Maintaining and repairing your outdoor power tools requires a solid grasp of their individual elements. Each piece plays a crucial role in ensuring the machinery operates efficiently and safely. Familiarizing yourself with these components can greatly enhance your ability to troubleshoot issues and perform necessary upkeep.

In this section, we will delve into the intricate details of a specific model’s structure. By examining the various segments, you will gain insights into how they interact and contribute to the overall functionality. This knowledge not only aids in repairs but also empowers you to make informed decisions when upgrading or replacing parts.

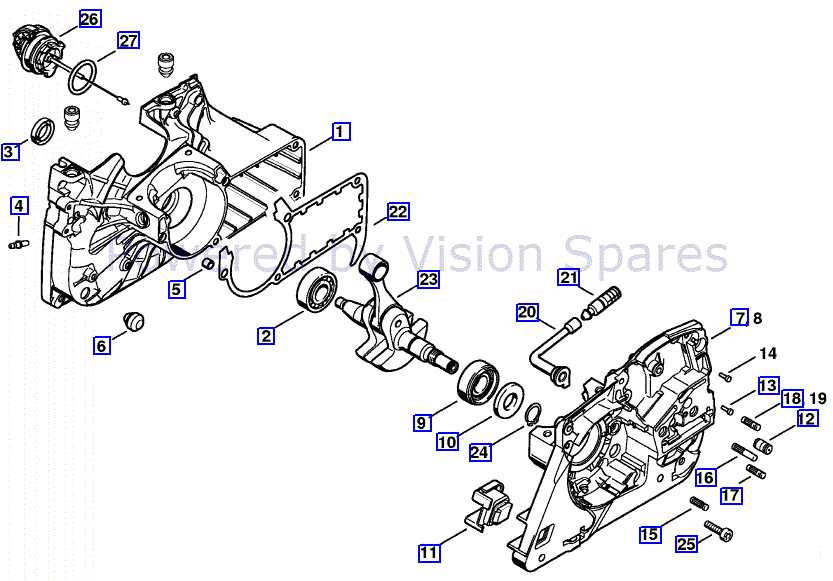

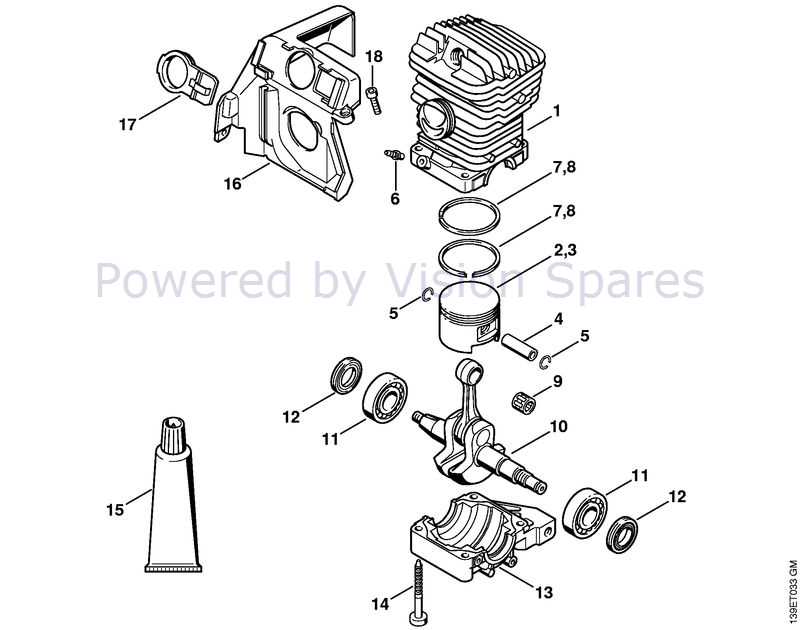

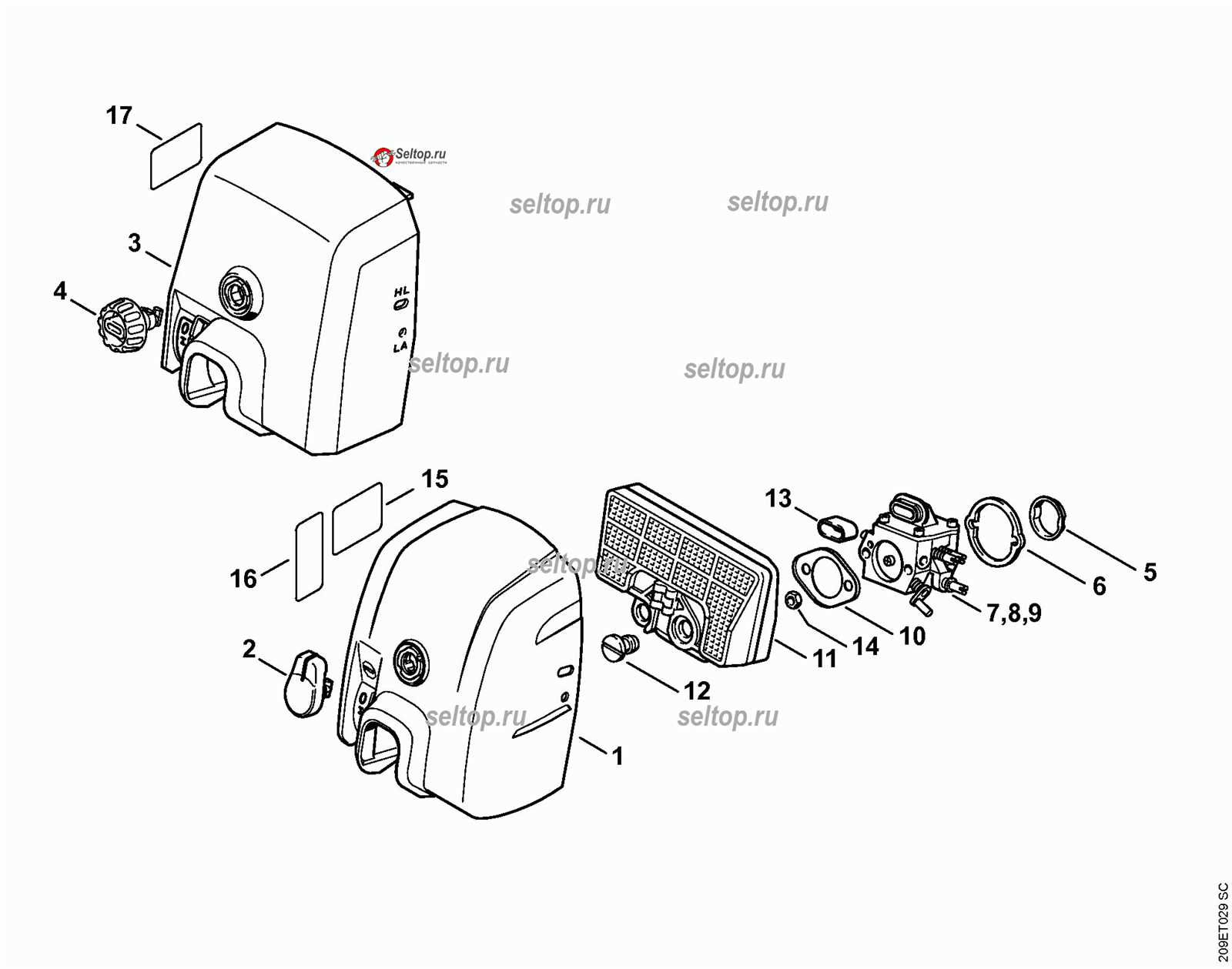

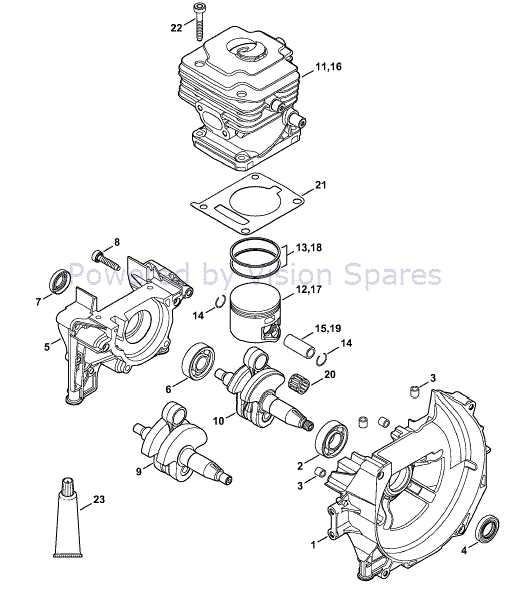

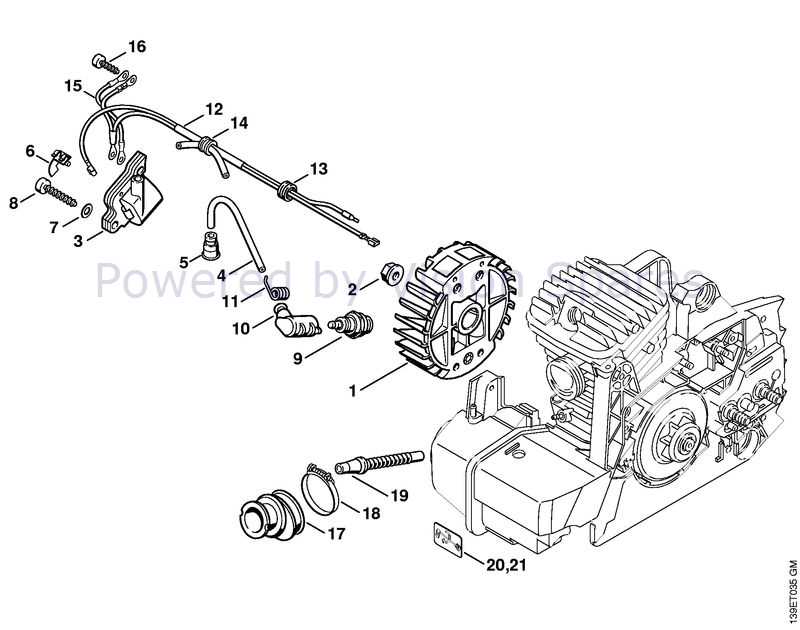

