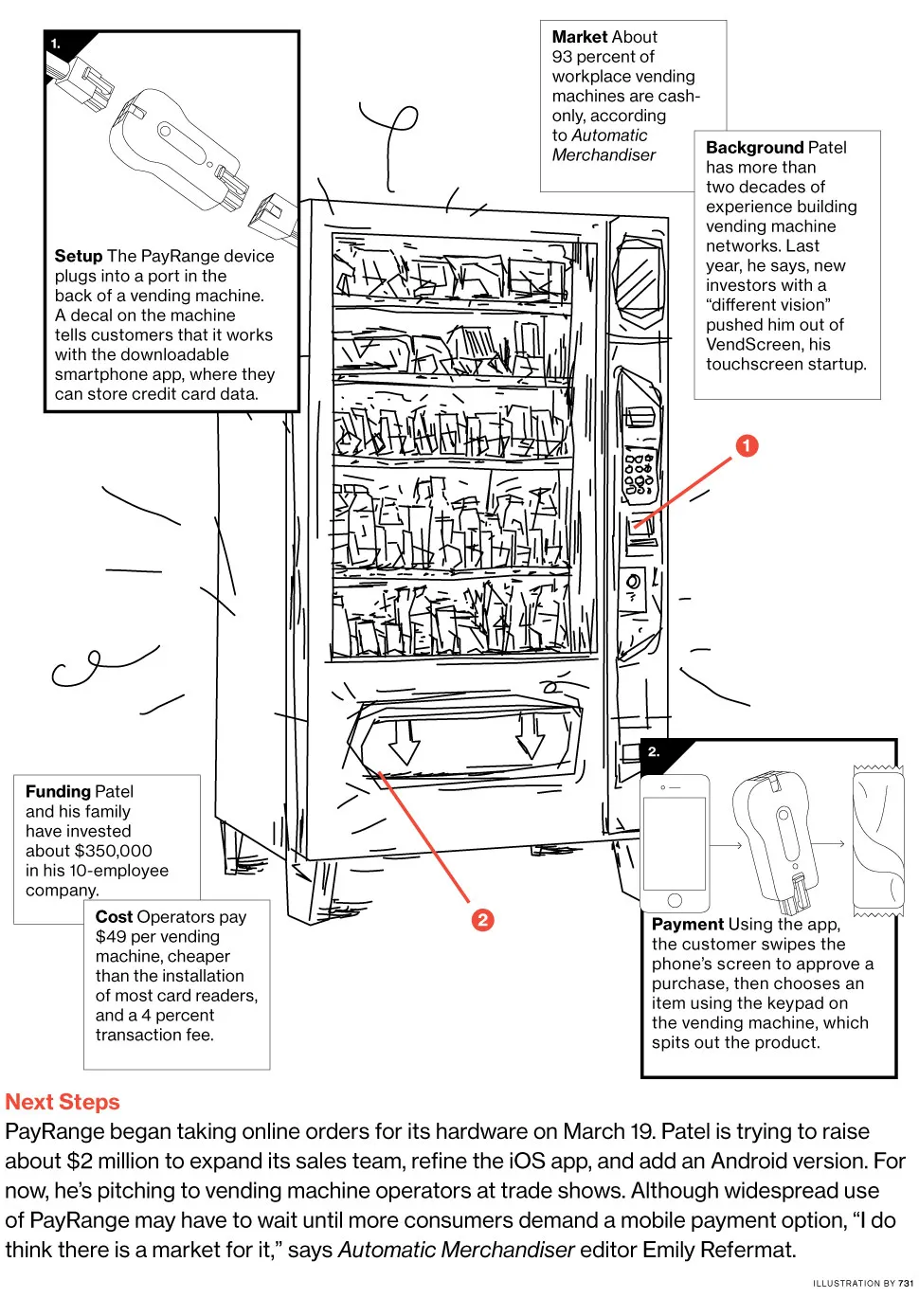

In today’s world, self-service devices have become an integral part of our daily lives. These clever units offer convenience, speed, and a touch of innovation in providing various items without the need for human assistance. While we often interact with these machines without giving much thought to their complexity, there’s a fascinating network of components working together behind the scenes.

Exploring the internal structure of these devices reveals a combination of intricate elements designed to ensure smooth operation. Each section has its unique role, from managing item selection to handling secure transactions. With proper understanding, one can appreciate the engineering marvels that bring these modern conveniences to life.

Whether you’re curious about how products are delivered with precision or how different mechanisms function in harmony, diving deeper into this subject provides insight into the brilliance of automated systems and their practical design.

