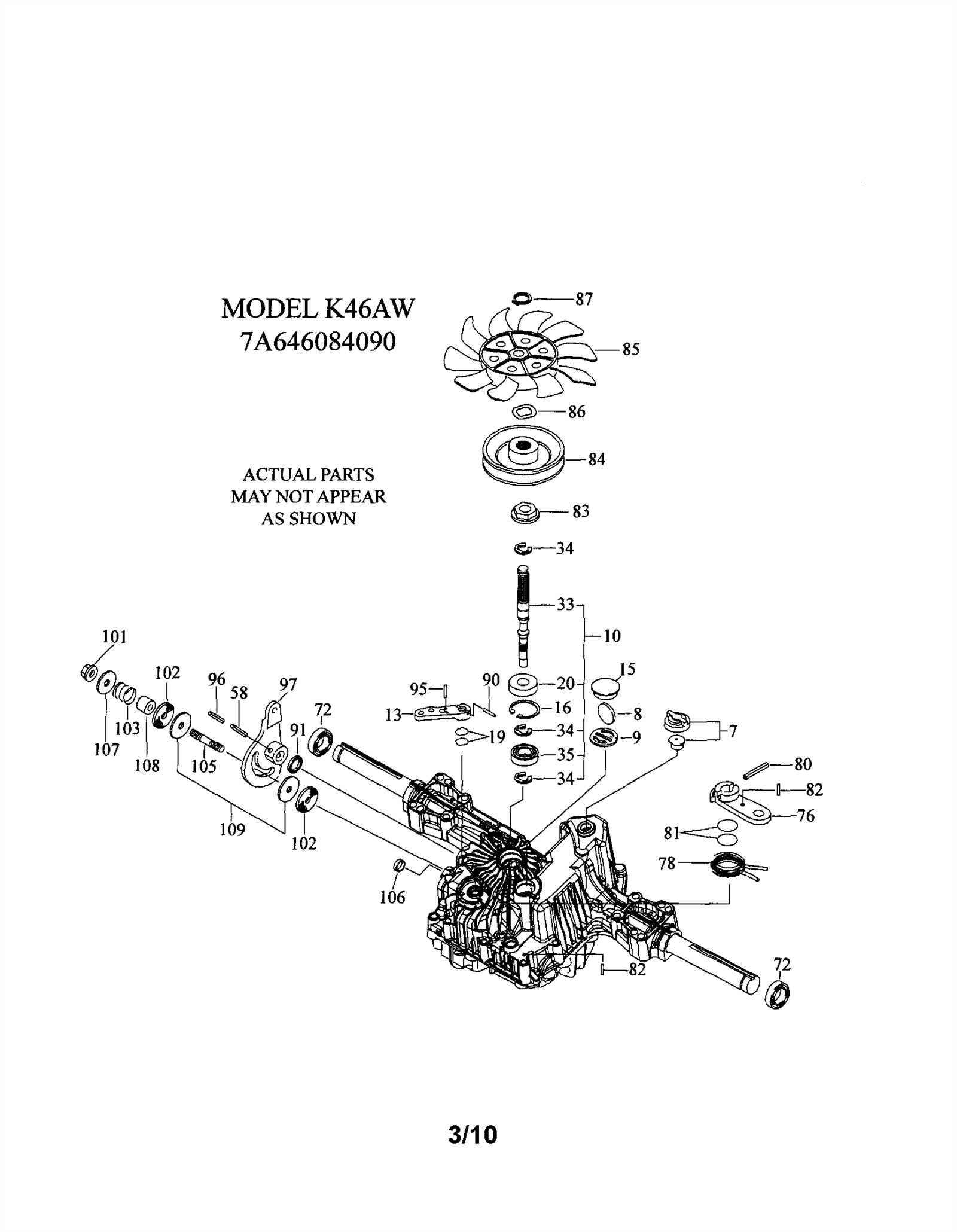

Understanding the layout and interaction of mechanical components is essential for effective maintenance and repair of machinery. These schematics provide a visual representation of how various elements fit together, ensuring that users can identify and troubleshoot issues efficiently. Such diagrams serve as a valuable resource for both professionals and enthusiasts alike, offering clarity on the assembly and function of complex systems.

