Every outdoor machine is composed of various elements that work in harmony to ensure optimal performance. Grasping the arrangement and function of these components is essential for effective maintenance and troubleshooting. This knowledge not only enhances the longevity of your device but also empowers users to tackle common issues with confidence.

Assembling insights into the various sections allows for a clearer understanding of how each piece interacts within the overall system. Recognizing the roles of individual units, from the engine to the control systems, can facilitate smoother operation and timely repairs. Familiarity with these components can transform the way users approach upkeep, making it an easier and more manageable task.

In this section, we will explore the essential elements of your equipment’s configuration, offering a comprehensive overview. With a focus on clarity and detail, this guide will serve as a valuable resource for both novice and experienced users seeking to enhance their operational knowledge.

Understanding Lawn Mower Functionality

Mechanized grass cutters operate through a combination of essential components working in harmony to achieve optimal performance. Each element plays a significant role in ensuring the machine efficiently trims grass while maintaining user control and comfort.

Power Source serves as the heart of the device, providing the necessary energy for operation. This can vary from gasoline engines to electric motors, each having its own advantages and drawbacks. The choice of power source affects the overall efficiency and ease of use.

The cutting mechanism is critical for achieving the desired length of the vegetation. Various styles, such as rotary blades or reel systems, determine how effectively the cutting process is carried out. The design of this mechanism impacts both the quality of the cut and the health of the grass.

Chassis and frame design contribute to stability and maneuverability. A well-constructed base allows for easy navigation across different terrains, while the layout ensures the operator’s comfort during prolonged use.

Lastly, control systems provide the user with the ability to adjust settings and manage the operation seamlessly. These features enhance the overall experience by allowing for customization according to specific needs and preferences.

Identifying Common Replacement Parts

Understanding the various components that may need to be replaced during maintenance can significantly enhance the longevity and performance of your equipment. Familiarity with these elements not only aids in efficient troubleshooting but also ensures that the necessary replacements are readily available when needed.

Here are some of the frequently encountered components that may require attention:

- Blades: Essential for cutting, these elements can become dull or damaged over time, necessitating replacement for optimal performance.

- Filters: Air and fuel filters are crucial for maintaining engine efficiency. Regular replacement can prevent buildup that may lead to performance issues.

- Batteries: A reliable power source is vital for starting and operating equipment. Periodic checks and replacements may be necessary to ensure functionality.

- Belts: These components facilitate movement and power transfer. Over time, they can wear out or break, requiring timely replacement.

- Wheels: Support and mobility are dependent on these elements. Damage or wear can lead to stability issues, making their replacement essential.

By recognizing these common components, operators can better prepare for maintenance tasks and ensure their machinery runs smoothly and efficiently.