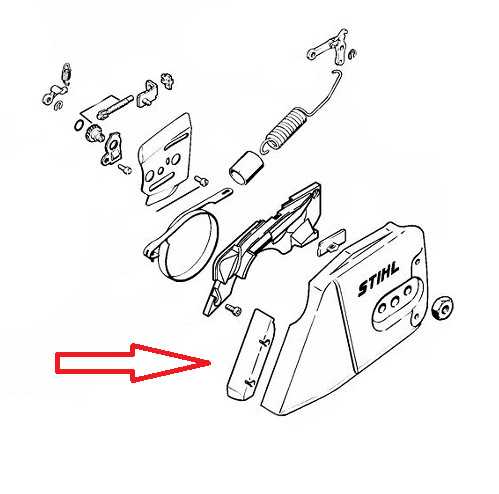

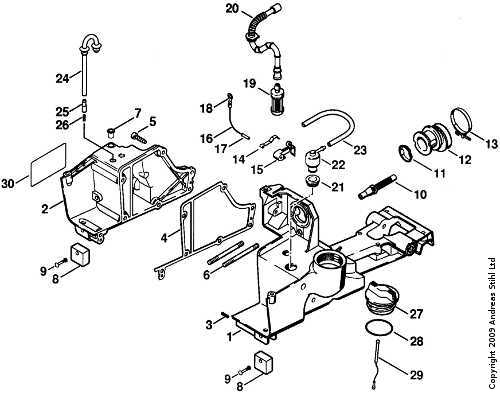

Utilizing a visual representation of these components can significantly simplify the understanding of their arrangement and relationship. By studying these illustrations, you can easily identify each element, facilitating a more streamlined maintenance process. Whether you are a seasoned professional or a novice user, having this information at your fingertips is invaluable.