By studying these visual aids, individuals can gain insights into the intricacies of machinery operation. This knowledge empowers users to make informed decisions regarding repairs, replacements, and upgrades. Whether you are dealing with garden equipment or industrial machines, familiarizing yourself with the structure of these components will significantly enhance your understanding and capabilities in managing mechanical systems.

Incorporating these illustrations into your maintenance routine not only simplifies the repair process but also fosters a deeper appreciation for the technology at play. The ability to visualize how different parts work in unison can lead to improved performance and longevity of the equipment.

This section presents an organized examination of various essential elements that contribute to the functionality of a specific mechanical system. By understanding these components, users can gain insights into their roles and interactions within the overall framework.

Introduction to Key Elements

The components of this system are designed to work in unison, ensuring efficient operation. Each part has a distinct purpose that aids in the smooth functioning of the entire assembly.

Types of Components

Different types of elements are categorized based on their functions. These include:

| Component Type | Description |

|---|---|

| Drive Mechanism | Responsible for transferring power and enabling movement. |

| Control Systems | Facilitates user interaction and regulation of operations. |

| Support Structures | Provides stability and alignment for various assemblies. |

| Transmission Parts | Assists in the effective transfer of energy throughout the system. |

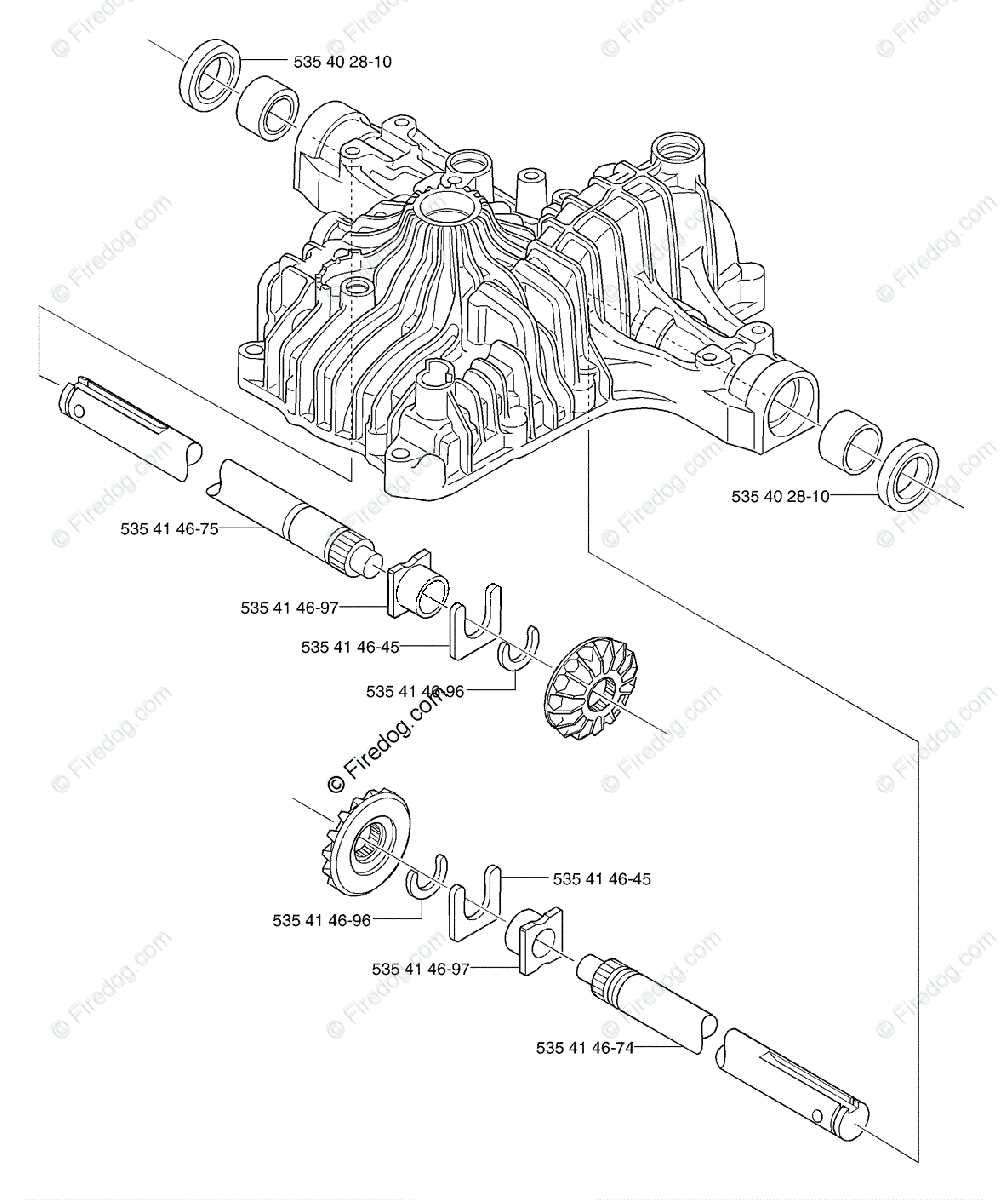

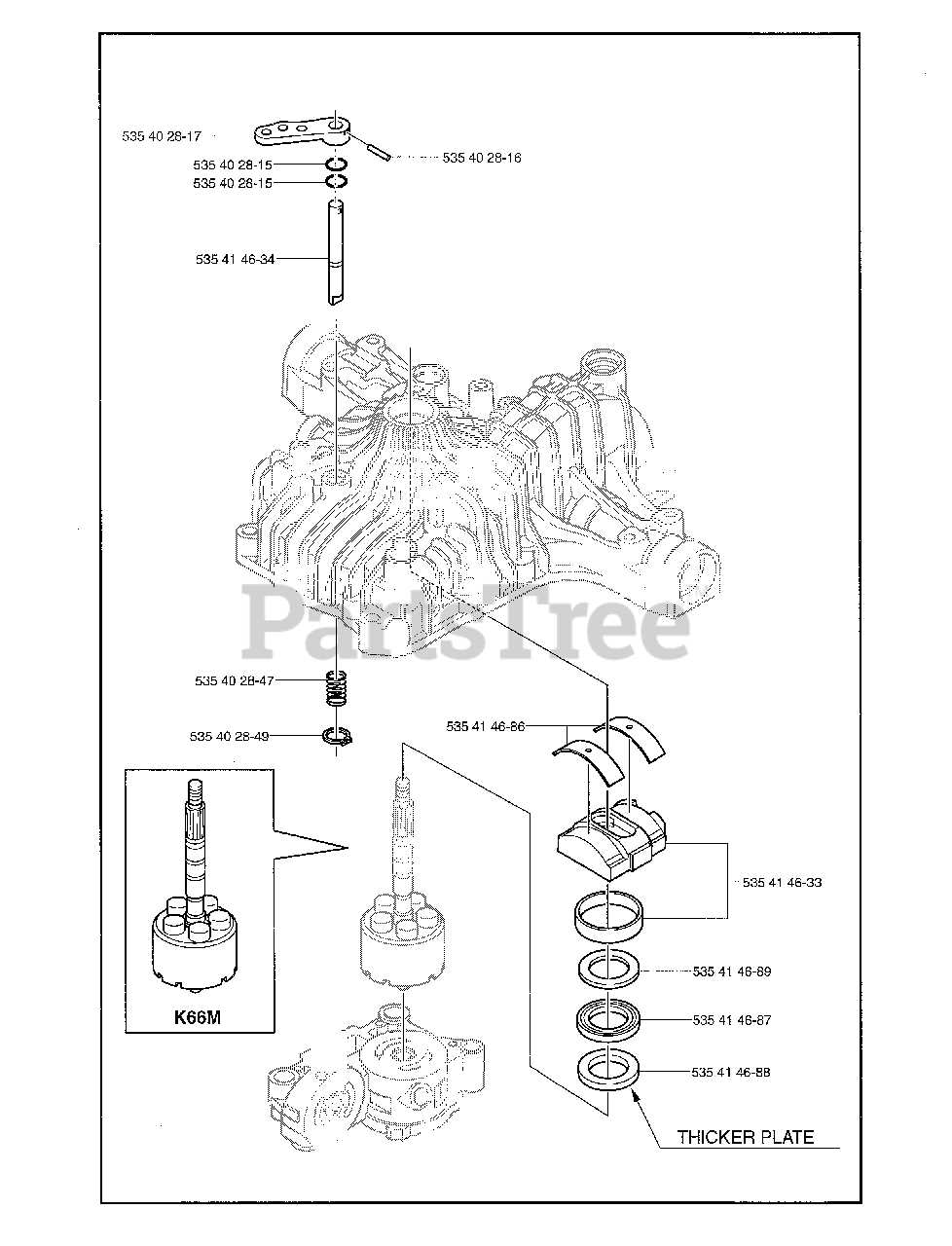

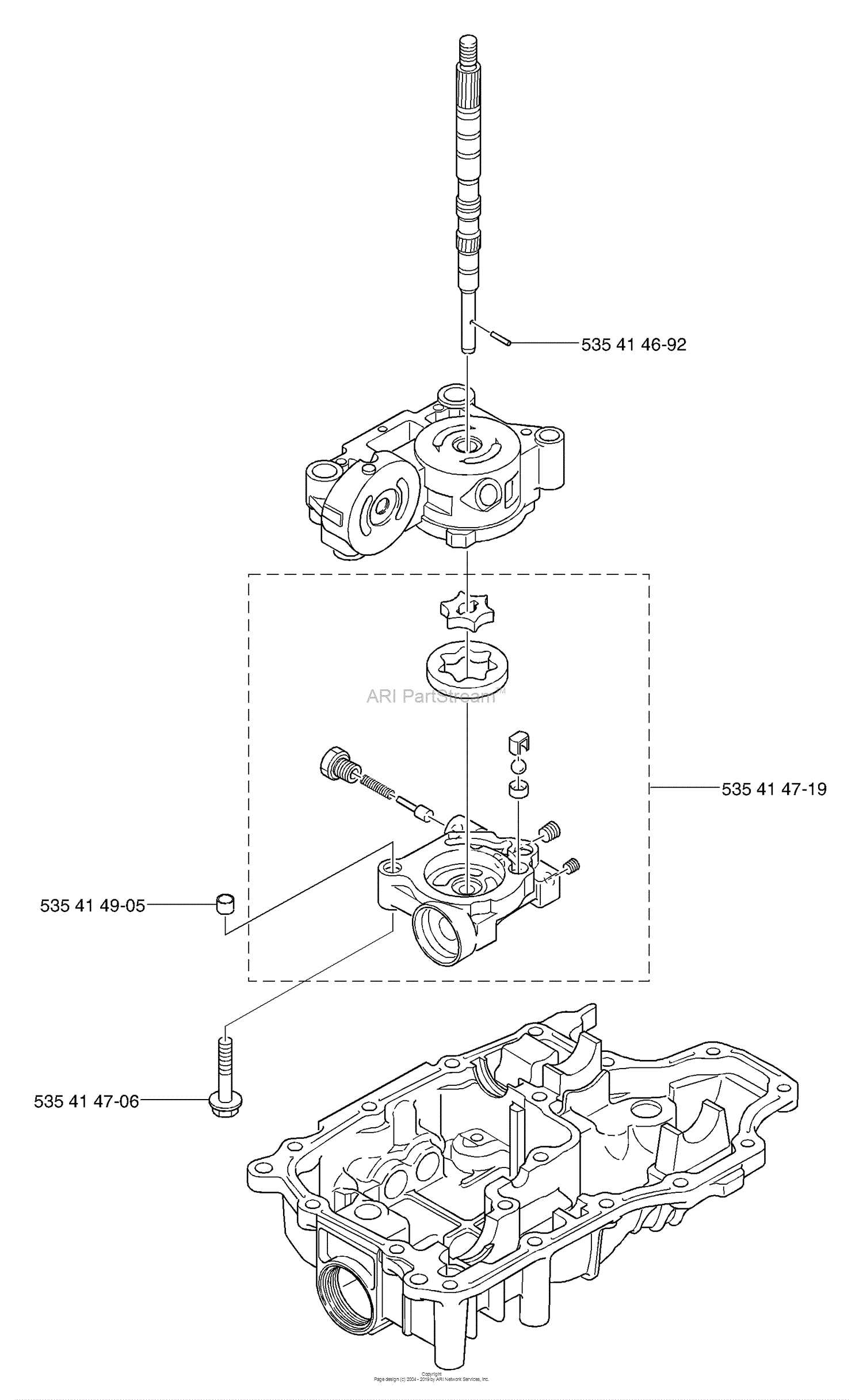

Understanding Tuff Torq Mechanisms

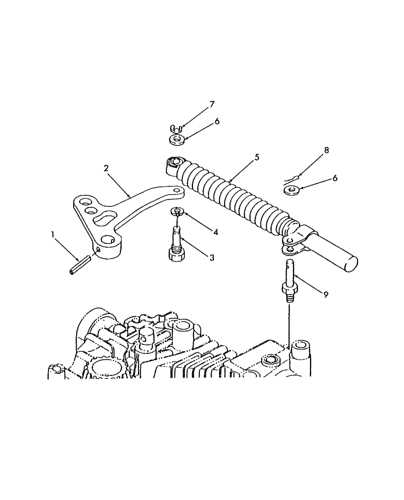

In the realm of mechanical systems, the operation of various components plays a crucial role in overall functionality. This section delves into the intricate workings of specific drive systems, shedding light on their design and interaction. A solid grasp of these mechanisms can significantly enhance one’s ability to troubleshoot and maintain equipment effectively.

Key Components and Their Functions

