Maintaining outdoor equipment efficiently relies on understanding the intricate setup of each critical component within the system. This section delves into the structural breakdown of essential machinery elements, helping users gain clarity on the positioning and role of each part. This overview is aimed at both enthusiasts and seasoned users, providing insights that simplify upkeep and troubleshooting.

Having an organized reference for every element within this equipment type ensures a smooth maintenance experience, reducing the time spent diagnosing or repairing. By breaking down the assembly into accessible visuals and descriptions, this guide empowers users to approach routine checks and minor repairs with greater confidence and precision.

Whether tackling regular upkeep or addressing specific issues, familiarity with the machine’s layout and core pieces is invaluable. Here, readers will find practical insights that enhance understanding of each element’s placement and function, enabling more effective care and extending the life of their equipment.

Key Components of Stihl BR400

The following section provides an overview of the essential elements within this powerful backpack leaf blower, focusing on both primary and supportive elements critical for smooth operation. Understanding the role of each component can greatly aid in maintenance and ensure efficient functionality over time.

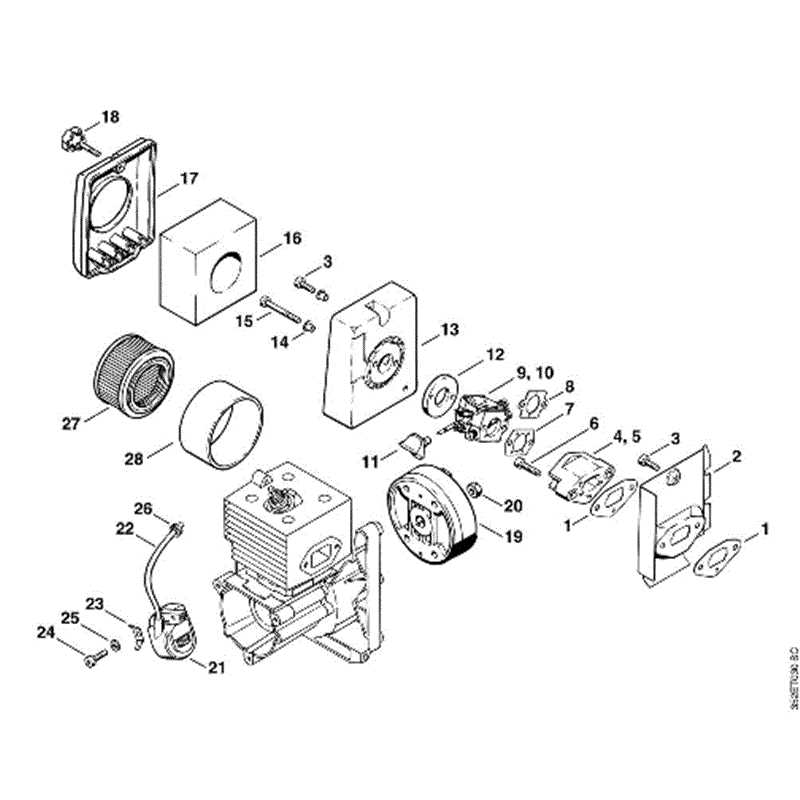

Engine Assembly: The core of the blower, the engine, drives the unit’s performance. Designed to deliver power while maintaining manageable weight, this section includes various subparts that work together to generate the air pressure needed for effective debris clearing.

