Understanding the various elements of a widely used gardening device can be crucial for maintaining its efficiency and ensuring smooth operation. Each mechanical tool consists of a complex system of interconnected pieces, and knowing how they work together can help with timely repairs and adjustments.

In this section, we will delve into the individual elements that contribute to the performance of this trimming equipment. By breaking down the structure, you’ll gain valuable insight into how these components function as a unit. Whether you are looking to fix an issue or enhance the tool’s durability, familiarizing yourself with its inner workings is essential.

From the engine to the cutting mechanism, each piece has a specific role. By identifying and understanding these, you can ensure your equipment stays in top condition. Regular upkeep and attention to detail will go a long way in extending its life and maintaining peak performance.

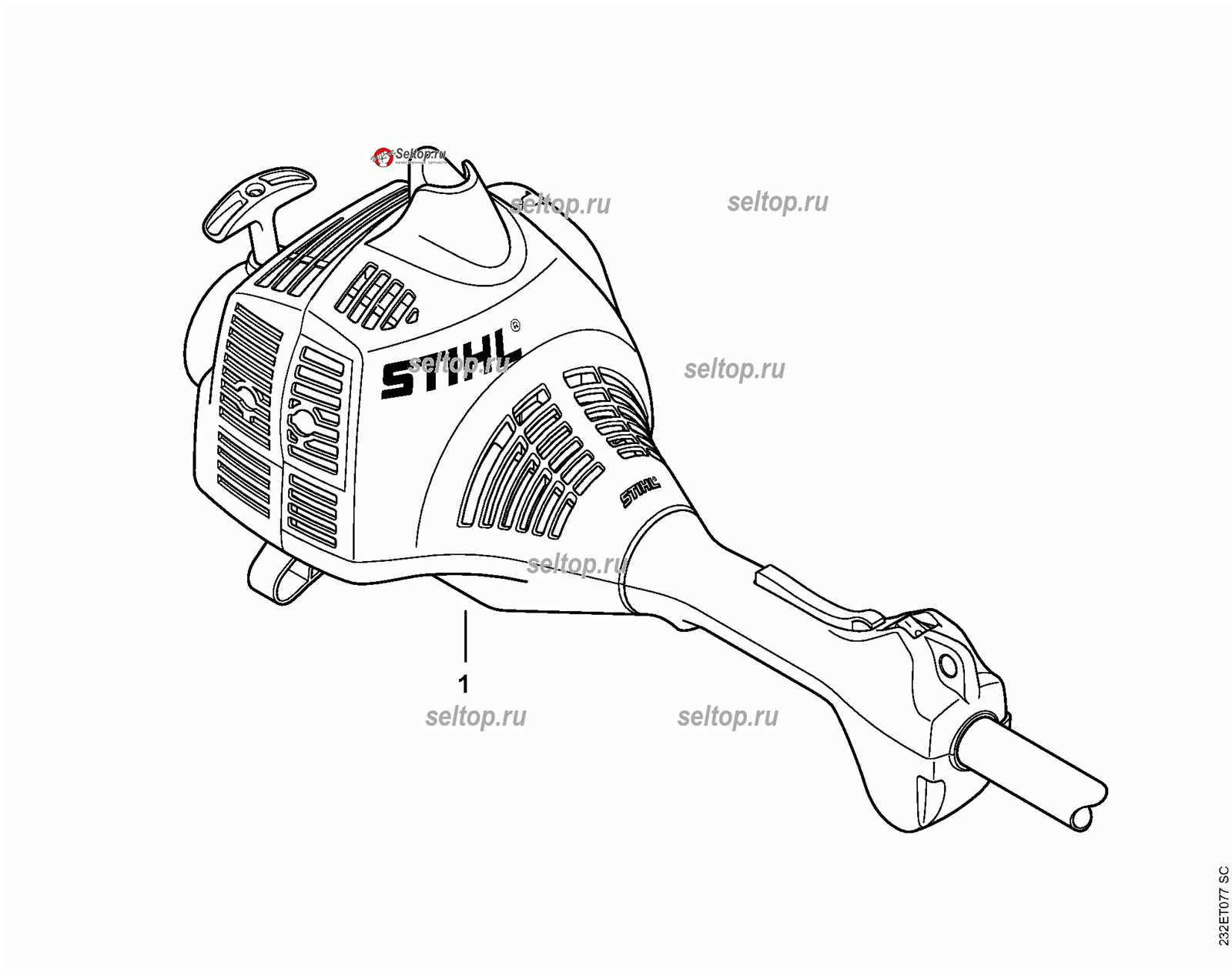

Essential Components of Stihl FS46

Understanding the key mechanical elements of this trimmer model is crucial for effective maintenance and repairs. These components ensure smooth operation and optimal performance, contributing to the machine’s durability and efficiency in regular use.

