In the world of machinery, a profound comprehension of the various elements that contribute to functionality is essential. Each component plays a pivotal role in the overall performance and efficiency of the equipment. By delving into the intricate structure of these tools, users can enhance their maintenance skills and ensure longevity.

Exploring the intricacies of the various segments allows enthusiasts and professionals alike to grasp how each piece interacts with others. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades. A thorough understanding of these mechanisms is vital for achieving optimal results in any endeavor.

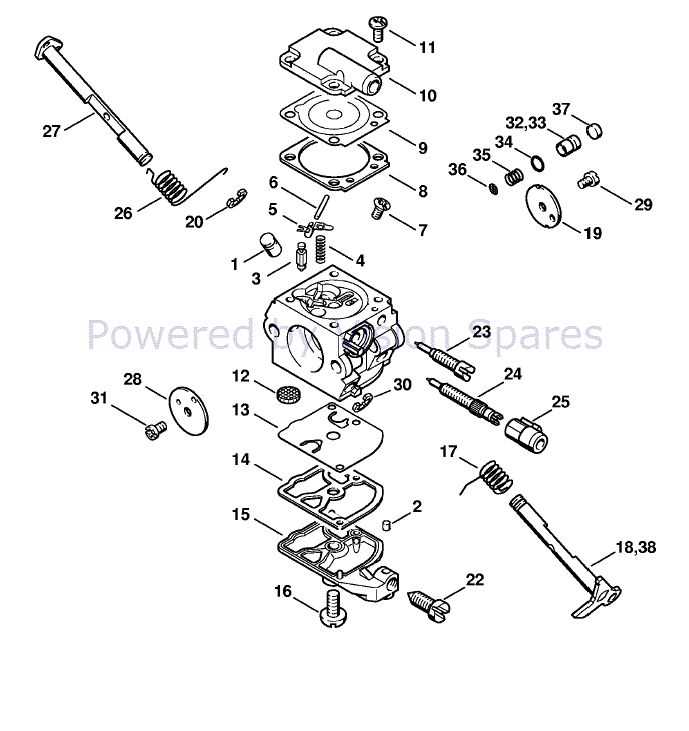

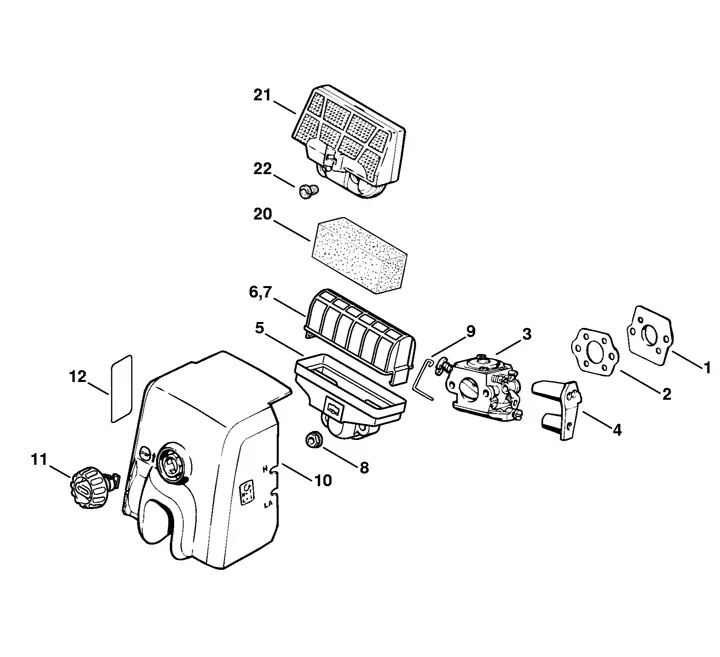

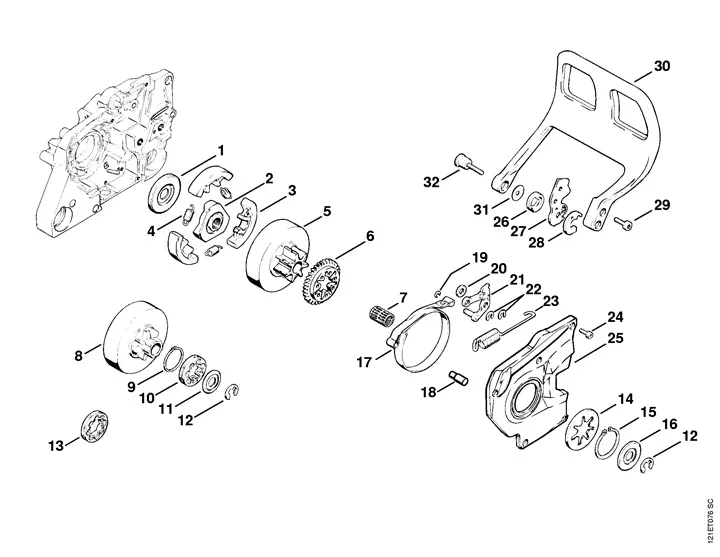

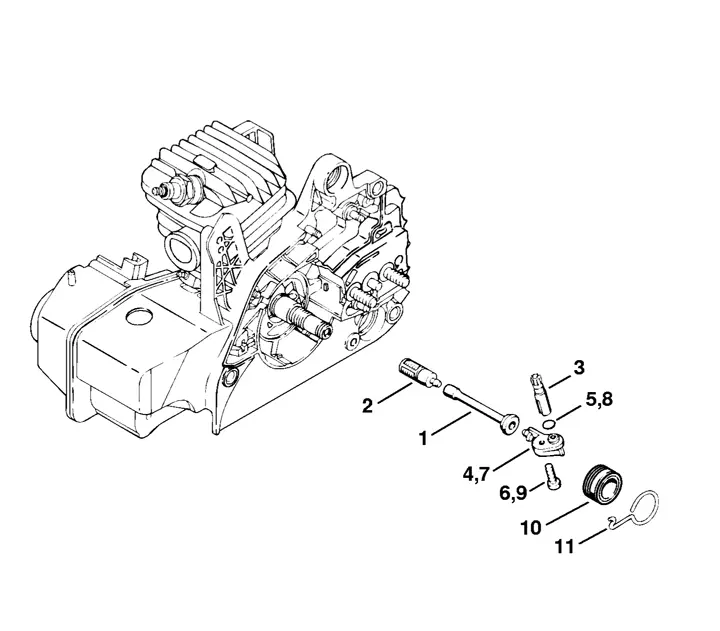

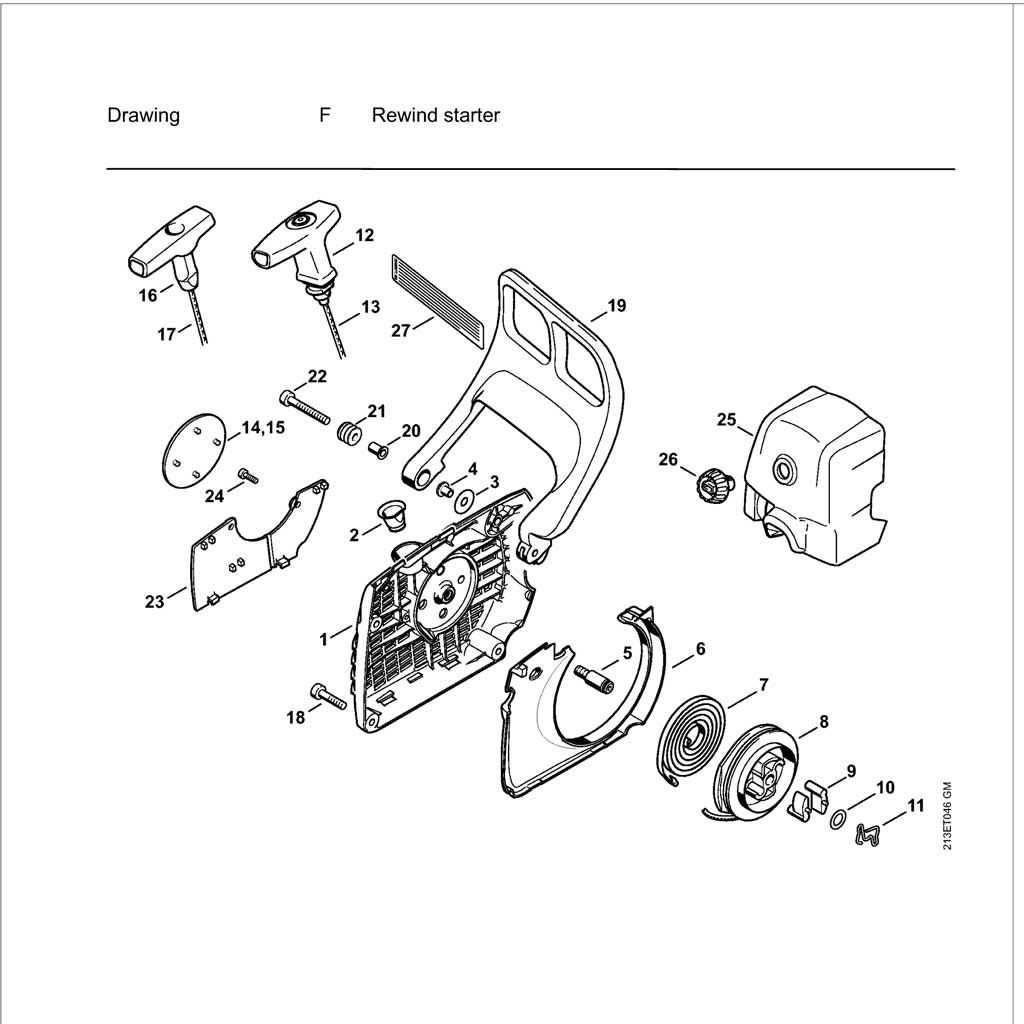

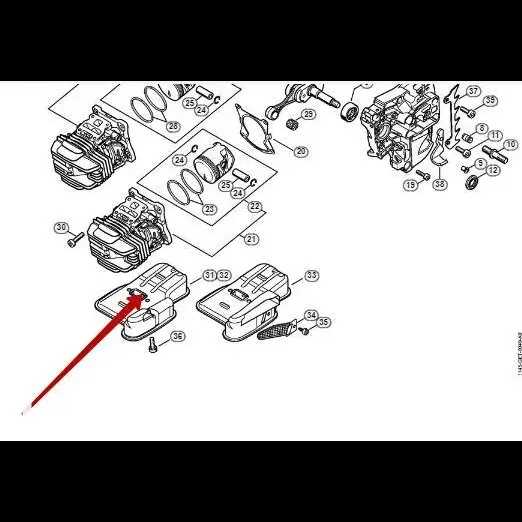

