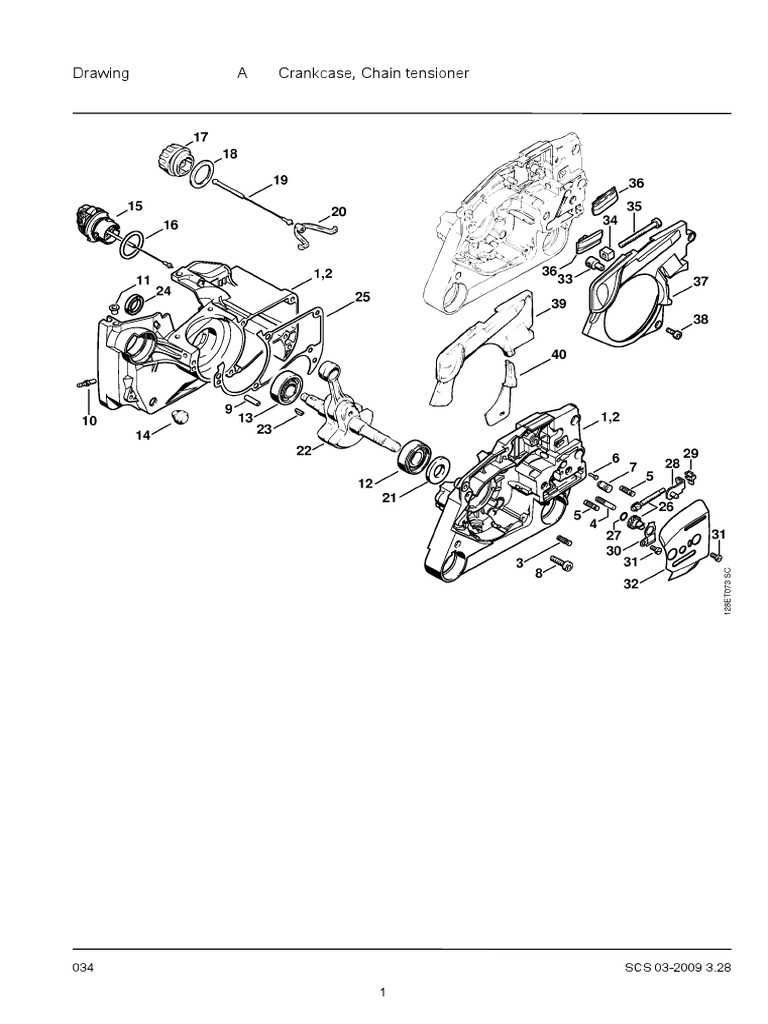

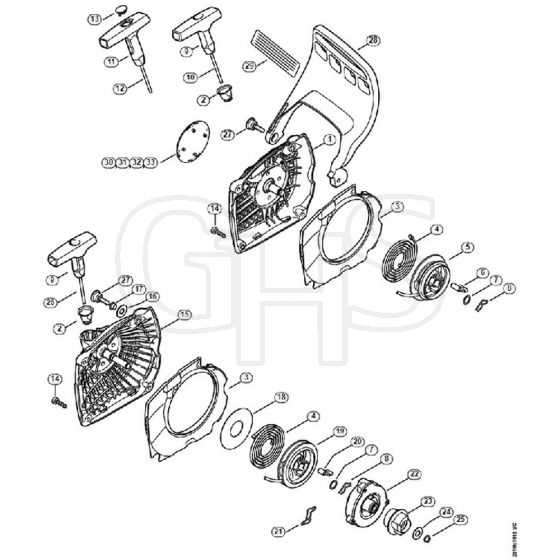

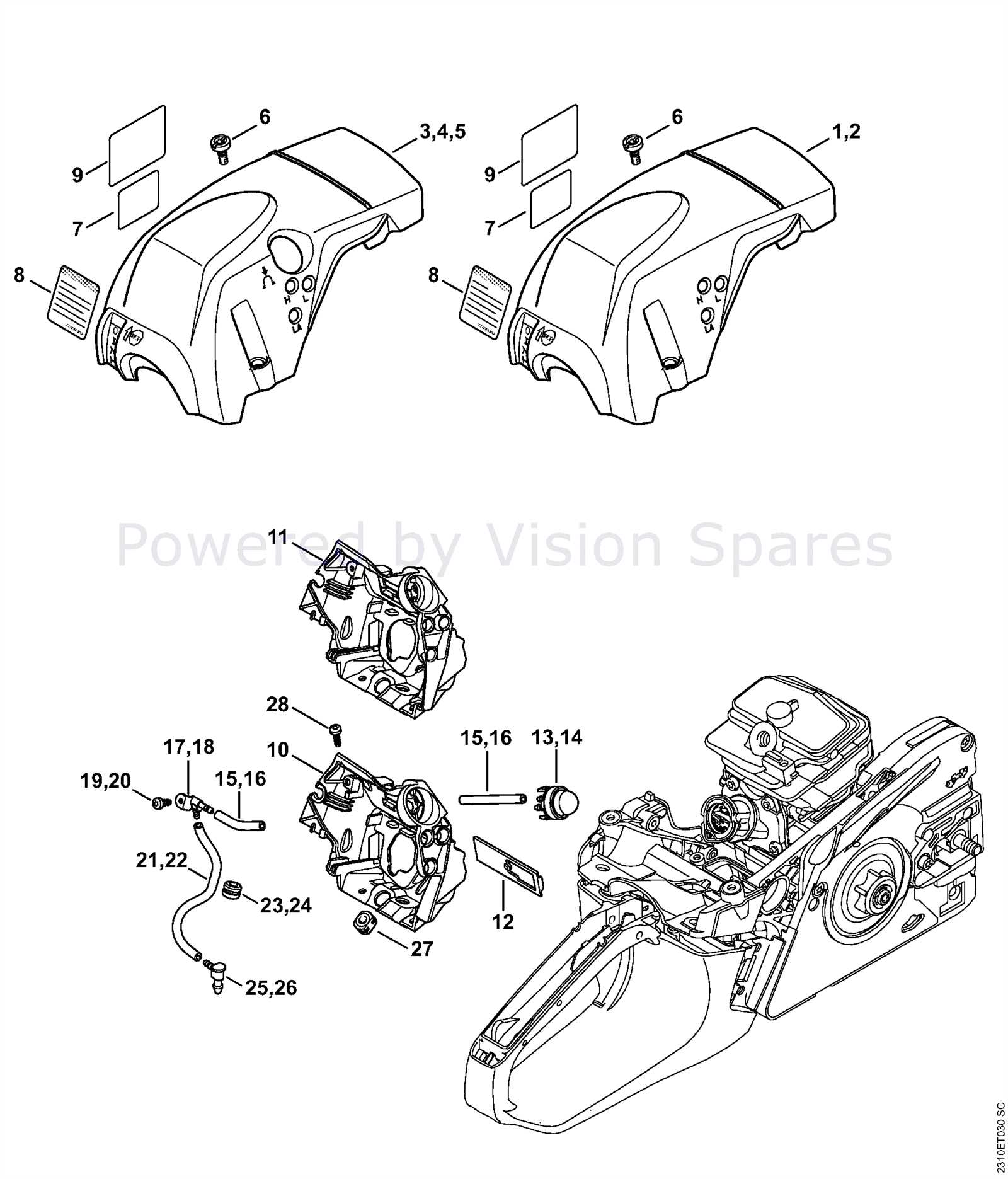

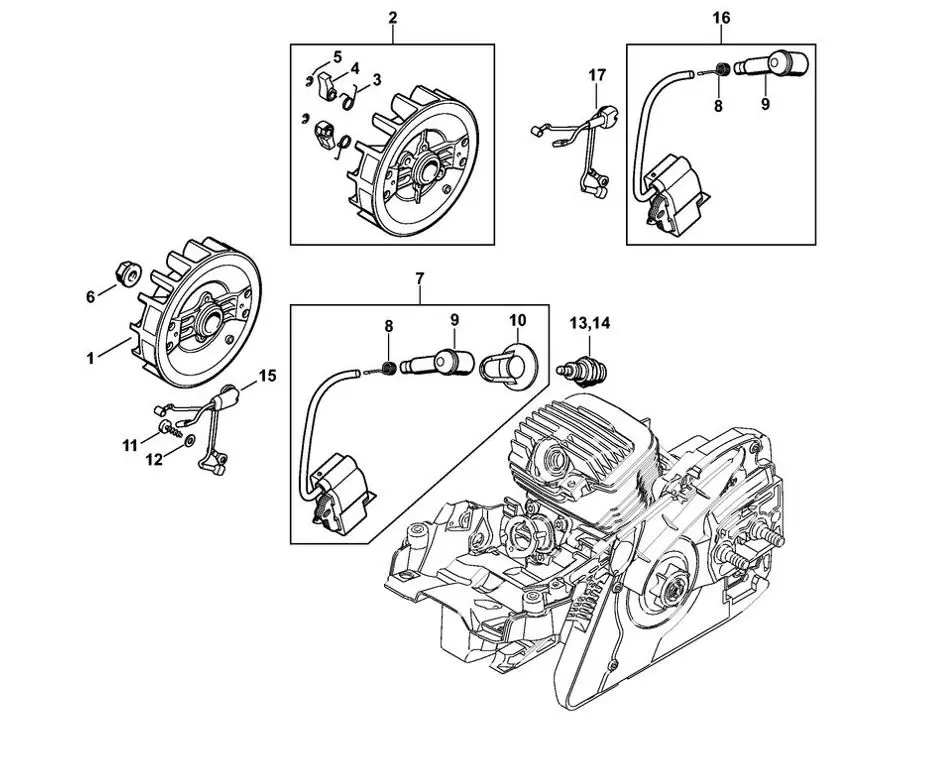

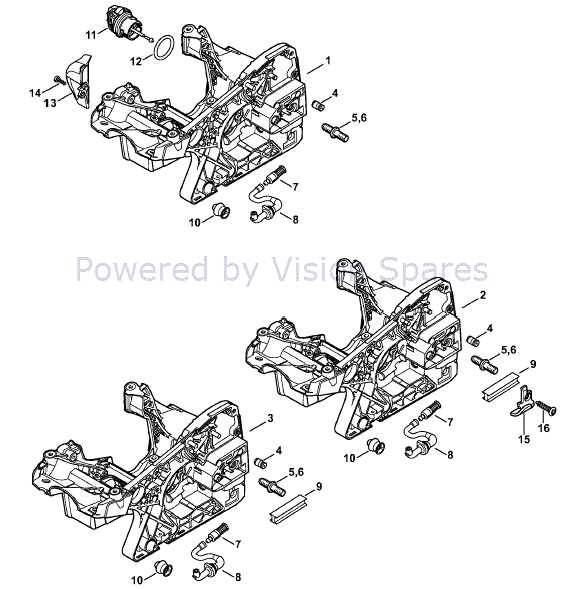

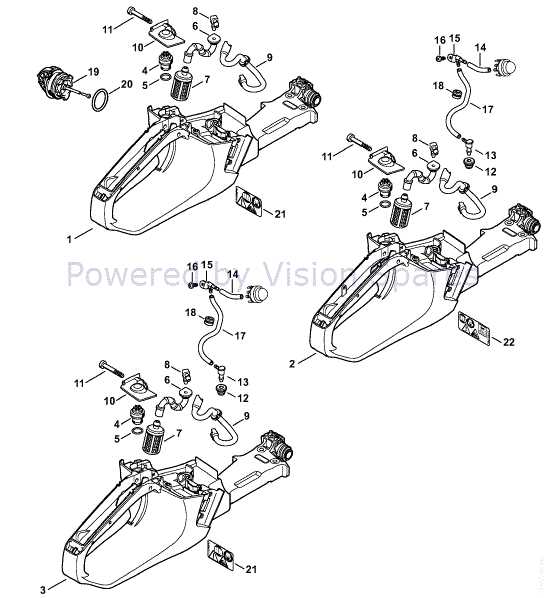

How to Read the Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair. This illustration provides a detailed layout of each element, allowing users to identify parts and their functions easily. Familiarity with the key features of the chart enhances the ability to navigate and utilize it effectively.

Begin by locating the legend, which usually explains symbols and codes. Each section is typically numbered or labeled, correlating with specific pieces. Pay attention to the grouping of components, as related items are often clustered together, facilitating a comprehensive grasp of the assembly.

As you examine the visual, note any arrows or lines indicating connections or interactions between parts. This will help in understanding how elements fit together and their roles in the overall operation. Taking the time to analyze these details can significantly improve repair efficiency and accuracy.

Lastly, always refer to accompanying documentation for detailed descriptions and specifications. This combination of visual and textual information ensures you have the ultimate understanding necessary for successful maintenance tasks.

Common Issues and Solutions

When working with outdoor power equipment, it’s not uncommon to encounter various challenges that can affect performance and reliability. Understanding these common problems and their potential solutions can help users maintain their machines effectively and ensure they operate smoothly.

Starting Difficulties

One prevalent issue is trouble starting the machine. This can stem from several factors, including a clogged air filter, old fuel, or issues with the spark plug. Regular maintenance, such as cleaning or replacing the air filter, using fresh fuel, and inspecting the spark plug for wear, can greatly enhance starting performance.

