Exploring the intricate systems and essential elements of all-terrain vehicles can greatly enhance maintenance and repair efforts. For those who seek to keep their machines in peak condition, familiarizing oneself with the various components is a crucial step. This knowledge empowers enthusiasts to identify issues more accurately and tackle them effectively, ensuring a smooth and reliable performance on rugged terrain.

Knowing the structure and arrangement of key elements in an off-road machine’s assembly is vital for any owner. Each component serves a unique function, contributing to the overall stability, power, and agility of the vehicle. From the engine layout to suspension connections, gaining insights into these systems allows for informed upgrades or timely replacements when necessary.

Understanding these mechanisms not only simplifies troubleshooting but also makes routine upkeep more manageable. By taking the time to become familiar with these essential parts, owners can extend the life of their vehicles and enjoy a safer, more efficient experience during their outdoor adventures.

Polaris Ranger 1000 Parts Diagram

Understanding the structure and components of this off-road vehicle is essential for maintenance and upgrades. Visual guides play a significant role in identifying various elements, enabling users to locate specific areas and perform necessary tasks with ease. This approach simplifies the upkeep, making the process more intuitive and accessible for enthusiasts and professionals alike.

The visual representation offers a clear breakdown of the different sections, providing an overview of how each component interacts within the system. Such clarity helps streamline the troubleshooting process, enhancing the ability to pinpoint areas that may require attention or replacement.

For those looking to enhance the performance or ensure proper upkeep, these illustrative aids serve as a valuable resource. By presenting a detailed view of the individual segments, they facilitate better understanding and allow for more effective interventions when needed.

Understanding the Engine Components

The engine is a complex assembly made up of various interconnected elements, each playing a crucial role in ensuring optimal performance. These components work together to convert fuel into mechanical power, enabling efficient operation and smooth functioning. Familiarizing yourself with the key elements can help in better maintaining and troubleshooting issues, ensuring long-term reliability.

Main Elements of the Engine

The engine comprises several primary parts that contribute to its overall function. These include components responsible for fuel management, ignition, cooling, and mechanical movement. Understanding the purpose of each can facilitate timely maintenance and effective repairs.

| Component | Description |

|---|---|

| Piston | Moves within the cylinder to convert pressure into mechanical force, driving the crankshaft. |

| Crankshaft | Transfers the motion from the pistons to rotate the flywheel, providing power to other systems. |

| Spark Plug | Ignites the air-fuel mixture within the combustion chamber, initiating the power stroke. |

| Cylinder Head | Houses the valves and spark plugs, sealing the top of the combustion chamber. |