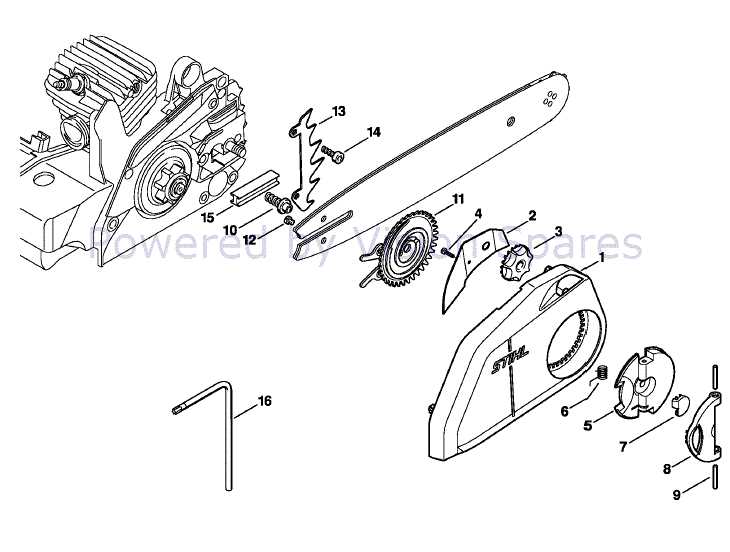

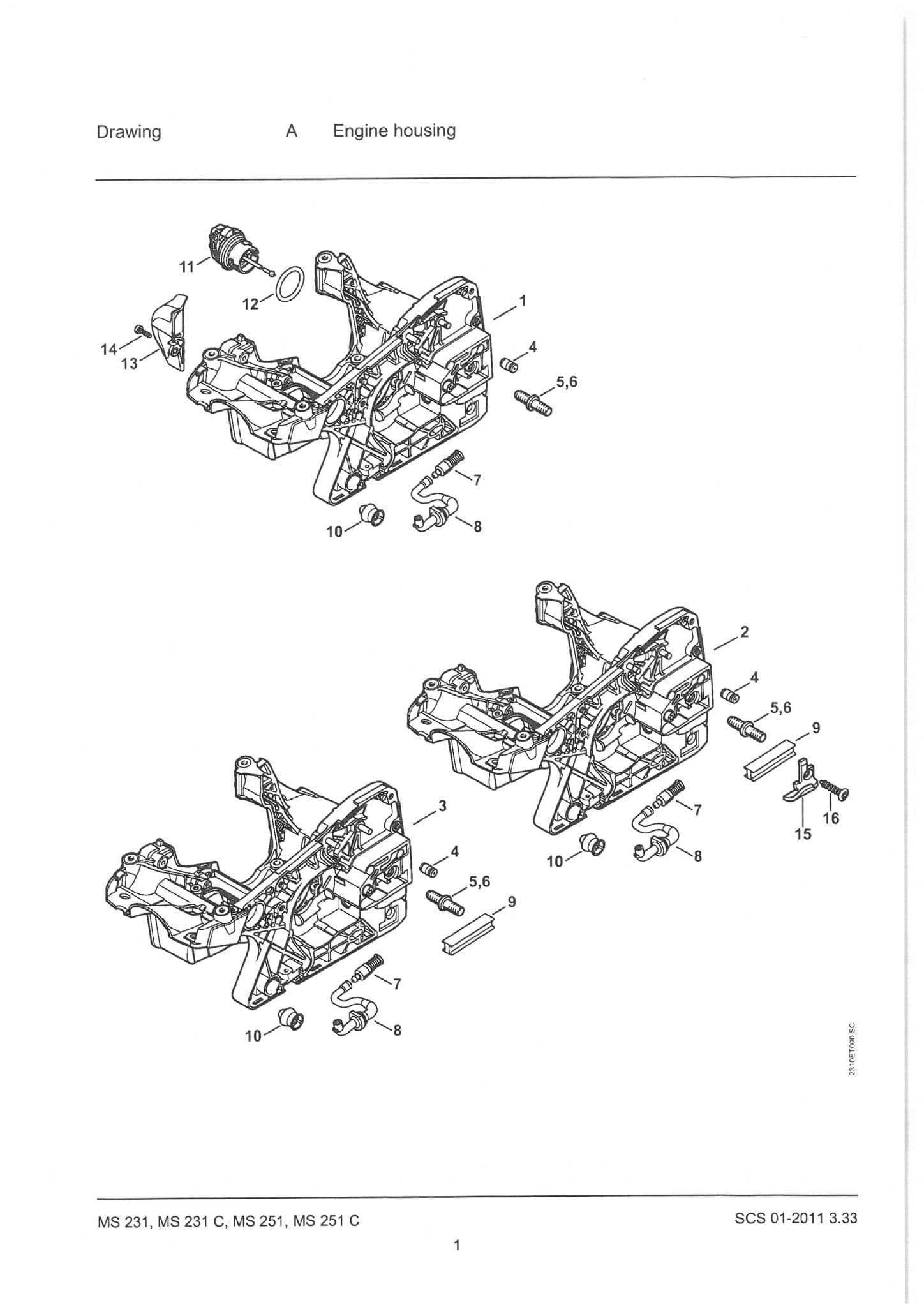

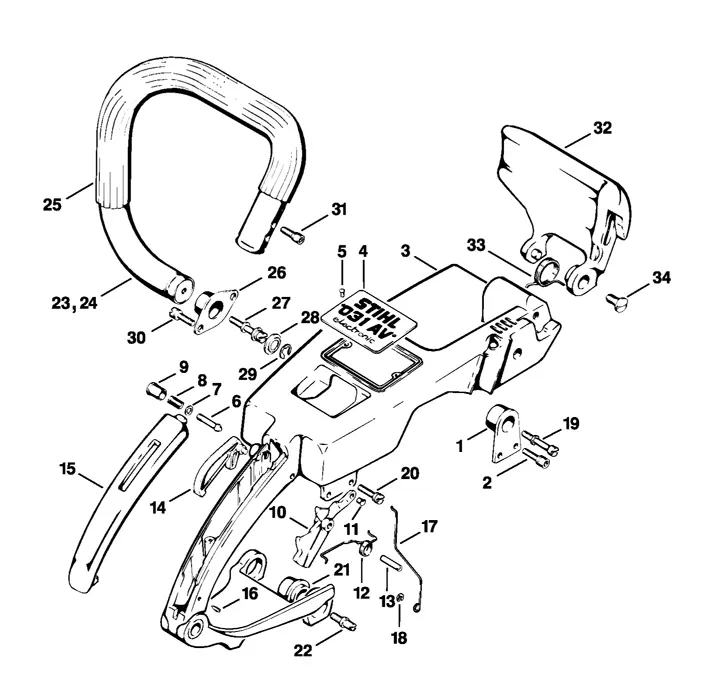

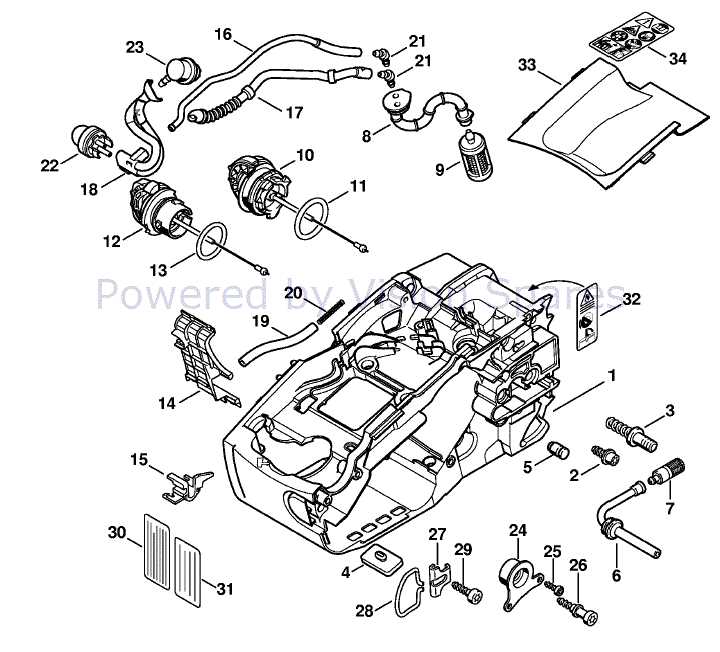

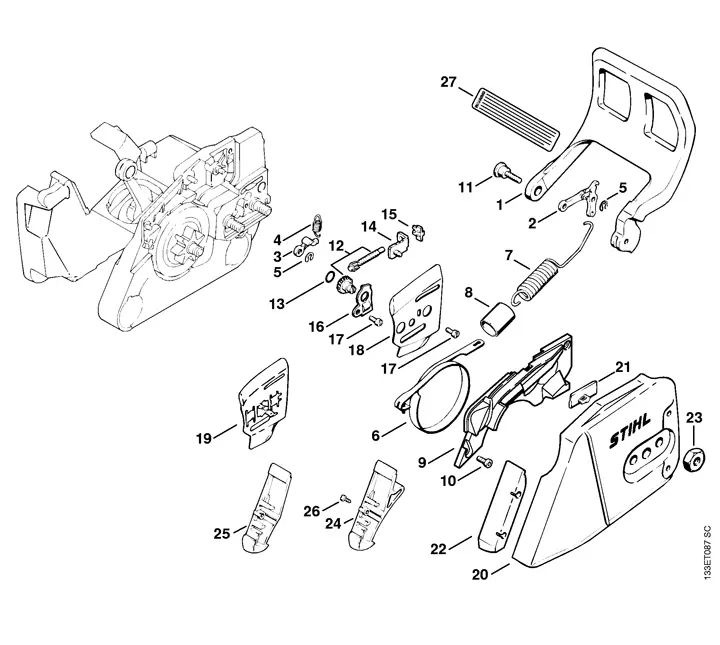

Additionally, visual representations serve as valuable guides for identifying and understanding these components. Through detailed illustrations, users can easily navigate the complexities of assembly and disassembly, thus promoting a deeper connection with their tools. Engaging with these resources enhances the overall experience and effectiveness of tool operation.

