Exploring the intricate layouts of mechanical systems is essential for anyone looking to enhance their knowledge of machinery. A comprehensive understanding of how various elements interact can significantly improve maintenance and repair processes. By grasping the relationship between different components, users can troubleshoot issues more effectively.

In this section, we will delve into the detailed configuration of a specific model, shedding light on each element’s function and placement. Recognizing how these parts fit together is crucial for achieving optimal performance and longevity in equipment. The ultimate goal is to empower users with the knowledge needed to navigate the complexities of mechanical assemblies.

Whether you are a seasoned technician or a novice, having access to a clear layout will serve as a valuable resource. It not only aids in understanding the overall system but also enhances the ability to perform repairs and upgrades with confidence. Join us as we unravel the specifics of this machinery, making the journey into the world of mechanics both informative and engaging.

Understanding Yth24k48 Components

Grasping the intricacies of machinery requires a deep dive into its individual elements. Each component plays a vital role in the overall functionality, contributing to the efficiency and performance of the system. By examining these elements closely, one can gain insights into how they interact and support the machine’s operations.

Key Elements of the System

Every machine consists of various parts that serve distinct purposes. These crucial segments work together harmoniously, ensuring that the device operates smoothly. Understanding the role of each element allows for better maintenance practices and informed decision-making when repairs are necessary. Regular inspection of these components can help identify potential issues before they escalate, promoting longevity and reliability.

Interconnectivity and Functionality

The interdependence of different parts is essential for optimal performance. A malfunction in one area can lead to a cascade of failures in others, underscoring the importance of comprehensive knowledge about the entire assembly. Familiarizing oneself with the arrangement and function of these elements aids in troubleshooting and enhances operational efficiency, making it a crucial aspect for any operator or technician.

