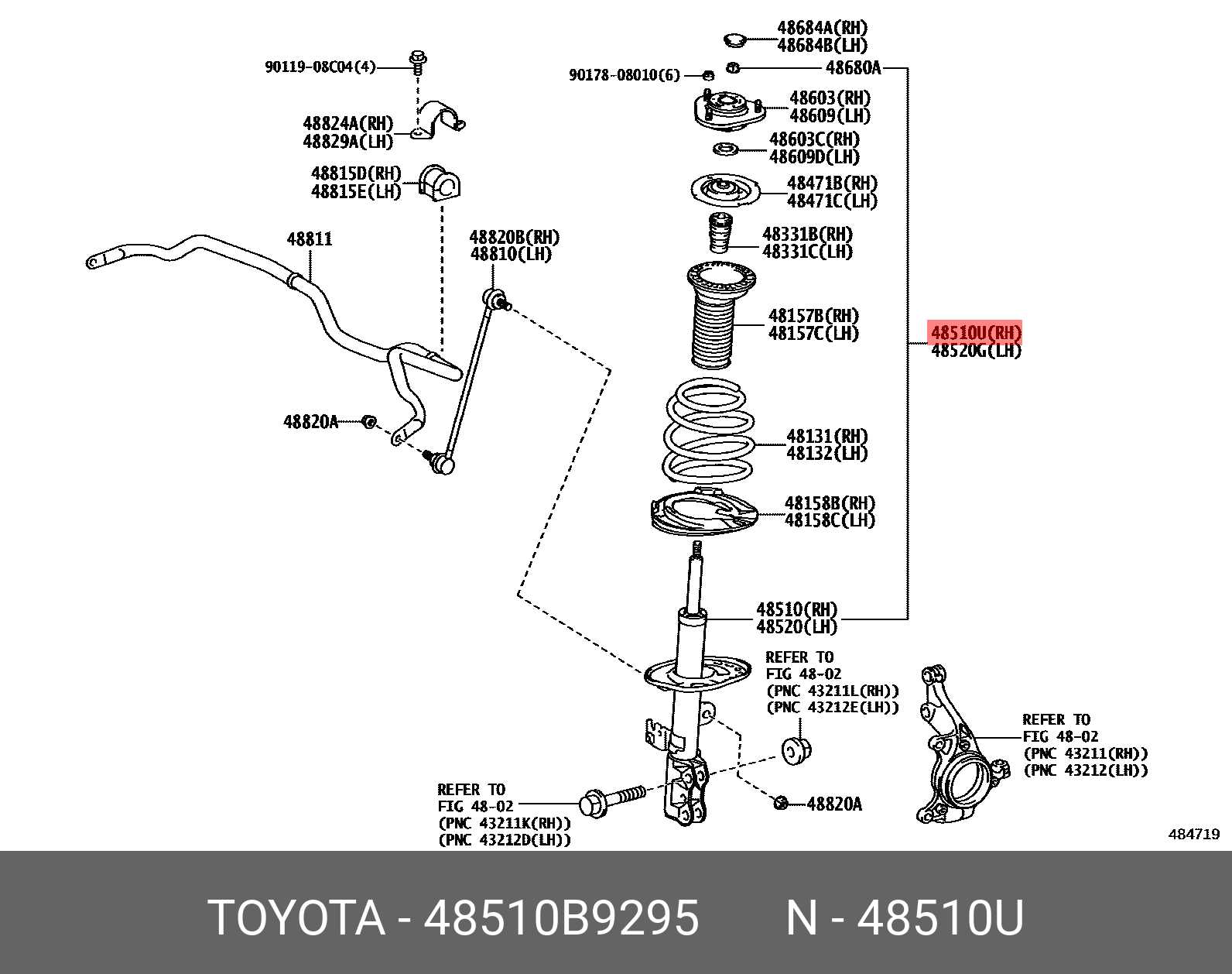

In the realm of mechanical systems, a clear representation of individual elements is crucial for effective maintenance and troubleshooting. Such illustrations not only enhance comprehension but also facilitate the identification of various components, ensuring that operators can address issues promptly and accurately.

By exploring detailed schematics, one can gain insights into the arrangement and interaction of essential units. This knowledge empowers users to navigate complexities and enhances their ability to perform repairs or replacements efficiently. The ability to visualize how each part contributes to the overall functionality of the machine is invaluable.