Engine Assembly

The power source of the trimmer includes several important elements that drive the tool. It contains both internal and external parts that work together to generate the force needed to power the cutting mechanism. Proper care of the engine ensures the machine operates reliably and lasts longer.

Cutting Mechanism

The system responsible for cutting consists of a series of essential elements designed to work in harmony. The cutting tool is connected to the engine by a shaft, transferring power from the motor to the blade or string. Maintaining these parts guarantees smooth cutting action and consistent performance.

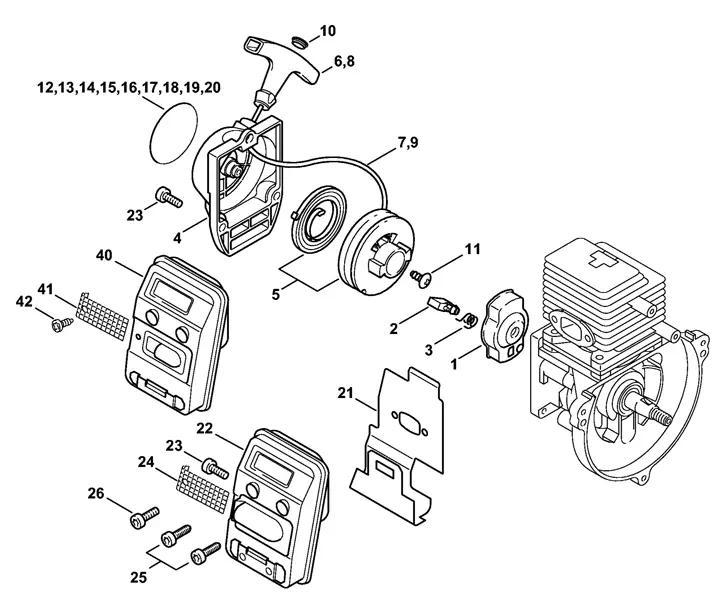

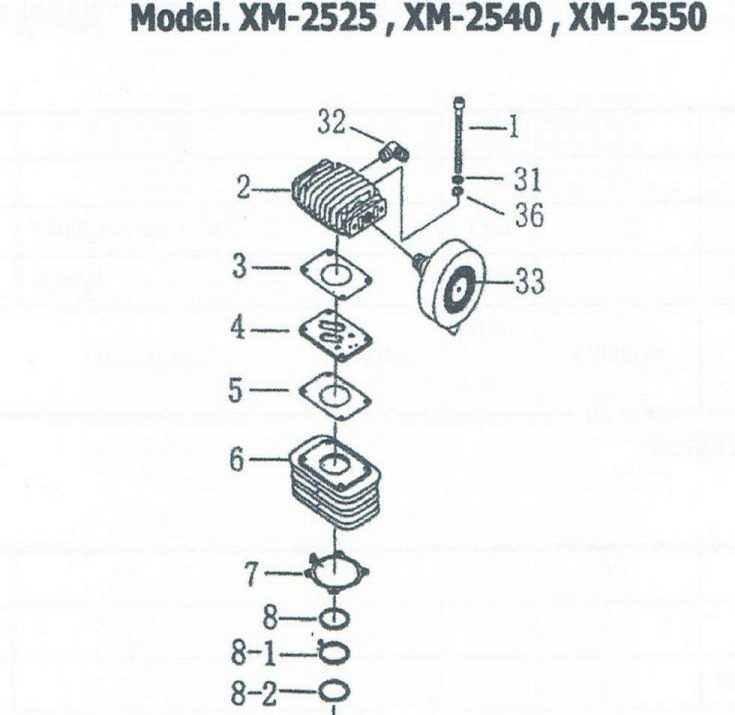

Understanding the Engine Structure

The internal components of a small engine are meticulously designed to ensure efficiency and longevity. To fully comprehend how these components work together, it is essential to explore the primary sections that contribute to the overall function. Each part has a distinct role, and when combined, they allow the engine to operate smoothly and generate power.

