In the world of outdoor machinery, having a clear grasp of the intricate elements that make up a cutting instrument is essential for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance, contributing to the overall functionality of the device.

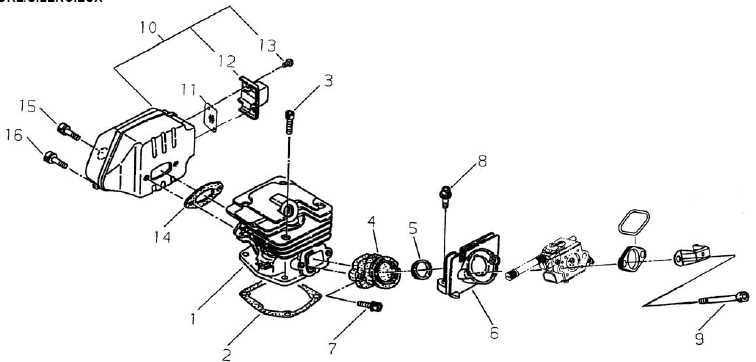

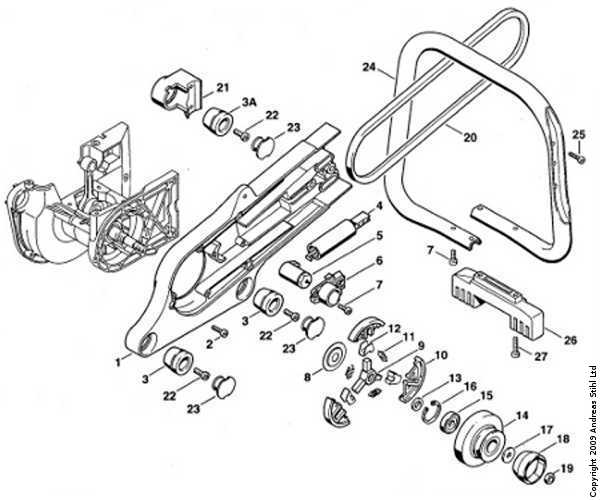

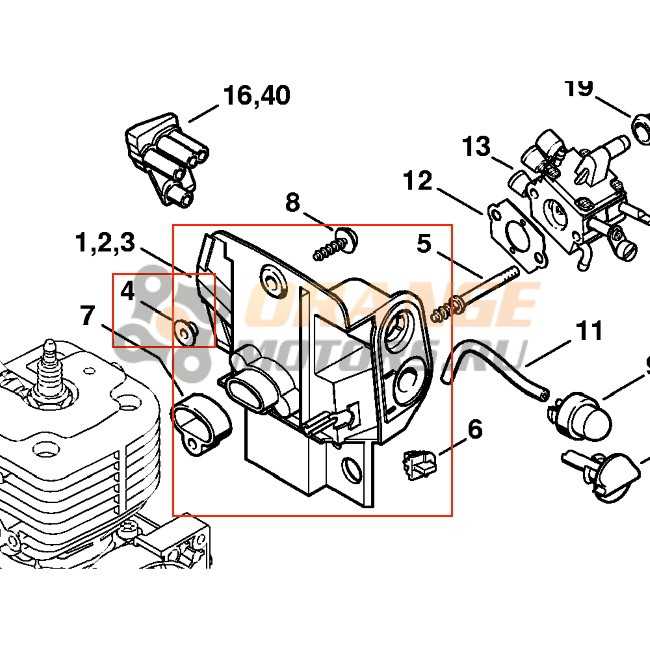

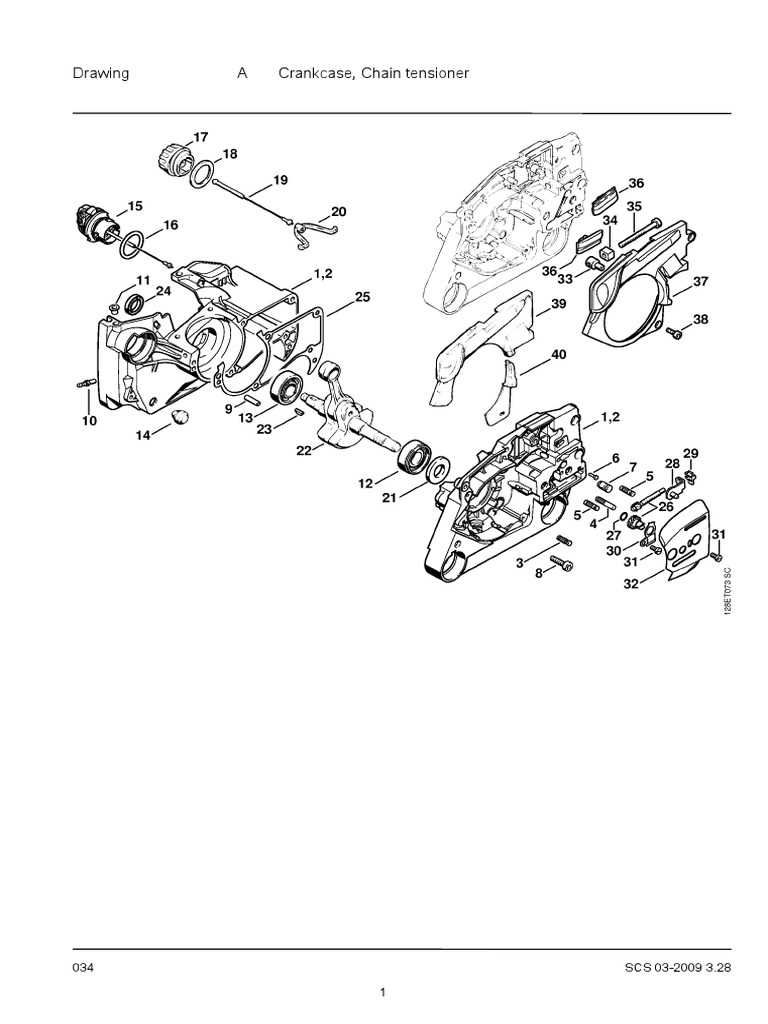

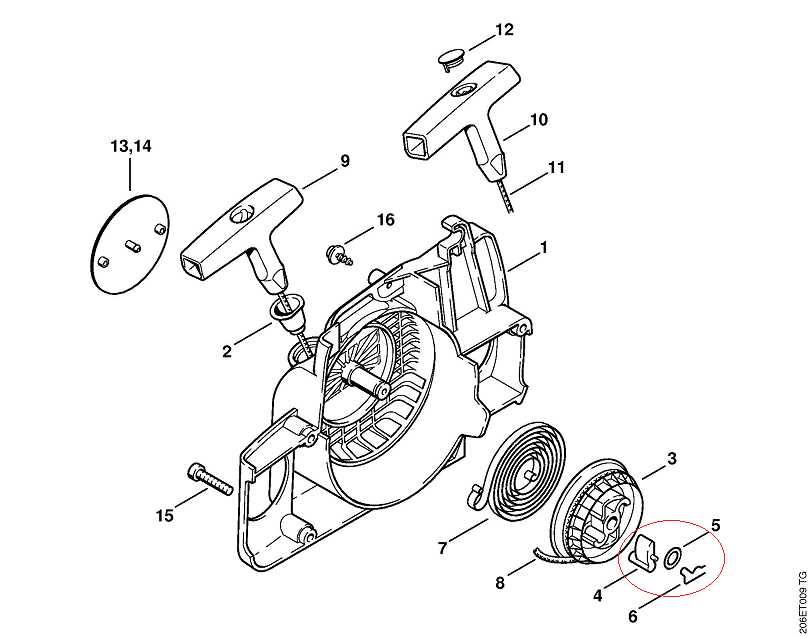

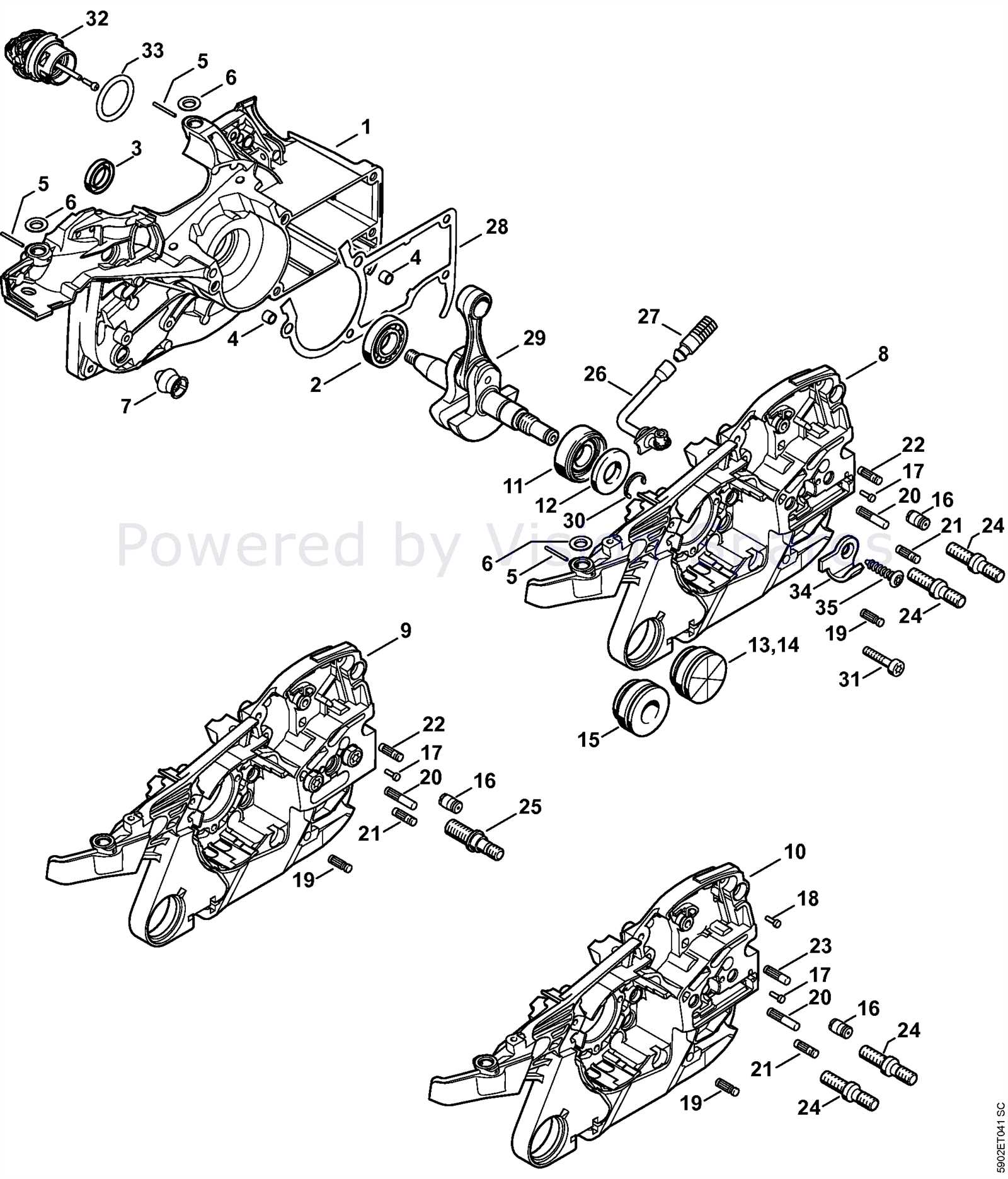

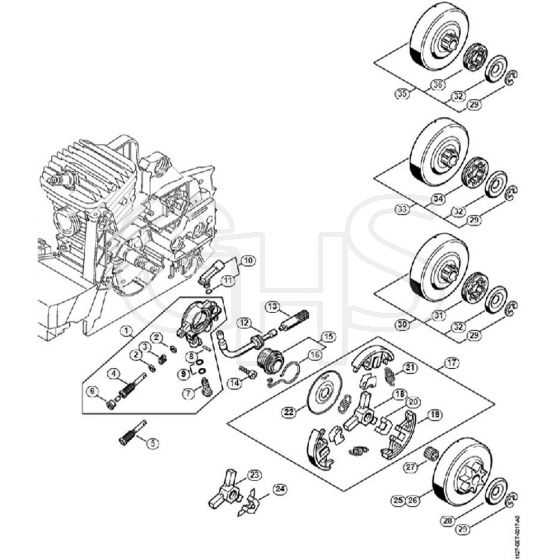

Visual representation of these components can significantly enhance the user’s understanding. By examining a detailed outline, one can easily identify the various segments involved, making troubleshooting and repair processes much more manageable.