Moreover, having access to comprehensive visual guides can significantly reduce downtime and enhance operational reliability. Understanding the configuration of every unit helps technicians make informed decisions, streamlining repair processes and minimizing disruptions in service. Engaging with these resources fosters a deeper appreciation for the intricate designs that underpin modern machinery.

Understanding the True T-49 Parts Diagram

Comprehending the components of refrigeration units is crucial for effective maintenance and repair. A visual representation detailing each element serves as an essential tool for technicians and enthusiasts alike. This guide explores the intricate layout, highlighting the significance of each segment and how they interconnect.

Each individual piece plays a vital role in the overall functionality, contributing to the unit’s efficiency and reliability. By familiarizing oneself with the schematic layout, one can identify potential issues more swiftly, facilitating timely interventions. This knowledge empowers users to make informed decisions regarding repairs and replacements.

Moreover, understanding the configuration enhances the ability to troubleshoot common problems. A well-versed technician can quickly pinpoint malfunctioning components, ensuring minimal downtime. In addition, this familiarity promotes better communication with suppliers and service professionals when sourcing replacements or discussing specific concerns.

In summary, a thorough grasp of the component layout not only aids in effective maintenance but also enhances overall operational understanding. By investing time in learning about these essential elements, individuals can ensure their refrigeration systems remain in optimal condition.

Importance of Accurate Parts Diagrams

Clear visual representations of components play a crucial role in various industries, ensuring efficiency and reducing errors. These illustrations not only facilitate assembly and maintenance but also enhance communication among team members, ultimately contributing to smoother operations.

Enhanced Understanding

Detailed visuals enable technicians and engineers to grasp the intricacies of complex systems quickly. When each element is represented accurately, it minimizes confusion and streamlines processes.

Facilitating Maintenance

Properly annotated images are vital for repair tasks. They provide guidance, helping users identify the correct items needed for replacements and ensuring that maintenance is conducted effectively.

| Benefits | Description |

|---|---|

| Efficiency | Reduces time spent on identifying components. |

| Accuracy | Minimizes the risk of mistakes during assembly. |

| Training | Aids in educating new employees about systems. |

Common Components of the True T-49

This section explores the essential elements that contribute to the functionality and efficiency of commercial refrigeration units. Understanding these components helps in maintaining optimal performance and reliability in various environments.

Refrigeration System

The refrigeration system is crucial for temperature control, consisting of a compressor, condenser, and evaporator. Each component plays a significant role in ensuring that the unit operates efficiently and effectively.

Interior Features

Interior features include shelving, lighting, and door mechanisms, all designed to enhance accessibility and visibility. These aspects not only improve user experience but also facilitate organization and inventory management.

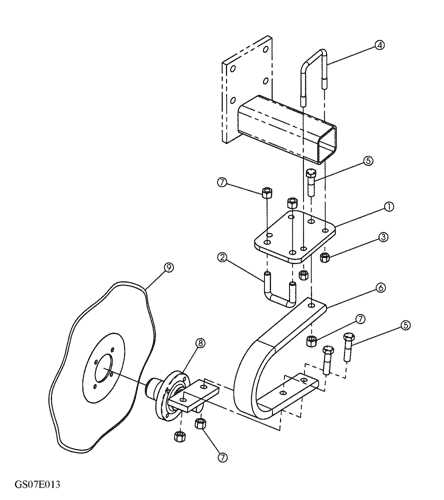

How to Read the Parts Diagram

Understanding the visual representation of components in a system is essential for effective maintenance and repair. This section will guide you through the process of interpreting these illustrations to identify the various elements and their relationships within the unit.

Familiarizing Yourself with the Layout

The first step in comprehending the illustration is to get acquainted with its overall structure. Look for the following:

- Legend: A key indicating what symbols or colors represent.

- Labels: Text that identifies each component, usually accompanied by reference numbers.

- Sections: Divisions that group related parts together for easier navigation.

Identifying Components

Once you understand the layout, focus on recognizing individual elements:

- Start with the major assemblies and work your way down to the smaller components.

- Cross-reference the numbers or labels with the accompanying documentation for further details.

- Note any specific requirements for assembly or maintenance indicated in the notes or annotations.

By following these steps, you will gain confidence in analyzing the visual guides, allowing for more efficient repairs and part replacements.

Identifying Replacement Parts Easily

Finding the right components for your equipment can often be a daunting task. However, with the right approach, you can streamline the process and ensure you get what you need without unnecessary hassle. Here are some effective strategies to simplify the identification of necessary replacements.

