The intricate design of a powerful cutting tool is often a marvel of engineering, where each element plays a crucial role in its performance and reliability. When exploring the various elements that contribute to its operation, it becomes essential to comprehend how these parts work together seamlessly. A detailed overview of these components can provide valuable insights into maintaining and enhancing the functionality of the tool.

Familiarity with the specific elements that constitute this machinery allows users to diagnose issues effectively and perform necessary repairs with confidence. Whether you’re an experienced user or a novice, having access to comprehensive visual references can greatly simplify the process of understanding how each segment interacts with the others. This knowledge is vital for ensuring optimal performance and longevity.

By delving into the structure of these devices, one can identify the unique characteristics and functions of each part. This exploration not only aids in troubleshooting but also fosters a deeper appreciation for the craftsmanship involved in their creation. Engaging with the detailed layout of the components enhances one’s ability to operate the equipment safely and efficiently.

Understanding Ms250 Stihl Components

When delving into the mechanics of a popular power tool, it’s essential to familiarize oneself with its various elements. Each component plays a critical role in ensuring optimal performance and longevity. By gaining insight into these integral parts, users can enhance their maintenance practices and troubleshoot issues more effectively.

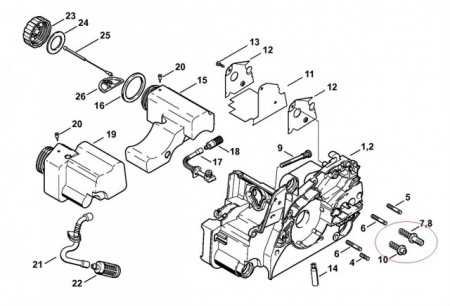

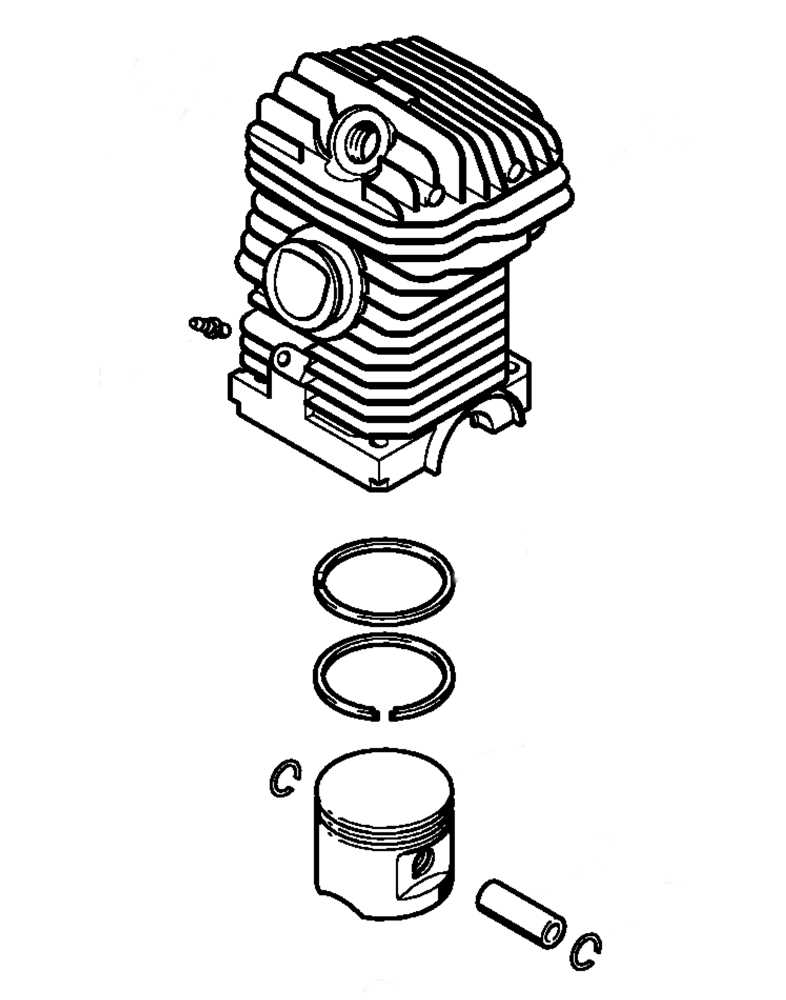

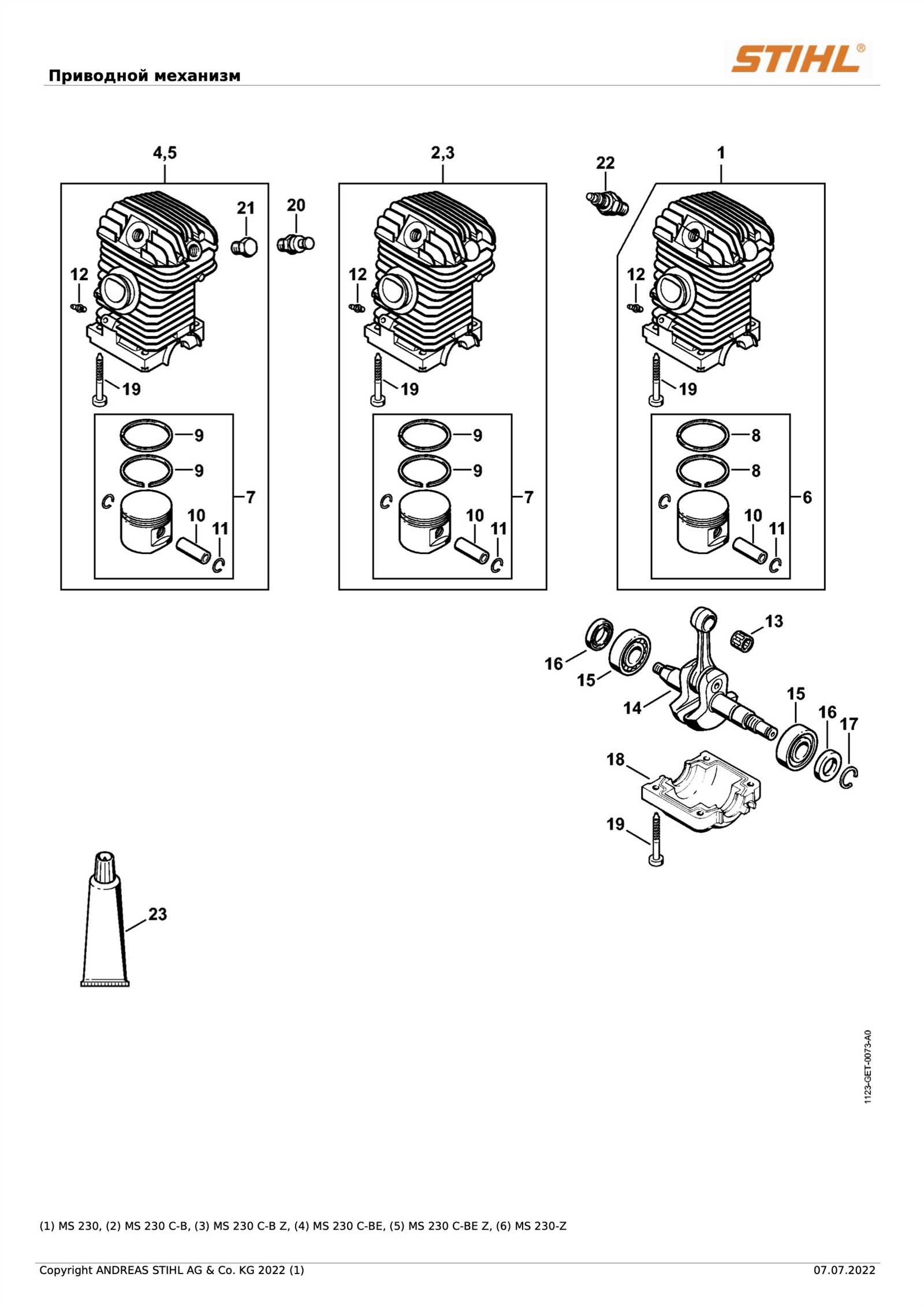

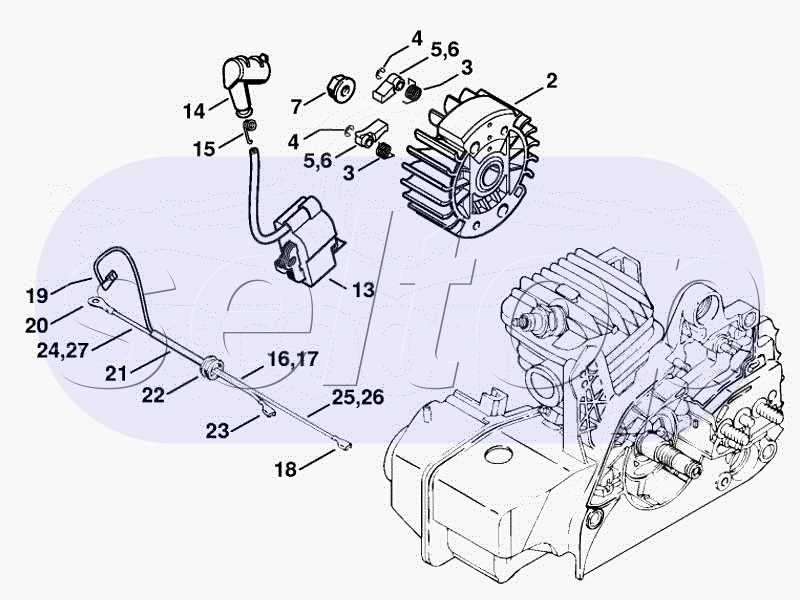

Engine Assembly: At the heart of the tool lies the engine, which powers the entire unit. Understanding its layout helps in recognizing how fuel, air, and ignition work together to generate energy.