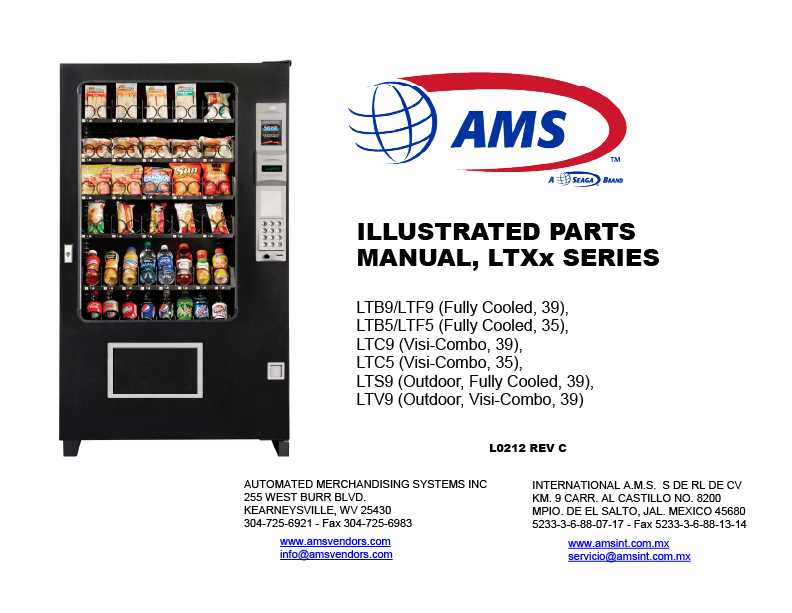

Understanding Vending Machine Components

To ensure efficient operation, it is important to have a good grasp of the key elements that make up automated dispensing systems. Each component plays a crucial role in ensuring functionality, from managing inventory to delivering products seamlessly. Familiarity with these elements enhances troubleshooting and maintenance efforts.

Core Elements

Automated product dispensers are designed with several primary sections that work together. These include a control unit, dispensing mechanism, and storage compartment. Each section has distinct responsibilities but must interact cohesively to provide reliable service. The proper functioning of each segment is vital for smooth operations.

Functional Overview

The following table outlines the essential components, highlighting their role in the system. By understanding these, operators can better maintain the equipment and address any performance issues that arise.

