In the realm of winter machinery, a comprehensive understanding of various elements and their configurations is crucial for optimal performance and maintenance. This section delves into the intricacies of essential components, shedding light on their roles and interconnections. A well-structured overview can significantly enhance the efficiency of operations, ensuring reliable results in challenging conditions.

Efficient operation hinges on knowing how each piece functions within the larger system. By examining the relationships and placements of different segments, users can make informed decisions regarding repairs and enhancements. Recognizing the layout of these vital components not only simplifies troubleshooting but also fosters better preparedness for seasonal demands.

Moreover, a clear representation of these elements serves as a valuable resource for both novices and seasoned operators alike. Whether for routine checks or complex modifications, a detailed guide to the configuration can streamline processes and minimize downtime. Understanding these foundational aspects empowers individuals to maintain their equipment with confidence and precision.

Understanding Boss Snow Plow Components

When it comes to efficient winter management, a thorough comprehension of the various elements that contribute to performance is crucial. Each component plays a significant role in the overall functionality, ensuring that operations run smoothly even in challenging conditions.

Key Elements of Operation

Among the essential features, the lifting mechanism stands out, allowing for effective adjustment of the equipment’s height. Additionally, the control system offers users the ability to maneuver effortlessly, enhancing user experience and safety during usage.

Maintenance and Durability

Regular upkeep is vital for longevity and reliability. Understanding the wear patterns and vulnerabilities of each segment can ultimately lead to better performance and fewer interruptions. Investing time in familiarizing oneself with these components pays off in the long run.

Essential Parts of Boss Snow Plows

Understanding the crucial components of a winter clearing system is vital for efficient operation and maintenance. Each element plays a significant role in ensuring optimal performance during challenging weather conditions. Below, we explore the primary elements that contribute to the functionality and effectiveness of these winter equipment systems.

Main Components

The key elements involved in winter maintenance machinery are designed to work in harmony, providing reliability and durability. Here are some essential components:

| Component | Description |

|---|---|

| Frame | Supports the entire structure and withstands heavy loads. |

| Blade | Removes debris and material from surfaces efficiently. |

| Lift Mechanism | Enables the blade to be raised and lowered as needed. |

| Hydraulic System | Powers the lift mechanism and provides necessary control. |

| Control Unit | Allows the operator to manage various functions from the vehicle. |

Importance of Maintenance

Regular upkeep of these critical components ensures longevity and effective performance. Understanding how each piece contributes to overall functionality can prevent breakdowns and improve efficiency, especially during peak usage seasons.