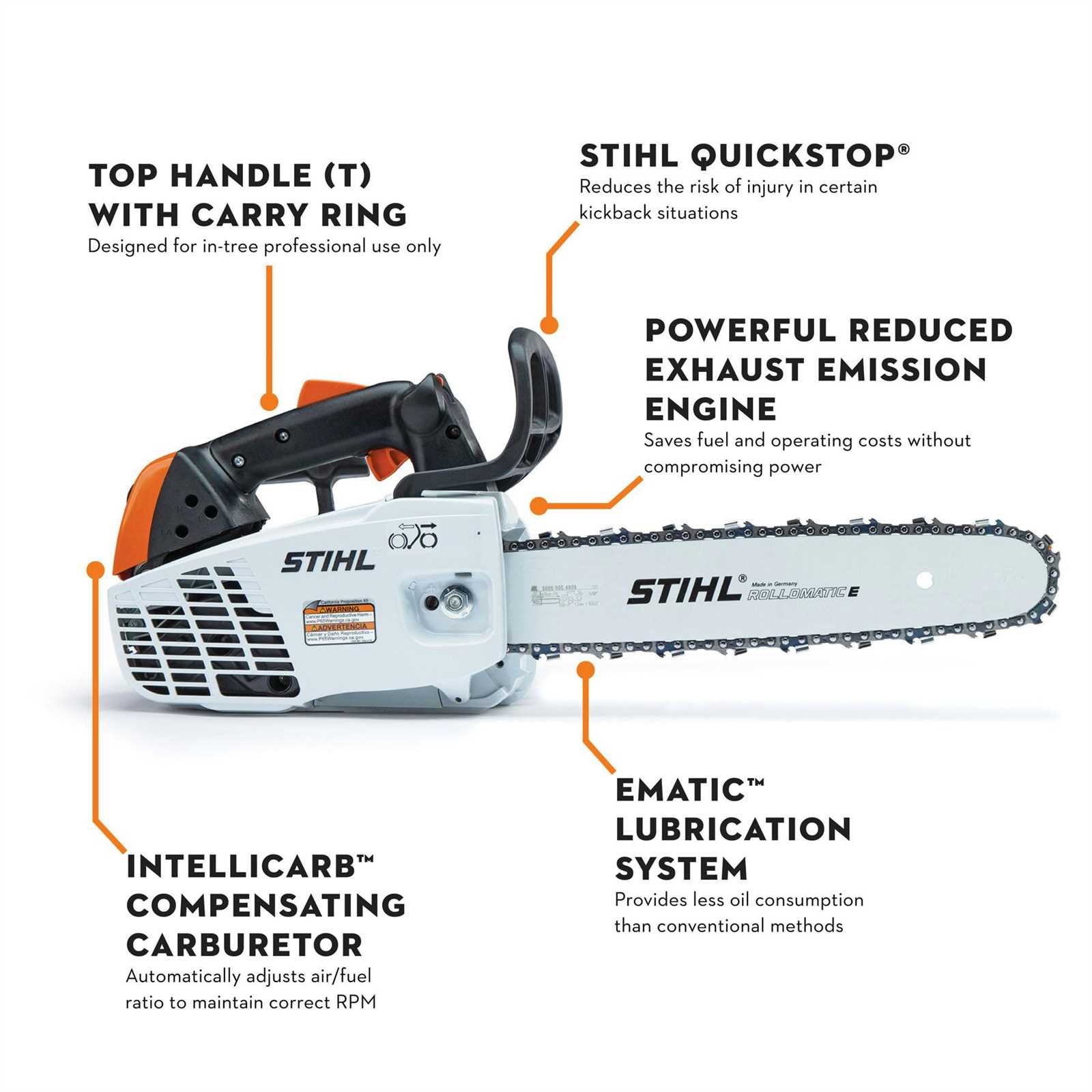

Understanding Stihl Chainsaw Components

To effectively operate a cutting tool, it’s essential to grasp the various elements that contribute to its functionality. Each component plays a vital role, ensuring smooth operation and optimal performance. By familiarizing oneself with these elements, users can better maintain their equipment and troubleshoot issues when they arise.