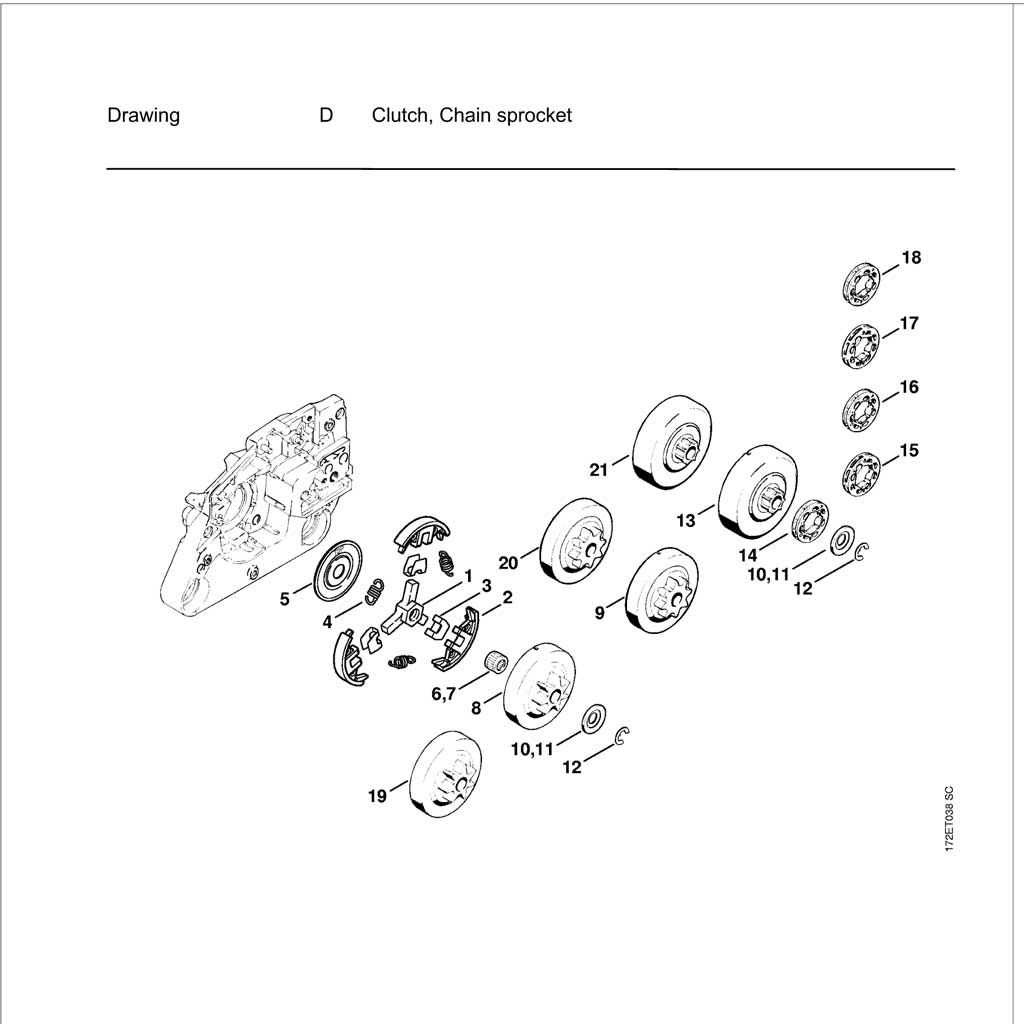

Cutting Mechanism: The cutting system is crucial for achieving precision in tasks. Familiarity with the blade attachment and the drive system can greatly impact cutting efficiency and safety.

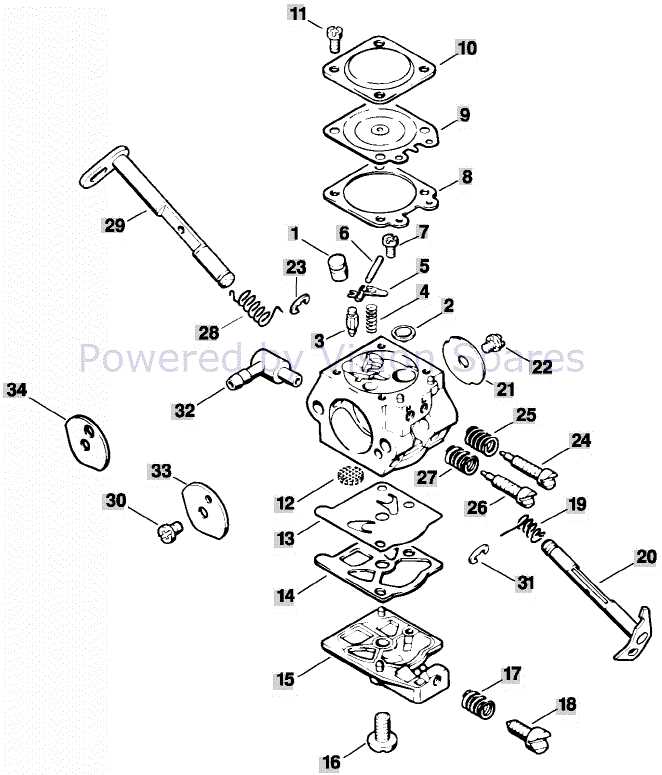

Fuel System: The fuel assembly includes the tank, lines, and filter, each