Exploring the core elements of garden cultivators reveals the intricate design that empowers them to effectively work through soil. By examining the layout of these essential elements, users can gain insight into how each component interacts, contributing to the overall performance of the tool. Whether one is addressing maintenance needs or preparing for a replacement, understanding the framework of each piece can streamline both repair and upkeep processes.

The various elements of these cultivators are crafted to manage different tasks, from loosening soil to breaking through compact layers. Recognizing the function of each segment allows for better handling and effective troubleshooting. This guide will delve into the specifics of each core part, ensuring that users can confidently maintain and improve the equipment’s functionality over time.

By acquiring a clear overview of each functional section, users can better identify areas requiring attention and ensure optimal performance. With practical guidance on key components, users are equipped to approach repairs and enhancements with ease, extending the lifespan and efficiency of this invaluable gardening tool.

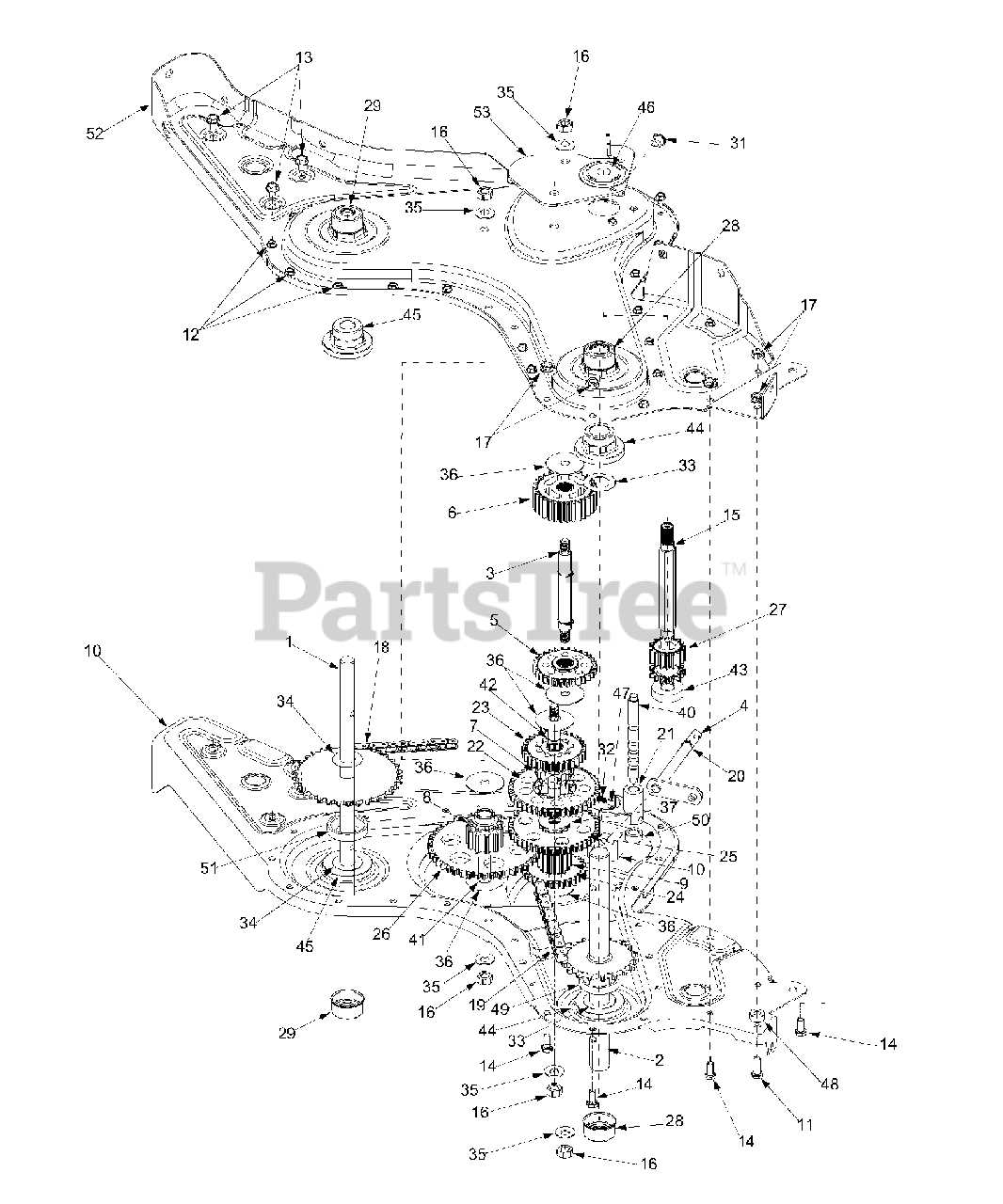

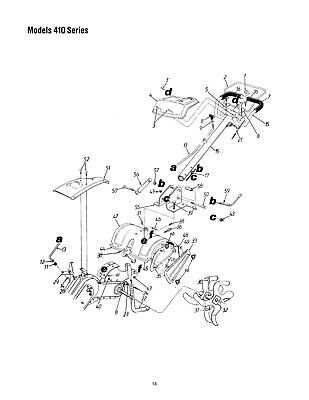

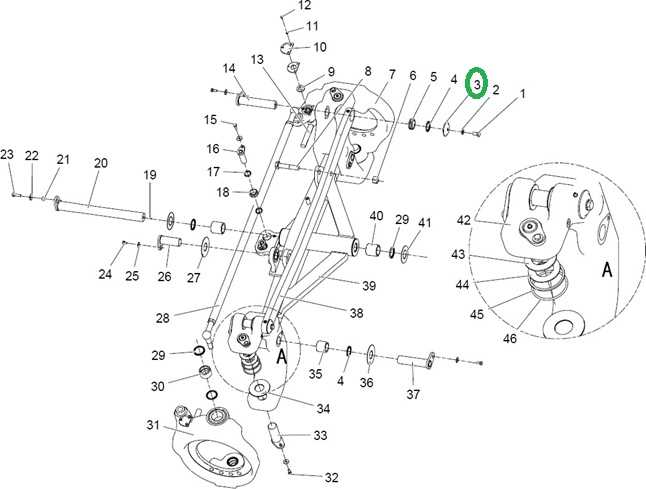

Overview of Yard Machine Tiller Components

This section provides a comprehensive view of the essential components that enable a soil preparation tool to function effectively. Understanding each part’s role in the overall mechanism helps ensure optimal performance and easier maintenance. By familiarizing yourself with these integral pieces, you can maintain, repair, and even enhance the tool’s efficiency for prolonged use.