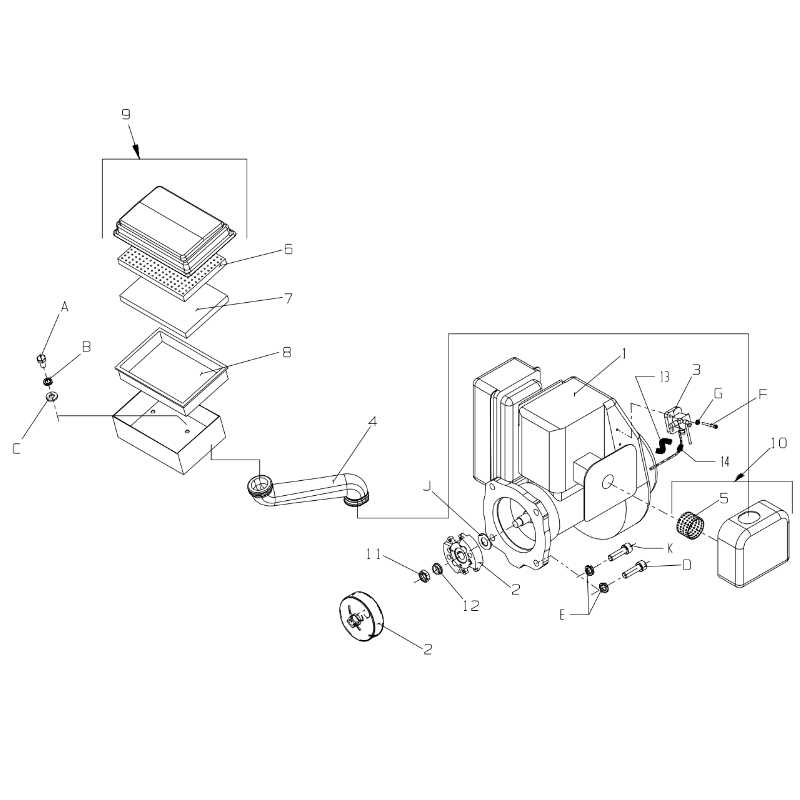

Air Filtration System: This essential component filters incoming air, ensuring that dust and debris are kept out of the engine. A clean and efficient filter supports optimal performance and extends the longevity of the engine by preventing potential clogs and buildup.

Fuel System: This part handles fuel intake and delivery, including the fuel tank and associated lines. Proper fuel flow is crucial for maintaining consistent power, and keeping this system in good condition helps reduce the likelihood of engine stalling or inefficiency.