Whether you are a seasoned professional or a novice enthusiast, delving into the specifics of these elements will equip you with the ultimate knowledge needed for effective care. Understanding each part’s purpose and interaction fosters confidence and efficiency in handling your equipment.

Understanding the Stihl 029 Chainsaw

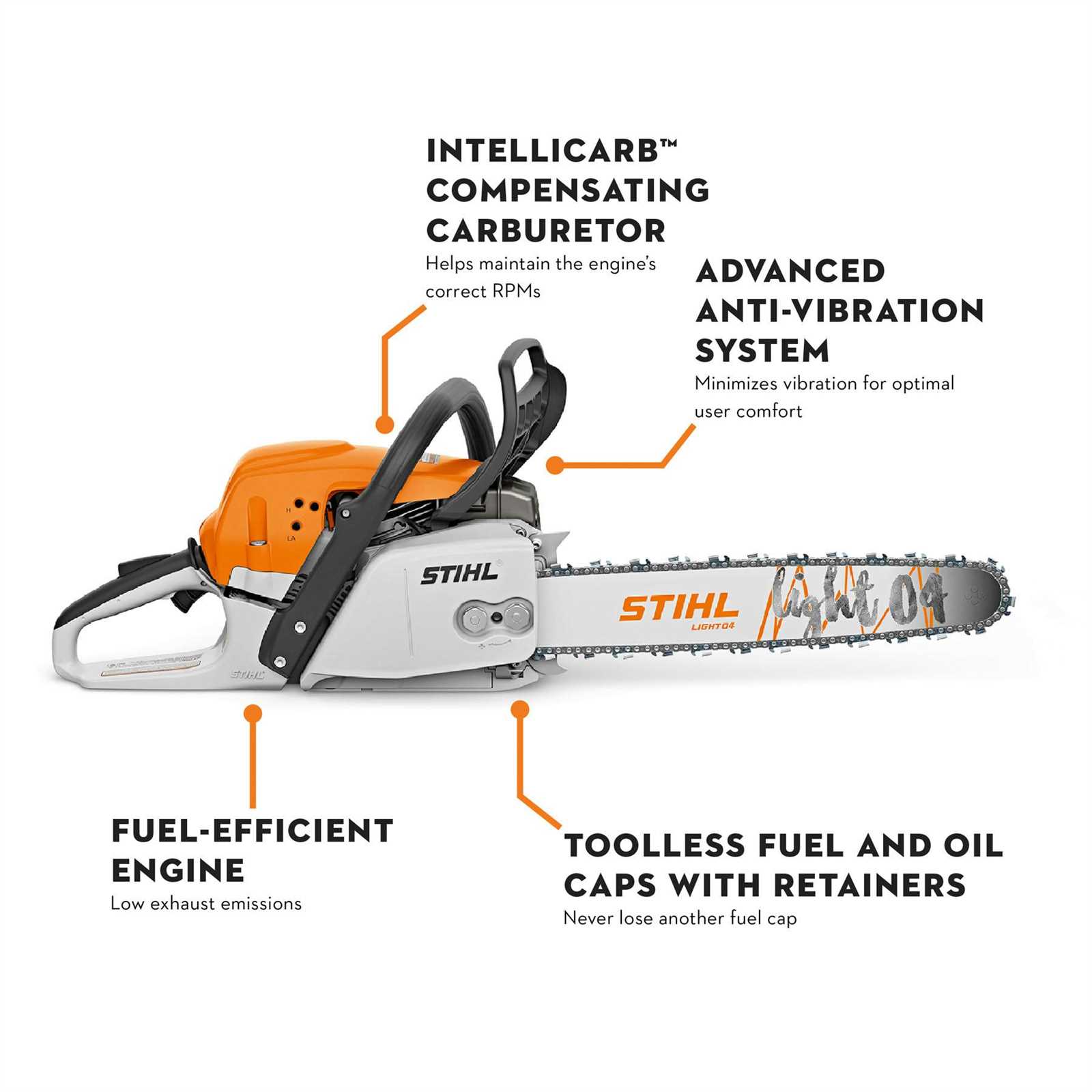

This section aims to provide a comprehensive overview of a popular cutting tool, focusing on its components, functionality, and maintenance. By exploring the inner workings of this equipment, users can enhance their understanding and improve their operational skills.