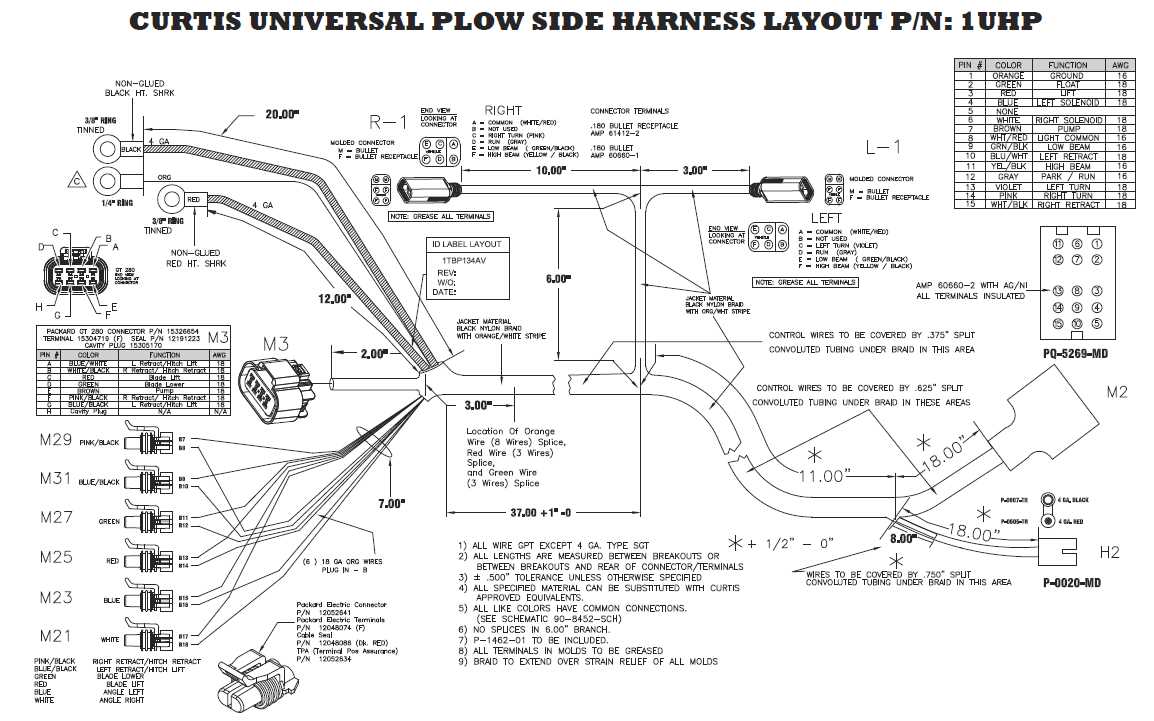

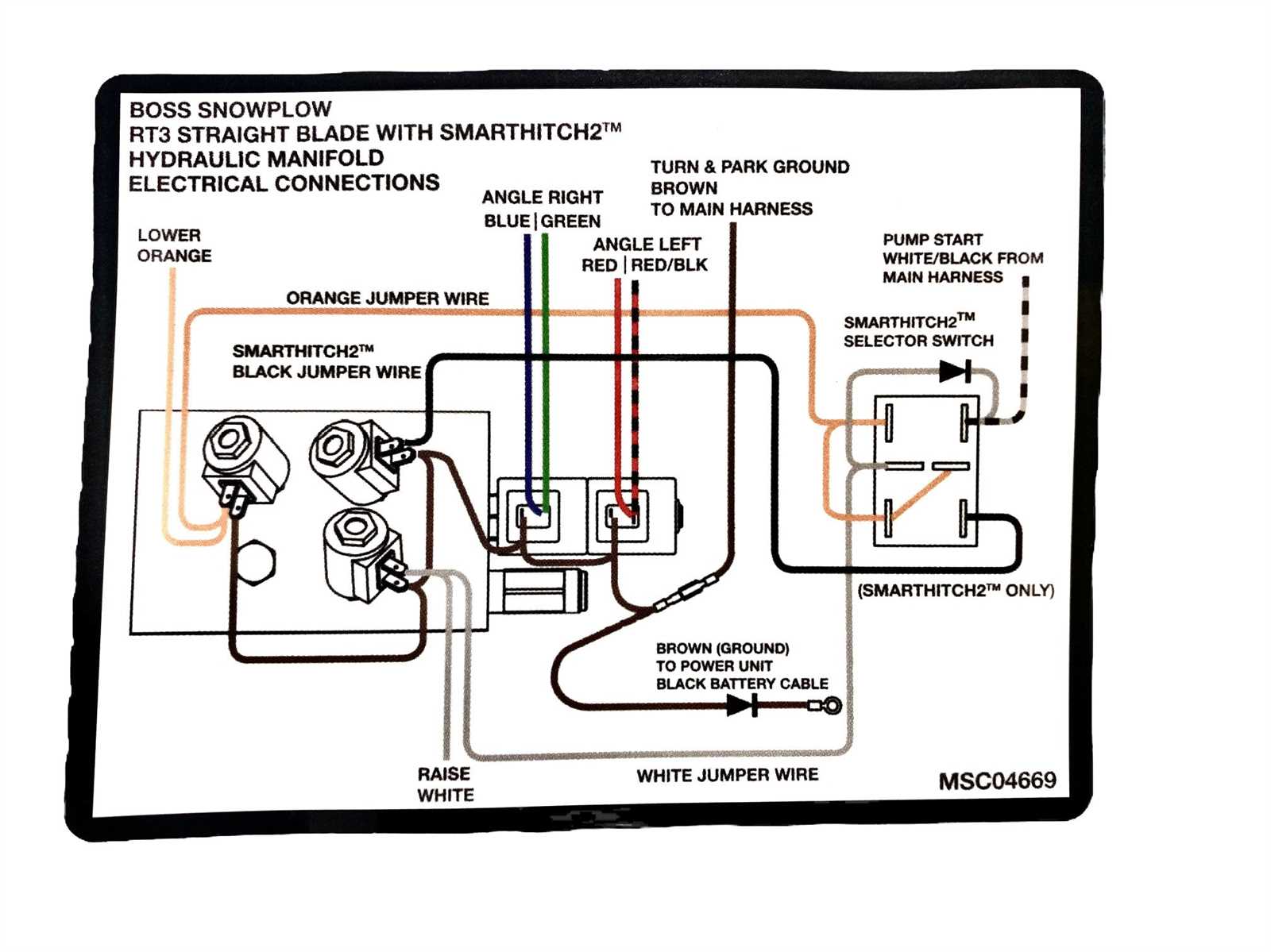

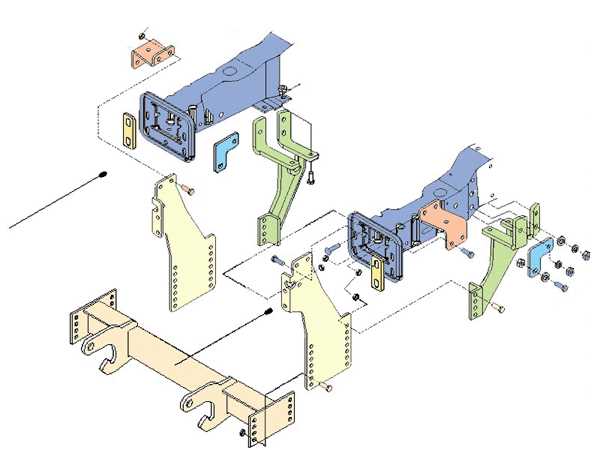

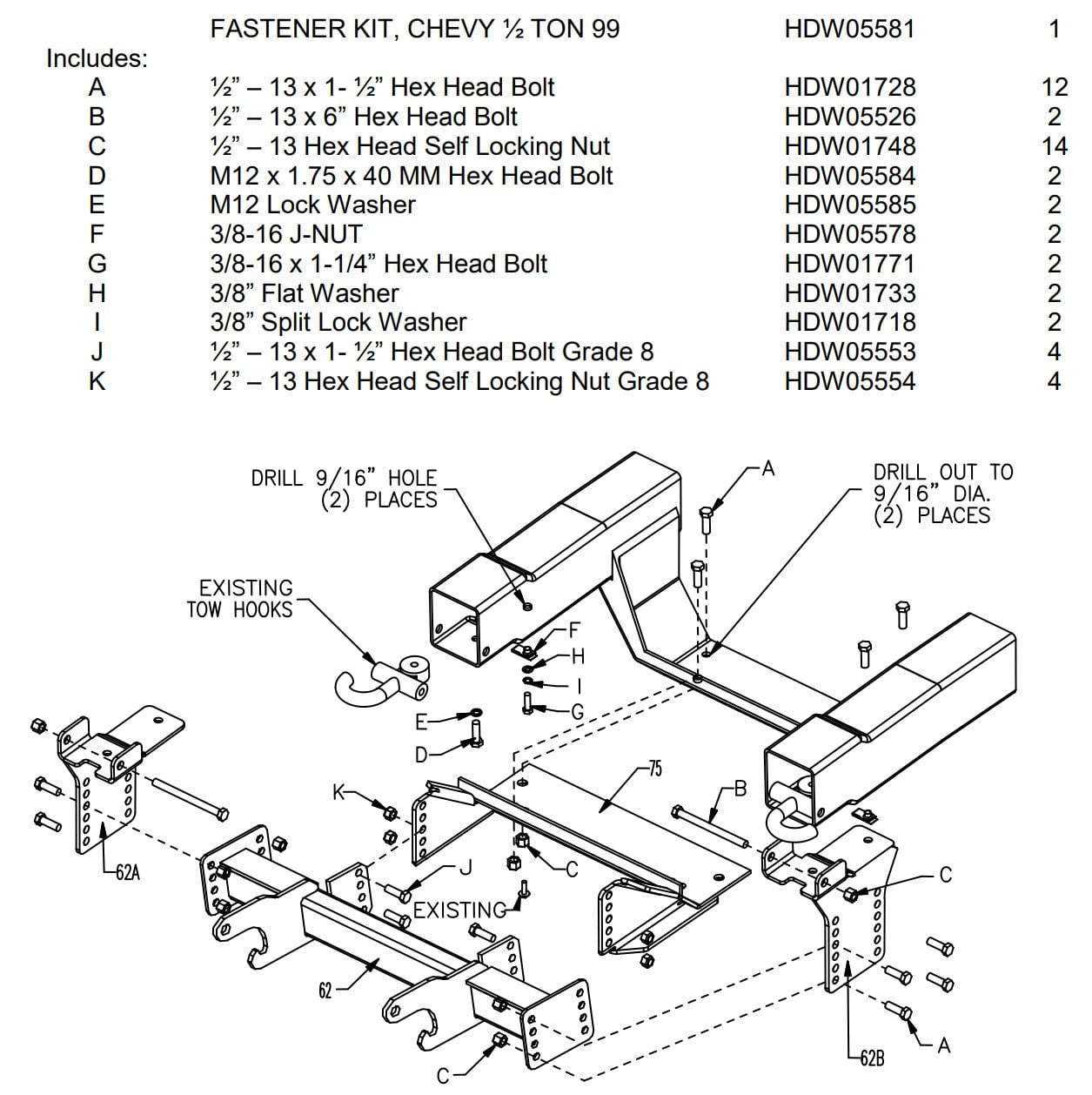

How to Read a Parts Diagram

Understanding an assembly representation is essential for efficient maintenance and repairs. These visual guides provide a comprehensive overview of components, their relationships, and functions. By familiarizing yourself with the layout and symbols used, you can navigate the complexities of machinery more effectively.

Identify the Sections: Most illustrations are divided into distinct segments, each representing a specific area of the equipment. Recognizing these sections helps you focus on the relevant parts you need to address.

Study the Legend: Every visual aid typically includes a legend or key. This section explains the symbols and notations used throughout the illustration, allowing you to decipher the information presented.

Locate Reference Numbers: Components are usually marked with reference numbers or letters. These identifiers correspond to a parts list, making it easier to find the exact items required for repairs or replacements.