Overheating

Overheating is another frequent concern, often caused by insufficient lubrication or blocked cooling fins. To address this, ensure that the oil levels are adequate and that all cooling components are clean and free of debris. Taking these steps can help maintain optimal operating temperatures and prolong the lifespan of the equipment.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By following a few essential practices, you can enhance performance and extend the lifespan of your machinery. Proper maintenance not only prevents unexpected breakdowns but also ensures safety during use.

- Regular Cleaning: After each use, clean the exterior to remove dirt and debris. Pay special attention to air filters and cooling vents to prevent overheating.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Regular lubrication can significantly prolong operational life.

- Sharp Blades: Keep cutting edges sharp for optimal performance. Dull blades increase strain on the engine and can lead to premature failure.

- Check Fuel Quality: Use fresh, high-quality fuel to prevent clogging and engine issues. Store fuel properly and replace it as needed.

- Inspect Components: Regularly examine essential parts such as spark plugs, filters, and fuel lines for signs of wear or damage. Replace them promptly if needed.

Implementing these simple yet effective maintenance strategies will not only enhance your equipment’s functionality but also contribute to a safer working environment. Make maintenance a routine part of your operation to achieve the best results.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining optimal performance and longevity. Several reliable sources can help you obtain high-quality replacements tailored to your specific model.

- Authorized Dealers: Visit local retailers that specialize in your brand. They often stock genuine components and can provide expert advice.

- Online Marketplaces: Websites such as Amazon, eBay, and others feature a wide range of options. Be sure to check seller ratings and reviews.

- Specialty Websites: Numerous online platforms focus exclusively on outdoor power equipment. These sites usually offer detailed catalogs and diagrams for easier navigation.

- Repair Shops: Local repair facilities may have access to parts or can order them for you, ensuring compatibility with your machine.

- Manufacturer’s Website: Check the official website of the brand for an online store or a parts locator tool, which can direct you to authorized sellers.

Always compare prices and verify the authenticity of the components before making a purchase to ensure reliability and performance.

Comparing with Other Stihl Models

When evaluating various models from a leading brand, it’s essential to explore the differences and similarities that can impact performance and usability. Each design caters to specific tasks, making some tools more suitable for certain users than others.

One significant aspect is the engine capacity, which can greatly influence power and efficiency. For instance, while some models may excel in lightweight tasks, others are built for heavy-duty use, providing greater torque and speed.

Another factor to consider is the overall weight and ergonomics of the equipment. A well-balanced tool enhances user comfort and reduces fatigue during prolonged operation, which is crucial for professional users.

Additionally, examining the availability of attachments and accessories can also reveal which model offers the most versatility, catering to diverse needs. Understanding these distinctions will help users make informed decisions tailored to their specific requirements.

Importance of Genuine Stihl Parts

Using authentic components for your outdoor power tools is essential for maintaining performance and longevity. These elements are engineered to meet specific standards, ensuring optimal functionality and safety. When substitutes are used, the risk of malfunctions and decreased efficiency increases significantly.

Quality Assurance

Authentic components are rigorously tested to withstand demanding conditions. This commitment to quality translates into better durability and reliability, reducing the frequency of replacements and repairs. Investing in genuine parts ultimately saves time and money in the long run.

Optimal Performance

Utilizing original components ensures that your equipment operates at its peak efficiency. This results in smoother operation and enhanced productivity, allowing users to achieve the best results in their tasks. Moreover, maintaining the integrity of your tools helps preserve their resale value.

Upgrades and Modifications for Performance

Enhancing the efficiency and capability of your cutting equipment can significantly improve its overall performance. By implementing specific upgrades and modifications, users can achieve better power output, increased durability, and improved handling. This section explores various options that can help you get the most out of your machine.

| Upgrade/Modification | Description | Benefits |

|---|---|---|

| High-Performance Filter | Replacing the standard air filter with a high-performance model. | Improved airflow and better engine efficiency. |

| Modified Muffler | Installing a custom muffler designed for enhanced exhaust flow. | Increased horsepower and reduced weight. |

| Enhanced Chain | Upgrading to a chain with a lower gauge and better cutting geometry. | Faster cutting speeds and smoother operation. |

| Performance Spark Plug | Using a spark plug designed for higher performance. | Improved ignition and more efficient combustion. |

| Adjustable Carburetor | Replacing the fixed carburetor with an adjustable model. | Fine-tuning fuel-air mixture for optimal performance. |

By carefully selecting and implementing these modifications, operators can enhance their machine’s capabilities, making tasks more efficient and enjoyable. Always ensure that any upgrades comply with safety standards and manufacturer guidelines.