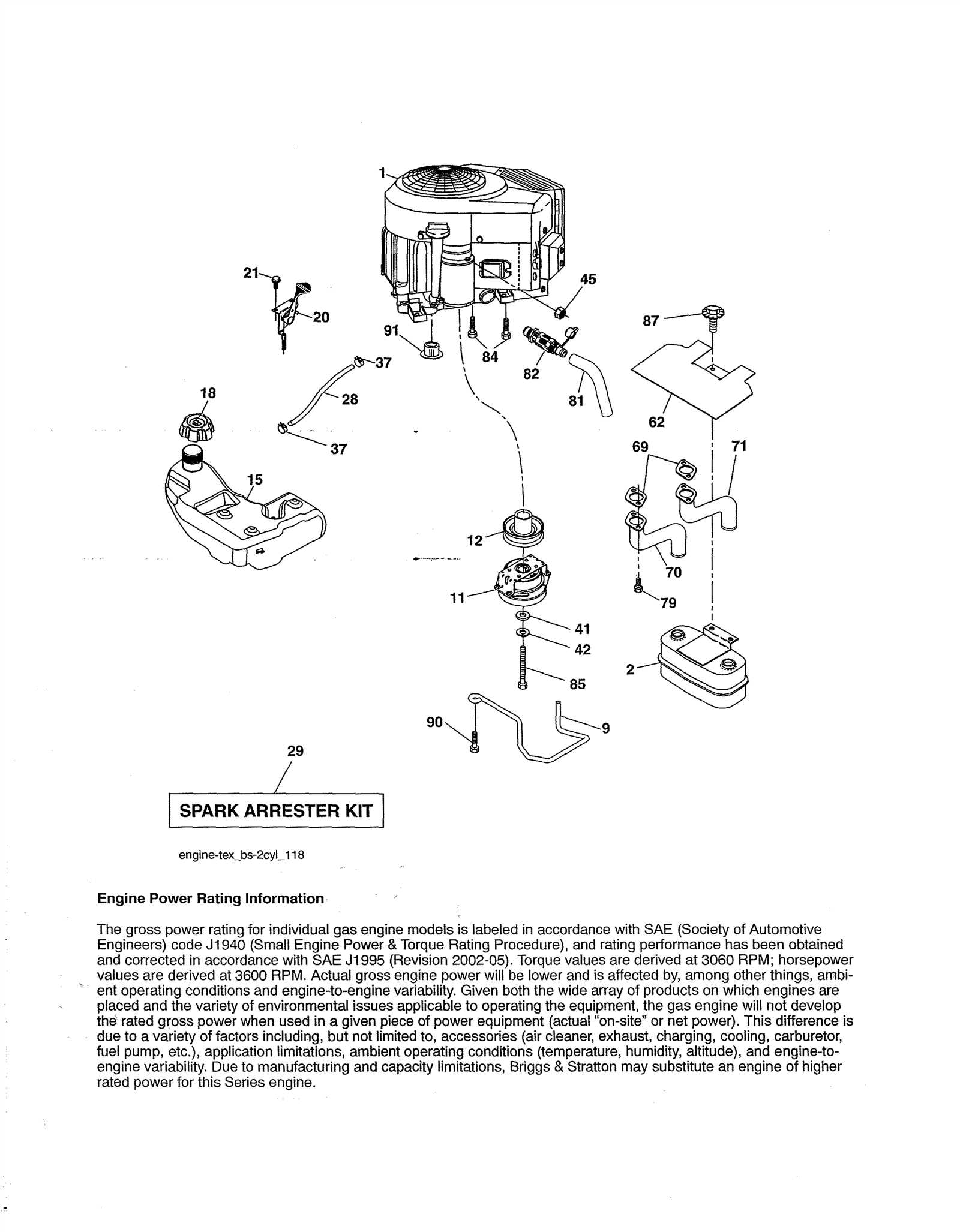

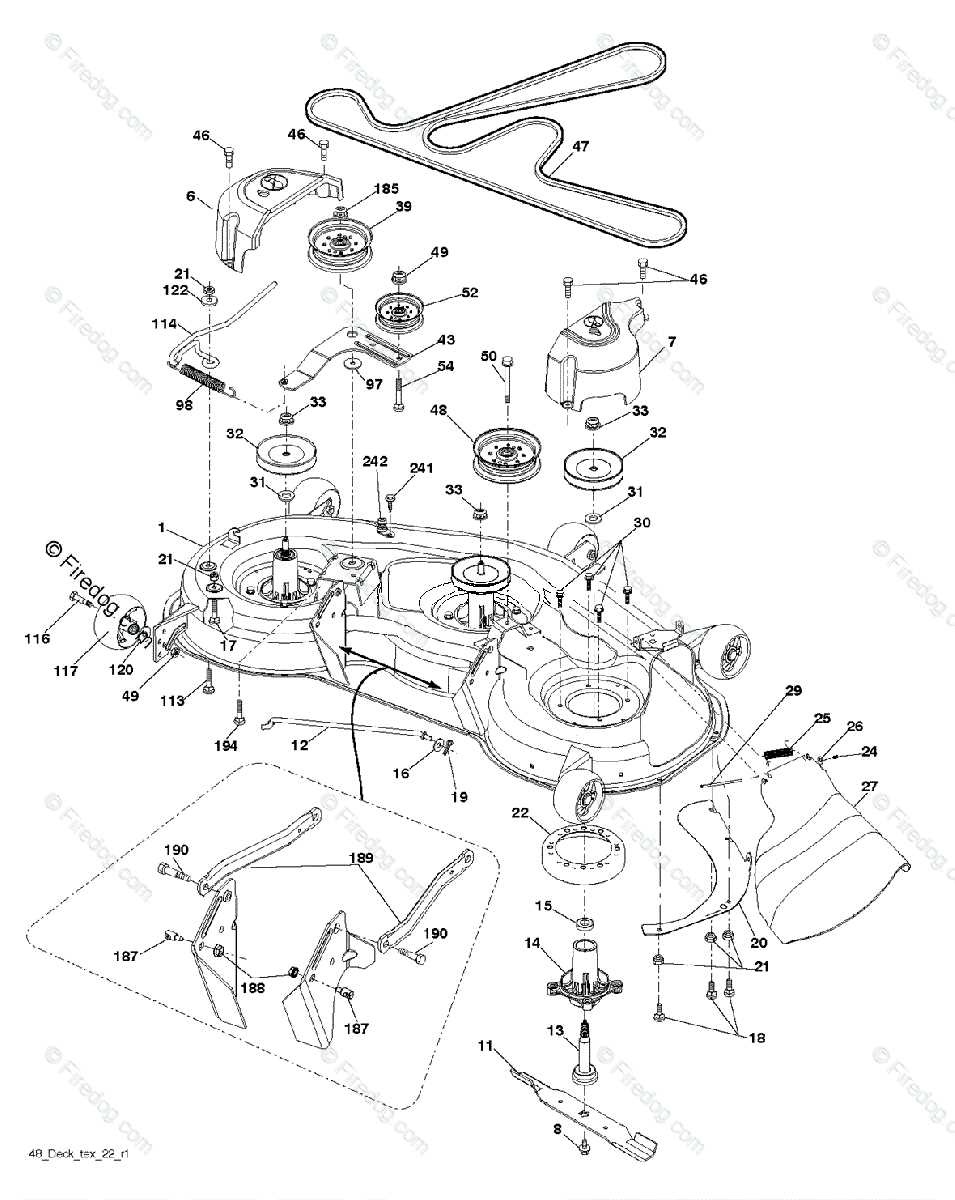

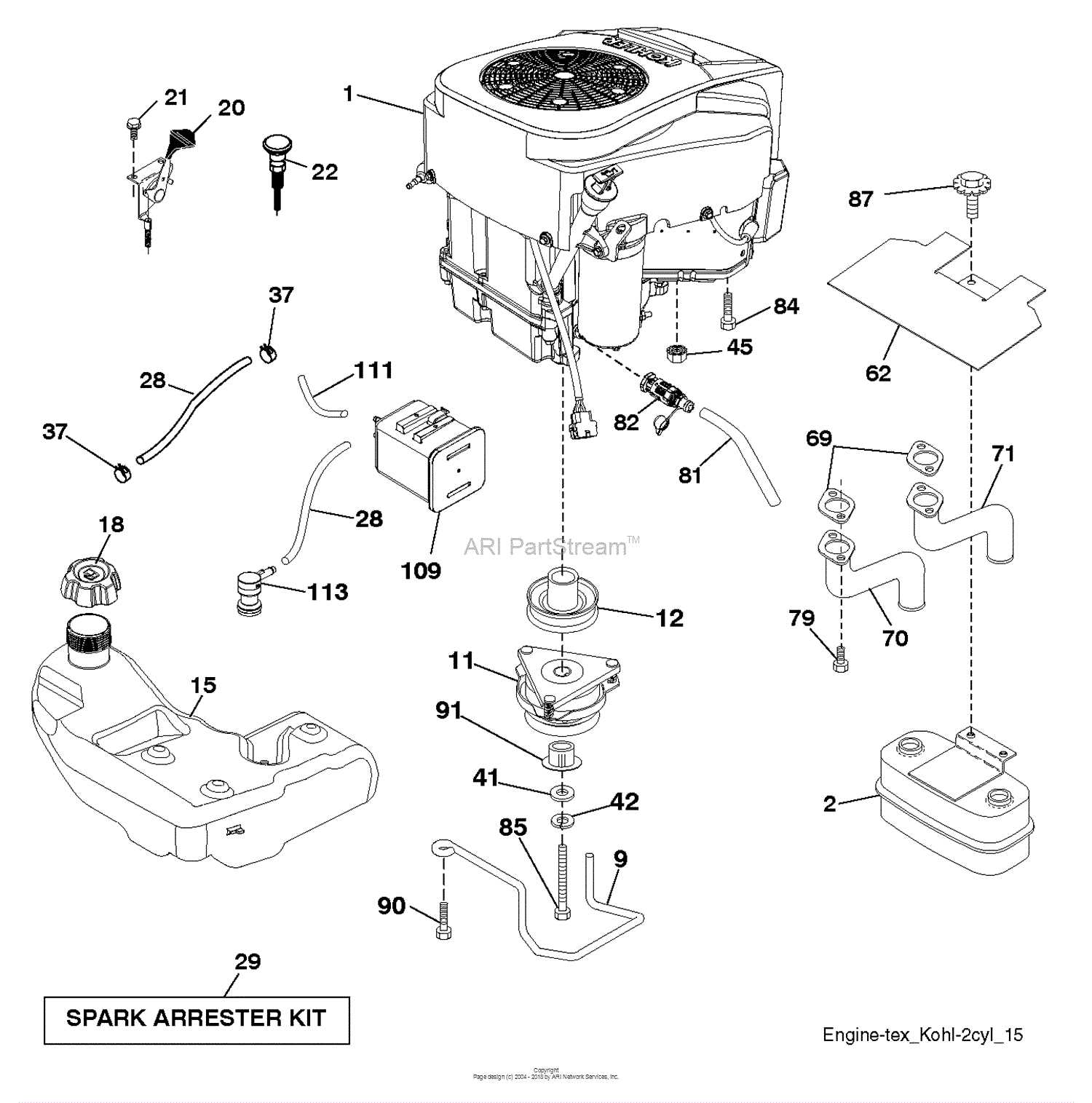

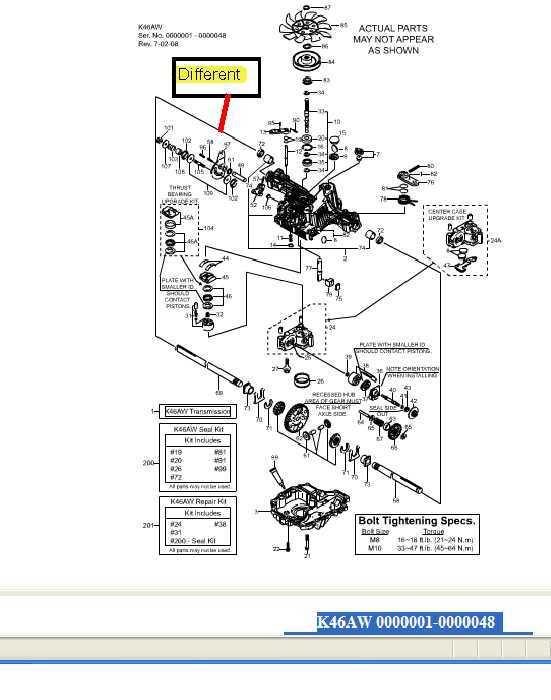

Importance of Parts Diagrams

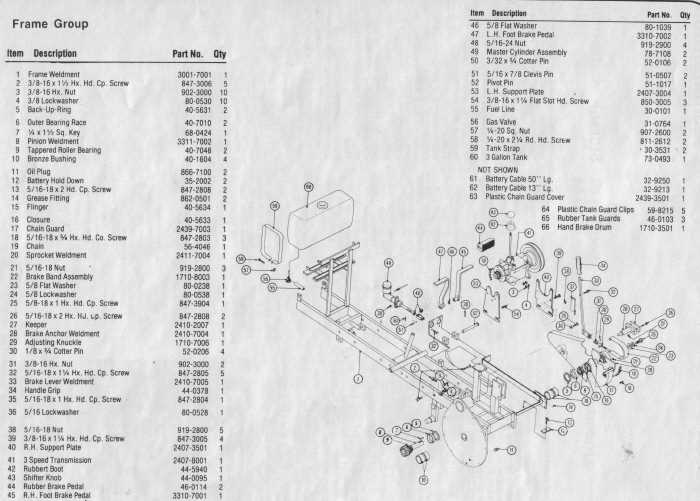

The significance of visual representations in mechanical systems cannot be overstated. These illustrations serve as vital tools for understanding the intricate components that make up machinery. By providing a clear view of how individual elements interact, they enable users to grasp complex structures more effectively.

Understanding and Maintenance: Such representations are essential for both comprehension and upkeep. They allow technicians and users to identify various segments quickly, facilitating efficient troubleshooting and repairs. When one can see where each component fits, it reduces the likelihood of errors during reassembly.