contributing to the tool’s operation. Regular checks on this system prevent performance issues and ensure a smooth workflow.

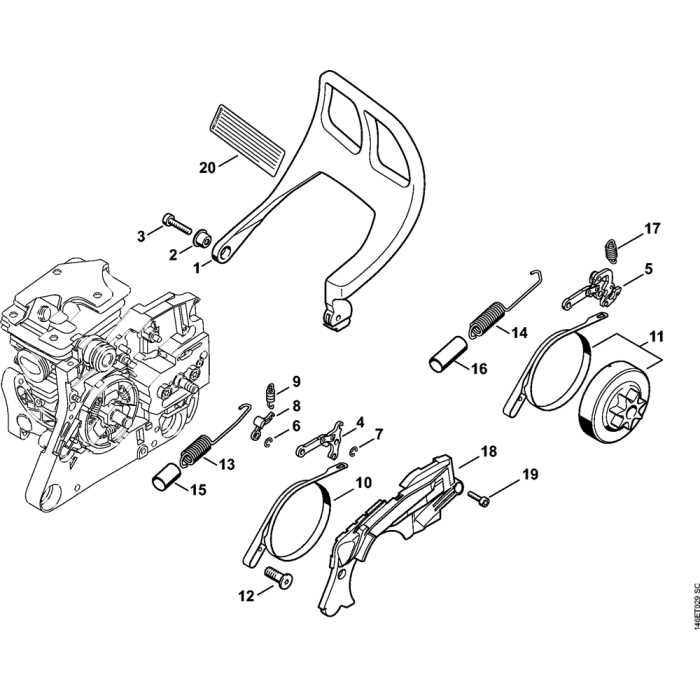

Safety Features: Modern tools come equipped with various safety mechanisms designed to protect the user. Understanding these features is vital for safe operation and accident prevention.