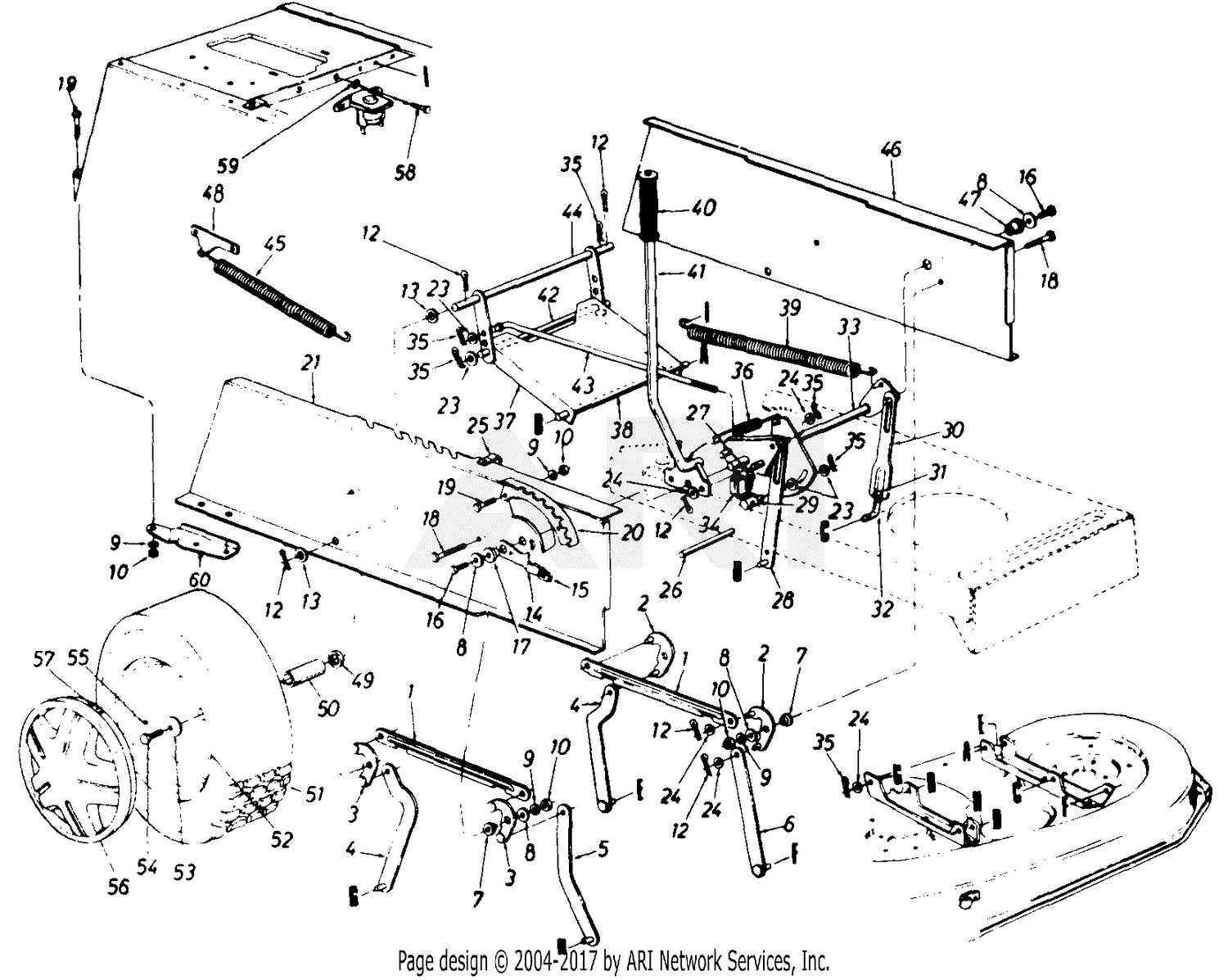

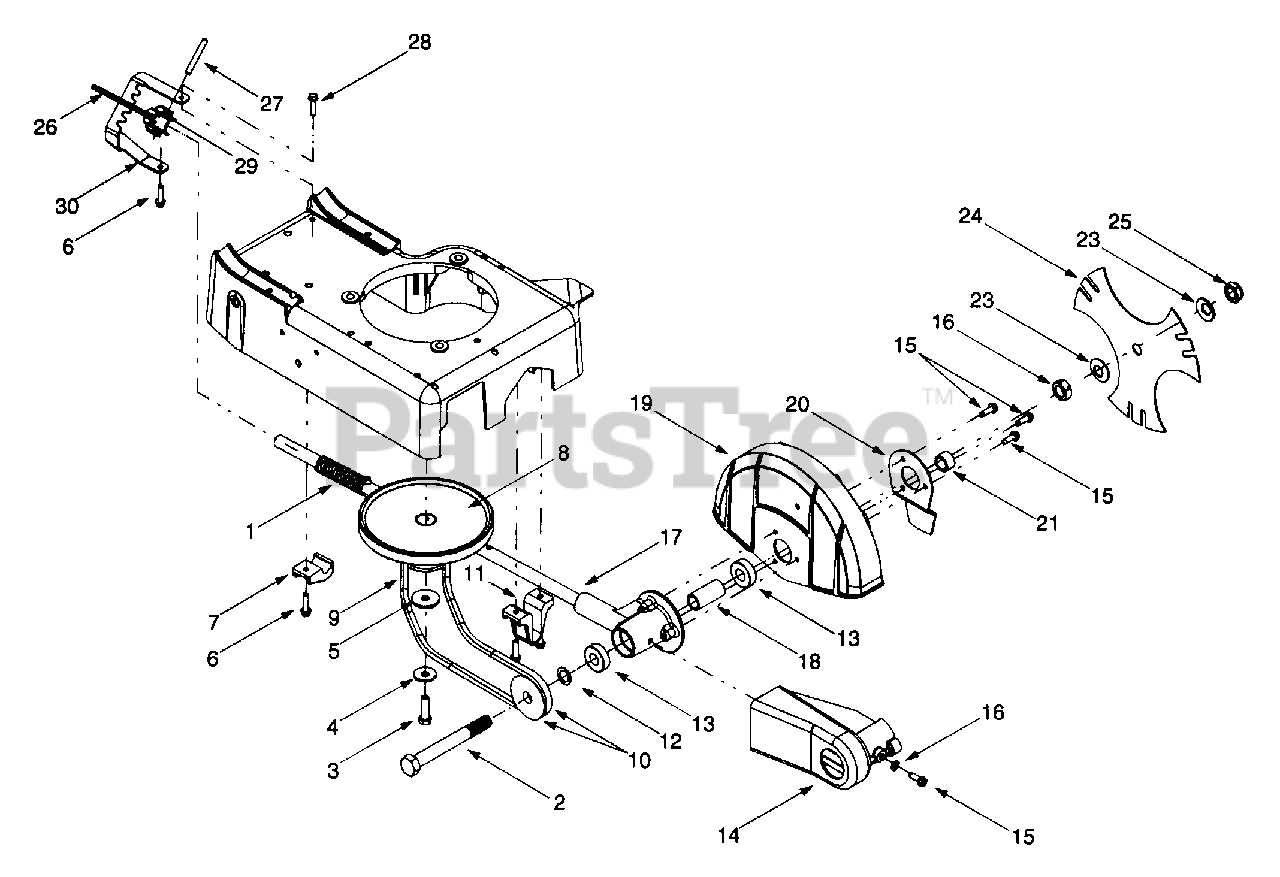

Diagram Overview for Maintenance Tasks

This section provides a comprehensive outline for executing essential upkeep tasks. Understanding the visual representation of components facilitates efficient servicing and enhances the longevity of the equipment.

Regular maintenance is crucial for optimal performance. Familiarizing yourself with the arrangement of elements allows for better troubleshooting and identification of necessary actions. Key activities include:

- Routine inspections for wear and tear

- Replacement of worn components

- Adjustment of moving parts

- Cleaning and lubrication of critical areas

Prioritizing these tasks ensures the machinery operates smoothly, reducing the risk of unexpected breakdowns. The layout serves as a reference point, guiding you through the upkeep process with clarity.

By following a structured approach, you can maintain high efficiency and reliability in your equipment. Engaging with the schematic fosters a deeper understanding, empowering you to carry out repairs with confidence.

Tools Needed for Repair Work

To effectively address maintenance and repair tasks, having the right equipment is essential. A well-prepared toolkit can significantly streamline the process, ensuring efficiency and precision. Understanding which instruments are necessary allows for a smoother workflow and better outcomes.

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for disassembly and reassembly. Additionally, specialized devices like spark plug wrenches and socket sets may be required for more intricate tasks. Ensuring that these items are readily available can reduce downtime and enhance productivity.

Furthermore, safety equipment should not be overlooked. Gloves, goggles, and protective gear are vital to safeguarding the user while handling various components. Having a clean workspace and organization of tools can also contribute to a safer and more efficient repair experience.

Safety Precautions While Servicing

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Following specific guidelines helps create a secure environment for both the technician and the equipment. Always adhere to recommended practices when handling tools and machinery.