Main Structural Elements

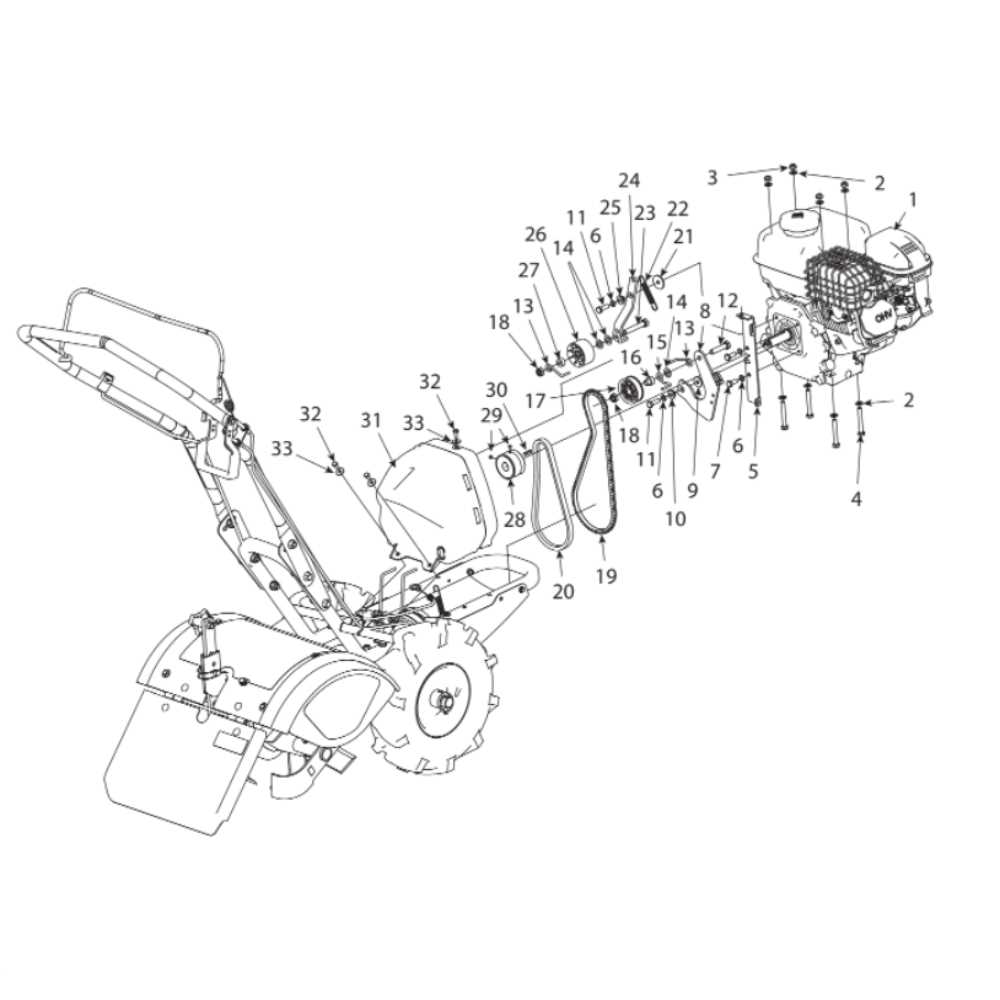

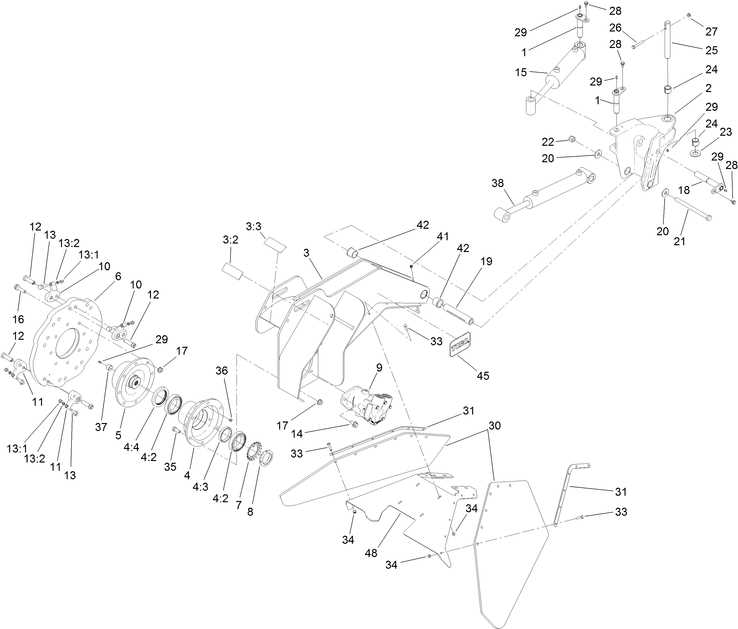

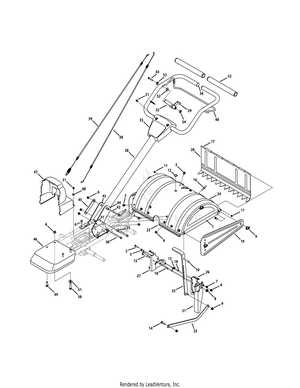

The core framework comprises key elements that lend support and stability to the device. These parts work in unison, allowing the machine to perform consistently under various conditions. The handles and levers, for example, provide control, while the central frame anchors the device’s weight, helping it remain steady during operation.