Key Features and Benefits

This tool is renowned for its robust design and efficiency, making it suitable for a variety of tasks. It offers an optimal balance of power and weight, which ensures ease of handling during prolonged use.

Maintenance and Care

Key Components of the Stihl 029

Understanding the fundamental elements of a power tool can greatly enhance its performance and longevity. Each component plays a crucial role in ensuring efficient operation and safety during use. Below, we explore the essential parts that contribute to the overall functionality of this model.

Major Elements

- Engine: The heart of the machine, responsible for generating the necessary power.

- Bar and Chain: Essential for cutting, these components work together to slice through materials effectively.

- Fuel System: This includes the tank and lines, which deliver the necessary fuel for operation.

- Air Filter: Critical for maintaining engine performance by filtering out dirt and debris.

- Starter Mechanism: Facilitates easy ignition of the engine for immediate use.

Supportive Features

- Clutch: Engages and disengages the chain from the engine, providing safety during idle times.

- Handle: Designed for comfort and control, it ensures stability while operating.

- Chain Brake: An important safety feature that stops the chain quickly in case of kickback.

- Throttle Control: Allows the user to regulate speed and power output as needed.

How to Access the Parts Diagram

Understanding the components of your equipment is essential for effective maintenance and repairs. Accessing a visual representation of these elements can greatly enhance your ability to identify and troubleshoot issues. This guide will help you locate and utilize the necessary resources.

Finding the Right Resources

To access the visual schematic, start by searching online for official manuals or manufacturer websites. Many resources are available that offer downloadable content, ensuring you have the most accurate information.

Using the Diagram Effectively

Once you have the schematic, familiarize yourself with the layout. This will aid in understanding the relationship between different components, making repairs more manageable.

| Resource Type | Access Method |

|---|---|

| Manufacturer Website | Visit the official site and navigate to the support section. |

| User Manuals | Download PDFs from online databases or forums. |

| Repair Guides | Utilize third-party sites specializing in equipment maintenance. |

Common Issues and Replacement Parts

Understanding the typical problems that arise with power tools is essential for effective maintenance and repair. Many users encounter similar challenges, and knowing the common components that may require replacement can significantly enhance the tool’s performance and longevity.

Frequent Problems

- Starting Difficulties: Often caused by fuel issues or ignition failures.

- Chain Slippage: Can result from improper tension or worn sprockets.

- Overheating: Typically linked to dull blades or insufficient lubrication.

- Vibration Issues: May indicate unbalanced components or loose fittings.

- Fuel Leaks: Often caused by damaged gaskets or hoses.

Essential Components for Replacement

- Fuel Filter: Regular replacement ensures proper fuel flow.

- Air Filter: Keeping this clean prevents engine damage.

- Chains: Regularly checking and replacing worn chains is crucial for safety and efficiency.

- Sprocket: Replacing worn sprockets can improve chain engagement.

- Gaskets and Seals: Ensuring these are intact prevents leaks and maintains performance.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for maximizing the lifespan of your cutting equipment. By following a few simple practices, you can ensure that your tool remains efficient and reliable for years to come.

Regular Cleaning: After each use, take the time to clean the exterior and interior components. Removing debris and residue will help prevent damage and maintain optimal performance.

Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and wear, extending the life of the machine. Use the recommended oil for the specific type of equipment.

Sharpening Blades: Keep the cutting edges sharp. Dull blades require more effort, increasing wear on the tool and potentially leading to accidents. Regularly inspect and sharpen them as needed.

Fuel Maintenance: Use fresh fuel and store it properly. Old or contaminated fuel can lead to poor performance and engine damage. Consider using fuel stabilizers if you plan to store the equipment for an extended period.

Storage: Store your tool in a cool, dry place away from direct sunlight. Proper storage helps prevent rust and degradation of components. Consider using a protective cover for added safety.