Before starting any service tasks, consider the following essential precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Disconnect the power source to prevent accidental starts while working on the machine.

- Ensure the work area is clean and free of obstacles to avoid tripping hazards.

- Use tools that are in good condition and designed for the specific tasks at hand.

Additionally, take into account the following steps for enhanced safety:

- Read the manufacturer’s manual for specific safety instructions related to the equipment.

- Keep children and pets away from the service area during maintenance.

- Do not attempt repairs if unsure about the process; seek professional assistance when needed.

- Store hazardous materials, such as fuels and oils, in designated containers away from heat sources.

By implementing these safety measures, you can ensure a safe and efficient servicing experience.

Frequently Asked Questions on Repairs

This section addresses common inquiries regarding maintenance and restoration processes for outdoor machinery. Understanding these aspects can significantly enhance the lifespan and efficiency of your equipment.

What should I do if my equipment won’t start?

There could be several reasons for startup issues, including fuel blockage, battery failure, or electrical problems. Begin by checking the fuel level and ensuring it is fresh. If the battery is weak, try recharging or replacing it.

How can I identify worn-out components?

Signs of wear may include unusual noises, vibrations, or decreased performance. Regular inspections and cleaning can help detect damaged elements early. Look for cracks, rust, or other signs of deterioration on visible surfaces.

What maintenance should I perform regularly?

Regular tasks include changing the oil, cleaning or replacing air filters, and checking spark plugs. Adhering to a consistent maintenance schedule can prevent major repairs and ensure optimal functionality.

When should I seek professional assistance?

If you encounter persistent issues that you cannot resolve, it may be time to consult a professional. Complex repairs, particularly those involving the engine or electrical system, are best left to experienced technicians.