Training and Education: In educational settings, these visuals play a crucial role in teaching mechanics and engineering principles. They serve as valuable references, helping students visualize and comprehend theoretical concepts through practical examples.

Improved Communication: Clear visual aids enhance communication among professionals in the field. When discussing modifications or repairs, having a shared reference point minimizes misunderstandings and fosters collaboration.

Enhanced Efficiency: Ultimately, such illustrations contribute to increased efficiency in both manufacturing and maintenance processes. By streamlining the understanding of machinery, they allow for quicker decision-making and reduce downtime, leading to improved overall productivity.

Common Issues with Yth24k48

In any mechanical system, various challenges may arise that can affect overall performance and reliability. Identifying these problems early is crucial for ensuring longevity and optimal functionality. Below are some prevalent issues that users often encounter.

Mechanical Failures

- Wear and Tear: Components may experience degradation over time, leading to decreased efficiency.

- Alignment Problems: Misalignment can cause excessive strain, resulting in malfunction.

- Lubrication Issues: Insufficient lubrication may lead to overheating and increased friction.

Electrical Concerns

- Wiring Faults: Damaged or corroded wires can interrupt power supply, causing operational failures.

- Sensor Malfunctions: Defective sensors may provide inaccurate readings, affecting performance.

- Battery Problems: Weak or dead batteries can lead to starting issues or erratic operation.