Understand the Connections: Pay attention to how elements are linked together. Lines and arrows often indicate the relationships and assembly order, which is crucial for proper installation and functionality.

Consult Additional Resources: If something is unclear, consider seeking supplementary materials, such as manuals or instructional videos. These can provide further insights and clarify complex aspects of the assembly.

Common Issues with Snow Plow Parts

In the realm of winter equipment, various challenges may arise that can hinder performance and efficiency. Understanding these frequent complications can aid operators in maintaining optimal function and prolonging the lifespan of their machinery. By identifying common pitfalls, one can effectively mitigate issues and ensure smooth operation throughout the season.

One prevalent concern involves wear and tear on critical components due to harsh conditions. Components such as blades and hydraulic systems may experience fatigue over time, leading to reduced effectiveness. Regular inspections and timely replacements are essential to prevent operational failures.

Another issue stems from improper alignment and installation. Misalignment can cause uneven wear and reduce the effectiveness of the system. Ensuring that all elements are correctly positioned and securely fastened is vital for achieving the best results.

Additionally, inadequate maintenance often leads to mechanical malfunctions. Neglecting routine checks can result in unforeseen breakdowns, which can be costly and time-consuming. Implementing a regular maintenance schedule helps identify potential problems before they escalate.

Finally, environmental factors, such as ice and debris accumulation, can hinder performance. Clearing these obstacles promptly can enhance functionality and ensure that the equipment operates as intended, providing the ultimate performance when it matters most.

Replacing Worn-Out Components Efficiently

Maintaining optimal functionality requires timely replacement of aged elements. Identifying the right moments for these updates can enhance performance and longevity.