Key components can be categorized into several groups:

- Power Source: This is the engine or motor that provides the necessary energy for operation.

- Cutting Mechanism: Typically consists of a rotating bar and a chain, designed for efficient cutting through different materials.

- Control Features: Includes triggers and switches that allow for precise handling and operation.

- Safety Elements: Such as chain brakes and protective guards, essential for user safety during use.

- Maintenance Parts: Filters, spark plugs, and lubricants that ensure longevity and reliability of the tool.

Each of these elements must work in harmony to achieve the desired outcome. Understanding their functions and interactions can significantly enhance the user experience and ensure successful results in various applications.

How Diagrams Enhance Maintenance Practices

Visual representations play a crucial role in simplifying complex maintenance tasks. They provide a clear and organized overview, allowing users to quickly understand the components involved and their relationships.

Effective visualization reduces the likelihood of errors during upkeep and repairs. By referencing these illustrations, individuals can ensure they are handling each element correctly, ultimately leading to improved performance and longevity.

Moreover, these visual tools can aid in troubleshooting, enabling users to pinpoint issues more efficiently. This results in less downtime and a more streamlined maintenance process.

Incorporating such visual aids into regular upkeep practices not only enhances understanding but also fosters confidence in managing equipment effectively.

Identifying Key Parts of Stihl Models

Understanding the essential components of outdoor power tools is crucial for efficient maintenance and operation. Familiarity with these elements enables users to troubleshoot issues, perform repairs, and enhance overall performance.

Below is a list of significant components commonly found in these devices:

- Engine: The heart of the machine, responsible for providing the necessary power.

- Guide Bar: The long, flat metal piece that supports the cutting chain.

- Cutting Chain: The loop of teeth that performs the cutting action.

- Chain Tensioner: A mechanism that adjusts the tightness of the cutting chain.

- Handle: The part that allows for comfortable and controlled operation.

- Fuel Tank: A container that holds the fuel for the engine.

- Oil Tank: A reservoir that supplies lubrication to the cutting chain.

- Air Filter: A filter that prevents dirt and debris from entering the engine.

By recognizing these critical components, users can ensure proper functioning and extend the lifespan of their equipment.

Common Issues with Chainsaw Components

Understanding the common challenges associated with power tools is essential for ensuring optimal performance and longevity. Various elements can experience wear and tear or malfunction, leading to decreased efficiency and potential safety hazards. This section outlines frequent problems encountered in these machines and provides insights into their causes and solutions.

| Component | Common Issue | Possible Cause | Recommended Solution |

|---|---|---|---|

| Engine | Hard starting | Fuel blockage | Check fuel lines and filter; clean or replace as needed. |

| Bar | Uneven wear | Improper lubrication | Ensure proper oiling; check oil reservoir and adjust flow. |

| Chain | Sluggish movement | Chain dullness | Sharpen the chain or replace if excessively worn. |

| Filter | Reduced airflow | Dirt accumulation | Clean or replace the air filter regularly. |

| Clutch | Slipping | Wear and tear | Inspect and replace if necessary; check for proper engagement. |

Step-by-Step Guide to Repairs

Repairing power tools can seem daunting, but with the right approach, it becomes a manageable task. This guide provides clear, concise instructions for addressing common issues, ensuring that your equipment runs smoothly and efficiently. Following these steps will help you diagnose problems, replace components, and maintain optimal performance.

Begin by gathering the necessary tools and a clean workspace. Ensure you have screwdrivers, wrenches, and replacement components ready for use. Always consult the user manual for specific details related to your model.