Camshaft

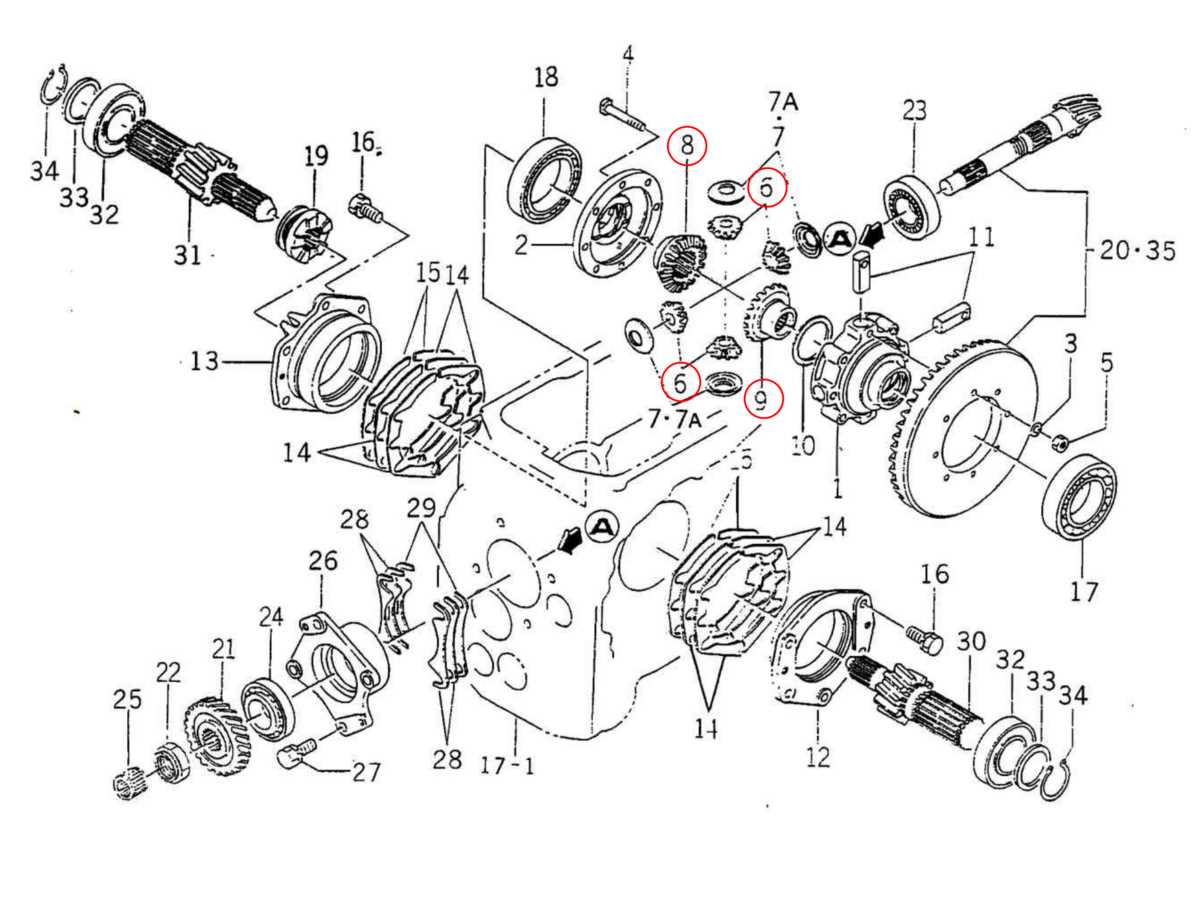

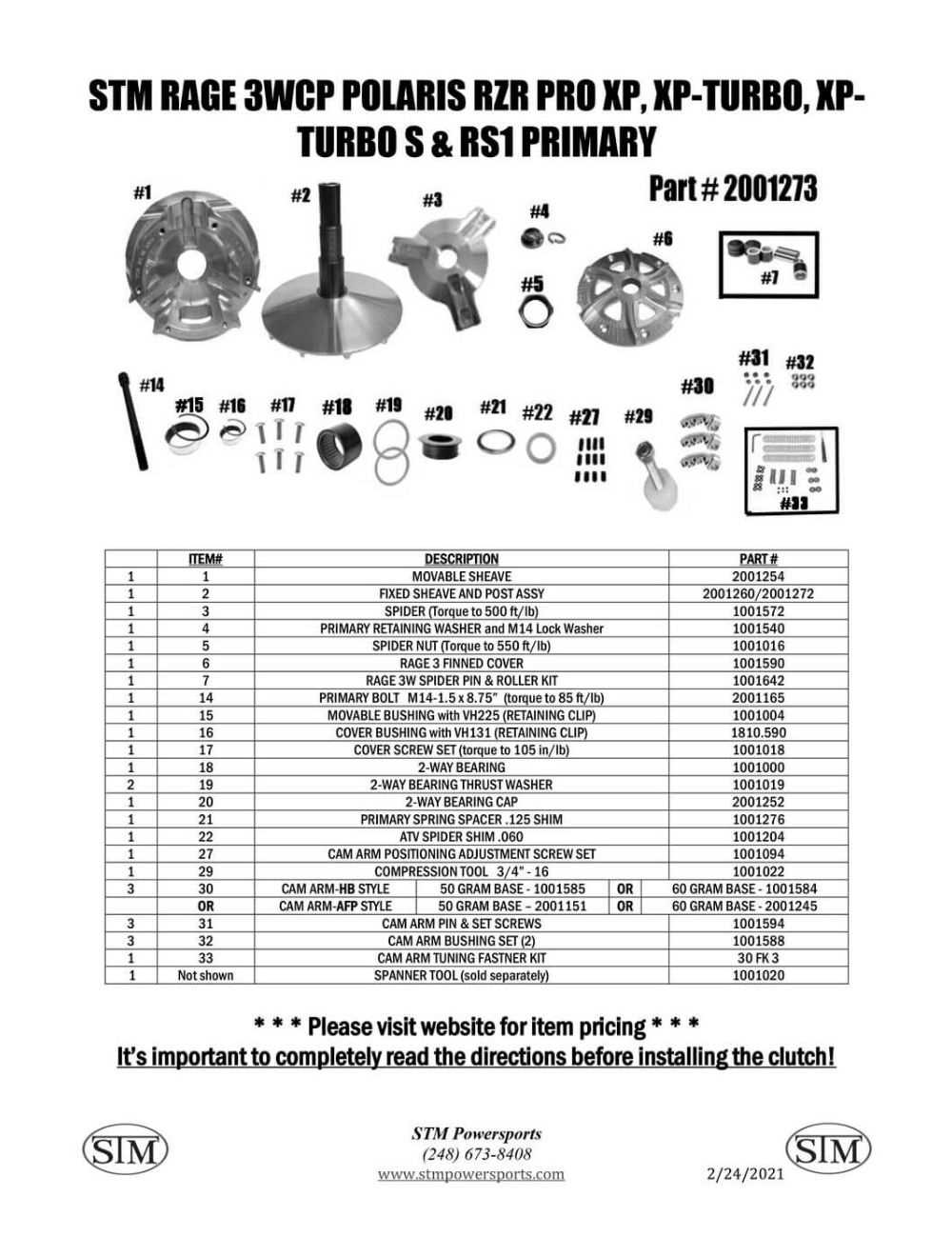

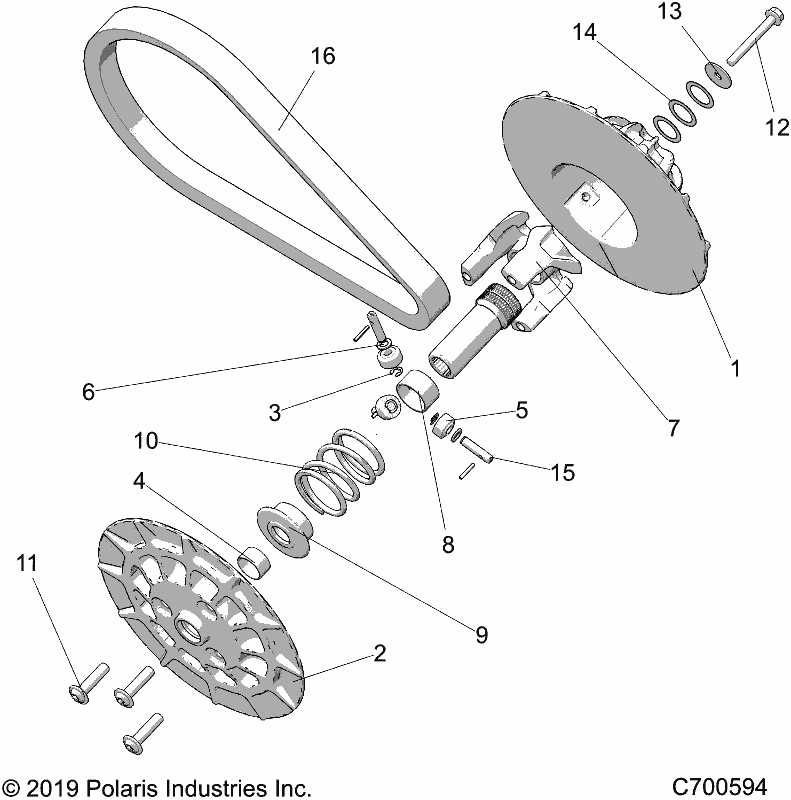

Transmission Parts and Their FunctionsThe transmission system plays a crucial role in transferring power from the engine to the wheels, enabling smooth and efficient movement. Understanding the different components within this system and their roles is essential for maintaining optimal performance. Each element contributes to ensuring that the power is transmitted correctly, providing the right amount of torque and speed. Gears are the primary elements that adjust the output speed and torque by changing the gear ratio. They interlock to transfer motion, allowing the vehicle to accelerate or decelerate effectively. Clutch serves as a bridge between the engine and transmission, engaging or disengaging the power flow to allow for seamless gear changes. This helps to prevent abrupt movements when shifting speeds. Shift forks are responsible for moving the gears into position as the driver changes gears, ensuring the proper gear is selected and engaged. Synchronizers help match the speed of the gears during gear changes, allowing for smoother transitions and reducing wear on the components. The output shaft transmits the adjusted power from the transmission to the driveshaft, which ultimately delivers it to the wheels. It ensures that the vehicle moves forward or backward based on the selected gear. Suspension System BreakdownThe suspension system plays a crucial role in enhancing comfort and handling by absorbing impacts and maintaining stability across various terrains. This section provides an in-depth look at the key components that make up the system, outlining their functions and how they contribute to a smoother ride. Main Components