Frame and Housing: The outer shell provides structural integrity and protection for internal components. Being aware of its condition can help in identifying wear and tear that may affect performance.

Overall, comprehending the individual elements that comprise this power tool enhances user experience and extends the tool’s lifespan. By staying informed, users can ensure their equipment remains in peak condition for any task at hand.

Importance of Accurate Parts Diagrams

Precision in technical illustrations is crucial for effective maintenance and repair tasks. These visual guides serve as essential resources for understanding the configuration and relationship between various components. By providing a clear overview, they enable users to identify the necessary elements for successful assembly or disassembly.

When individuals engage with detailed representations, they can avoid costly mistakes that often arise from misidentification or incorrect installations. Accurate illustrations enhance efficiency by streamlining the troubleshooting process, ensuring that the right components are addressed promptly. Furthermore, they contribute to a safer working environment, as users can clearly see how parts interact and the potential hazards associated with their handling.

In addition to facilitating repairs, high-quality technical visuals support training and education efforts. New users or technicians benefit significantly from these resources, as they offer a visual context that complements theoretical knowledge. This combination fosters a deeper understanding and enhances skill development, ultimately leading to improved performance and confidence in tackling maintenance tasks.

In summary, precise technical visuals play a vital role in maintenance, training, and safety. Their importance cannot be overstated, as they empower users to work more effectively and with greater assurance in their abilities.

Common Issues with Ms250 Parts

Understanding the frequent challenges associated with various components of a specific model can significantly enhance performance and longevity. Many users encounter similar problems, which can be addressed with proper knowledge and maintenance.

- Fuel System Problems:

- Clogged filters leading to reduced power.

- Improper fuel mixture causing engine stalling.

- Ignition Difficulties:

- Worn spark plugs affecting starting efficiency.

- Faulty ignition coils leading to misfires.

- Chain and Bar Issues:

- Excessive wear resulting in poor cutting performance.

- Improper tension causing chain derailment.

- Lubrication Failures:

- Blocked oil passages leading to overheating.

- Insufficient oil flow resulting in damage.

By recognizing these common issues and implementing preventative measures, users can ensure smoother operation and extend the lifespan of their equipment.

How to Interpret Diagrams Effectively

Understanding visual representations is essential for effectively utilizing complex machinery or components. These illustrations provide critical insights into the structure and function of various elements. By mastering the interpretation of these visuals, users can enhance their comprehension and make informed decisions during assembly, repair, or maintenance tasks.

Key Strategies for Effective Interpretation

- Familiarize Yourself with Symbols: Before diving into the illustration, take time to understand the specific symbols and notations used. This foundational knowledge will facilitate a smoother interpretation.

- Break It Down: Analyze the visual in sections. Focus on one part at a time to avoid feeling overwhelmed by the complexity.

- Refer to Annotations: Pay close attention to any labels or notes. These details often provide critical information about connections and functionalities.

- Utilize Color Coding: Many visuals use color to indicate different functions or categories. Make sure to understand what each color signifies.

Practical Tips for Application

- Cross-Reference with Manuals: Use accompanying documentation to enhance your understanding and provide context to the visual representation.

- Practice with Real Components: Whenever possible, refer to the actual items while examining the visual. This hands-on approach reinforces your understanding.

- Seek Guidance: If you encounter challenges, don’t hesitate to reach out to knowledgeable individuals or online communities for support.

By employing these strategies, you will not only improve your ability to decode complex visuals but also gain confidence in handling various technical tasks effectively.

Replacing Worn Parts on Ms250

Maintaining optimal performance in your equipment requires regular attention to components that may degrade over time. Identifying and swapping out these elements can significantly enhance efficiency and longevity. Knowing when and how to replace these items is essential for any user looking to keep their machinery in top shape.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Chain | Stretched or damaged links | Ensure correct tension and alignment during installation. |

| Sprocket | Worn teeth | Replace both the chain and sprocket simultaneously for best results. |

| Filter | Reduced airflow | Check and replace regularly to maintain performance. |

| Spark Plug | Rough idle or difficulty starting | Use the manufacturer’s specifications for replacements. |

Essential Tools for Maintenance

Proper upkeep of your equipment requires a selection of key instruments that ensure efficiency and longevity. Familiarity with these tools can help prevent issues and streamline repair processes, making maintenance tasks more manageable and effective.