Understanding Stihl 029 Components

To effectively operate and maintain any machine, it is crucial to grasp the essential elements that make it function. Each component plays a unique role, contributing to the overall efficiency and reliability of the equipment. By comprehending how these parts interconnect, users can ensure optimal performance and longevity.

Engine: The heart of the system, responsible for converting fuel into mechanical energy.

Fuel System: Comprising various elements that facilitate the delivery of fuel to the engine, ensuring it runs smoothly.

Ignition: This component triggers combustion, allowing the machine to start and operate efficiently.

Cooling System: Essential for regulating temperature, preventing overheating and potential damage during operation.

Body: The outer shell that houses all internal mechanisms, providing protection and structural integrity.

Drive Mechanism: A vital aspect that transmits power from the engine to the working parts, enabling effective operation.

Understanding these key components can greatly enhance your ability to troubleshoot and perform maintenance, ensuring that your machine operates at its ultimate potential.

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for effective maintenance and repair. Visual representations of components offer a clear roadmap for identifying parts and their functions within a system. Such illustrations are invaluable for both novice and experienced users, enabling them to navigate complex assemblies with ease.

Utilizing these visual aids can significantly reduce the time spent on repairs, ensuring that each element is properly addressed. They also enhance communication among technicians, as everyone can refer to the same reference for clarity. Furthermore, these guides assist in ordering the correct components, minimizing the risk of errors that can arise from misidentification.

Ultimately, these representations empower users to delve deeper into the mechanics of their equipment, fostering a greater understanding and proficiency in handling repairs. This knowledge not only leads to better performance but also prolongs the lifespan of the machinery involved.

Common Issues with Stihl 029

When operating outdoor power equipment, users often encounter various challenges that can hinder performance and efficiency. Understanding these common problems can lead to easier troubleshooting and better maintenance practices.

Typical Challenges

- Poor starting or failure to start

- Excessive vibration during operation

- Loss of power while cutting

- Fuel leaks or unusual consumption

Maintenance Tips

- Regularly clean or replace air filters.

- Check spark plugs for wear and replace as needed.

- Inspect fuel lines for cracks or leaks.

- Ensure proper chain tension and lubrication.

How to Access the Diagram

Understanding the layout of components is essential for effective maintenance and repair tasks. Accessing visual representations of these elements can simplify the process significantly. Here are the steps to find and utilize these resources:

- Visit the Manufacturer’s Website:

Most manufacturers provide a dedicated section for resources where you can find detailed illustrations. Look for areas labeled as “Support” or “Resources.”

- Check Online Retailers:

Several online stores offer not only products but also helpful manuals and visuals. Use the search function to locate specific models.

- Explore Community Forums:

Many enthusiasts share valuable insights and links to resources. Engage with these communities to find recommendations.

- Consult Local Dealers:

Authorized dealers often have access to detailed manuals and can provide printed copies or guidance on where to find them.

- Utilize Repair Manuals:

Look for comprehensive repair guides that often include illustrations. These can be found both in print and online.

By following these steps, you can efficiently locate and access the necessary visuals, making your repair and maintenance tasks much more manageable.

Replacement Parts Availability

Access to suitable components is essential for maintaining the longevity and efficiency of your equipment. Whether for routine maintenance or unexpected repairs, knowing where to find quality replacements can save time and enhance performance. Various options exist for sourcing these essential items, catering to different preferences and needs.

Sources for Components

- Authorized Dealers: These outlets provide original items, ensuring compatibility and quality.

- Online Retailers: Many websites specialize in selling a wide range of replacements, often at competitive prices.

- Local Hardware Stores: Check local shops for common items that might be available without the need for shipping.

- Aftermarket Suppliers: These vendors offer alternative options, which may be more budget-friendly, though quality can vary.