Regular Inspections: Periodically check all parts for signs of wear or damage. Addressing issues early can prevent more significant problems down the line. Pay special attention to the air filter, spark plug, and fuel lines.

By following these maintenance tips, you can enjoy a reliable and efficient performance from your equipment while ensuring its longevity and functionality.

Identifying OEM vs. Aftermarket Parts

When maintaining or repairing equipment, understanding the difference between original manufacturer components and those made by third parties is crucial. This knowledge not only impacts performance but also affects longevity and reliability. Recognizing these distinctions can help users make informed choices, ensuring optimal functionality and safety.

Characteristics of OEM Components

Original manufacturer components are specifically designed for a particular machine. They typically offer superior quality, as they undergo rigorous testing and meet strict standards set by the manufacturer. Using these components often guarantees compatibility, ensuring that each piece works seamlessly with the original design.

Understanding Aftermarket Options

Aftermarket alternatives can vary widely in quality and performance. While some third-party components may provide a cost-effective solution, others might compromise on durability or reliability. It is essential to research the reputation of aftermarket brands and consider factors such as customer reviews and warranty options before making a purchase.

Ultimately, the choice between original and aftermarket options depends on individual needs, budget, and priorities regarding quality and performance. Making an educated decision can significantly enhance the experience of equipment use and maintenance.

Tools Needed for Repairs

When it comes to maintaining and fixing outdoor power equipment, having the right tools at your disposal is essential. Properly equipped, you can efficiently address any issues that arise, ensuring optimal performance and longevity of your machinery. This section outlines the key instruments you’ll need for effective repairs.

Essential Hand Tools

A set of quality hand tools is fundamental for any repair task. Wrenches, screwdrivers, and pliers are necessary for disassembling and reassembling components. Having a torque wrench is also beneficial to ensure that all fasteners are tightened to the manufacturer’s specifications. Don’t forget to include a utility knife and a set of Allen keys, which are often required for intricate tasks.

Specialized Equipment

In addition to basic hand tools, certain specialized equipment can significantly enhance your repair capabilities. A compression tester helps assess engine health, while a fuel system cleaner can be invaluable for resolving performance issues. Safety gear, including gloves and goggles, is crucial to protect yourself during maintenance work. Having a parts cleaner and a multimeter on hand can also streamline the repair process and diagnose electrical problems effectively.

Safety Precautions During Repairs

When undertaking any maintenance work on machinery, it is crucial to prioritize safety. Proper precautions not only protect the individual performing the repairs but also ensure that the equipment remains in optimal condition. Adhering to safety guidelines minimizes the risk of accidents and injuries, creating a secure working environment.

Essential Safety Gear

Before starting any repair tasks, equip yourself with the appropriate safety gear. This includes protective gloves to shield your hands from sharp components, safety goggles to protect your eyes from debris, and ear protection to guard against loud noises. Additionally, wearing sturdy footwear will help prevent slips and falls during the process.

Work Environment Considerations

Ensure that your workspace is well-lit and free from clutter. A tidy area reduces the chances of mishaps and allows for better focus on the task at hand. Furthermore, having all necessary tools within reach prevents unnecessary movements that could lead to accidents. Always follow the manufacturer’s instructions and handle all components with care to avoid damaging parts or injuring yourself.

Where to Find Genuine Parts Online

When it comes to maintaining and repairing your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. The internet offers a variety of platforms where you can easily locate high-quality replacements, making your search more convenient than ever.

Start by visiting the official websites of manufacturers, as they typically provide a comprehensive selection of original components. These sites often include user-friendly catalogs that help you identify the specific items you need. Additionally, many authorized retailers have online stores that carry genuine products, ensuring you receive reliable and durable materials.

Online marketplaces can also be a valuable resource. Look for reputable sellers with positive reviews, as this indicates a commitment to quality and customer satisfaction. Always check for authenticity guarantees to avoid counterfeit items that may compromise your equipment’s performance.

Lastly, consider joining online forums or communities dedicated to enthusiasts and professionals. These platforms can provide recommendations on trustworthy sources and may even offer group discounts or bulk purchase options, enhancing your chances of finding exactly what you need.