Throttle Control: The throttle

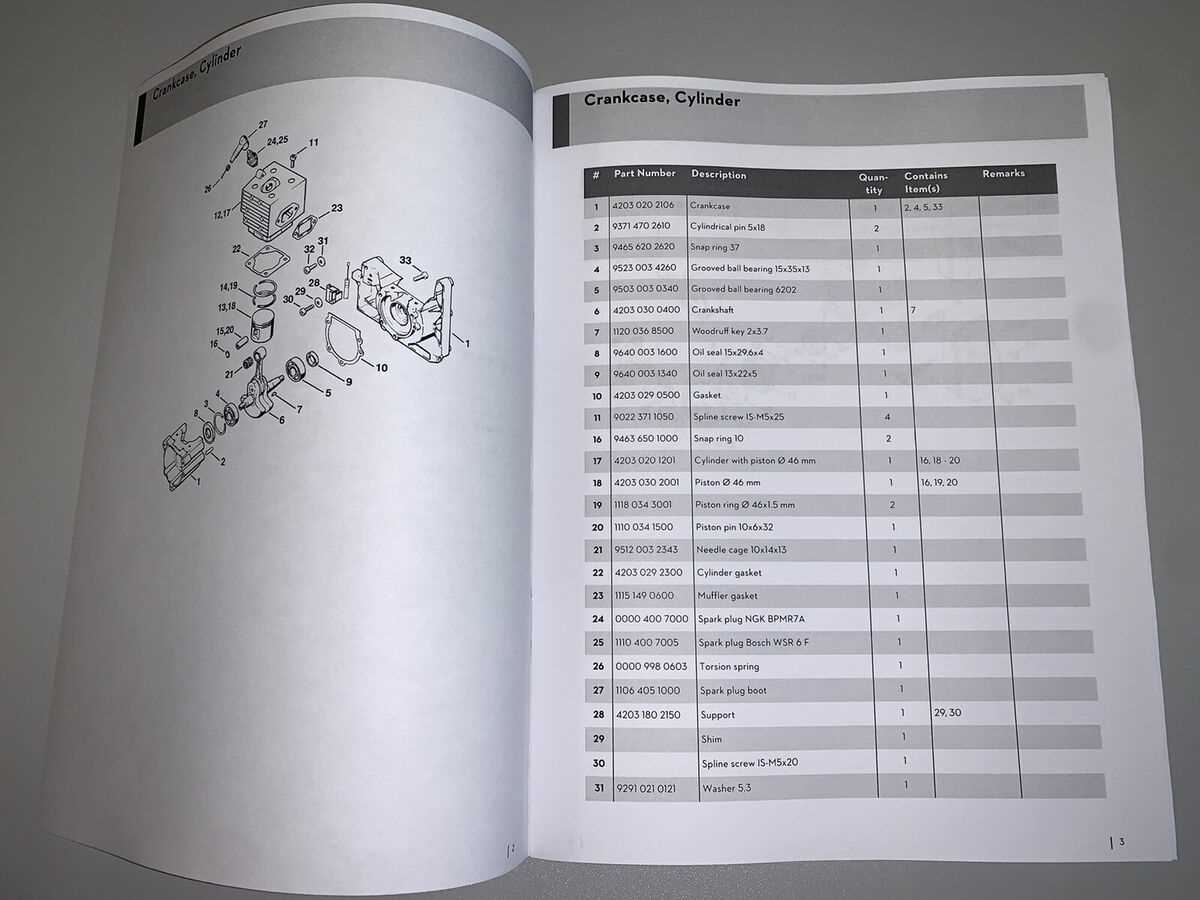

Understanding the Engine Assembly

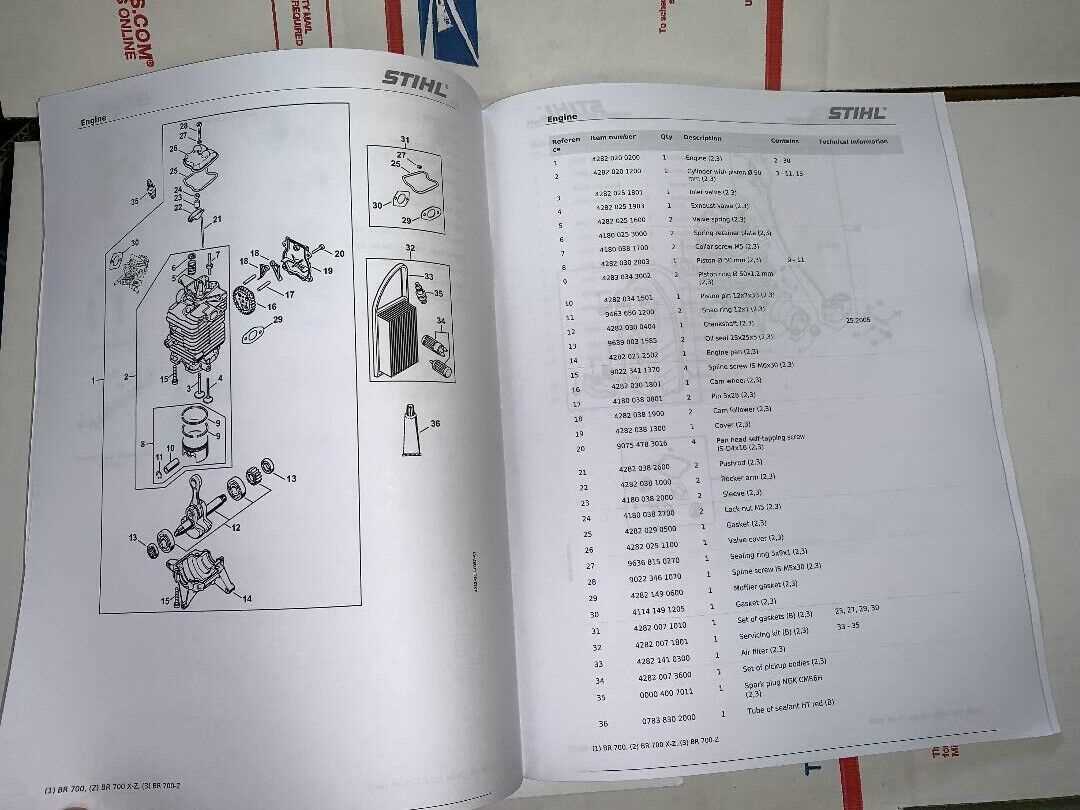

In this section, we’ll delve into the structure and key components involved in the engine assembly of a backpack blower. Knowing how each element works together in the engine will help in maintaining optimal performance and troubleshooting effectively.

| Component | Description |

|---|---|

| Cylinder | Central to generating power, the cylinder is where fuel combustion takes place. This part requires regular inspection for signs of wear to ensure efficient operation. |

| Piston | The piston moves within the cylinder to compress air and fuel, sparking ignition. Smooth movement and secure seals around this part are crucial for consistent power output. |

| Crankshaft | This component converts the linear motion of the piston into rotational force. It links with other engine elements to drive the blower fan and requires precise