Considerations When Purchasing

- Compatibility: Ensure the item matches your model to avoid issues.

- Quality: Look for reviews and ratings to assess the reliability of the supplier.

- Warranty: Check if the component comes with a guarantee to protect your investment.

- Pricing: Compare costs across different sources to find the best deal.

By exploring these options and considering key factors, you can effectively secure the necessary components to keep your equipment running smoothly.

Maintenance Tips for Longevity

Proper care is essential for ensuring the durability and optimal performance of your outdoor power equipment. Regular maintenance not only enhances efficiency but also extends the lifespan of your tools. Implementing a few key practices can make a significant difference in how long your equipment remains in top condition.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and residue after each use to prevent buildup that can affect performance. |

| Routine Inspections | Check for wear and tear on essential components regularly to catch issues early. |

| Lubrication | Keep moving parts well-lubricated to reduce friction and prevent premature wear. |

| Correct Fuel Mixture | Use the appropriate fuel and oil mixtures to ensure efficient combustion and minimize engine damage. |

| Storage Practices | Store your equipment in a dry place and protect it from extreme temperatures and moisture. |

By following these maintenance tips, you can significantly enhance the reliability and longevity of your tools, ensuring they are ready for any task you take on.

Identifying Specific Parts Quickly

Efficiently recognizing individual components within machinery is crucial for maintenance and repair tasks. Understanding how to pinpoint these elements can save time and enhance the overall workflow. Here are some strategies to streamline the identification process.

- Familiarize Yourself with the Manual: Always refer to the user guide or service manual for detailed information about each component.

- Utilize Visual Aids: Diagrams and illustrations can significantly aid in visualizing where each part is located and how it connects to the rest of the machine.

- Labeling Systems: Implement a consistent labeling method for components to quickly locate them during repairs.

Additionally, consider the following tips to enhance your identification skills:

- Group Similar Components: Organizing items by category can help in locating them faster.

- Maintain an Inventory: Keeping a checklist of available parts ensures you know what you have on hand.

- Use Technology: Mobile applications and software can provide quick access to information and images of components.

By employing these techniques, you can make the process of identifying specific machinery elements much more efficient and effective.

Visual Aids for Assembly Guidance

When it comes to assembling machinery, having clear visual aids can significantly enhance the understanding of complex structures and components. These resources serve as invaluable tools for both novice and experienced users, allowing for a smoother and more efficient assembly process.

Diagrams and illustrations provide a visual representation of parts and their relationships, making it easier to identify each element and its function. By breaking down the assembly process into manageable sections, users can follow along step by step, reducing the likelihood of errors.

Additionally, exploded views can be particularly beneficial, as they show the arrangement of components in a three-dimensional context. This perspective allows users to visualize how parts fit together, fostering a deeper understanding of the overall assembly. Furthermore, incorporating color-coded elements can enhance clarity, helping to differentiate between various components and their respective placements.

Incorporating these visual aids into the assembly process not only streamlines the experience but also builds confidence among users, ultimately leading to a more successful outcome.

Where to Find Expert Support

When dealing with complex machinery, having access to knowledgeable assistance can make all the difference. Whether you’re facing operational issues or need guidance on maintenance, finding the right resources is essential for optimal performance.

Here are some reliable sources to consider when seeking expert help:

- Authorized Service Centers: Look for certified facilities that specialize in equipment repair and support. These centers often have trained technicians who understand the intricacies of various models.

- Online Forums and Communities: Engage with enthusiasts and professionals in dedicated online groups. Platforms such as Reddit or specialized forums provide a space for sharing experiences and solutions.

- Manufacturer’s Website: Visit the official website for access to manuals, FAQs, and customer support services. Many manufacturers offer comprehensive resources to assist users.

- Local Repair Shops: Seek out neighborhood mechanics or repair shops that have a good reputation. Often, these establishments have experienced staff who can provide personalized assistance.

By leveraging these resources, you can ensure that you receive the expert support necessary to keep your equipment running smoothly and efficiently.