Start the repair process by identifying the issue. Listen for unusual sounds and check for any visible wear or damage. Once you have pinpointed the problem, disconnect the power source to ensure safety during the repair.

Next, remove any protective covers or casings to access the internal mechanisms. Carefully document the disassembly process, taking notes or photos if needed, so that reassembly is straightforward. Replace any worn or damaged components with new parts, ensuring a secure fit.

After replacing the necessary elements, reassemble the tool in the reverse order of disassembly. Tighten screws and fasteners appropriately, avoiding over-tightening that could lead to further damage. Once fully reassembled, reconnect the power source and conduct a thorough test to ensure everything functions as intended.

Regular maintenance following repairs will extend the life of your equipment. Keep it clean and lubricated, and periodically check for any signs of wear to address issues before they escalate.

Choosing Replacement Parts Wisely

When it comes to maintaining outdoor power equipment, selecting the right components is crucial for optimal performance and longevity. Understanding the intricacies of these mechanical devices can significantly enhance their efficiency and reliability.

Before making a purchase, consider the following key factors:

- Quality Over Cost: Always prioritize high-quality items. Cheaper alternatives may save money initially but can lead to increased wear and tear.

- Compatibility: Ensure that the new component is specifically designed for your equipment model. Mismatched items can cause operational issues.

- Manufacturer Reputation: Research brands and their histories. Well-regarded manufacturers often provide better warranties and support.

- User Reviews: Look for feedback from other users. Reviews can provide insights into durability and performance.

By keeping these factors in mind, you can make informed choices that will enhance the functionality of your equipment and extend its service life.

Comparing Diagrams Across Different Models

Understanding the differences in visual representations of mechanical components across various models is crucial for effective maintenance and repair. Each variant often features unique configurations, which can influence performance and compatibility. By analyzing these representations, users can better grasp the intricacies of their tools and ensure optimal functionality.

Key Differences in Component Layout

When examining different variants, the arrangement of individual elements can vary significantly. This can affect not only the assembly but also the ease of access during servicing. Identifying these variations helps in making informed decisions about repairs and upgrades.

| Model | Component Arrangement | Access Difficulty |

|---|---|---|

| Model A | Linear Configuration | Easy |

| Model B | Compact Design | Moderate |

| Model C | Clustered Setup | Challenging |

Impact on Maintenance Procedures

Different configurations necessitate varied maintenance approaches. Understanding these distinctions can enhance repair efficiency and reduce downtime. Familiarity with specific layouts allows users to anticipate potential challenges and streamline their workflow.

Tools Needed for Chainsaw Assembly

Proper assembly of outdoor power equipment requires a variety of essential instruments to ensure efficiency and safety. Having the right tools at hand not only simplifies the process but also enhances the longevity of the machine. Below is a guide to the key tools that will facilitate a smooth assembly experience.

Essential Instruments

When assembling your equipment, consider the following tools:

| Tool | Purpose |

|---|---|

| Wrench Set | To tighten and loosen bolts and nuts. |

| Screwdriver Set | For securing and adjusting screws. |

| Torque Wrench | To apply the correct amount of torque to fasteners. |

| Hex Key Set | To work with hexagonal screws and bolts. |

| Pliers | For gripping and bending materials. |

Safety Gear

In addition to the basic tools, ensuring personal safety during assembly is paramount. The following items are recommended:

| Gear | Function |

|---|---|

| Safety Goggles | To protect eyes from debris. |

| Gloves | For hand protection against sharp objects. |

| Ear Protection | To guard against noise exposure. |

Safety Precautions During Maintenance

Ensuring safety during the upkeep of power tools is paramount. Proper precautions can prevent accidents and injuries while enhancing the efficiency of the equipment. Familiarizing oneself with essential safety guidelines is crucial before engaging in any maintenance activities.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes safety goggles to shield the eyes from debris, gloves to protect the hands, and sturdy footwear to prevent slips. Additionally, hearing protection should be considered, especially during prolonged use of noisy machinery.

Work Area Setup

Maintaining a clean and organized workspace is vital for safety. Ensure that the area is free of clutter, and that tools and materials are stored properly. Good lighting can also help in spotting potential hazards. Always keep a first aid kit nearby for quick access in case of emergencies.