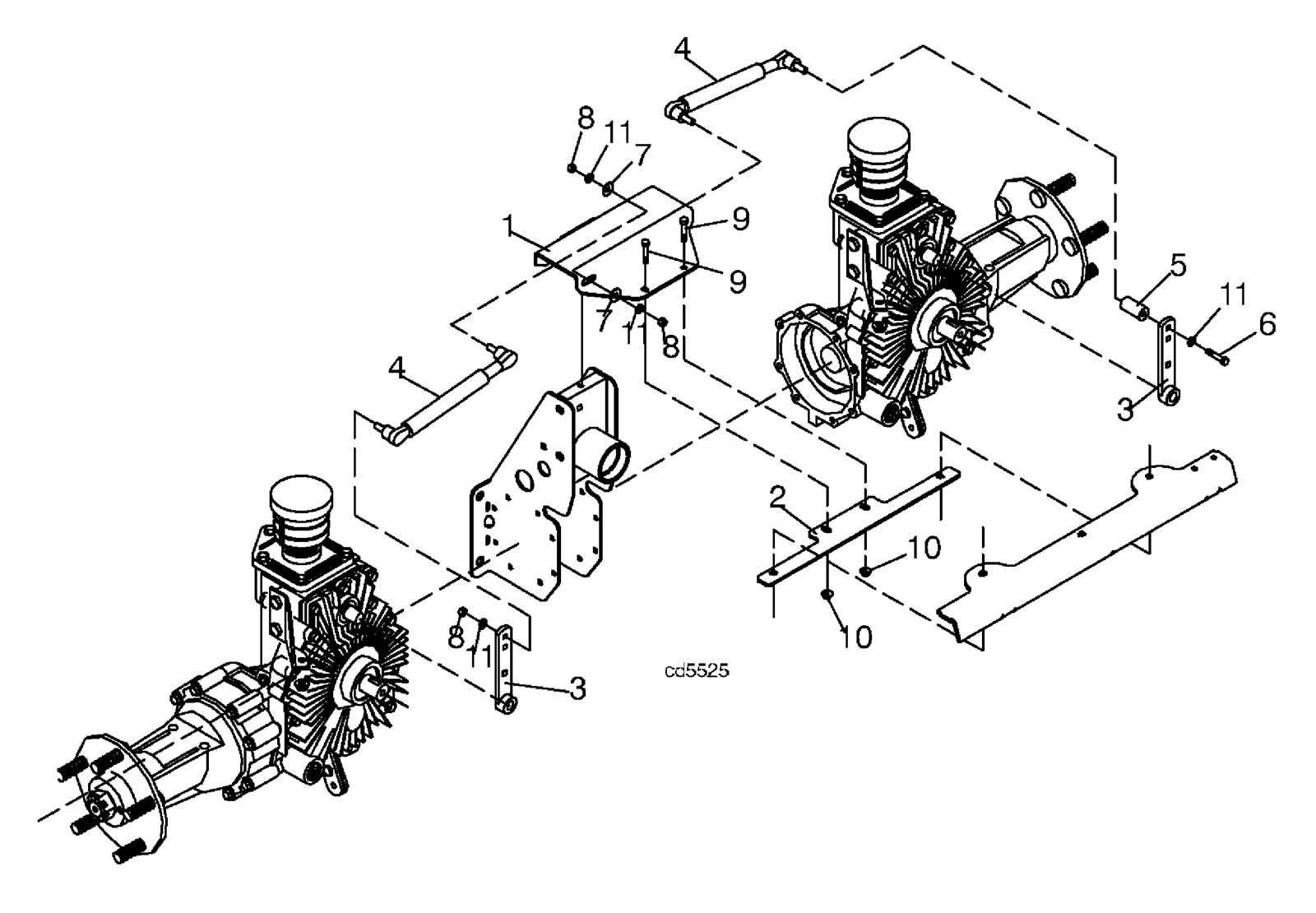

Detailed Breakdown of the Fuel System

The fuel system is designed to ensure efficient power delivery by seamlessly mixing and transferring fuel to maintain optimal performance. This section provides a comprehensive overview of the components and their roles, highlighting how each part contributes to the smooth operation of the entire setup. Key Components of the Fuel Assembly

|