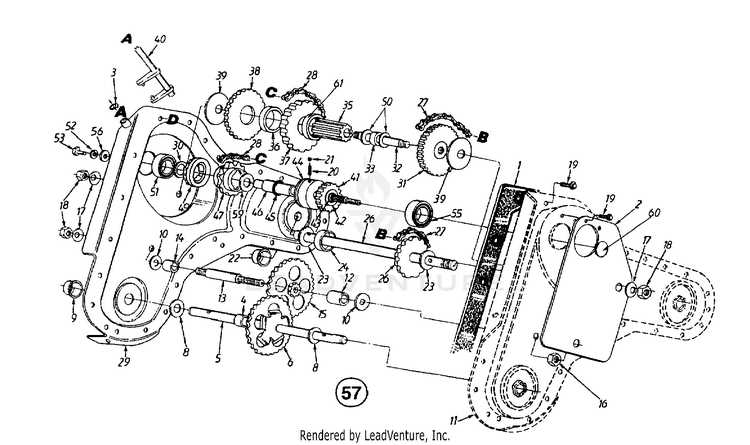

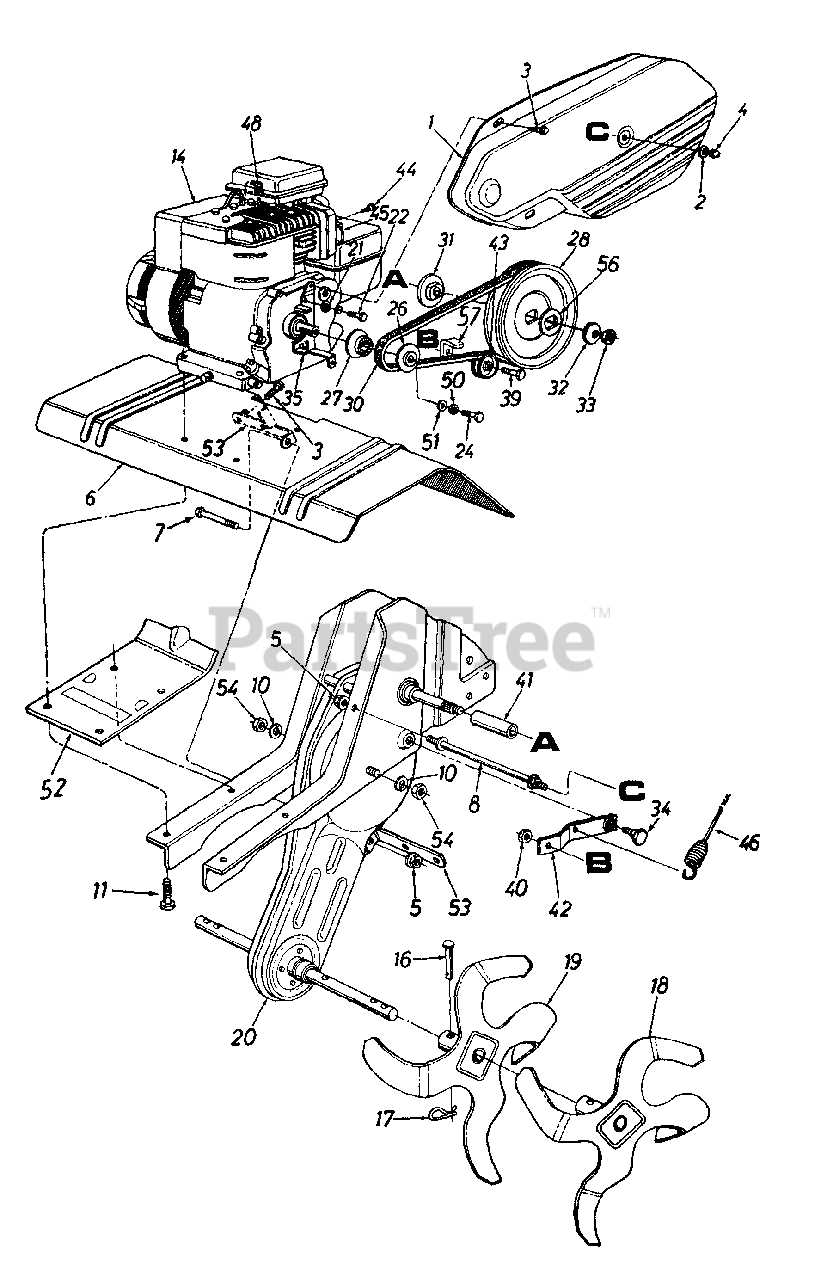

Engine and Drive System

The engine, along with its supporting drive system, powers the tool and moves the blades to cultivate the soil. This system is composed of various gears, belts, and shafts, which work together to transfer energy effectively. Proper upkeep of this section ensures that the machine runs smoothly and avoids excessive wear.