Addressing these common challenges promptly can prevent more serious complications and ensure the equipment operates smoothly.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to troubleshooting and fixing issues with your machinery. By following these structured steps, you can systematically identify the root cause of the problem and implement effective solutions. Proper maintenance and repair can extend the lifespan of your equipment and enhance its performance.

Preparation Before Starting

Before diving into repairs, gather all necessary tools and materials. Create a clean workspace and ensure you have access to any relevant documentation that outlines the assembly and components of the unit. Taking safety precautions, such as wearing gloves and goggles, is essential to prevent accidents during the repair process.

Identifying the Issue

Begin by conducting a thorough inspection of the equipment. Look for any visible signs of wear, damage, or malfunction. Listen for unusual sounds and observe any irregular behavior during operation. Document your findings to assist in the repair process. Once you have pinpointed the issue, you can proceed to take corrective measures, whether it involves replacing a faulty component or adjusting settings.

By following these steps, you will be well-equipped to tackle the repair task effectively. Stay focused and patient, and ensure that all repairs are completed to maintain optimal functionality.

How to Interpret Diagrams Effectively

Understanding visual representations can significantly enhance your comprehension of complex information. Mastering this skill allows you to decode intricate illustrations, making it easier to grasp underlying concepts and mechanisms. By familiarizing yourself with key elements and their relationships, you can navigate these visuals with greater ease and accuracy.

To effectively interpret visual aids, consider the following strategies:

| Strategy | Description |

|---|---|

| Identify Key Components | Focus on the main elements highlighted in the illustration, noting their function and significance. |

| Understand Relationships | Examine how different parts interact and relate to one another within the visual context. |

