A well-known and trusted model in the world of compact firearms stands out due to its reliability and robust design. Crafted with precision, it has earned a reputation among enthusiasts and professionals alike, thanks to its intuitive handling and dependable functionality.

This article delves into the intricate details of its construction, offering insights into each essential element that makes this model a favorite. By exploring the inner workings, one can better appreciate how various components come together to deliver consistent performance.

Whether you’r

Overview of Taurus 856 Components

This section provides a detailed exploration of the main elements and mechanisms that contribute to the functionality of this compact firearm. Each component is designed with precision, ensuring reliable performance and user safety. Here, we will outline the key assemblies and how they interact to form a cohesive system.

Frame and Cylinder Assembly

The core structure, built from durable materials, serves as the backbone, offering stability and housing crucial mechanisms. The revolving chamber, precisely engineered, aligns with the barrel for accurate discharge. Its smooth rotation and locking system ensure seamless operation, delivering consistent performance during usage.

Trigger Mechanism and Grip

The firing control mechanism is essential for managing the release of the internal mechanisms, providing a controlled and responsive action. Attached beneath the main housing, the handle design offers a firm and comfortable grasp, enhancing control and

Exploring the Frame Structure

The overall framework serves as the backbone, providing stability and housing various internal elements. This section delves into the intricate design that ensures a balance between durability and ease of handling. Understanding the structure helps appreciate how each component interacts, contributing to the overall functionality and robustness.

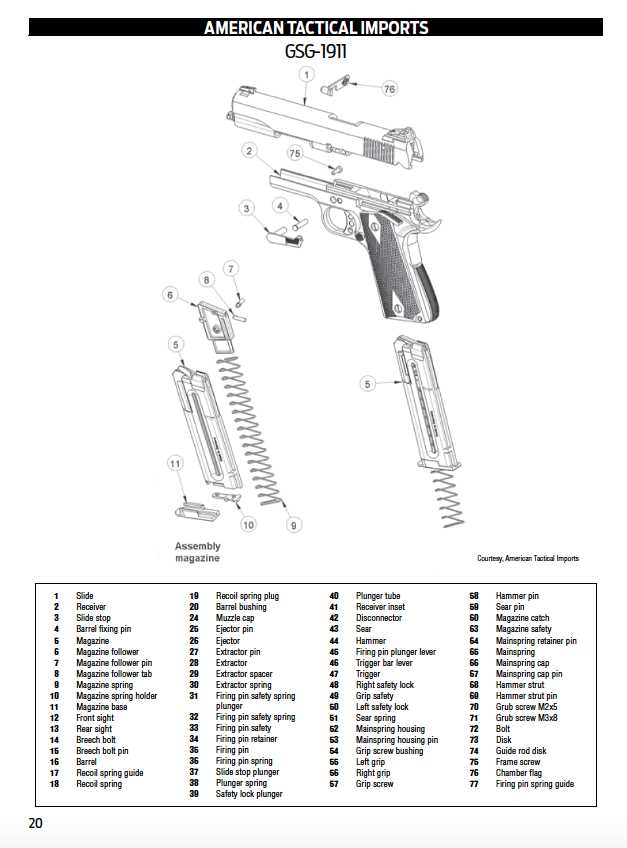

Main Components and Their Arrangement

- Upper Segment: Designed for secure placement, this part is engineered to withstand pressure while maintaining a streamlined form.

- Lower Section: Offers a solid foundation, ensuring a steady grip and support for all connected mechanisms.

- Mounting Points: Key areas where essential elements are fastened, ensuring proper alignment and minimal movement.

Material Composition and Design Considerations

The choice of materials impacts the

Understanding the Trigger Mechanism

The operation of the trigger assembly involves a coordinated sequence of interactions that ensure smooth functioning. This component plays a crucial role in managing the release process and ensuring precise control. Its intricate design allows for reliable action, contributing to the overall responsiveness and feel.