| Component | Function |

|---|---|

| Control Handles | Provide guidance and direction to the tool while in use. |

| Frame Structure | Supports the main body and stabilizes the device during operation. |

| Engine Unit | Powers the equipment, allowing it to cultivate soil efficiently. |

| Drive Mechanism | Transfers power from the engine to the blades for effective soil preparation. |

Main Functions of Key Tiller Parts

In soil preparation and maintenance, each component of this type of outdoor equipment has a specific role that aids in efficient ground cultivation. Understanding how these essential elements function allows for better control, effective use, and timely maintenance of the device.

Engine: The engine powers the equipment, providing the necessary force to break up and turn the soil. A strong, reliable engine ensures the device operates smoothly and consistently, even in tougher soil conditions.

Blades: The rotating blades are the primary tools for soil penetration and movement. They dig into the ground, cutting through compact soil, roots, and other obstacles, which facilitates aeration and prepares the land for planting.

Handlebars: These allow the operator to guide and control the device with ease. Properly designed handlebars reduce strain, improve stability, and enhance maneuverability during operation.

Wheels: The wheels support smooth movement across various types of terrain, providing balance and enabling easier transportation. They make it possible to adjust positioning efficiently while working in different areas.

Transmission: The transmission system controls the speed and direction of the device, adjusting the power from the engine to the blades. This component is essential for maintaining precise control over soil depth and cultivating pace.

Each of these elements plays a vital role in creating an effective and user-friendly experience, ensuring that ground preparation is done efficiently with minimal effort.

How to Identify Essential Parts

Recognizing key components in equipment ensures smooth operation and easy maintenance. Familiarity with each primary component allows for quicker troubleshooting and more efficient repairs.

To start, let’s explore some of the most critical areas:

- Power Source: The core that drives the entire system, usually connected to fuel or an energy source. Ensuring its proper function is crucial for consistent performance.

- Drive Mechanism: This part transfers energy from the power source to other sections. Inspecting it for wear or damage can prevent larger issues down the line.

- Blades or Tines: Essential for cutting or digging actions, these parts should be sharp and securely attached. Regular checks keep them effective and safe.

- Control Handles: Located within easy reach, these manage the main functions and direct movement. Keeping them responsive is important for safe and precise operation.

- Protective Coverings: Shields surrounding crucial components provide safety and durability. They should be free of cracks and firmly in place.

By understanding and regularly checking these primary sections, you’ll ensure each task proceeds safely and efficiently.

Maintenance Tips for Tiller Longevity

Ensuring the durability of your gardening equipment requires regular attention and care. By following a few essential practices, you can maximize its lifespan and efficiency.

- Regular Cleaning: After each use, remove dirt and debris to prevent rust and wear.

- Inspect and Tighten Fasteners: Periodically check all bolts and screws to ensure they are secure.

- Change Oil: Keep the engine running smoothly by changing the oil as recommended by the manufacturer.

- Sharpen Blades: Maintain optimal performance by keeping cutting tools sharp, which improves efficiency and reduces strain on the engine.

- Check Belts and Cables: Inspect for signs of wear and replace any damaged components promptly to avoid further issues.

Implementing these practices will not only enhance performance but also ensure that your equipment remains reliable for many seasons to come.

Understanding the Engine Assembly

The engine assembly is the powerhouse, responsible for generating the energy required to operate efficiently. By understanding the structure and key elements of the engine, users can better grasp how each part works together to produce the necessary force for operation. Examining these components helps with maintenance and enables troubleshooting of common issues.