Main Components

The engine consists of several key elements, each interacting to produce mechanical energy. These include the cylinder, piston, crankshaft, and connecting rod. Together, these parts convert fuel into motion, creating the necessary energy to drive the machine. Understanding their interplay is crucial for grasping how the engine functions as a whole.

Combustion Process

At the heart of the engine’s operation is the combustion process, where fuel is ignited to produce energy. The piston moves up and down within the cylinder, compressing the fuel mixture before ignition occurs. This motion is transferred to the crankshaft, turning it and generating rotational energy that powers the machine. Proper maintenance of this system ensures optimal performance and longevity.

Guide to Trimmer Head Assembly

Assembling the cutting mechanism for your grass trimmer is a crucial step to ensure efficient and smooth operation. Understanding the components and how they fit together will help you maintain your device for optimal performance.

Main Components

The assembly process begins with identifying the core elements of the cutting system. Typically, these include the spool, line, and outer casing, each playing a specific role in the cutting action. Ensuring these parts are correctly aligned is essential for functionality.

| Component |

Description |

Assembly Tip |

| Spool |

Holds the cutting line in place and controls its release. |

Ensure the line is wound evenly to avoid tangles. |

| Cutting Line |

Responsible for trimming grass and small brush. |

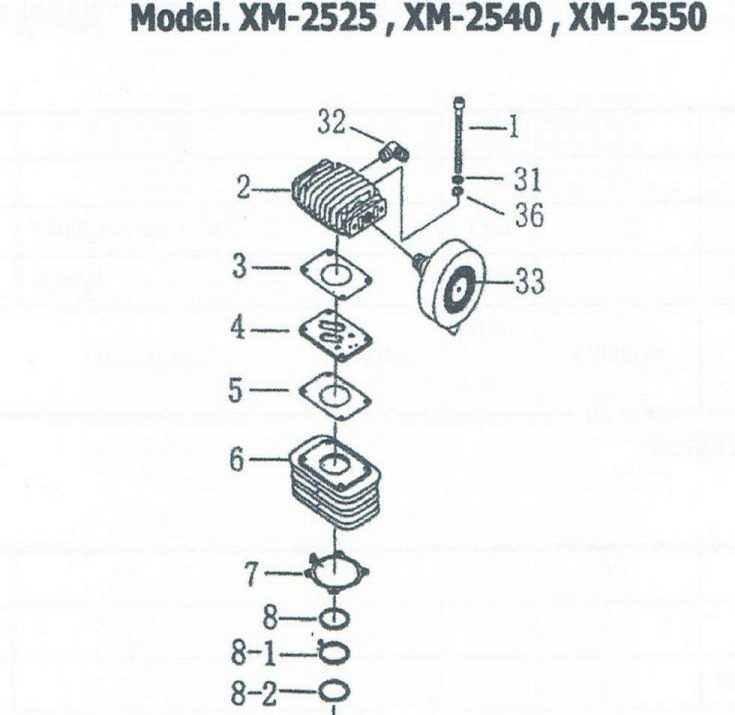

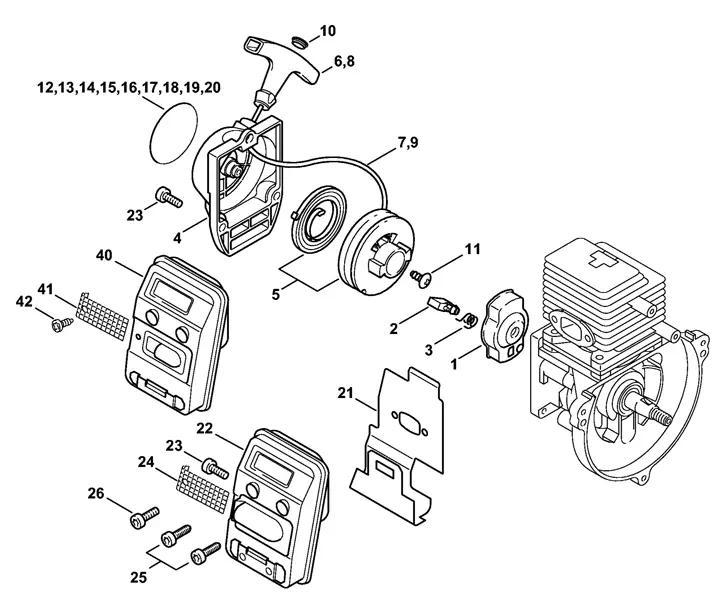

Replacing the Air Filter on Small Engine Trimmer

Over time, the air filter in your handheld trimmer can become clogged with debris, affecting performance. Regular maintenance ensures your tool runs smoothly by allowing the engine to breathe properly. In this guide, we’ll walk through the steps to replace the filter efficiently and keep your equipment in optimal condition.