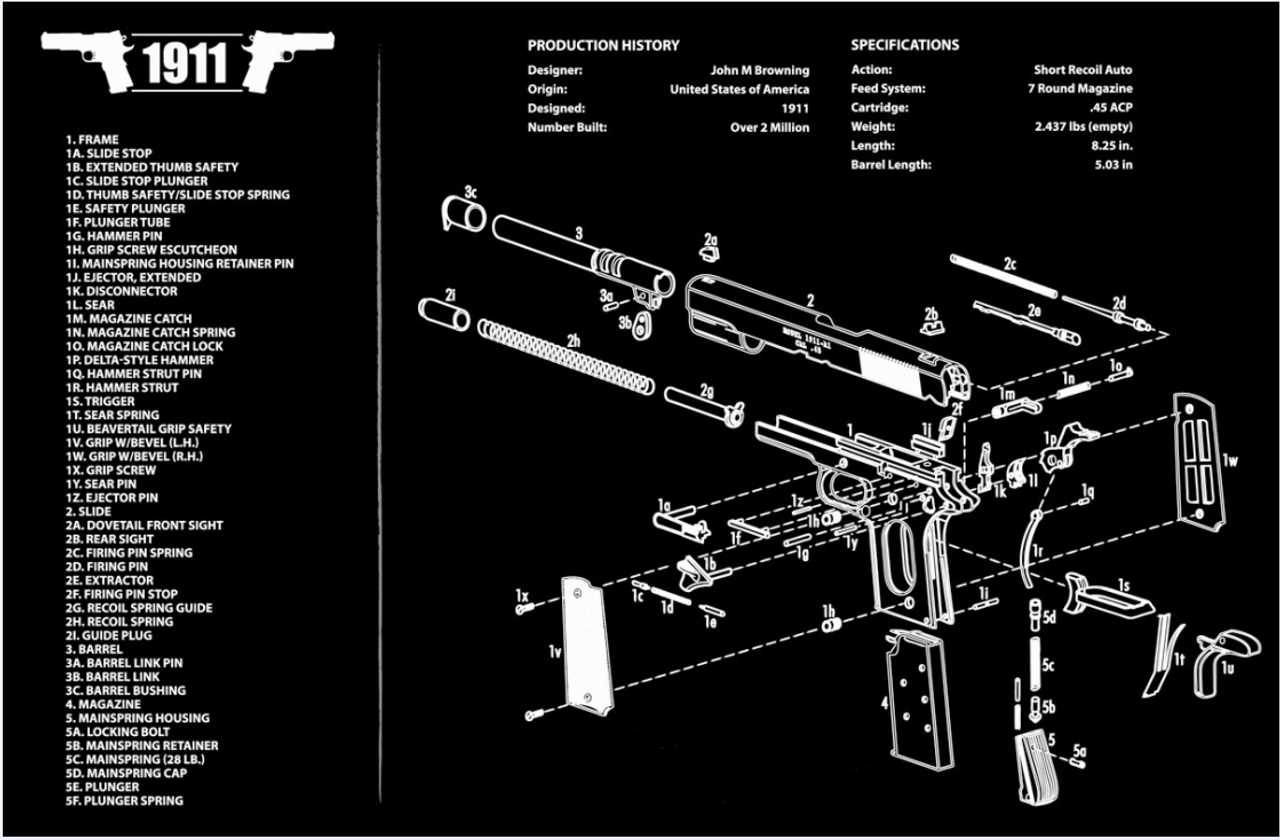

Core Components of the Mechanism

The system relies on various interconnected elements that work together seamlessly. A key part of this includes the sear, which manages the release with precision. The interaction between the hammer and spring is also pivotal, creating the necessary tension for consistent performance. Each of these parts is carefully designed to maintain balance and safety throughout operation.

How It Enhances Control

The design of this mechanism is aimed at providing enhanced user control and smooth operation. The coordination between its elements ensures that the release

Barrel and Cylinder Configuration

The relationship between the rotating chamber and the forward tube is crucial for the overall performance and precision of the mechanism. The alignment and design ensure smooth operation, contributing to the balance and control during use. This section explores the structural aspects and the way the components work together, emphasizing the harmony between key elements.

| Component | Description | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotating Chamber | Features multiple chambers for holding individual rounds, ensuring seamless rotation with each action. Its precise alignment plays a critical role in maintaining accuracy. | ||||||||||||||||||||||||

| Forward Tube | The guiding element that directs the projectile with stability. Its length and diameter directly influence the velocity and path of each shot. |

| Element | Description |

|---|---|

| Front Sight | This component typically appears at the muzzle end and aids in aligning the firearm with the target. |

| Rear Sight | Located near the shooting hand, this element complements the front sight, allowing for precise adjustments and alignment. |

| Sight Picture | The visual relationship between the front and rear sights when aiming at a target, critical for achieving accuracy. |

| Adjustment Mechanism | Features that enable the shooter to modify the alignment of the sights for improved accuracy over varying distances. |

| Dot or Fiber Optic Elements | Enhances visibility under different lighting conditions, providing an easier way to align the sights with the target. |

Internal Spring Systems Explained

The mechanisms that utilize coiled components play a crucial role in enhancing functionality and reliability. These systems are designed to store and release energy, allowing for smooth operation of various elements within a device. Understanding the intricacies of these components is essential for anyone interested in the mechanics of firearms.

At the heart of many devices, these coiled elements work by compressing and expanding in response to force. When tension is applied, they store energy, which is released when the force is removed. This action provides the necessary motion and support for moving parts, contributing to the overall efficiency and performance of the system.

| Type of Spring | Function | Characteristics |

|---|---|---|

| Compression Spring | Resists axial compression and returns to its original length | Coiled tightly, provides significant force |

| Tension Spring | Resists axial stretching and returns to its original length | Hooked ends, designed for pulling applications |

| torsion Spring | Exerts torque when twisted | Coiled in a helix, ideal for rotating mechanisms |

Proper maintenance and understanding of these internal systems are vital for ensuring longevity and reliability. Regular checks and replacements can prevent malfunctions, thereby enhancing the safety and performance of the overall mechanism.

Maintenance Tips for Longevity

Proper upkeep of your firearm is essential for ensuring its optimal performance and extending its lifespan. Regular care not only enhances functionality but also promotes safety and reliability in various situations.

1. Clean After Each Use: Immediately after firing, clean the mechanism to prevent residue buildup. Use appropriate cleaning solvents and brushes to remove any dirt or carbon deposits.

2. Regular Inspection: Frequently examine all components for signs of wear or damage. Pay close attention to moving parts, as well as springs and pins, and replace them as needed to maintain functionality.

3. Lubrication: Apply suitable lubricants to ensure smooth operation. Avoid over-lubricating, which can attract dirt and debris, leading to malfunctions.

4. Store Properly: Keep the weapon in a cool, dry place to prevent corrosion. Use a protective case to shield it from moisture and dust when not in use.

5. Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules and procedures provided by the manufacturer to ensure longevity and optimal performance.

By implementing these strategies, you can significantly enhance the durability and efficiency of your firearm, ensuring it remains reliable for years to come.