Each element within the system contributes to its efficiency and reliability. Understanding these components is essential for optimal performance. Here are some critical parts to consider:

- Transmission Housing: Houses internal gears and controls, providing structural integrity.

- Drive Shaft: Transfers power from the engine to the wheels, essential for movement.

- Control Linkage: Connects the operator’s controls to the mechanisms, ensuring responsive operation.

- Fluid Reservoir: Maintains hydraulic pressure, crucial for system functionality.

Operational Principles

Understanding how these components work together is vital. The principles governing their operation include:

- Hydraulic force generation for power transfer.

- Mechanical linkages facilitating smooth transitions between modes.

- Feedback systems allowing for precise control and adjustments.

By comprehending these elements and their functions, users can ensure that their equipment remains in optimal working condition, leading to enhanced performance and longevity.

Key Parts and Their Functions

This section delves into essential components commonly found in various mechanical systems, highlighting their roles and significance in overall functionality. Understanding these elements is crucial for anyone looking to enhance their knowledge about how these systems operate efficiently.

Main Components

- Drive Mechanism: This element converts energy into motion, enabling the system to function as intended.

- Gear Assembly: Gears work together to regulate speed and torque, ensuring smooth operation and power transfer.

- Control Unit: This component oversees the operational parameters, allowing for adjustments to enhance performance.

Supporting Elements

- Hydraulic System: Facilitates the transfer of power through fluid movement, providing necessary force for various operations.

- Frame Structure: Serves as the backbone, supporting all components and ensuring stability during operation.

- Safety Mechanisms: Incorporate features that protect the system and operator from potential hazards, promoting safe usage.

Maintenance Tips for Longevity

To ensure the extended lifespan of your machinery, it is essential to follow regular upkeep practices. Proper care not only enhances performance but also minimizes the risk of unexpected breakdowns. Implementing a routine maintenance schedule can significantly contribute to the durability and efficiency of your equipment.