- Consult Manuals: Always start with the user manual. It typically contains detailed information on the components, including specifications and part numbers.

- Online Resources: Utilize manufacturer websites and online forums. These platforms often provide visual aids and community support to help you identify what you need.

- Visual Identification: Take clear photos of the component in question. This can assist you when seeking advice or making comparisons with available options.

Once you gather the necessary information, consider the following tips:

- Cross-Referencing: Use the information obtained to cross-reference with suppliers or databases to ensure accuracy in your selection.

- Local Experts: Don’t hesitate to consult local technicians or service providers who may have valuable insights and recommendations.

- Check Compatibility: Ensure that any replacement you consider is compatible with your specific model, paying attention to dimensions and features.

By following these guidelines, you can effectively navigate the identification process and secure the right components for your needs.

Where to Find Genuine Components for the T-49 Refrigerator

In this section, we explore reliable sources for acquiring authentic components essential for maintaining and repairing your T-49 refrigerator model. Ensuring the longevity and efficiency of your appliance requires access to high-quality replacement parts tailored specifically to its design and functionality.

Authorized Dealers and Distributors

One of the most dependable avenues to procure components for your T-49 refrigerator is through authorized dealers and distributors. These entities specialize in stocking a comprehensive range of genuine parts, ensuring compatibility and reliability for your appliance repairs.

Online Platforms and Specialty Stores

For convenient access and a broader selection, online platforms and specialty stores cater specifically to those seeking components for refrigeration equipment. These outlets often provide detailed product descriptions and compatibility information, facilitating informed purchasing decisions.

Maintenance Tips for True T-49 Users

Regular upkeep is essential for ensuring optimal performance and longevity of your refrigeration unit. By following a few simple guidelines, you can prevent common issues and enhance efficiency.

1. Clean the Condenser Coils: Dust and debris can accumulate on the coils, leading to reduced cooling efficiency. Clean them at least every six months to maintain airflow.

2. Check Door Seals: Inspect the gaskets around the doors for wear and tear. A tight seal is crucial for maintaining the internal temperature and conserving energy.

3. Monitor Temperature Settings: Regularly verify that the temperature settings are within the recommended range. Adjust as necessary to prevent spoilage.

4. Inspect Drains: Ensure that drainage systems are clear of blockages. Proper drainage prevents water accumulation, which can lead to mold growth.

5. Schedule Professional Maintenance: Consider having a technician perform routine checks and servicing annually. Professional insights can identify potential problems before they escalate.

Common Issues and Their Solutions

Understanding typical problems that can arise in refrigeration equipment is essential for effective maintenance and troubleshooting. Addressing these challenges promptly can enhance performance and extend the lifespan of the unit. Below are some frequent issues encountered, along with their recommended solutions.

-

Temperature Fluctuations:

Inconsistent temperatures can lead to food spoilage. This may result from various factors.

- Check door seals for leaks.

- Ensure the thermostat is functioning properly.

- Inspect for any blockages in the air vents.

-

Excessive Noise:

Loud sounds may indicate underlying issues. Identifying the source is crucial.

- Examine the compressor for wear or damage.

- Ensure that the unit is level and stable.

- Inspect fan blades for debris or obstructions.

-

Inefficient Cooling:

A lack of adequate cooling can stem from several reasons.

- Check the condenser coils for dirt buildup.

- Make sure the refrigerant levels are adequate.

- Inspect the expansion valve for blockages.

-

Water Leakage:

Leakage can cause significant damage and may arise from multiple sources.

- Inspect the drain pan for cracks or clogs.

- Check the door gaskets for wear.

- Ensure the defrost drain is clear and unobstructed.

By addressing these common concerns with the suggested solutions, users can maintain optimal functionality and reliability of their refrigeration units.

Upgrades for Enhanced Performance

In this section, we explore methods to optimize and improve the operational capabilities of your equipment. Enhancing performance involves leveraging upgrades that can elevate efficiency, boost functionality, and extend longevity without altering the fundamental structure. These enhancements are designed to refine the overall operation and maximize output, promoting a seamless integration of advanced components that augment functionality and optimize performance metrics.

Key Areas for Improvement

- Enhanced components integration

- Performance optimization through advanced parts

- Efficiency improvements with upgraded features

By implementing these upgrades, you can achieve enhanced operational efficiency and optimize performance without compromising reliability or safety. These modifications are tailored to amplify the existing capabilities of your system, ensuring it operates at peak performance levels under various operational conditions.