Primary Components of the Engine

- Crankshaft: Converts linear motion into rotational force, driving other parts of the assembly.

- Cylinder and Piston: Work together to create pressure, producing the energy that powers the machine.

- Carburetor: Mixes fuel and air in the right ratio to ignite and power the engine.

- Spark Plug: Ignites the fuel-air mixture, setting off the combustion process.

Steps to Maintain Engine Health

- Check Oil Levels: Regularly ensure sufficient oil levels to prevent engine wear.

- Clean the Air Filter: Helps maintain efficient combustion by allowing clean air flow into the carburetor.

- Inspect Spark Plug: Periodically check for wear or deposits, which can affect ignition efficiency.

- Examine Fuel Lines: Keep an eye on fuel lines for cracks or blockages to prevent fuel issues.

Regular maintenance of these essential engine components can significantly extend its lifespan, ensuring smooth and reliable performance during use.

Common Issues with Tillers and Solutions

Working with soil cultivation tools can sometimes present challenges that affect performance and efficiency. Understanding these common problems and their solutions can significantly enhance the functionality of your equipment and ensure a successful gardening experience.

-

Engine Starting Issues:

If the engine fails to start, check the fuel level, spark plug condition, and battery charge. Cleaning or replacing the spark plug and ensuring fuel is fresh can often resolve the problem.

-

Insufficient Tilling Depth:

When the tool does not penetrate the soil adequately, it may be due to dull blades or incorrect settings. Sharpening the blades and adjusting the depth settings can improve performance.

-

Vibration and Noise:

Excessive vibration can indicate loose components or worn parts. Inspecting and tightening screws, as well as replacing any damaged components, can reduce noise and improve stability.

-

Overheating:

Overheating can result from prolonged use or inadequate airflow. Allowing breaks between uses and ensuring vents are clean can help maintain optimal temperatures.

-

Stalling:

If the tool stalls during operation, check for blockages in the tines or issues with the throttle. Clearing any debris and adjusting the throttle can help maintain a steady operation.

Regular maintenance and addressing these common issues can prolong the life of your soil cultivation tool and enhance its performance.

Replacing Worn or Damaged Components

Maintaining the efficiency of your cultivation equipment often involves addressing issues related to deteriorated or broken elements. Timely replacement of these components ensures optimal performance and prolongs the lifespan of the machinery. Understanding the importance of identifying and resolving these issues can save you time and resources in the long run.

Before initiating the replacement process, it is essential to conduct a thorough inspection of the equipment. Look for any signs of wear, such as cracks, breaks, or excessive rust. Components that exhibit these characteristics can hinder the functionality of the device and should be replaced promptly. Regular maintenance can help in detecting these problems early, preventing further damage.

When selecting replacement items, ensure they are compatible with your equipment. Consulting the manufacturer’s specifications or seeking advice from a knowledgeable dealer can guide you in choosing the right components. High-quality replacements contribute to better performance and reliability.

Once you have acquired the necessary items, follow the manufacturer’s instructions for installation. Make sure to use the proper tools and safety gear during the process. Taking the time to install replacements correctly will enhance the overall efficiency of your equipment and help avoid future complications.

Upgrading and Enhancing Tiller Performance

Improving the efficiency and effectiveness of your cultivation equipment can significantly impact your gardening experience. Various modifications and enhancements can lead to increased productivity and reduced effort. By exploring different options, you can tailor the machine to meet your specific needs and elevate its overall performance.

One way to enhance functionality is by upgrading the engine. A more powerful motor can provide better torque and speed, making it easier to break up tough soil and manage larger areas. Additionally, considering high-quality attachments can improve versatility. For instance, specialized tools designed for various soil types can help achieve desired results more efficiently.

Another key aspect to consider is regular maintenance. Ensuring that components are well-lubricated and free from debris will enhance the overall lifespan and performance of the equipment. Furthermore, replacing worn-out components with high-grade alternatives can lead to noticeable improvements in operation.

In summary, focusing on enhancements such as engine upgrades, quality attachments, and diligent maintenance can transform your cultivation experience. By investing in these areas, you will be well-equipped to tackle any gardening challenge that comes your way.