- Wrenches: Adjustable and fixed wrenches are crucial for loosening or tightening various components.

- Screwdrivers: A variety of screwdrivers, including flat-head and Phillips, will help in handling screws that secure parts in place.

- Chain Tensioner: This tool assists in adjusting the chain tension to ensure optimal performance.

- File: A round or flat file is useful for sharpening cutting edges, enhancing the effectiveness of the equipment.

- Fuel Mix Container: A dedicated container for preparing fuel mixtures ensures correct ratios, promoting engine health.

Having the right instruments at hand simplifies routine checks and repairs, allowing for timely interventions that can extend the lifespan of your tools.

- Regularly inspect your equipment to identify any worn parts.

- Keep tools organized and easily accessible for efficient maintenance sessions.

- Always refer to the manufacturer’s guidelines for specific tool recommendations.

By equipping yourself with these essential maintenance tools, you can ensure your equipment remains in peak condition, ready for any task at hand.

Where to Find Quality Parts

When seeking components for your machinery, it’s essential to locate reliable sources that offer durability and performance. High-quality replacements can significantly enhance the efficiency and longevity of your equipment, ensuring optimal functionality.

Online Retailers

- Official Brand Websites

- Reputable E-commerce Platforms

- Specialized Tool Suppliers

Exploring established online marketplaces can yield a variety of options. Ensure that the vendor has positive reviews and a solid reputation for customer service.

Local Suppliers

- Authorized Dealers

- Local Hardware Stores

- Specialty Repair Shops

Visiting local shops allows you to receive personalized assistance and expert advice. Building relationships with local suppliers can also lead to exclusive deals and insights into the best products for your needs.

Benefits of Regular Equipment Checks

Conducting routine inspections of machinery is crucial for ensuring optimal performance and longevity. By identifying potential issues early, operators can prevent costly breakdowns and extend the lifespan of their tools. Regular evaluations not only enhance safety but also improve efficiency in operations.

Enhanced Safety

One of the primary advantages of frequent equipment assessments is the significant boost in safety. Regular checks help in identifying wear and tear, loose components, or any signs of malfunction. By addressing these concerns promptly, the risk of accidents is minimized, creating a safer working environment for all.

Cost Efficiency

Investing time in regular maintenance can lead to substantial savings in the long run. Early detection of minor issues prevents them from escalating into major problems that require expensive repairs or replacements. Additionally, well-maintained equipment typically operates more efficiently, leading to reduced fuel and operational costs.

Tips for Efficient Repairs and Upgrades

When it comes to maintaining and enhancing your equipment, a systematic approach can make a significant difference. Proper preparation and understanding of your tools can lead to smoother repairs and successful upgrades. Here are some essential tips to help you navigate this process effectively.

1. Familiarize Yourself with the Components

Understanding the various elements of your device is crucial. Study the assembly and functionality of each part to identify potential issues or areas for improvement. A clear grasp of how everything works together will streamline your repair process.

2. Use Quality Replacement Parts

Invest in high-quality components when making replacements. Opting for durable and reliable options ensures that your equipment functions optimally and lasts longer, minimizing the need for frequent repairs.

3. Organize Your Workspace

A tidy and organized workspace can enhance your efficiency. Keep tools and parts sorted, and ensure you have adequate lighting. This not only saves time but also reduces the risk of losing essential components during repairs.

4. Follow Manufacturer Guidelines

Always consult the manufacturer’s instructions for repair and upgrade processes. Adhering to their recommendations can prevent damage and ensure that your modifications are safe and effective.

5. Document Your Work

Keeping a record of repairs and upgrades can be invaluable. Note down what you’ve changed, along with any issues encountered. This documentation will be a helpful reference for future maintenance and can assist in diagnosing recurring problems.

6. Seek Expert Advice When Needed

Don’t hesitate to consult with professionals or experienced peers if you’re uncertain about a procedure. Gaining insights from those with more experience can save time and help avoid mistakes.

By implementing these strategies, you can enhance the efficiency of your repair and upgrade endeavors, ensuring your equipment remains in excellent condition for years to come.