- First, make sure the tool is turned off and completely cool before proceeding with any maintenance.

- Locate the cover on the side of the engine that houses the filter. Use a screwdriver if necessary to open the cover.

- Carefully remove the old, dirty filter from its compartment. Pay attention to how it fits to ensure proper placement of the new one.

- Insert a fresh filter into the slot, making sure it sits securely without gaps around the edges.

- Replace the cover and tighten any screws that were removed earlier.

With the air filter replaced, your trimmer should perform at its best, maintaining consistent power an

Fuel System Overview and Maintenance Tips

The fuel delivery mechanism is essential for ensuring smooth operation and longevity of the machine. A well-maintained system guarantees optimal performance and reduces the likelihood of breakdowns. Understanding the key components involved in the process, as well as adopting a regular maintenance routine, can help in preventing common issues related to fuel supply.

To keep the mechanism functioning efficiently, it is important to perform periodic checks and servicing. Below is a table outlining key areas of focus and recommended maintenance tasks:

| Component |

Maintenance Task |

Frequency |

| Fuel Filter |

Inspect for clogging and replace if necessary |

Every 25 hours of operation |

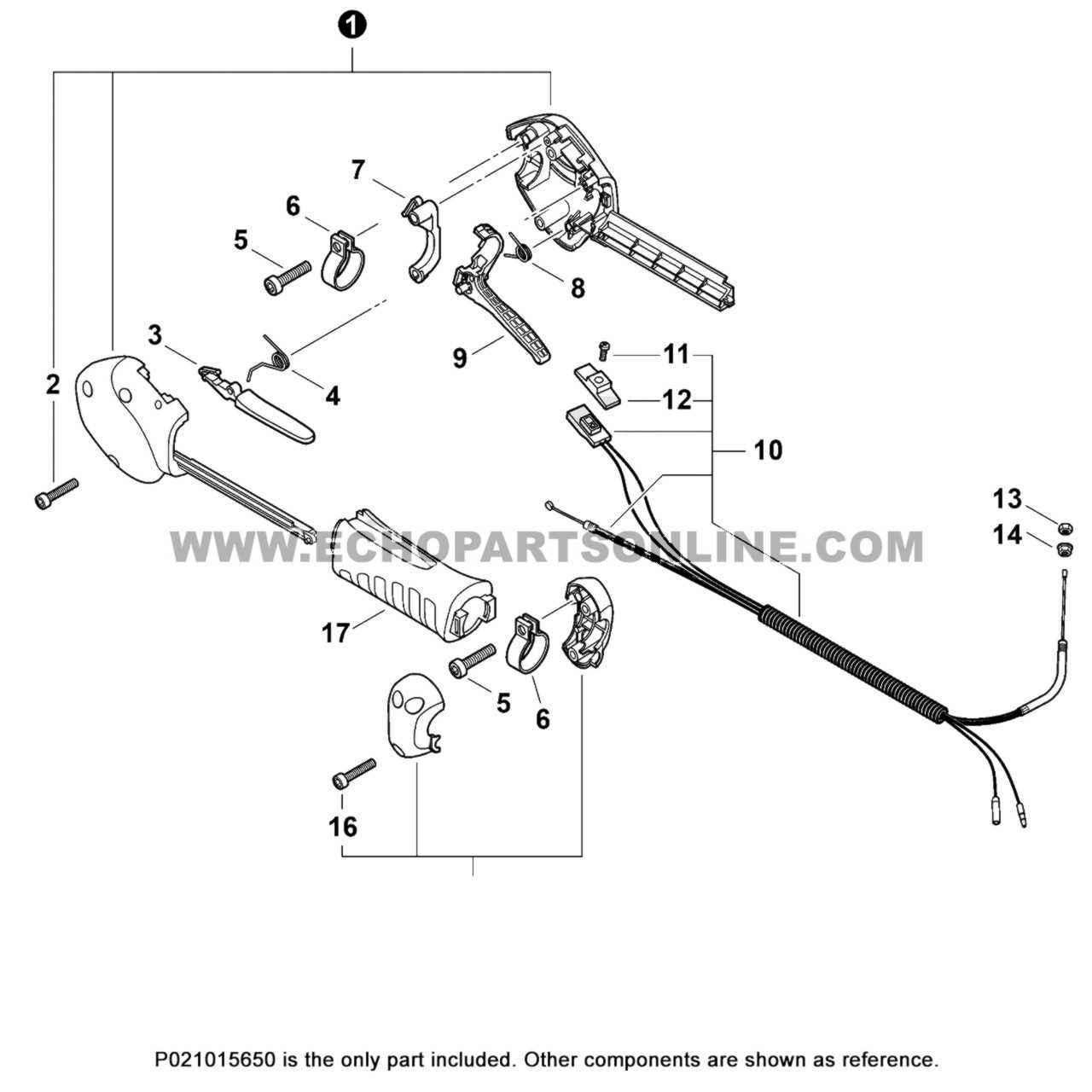

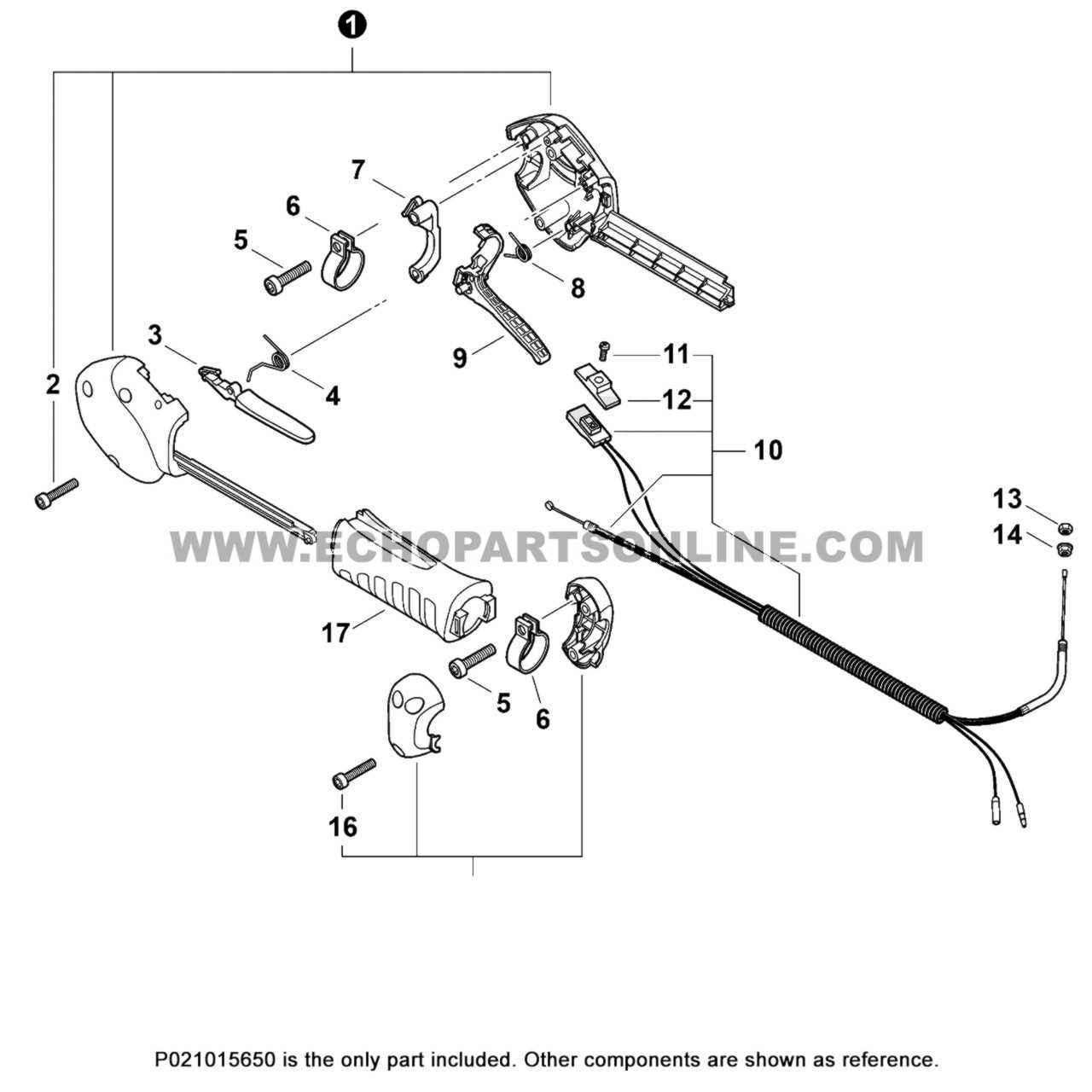

Throttle and Handlebar Mechanics Explained