Adjusting and Tuning the SystemRegular maintenance Electrical Wiring and ConnectorsElectrical wiring and connectors play a crucial role in ensuring a vehicle’s electronic systems function smoothly and reliably. The proper arrangement of wires and quality of connections significantly affect the performance of various components, including lights, sensors, and ignition systems. Understanding how different cables are linked and how connectors interact can help in diagnosing issues and maintaining efficient operation. Types of Connectors may vary, each serving a specific purpose depending on the location and required electrical load. Ensuring that each connector is securely fastened can prevent issues like voltage drops or intermittent connections, which may lead to malfunctions. Using high-quality materials for these connectors can further enhance durability. Wiring Configuration also matters, as the correct routing and bundling can minimize wear and potential damage. Protective covers and sleeves can shield cables from environmental factors like heat and moisture, extending their lifespan. It is essential to check the integrity of wires regularly to avoid unexpected electrical problems. Brake System Components Overview

The brake system is a crucial aspect of any vehicle, ensuring safe and efficient deceleration. It consists of various interconnected elements that work together to provide control over the vehicle’s speed and stop it when necessary. Understanding these components helps in recognizing signs of wear and planning maintenance effectively. Brake Pads are designed to create friction against the rotors, converting kinetic energy into heat and reducing wheel speed. These parts are subject to wear and require regular inspection to maintain optimal performance. Brake Rotors, or discs, are circular metal components that rotate along with the wheels. When the pads clamp onto the rotors, the friction slows down the rotation, enabling the vehicle to decelerate. Rotor surface condition significantly affects braking efficiency. Calipers play a vital role in the system by pressing the brake pads against the rotors. They house pistons that push the pads, utilizing hydraulic force generated by the brake fluid. Proper caliper function ensures even pressure distribution and consistent stopping power. The brake fluid acts as a medium for transferring force from the brake pedal to the calipers. It must be kept at the appropriate level and changed periodically to avoid moisture absorption, which can reduce braking effectiveness. Additional elements, such as brake lines and master cylinders, are integral Chassis and Frame StructureThe chassis and frame play a crucial role in ensuring the overall stability and durability of a vehicle. These foundational components are designed to support the weight and withstand the stresses encountered during various types of terrain use. A well-built frame helps maintain alignment and balance, providing a strong foundation for all other parts. Material selection and structural design are essential for optimizing strength while keeping the weight manageable. High-quality alloys or reinforced materials are often used to enhance rigidity without compromising flexibility where needed. This combination ensures that the vehicle remains responsive, stable, and resilient even under demanding conditions. The structural layout of the frame often incorporates multiple cross members and strategically placed reinforcements to minimize flex and prevent damage. Such features not only enhance safety but also contribute to a smoother ride by distributing forces more evenly across the entire structure. Cooling System Parts IdentificationUnderstanding the components of a cooling system is essential for maintaining optimal engine performance. By familiarizing yourself with various elements, you can ensure proper upkeep and quickly address any issues that may arise. This guide provides an overview of the main components involved in regulating engine temperature and how they work together to prevent overheating. Main Components OverviewThe cooling system consists of several key elements that help manage heat. These include the radiator, which disperses heat from the coolant; hoses, which transport the fluid between the engine and radiator; and the thermostat, which regulates the flow based on the temperature. Each of these plays a critical role in ensuring that the engine remains at a stable operating temperature. Additional Elements to ConsiderOther important parts include the water pump, which circulates the coolant throughout the system, and the fan, which enhances airflow through the radiator for better cooling efficiency. Additionally, temperature sensors monitor heat levels, allowing the system to make necessary adjustments. Regular inspection of these components can help detect potential problems early and extend the lifespan of the engine. Interior and Dashboard ComponentsThe interior of a utility vehicle plays a crucial role in providing comfort and functionality to the driver and passengers. This section explores the various elements found within the cockpit, emphasizing their significance in enhancing the overall driving experience. Key Elements of the CockpitSeveral components work together to create an efficient and user-friendly environment. These elements include:

Comfort and Convenience FeaturesIn addition to essential components, various features enhance comfort and convenience:

|