Here are some effective strategies to maintain optimal functionality:

| Task | Frequency | Description |

|---|---|---|

| Check fluid levels | Weekly | Ensure all fluids are at recommended levels to prevent overheating and ensure smooth operation. |

| Inspect belts and hoses | Monthly | Examine for wear or damage, replacing any parts that show signs of deterioration. |

| Clean air filters | Every 3 months | Remove debris and dirt to maintain proper airflow and engine efficiency. |

| Lubricate moving parts | Every 6 months | Apply lubricant to all moving components to reduce friction and wear. |

| Perform a thorough inspection | Annually | Conduct a complete assessment of the machinery to identify potential issues before they escalate. |

By adhering to these practices, you can significantly enhance the reliability and lifespan of your equipment, ensuring it remains in optimal condition for years to come.

Common Issues and Solutions

This section addresses frequent challenges encountered with specific machinery components and offers practical solutions to enhance performance and longevity. Understanding these issues is essential for effective maintenance and operation.

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Inconsistent performance | Wear in internal mechanisms | Inspect and replace worn components as needed |

| Unusual noises | Improper lubrication | Check lubrication levels and apply appropriate grease |

| Overheating | Blocked cooling vents | Clear debris from ventilation openings |

| Difficulty starting | Faulty electrical connections | Inspect wiring and repair or replace faulty connections |

| Fluid leaks | Deteriorated seals | Replace worn seals and ensure proper installation |

Parts Replacement Guidelines

Replacing components in machinery is essential for maintaining optimal performance and longevity. Adhering to the correct procedures ensures that each element functions effectively, reducing the risk of failure and enhancing overall efficiency.

When it comes to the process of substituting various elements, it is crucial to follow a structured approach. Below are some fundamental steps to consider:

| Step | Description |

|---|---|

| 1 | Identify the component that requires replacement and ensure you have the correct replacement ready. |

| 2 | Before starting, ensure the machinery is powered off and properly secured to prevent accidents. |

| 3 | Carefully remove the faulty component, taking note of how it is positioned and connected. |

| 4 | Install the new component in the exact manner as the original, ensuring all connections are secure. |

| 5 | Test the machinery to confirm that the replacement has been successful and that everything is operating smoothly. |

By adhering to these guidelines, users can ensure a smooth replacement process and prolong the life of their equipment.