The mechanics of controlling power tools often hinge on the interplay between throttle systems and handlebar designs. These components are essential for ensuring efficient operation, allowing users to manipulate speed and direction seamlessly. A comprehensive understanding of these mechanisms enhances user safety and tool performance.

Understanding Throttle Functionality

The throttle serves as a crucial interface between the operator and the machine. It regulates the flow of fuel or power to the engine, directly influencing the speed and power output. When the throttle is engaged, it allows for a precise adjustment of the engine’s performance, enabling users to adapt to varying tasks. This responsiveness is vital for achieving optimal results, particularly in demanding environments.

Handlebar Design and Ergonomics

Handlebars play a significant role in the overall user experience, combining functionality with comfort. An ergonomic design reduces strain on the operator’s hands and arms, facilitating extended use without fatigue. The positioning of controls and grips can greatly affect maneuverability, allowing for easy adjustments while maintaining a firm hold on the equipment. Properly designed handlebars not only enhance control but also contribute to safer operation.

In conclusion, understanding the dynamics of throttle and handlebar mechanics is essential for any operator looking to maximize efficiency and safety. A well-functioning throttle coupled with ergonomic handlebars creates an optimal user experience, making tool operation both effective and enjoyable.

Maintenance of Stihl FS46 Ignition System

Proper upkeep of the ignition assembly is crucial for the reliable performance of outdoor power tools. Regular checks and maintenance ensure efficient starting, optimal operation, and longevity of the equipment. Understanding the components involved and their function is essential for effective servicing.

Key Components to Inspect

The ignition system consists of several vital elements, including the spark plug, ignition coil, and wiring. The spark plug should be examined for wear and carbon buildup. A clean and functional spark plug ignites the fuel mixture effectively, leading to smooth engine performance. The ignition coil generates the high voltage necessary for the spark, and it should be free from damage and securely connected. Additionally, wiring should be checked for any signs of fraying or corrosion, as these can disrupt the electrical flow.

Maintenance Procedures

To maintain the ignition system, begin by removing the spark plug and inspecting it closely. If it shows signs of damage, replace it promptly. Clean the spark plug using a wire brush to remove any debris. Next, examine the ignition coil for any physical damage or signs of overheating. Ensure all connections are tight and free from corrosion. Finally, test the entire system for functionality after maintenance to guarantee that the equipment operates smoothly.