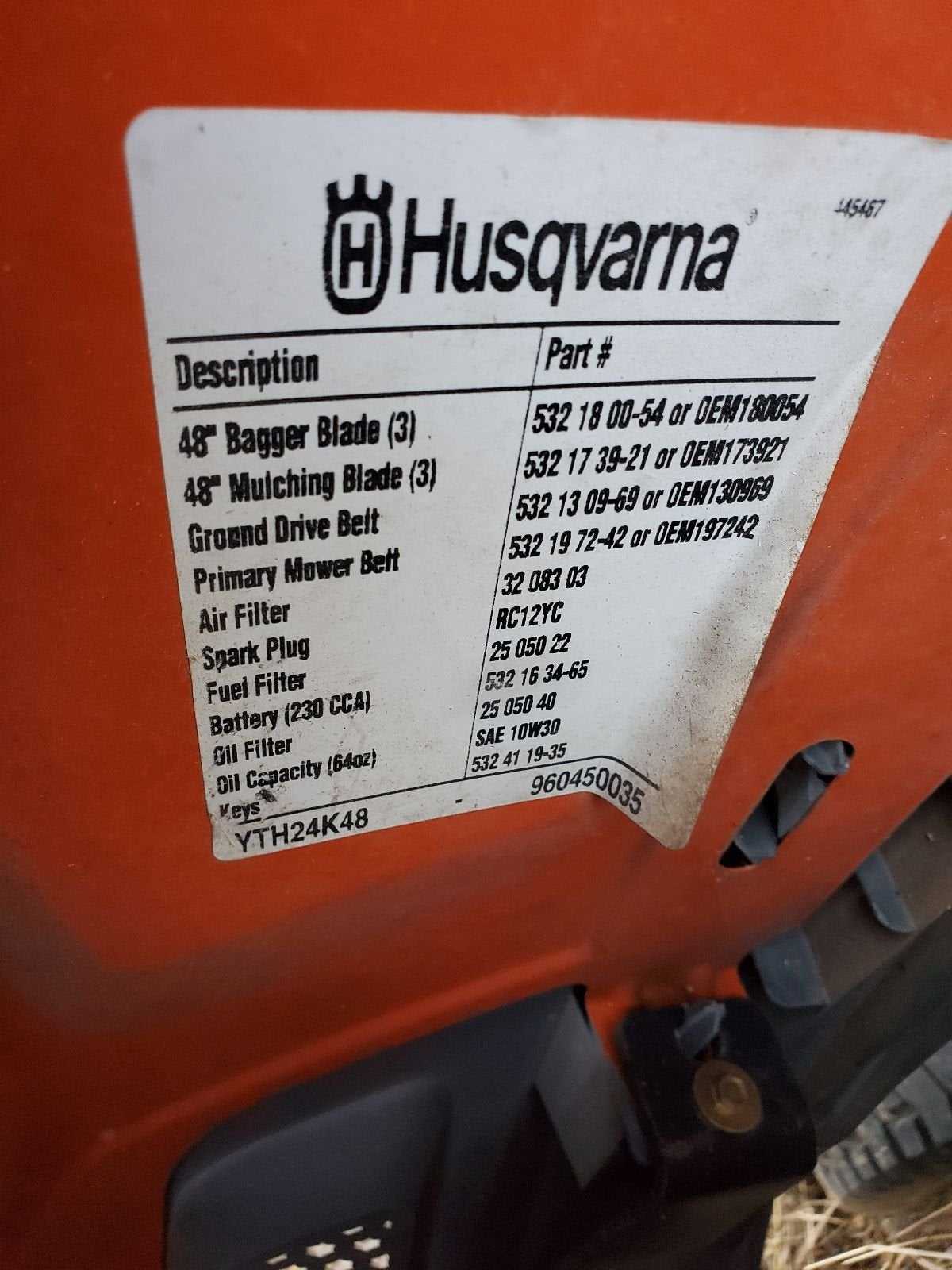

| Utilize Legends and Labels | Refer to any accompanying legends or labels to clarify meanings and functions of various elements. |

| Break Down Complexity | Divide the illustration into smaller sections to simplify understanding and enhance retention. |

| Practice Regularly | Engage with diverse visuals frequently to build familiarity and improve your interpretation skills over time. |

By applying these techniques, you can develop a more nuanced understanding of visual representations, enabling you to extract valuable insights and make informed decisions based on the information presented.

Maintaining Your Yth24k48 Equipment

Regular upkeep of your machinery is crucial for optimal performance and longevity. Understanding the components and their functions will help you ensure everything runs smoothly. A systematic approach to maintenance can prevent unexpected breakdowns and enhance efficiency.

Start with routine inspections to identify any wear and tear. Check fluids, belts, and connections regularly to catch potential issues early. Following the manufacturer’s recommendations for service intervals will keep your equipment in peak condition.

Cleaning is equally important. Removing debris and buildup not only improves performance but also extends the lifespan of various elements. Ensure that filters are replaced and air passages are clear to promote proper airflow and prevent overheating.

Finally, don’t overlook the importance of using quality replacement components. Investing in reliable parts will lead to better performance and reduce the likelihood of recurring issues. Keeping a well-organized inventory of essential supplies can streamline repairs and maintenance tasks.

Where to Find Quality Parts

Locating reliable components for your machinery is essential for maintaining performance and longevity. With a variety of options available, it’s important to know where to seek out high-quality items that meet your needs. Whether you are looking for replacements or enhancements, the right sources can make all the difference in ensuring optimal functionality.

One effective approach is to explore authorized dealers. These vendors often provide genuine products that are specifically designed for your equipment, ensuring compatibility and reliability. Additionally, they typically offer warranties, giving you peace of mind with your purchase.

Another avenue to consider is online marketplaces. Websites dedicated to machinery supplies can provide a vast selection, often at competitive prices. When shopping online, look for sellers with positive reviews and a solid return policy to safeguard your investment.

Local repair shops can also be invaluable resources. They not only have access to quality items but can also offer expert advice on what will work best for your situation. Establishing a relationship with a trusted technician can lead to better recommendations and deals over time.

Finally, industry forums and communities can be great places to gather insights. Enthusiasts and professionals often share their experiences and suggest reputable sources for obtaining superior components. Engaging with these communities can provide you with tips and guidance tailored to your specific requirements.

Upgrading vs. Replacing Components

When considering improvements for machinery, two primary approaches often come to mind: enhancement of existing elements or complete substitution with new ones. Each strategy offers distinct advantages and challenges that can significantly impact performance, longevity, and cost-efficiency.

Opting for upgrades typically involves modifying or enhancing current elements to boost functionality or efficiency. This can often lead to improved performance without the need for a full overhaul. Upgrading may also extend the lifespan of existing components, allowing users to benefit from advancements in technology while minimizing disruption.

On the other hand, complete replacement might be the best choice when components are outdated or excessively worn. This approach ensures that the machinery operates with the latest innovations and reliability. However, it often comes with higher upfront costs and may require more extensive downtime for installation.

Ultimately, the decision between upgrading and replacing hinges on specific needs, budget constraints, and the desired outcome. A thorough evaluation of the current system and future requirements will guide the best course of action for optimal performance and value.