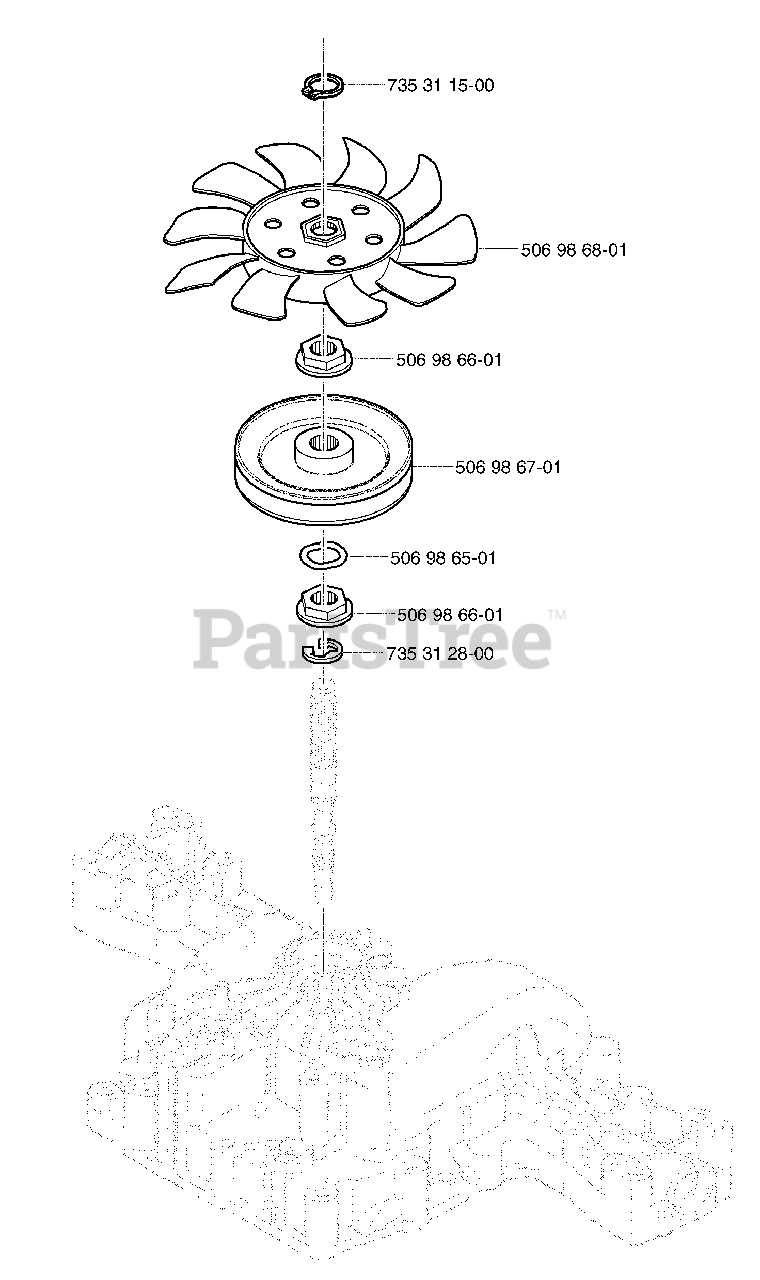

How to Read Diagrams Effectively

Understanding visual representations can significantly enhance your ability to interpret complex information. These illustrations serve as a guide, providing valuable insights into various components and their relationships within a system. Mastering this skill allows for improved comprehension and application in practical situations.

Begin with the Basics: Familiarize yourself with the symbols and notations commonly used in such visuals. Each mark or line typically carries a specific meaning, which is crucial for accurate interpretation.

Identify Key Elements: Look for the main components highlighted in the illustration. These often serve as focal points, allowing you to understand the structure and functionality of the entire system.

Follow the Flow: Trace the connections and paths represented in the image. Understanding how different parts interact and relate to each other is essential for grasping the overall operation.

Utilize Annotations: Pay attention to any accompanying notes or labels that provide further clarification. These additional explanations can be invaluable for comprehending intricate details.

Practice Regularly: The more you engage with these representations, the more proficient you will become. Regular practice will enhance your ability to quickly and accurately decipher similar visuals in the future.

Where to Find Genuine Parts

Locating authentic components for your machinery is essential for optimal performance and longevity. It’s crucial to source these items from reliable suppliers to ensure quality and compatibility with your equipment. Various options are available for acquiring original elements, whether through online platforms or local distributors.

Authorized Dealers

Authorized dealers are often the best choice when seeking genuine items. They typically offer a range of original components and can provide expert guidance on selecting the right ones for your specific needs. Visiting an authorized dealer ensures that you receive parts that meet the manufacturer’s standards and specifications.

Online Marketplaces

Another convenient option is to explore online marketplaces. Numerous websites specialize in offering a wide selection of authentic components at competitive prices. When purchasing online, ensure that the seller has a positive reputation and offers a return policy to safeguard your investment.

Comparing Different Tuff Torq Models

This section focuses on the evaluation of various models within a specific category of mechanical systems. Understanding the differences among these options can assist users in making informed decisions based on their unique requirements and preferences.

Key Features of Each Model

Each variant offers distinct functionalities and characteristics that cater to diverse applications. By examining specifications such as power output, efficiency, and compatibility, users can better assess which model aligns with their operational needs.

Performance and Reliability

When selecting among these systems, it is crucial to consider performance metrics and reliability factors. Evaluating how each model performs under different conditions will provide insights into their durability and maintenance requirements. Prioritizing reliability can lead to improved operational efficiency and longevity.