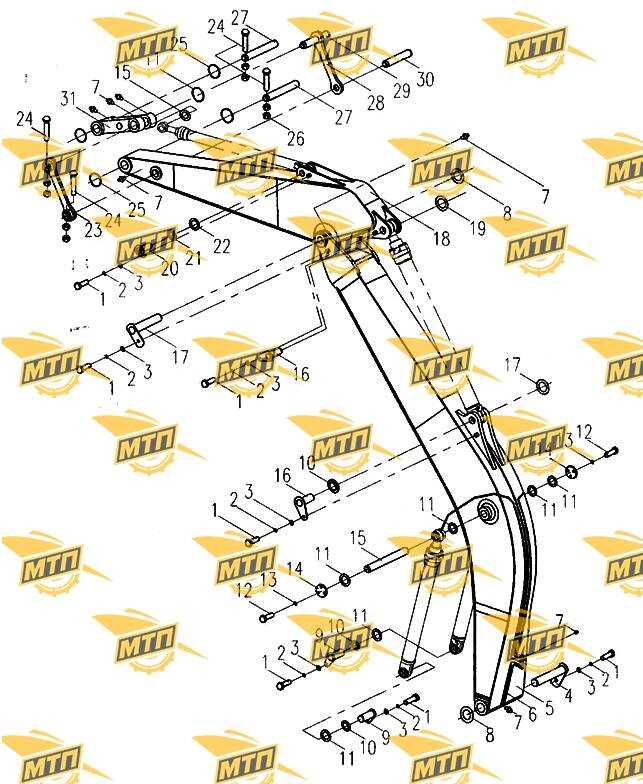

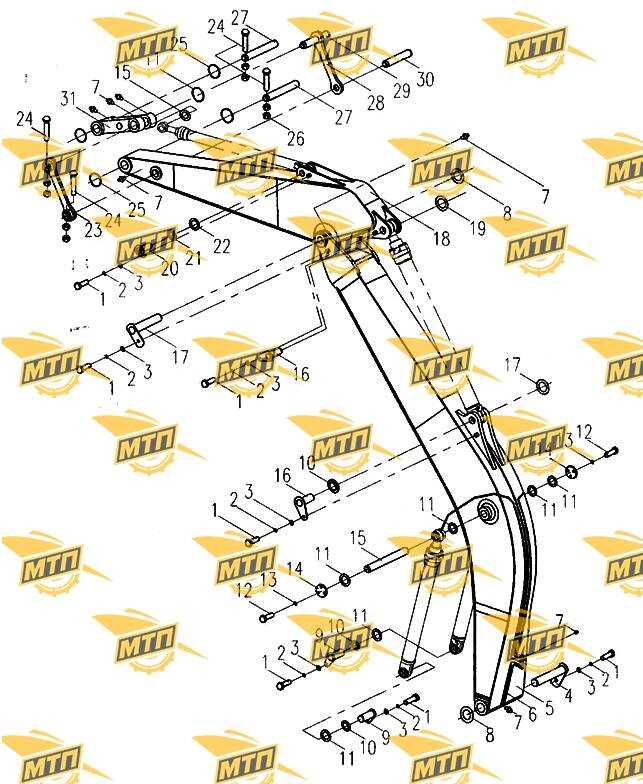

Exploring the Cutting Attachment Components

The efficiency of a cutting tool is significantly influenced by its attachment system. Understanding the various elements that make up these components can enhance performance and facilitate maintenance. This section delves into the essential parts involved in cutting attachments, providing insights into their functions and importance.

Key Elements of Cutting Attachments

Among the primary components are the blades, which are designed to provide precise cuts while enduring harsh conditions. These blades come in various shapes and sizes, each tailored for specific tasks, whether it be trimming grass or clearing dense brush. Additionally, the gearbox plays a crucial role by transferring power from the engine to the cutting head, ensuring optimal speed and torque for effective operation.

Maintenance and Replacement Considerations

Regular inspection of the attachment elements is vital for maintaining optimal performance. Components such as the cutting line and spool may require frequent replacement due to wear and tear. Ensuring that these parts are in good condition not only prolongs the life of the tool but also enhances safety during use.

How to Service the Drive Shaft

Maintaining the drive shaft is crucial for ensuring optimal performance and longevity of your equipment. Regular servicing helps prevent wear and tear, reduces the risk of mechanical failure, and enhances overall efficiency. This process involves inspecting, cleaning, and lubricating the components to keep them functioning smoothly.

Follow these steps to effectively service the drive shaft:

| Step |

Description |

| 1 |

Disconnect the power source and ensure the machine is completely turned off to prevent accidents during maintenance. |

| 2 |

Remove the casing or housing to access the drive shaft assembly. Take care not to damage any surrounding components. |

| 3 |

Inspect the drive shaft for any signs of wear, such as cracks, bends, or excessive play. Replace any damaged parts as needed. |

| 4 |

Clean the shaft and associated components using a suitable solvent to remove dirt, debris, and old lubricant. |

| 5 |

Apply a high-quality lubricant to the drive shaft, ensuring even coverage to minimize friction and enhance performance. |

| 6 |

Reassemble the housing and secure it properly. Double-check that all components are aligned and functioning correctly before powering up the machine. |

By following these steps, you can maintain the efficiency of the drive shaft and prolong the life of your equipment. Regular inspections and timely servicing will ensure that your machine operates at its best.