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Control Unit | Manages

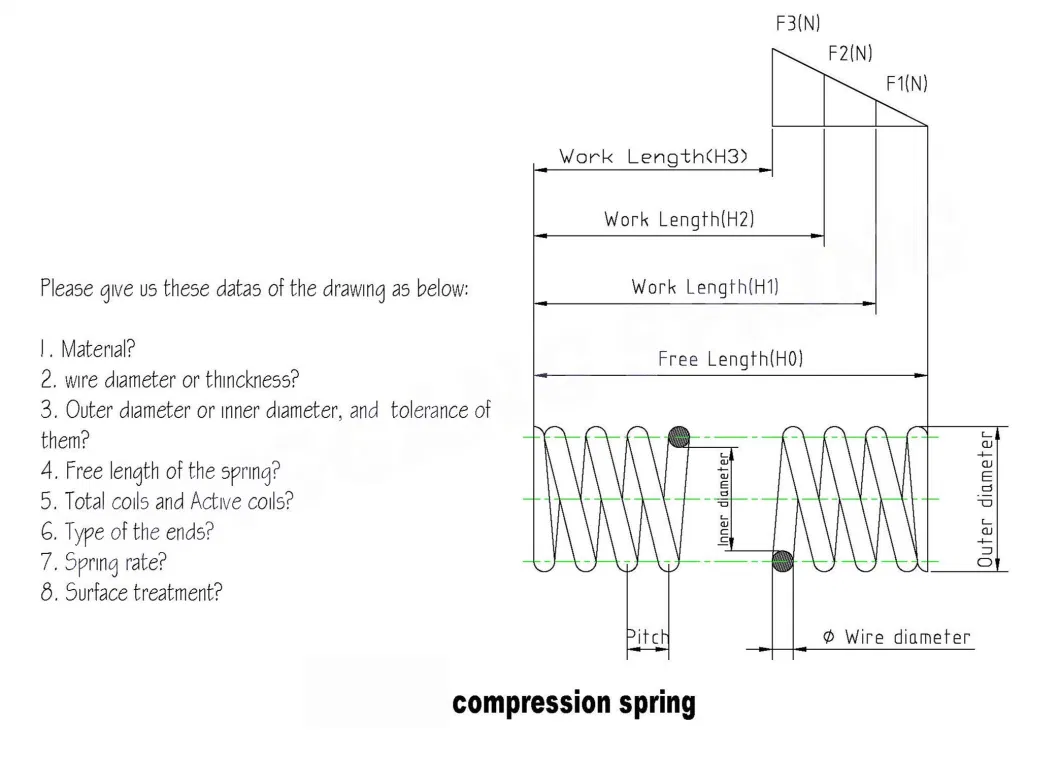

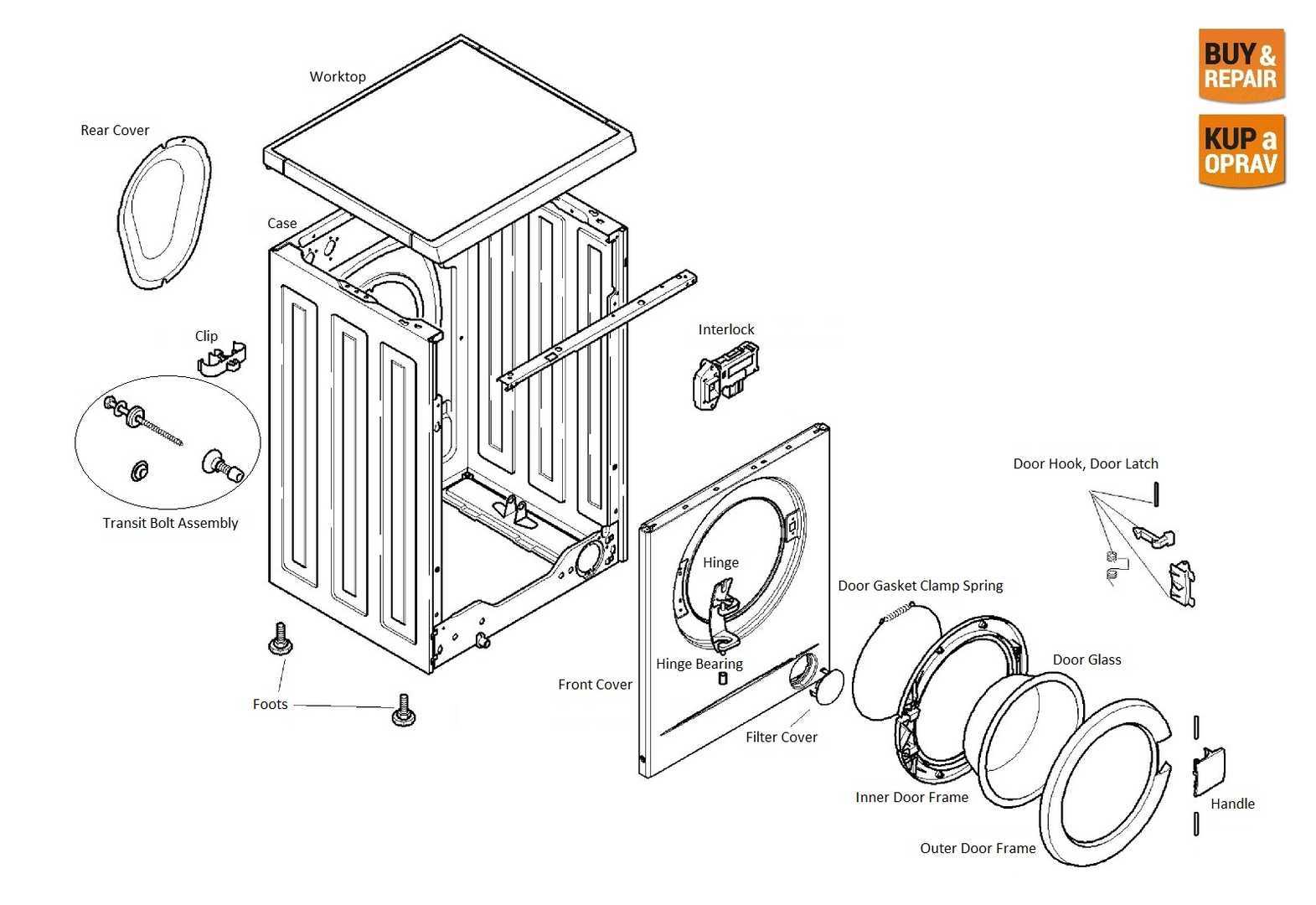

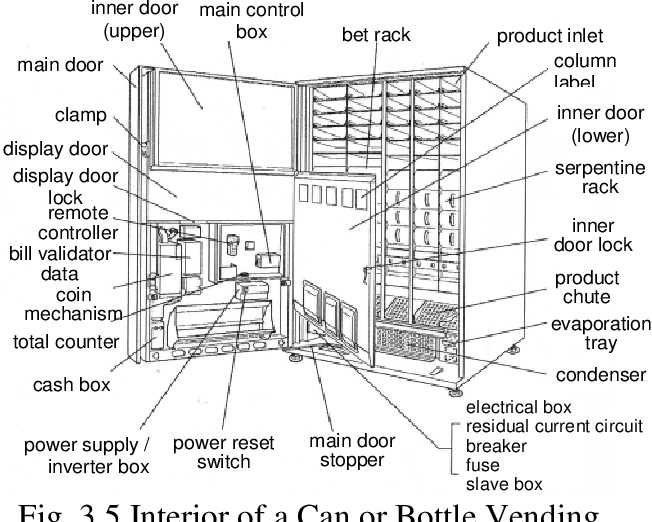

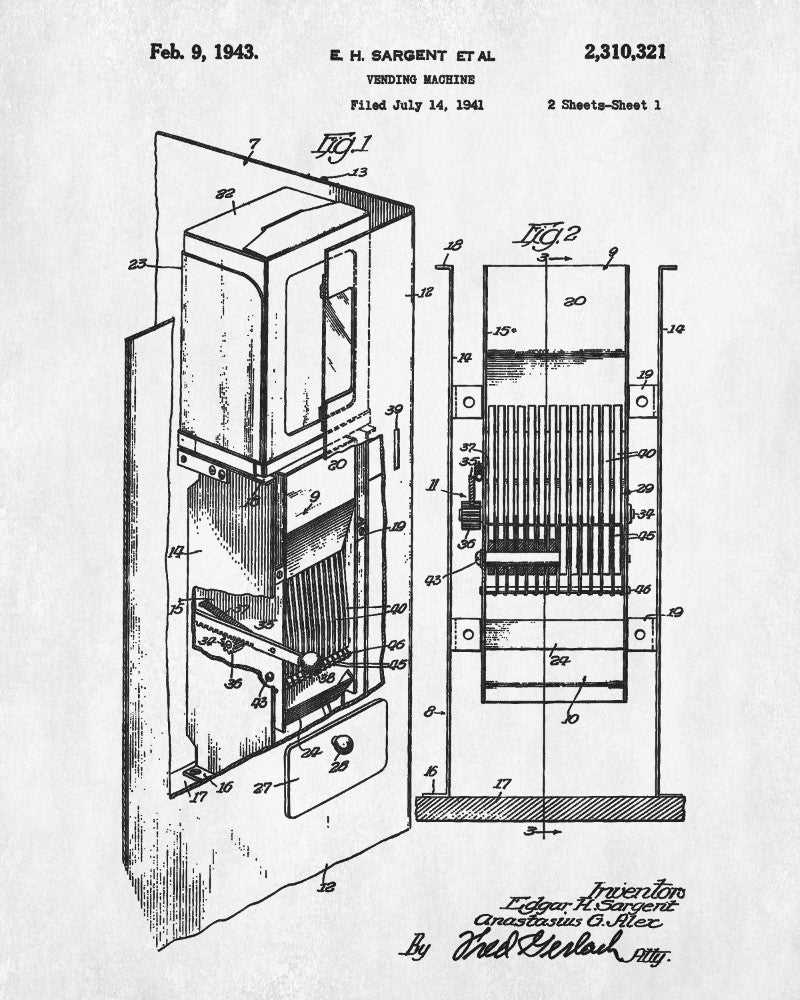

Internal Structure of a Vending UnitThe inner workings of an automated dispensing unit rely on a complex and well-organized system. Various components interact seamlessly to ensure a smooth user experience, enabling the unit to respond effectively to input commands. These internal mechanisms coordinate storage, selection, and delivery processes, all while maintaining the efficiency and reliability expected in such systems. At the core, the unit houses compartments designed to organize and store the available items. These sections work in tandem with precise mechanical systems that allow for accurate selection and controlled release. Sensors and motors play a critical role in identifying user choices and activating the corresponding mechanisms to retrieve the chosen product. These devices also monitor the stock levels, ensuring timely restocking when necessary. The power and control systems are crucial for coordinating the entire operation. Electrical components govern the unit’s processing capabilities, enabling communication between the control panel and internal mechanisms. Through integrated circuits, the unit processes inputs, manages commands, and ensures that the correct product is dispensed efficiently. All components are designed for durability and optimal performance, minimizing downtime and maximizing the unit’s f Key Mechanical Parts in Vending Systems

The efficiency and smooth operation of automated distribution devices depend on various critical components. Each element plays a vital role in ensuring the proper functionality of the system, contributing to its ability to serve users with precision and reliability. Understanding these elements can provide insights into how these systems maintain seamless performance over time.

|