Here are some steps to ensure efficient replacements:

- Assess the Condition: Regularly inspect components for signs of wear.

- Gather Necessary Tools: Prepare all required instruments for a smooth process.

- Follow Manufacturer Guidelines: Adhere to specific instructions for installation.

- Dispose of Old Parts Properly: Ensure environmentally responsible disposal methods.

By following these steps, you can maintain peak efficiency and extend the life of your equipment.

Maintenance Tips for Snow Plow Longevity

Ensuring the durability of your winter equipment requires a proactive approach to care and upkeep. Regular maintenance not only enhances performance but also extends the lifespan of your machinery. By following a few essential guidelines, you can avoid costly repairs and enjoy reliable operation throughout the season.

1. Regular Inspections: Schedule routine checks to identify wear and tear early. Examine key components such as blades, hydraulics, and electrical systems. Addressing minor issues promptly can prevent major breakdowns later.

2. Cleaning After Use: Remove ice, snow, and debris after each operation. Accumulation can lead to rust and corrosion, damaging critical parts. A thorough cleaning ensures that your equipment remains in optimal condition.

3. Lubrication: Apply lubricant to moving parts regularly to reduce friction and wear. Pay particular attention to joints, pivots, and chains. Proper lubrication minimizes operational strain and enhances efficiency.

4. Fluid Checks: Monitor and maintain fluid levels, including hydraulic fluid and engine oil. Keeping fluids at appropriate levels is vital for optimal performance and prevents overheating or malfunctioning.

5. Seasonal Preparation: Before the winter season begins, conduct a comprehensive service check. This includes replacing worn parts, checking battery condition, and ensuring all systems are functional. A well-prepared machine is more reliable when it’s needed most.

6. Storage Considerations: When not in use, store your equipment in a dry, sheltered area. Proper storage protects against harsh weather conditions that can cause deterioration over time.

By implementing these maintenance strategies, you can significantly enhance the reliability and lifespan of your winter machinery, ensuring it performs effectively when you need it most.

Finding Genuine Boss Replacement Parts

Ensuring the longevity and efficiency of your equipment requires sourcing authentic components. Genuine replacements are crucial for maintaining optimal performance and reliability.

- Research reputable dealers who specialize in original equipment.

- Check for manufacturer certifications to guarantee quality.

- Consult user reviews and forums for trusted sources.

Always compare part numbers to avoid mismatches. This practice helps in obtaining the correct items suited for your needs.

- Visit official websites for catalogs of available components.

- Inquire with local distributors about stock and ordering options.

- Consider joining community groups focused on your specific machinery for recommendations.

Taking these steps will lead you to the ultimate solutions for your equipment maintenance needs.

Upgrades for Enhanced Snow Removal

Enhancing your winter clearing operations can significantly improve efficiency and effectiveness. By investing in modern upgrades, operators can streamline their efforts and tackle challenging conditions with ease. The right modifications not only boost performance but also increase safety and longevity of the equipment.

1. Improved Blade Technology

Upgrading to advanced blade materials can enhance cutting efficiency and durability. High-quality alloys or composite materials resist wear and provide a better scraping action, allowing for cleaner surfaces.

2. Enhanced Hydraulic Systems

Modern hydraulic systems offer faster response times and greater lifting capabilities. By incorporating state-of-the-art hydraulics, operators can achieve more precise control over their machinery, making it easier to navigate varied terrains.

3. Advanced Control Systems

Integrating digital controls or GPS technology allows for optimized operation. These systems can help in tracking routes and managing time effectively, ensuring that no area is overlooked during the clearing process.

4. Better Lighting Solutions

Improving visibility with high-intensity LED lights can make a significant difference during night operations or low-visibility conditions. Enhanced lighting increases safety and helps operators maintain focus on their tasks.

5. Accessories for Versatility

Adding versatile accessories, such as adjustable wings or side extensions, can provide broader coverage and greater adaptability to various weather conditions. These additions allow for more efficient handling of accumulation, reducing the time spent on each job.

Investing in these upgrades not only enhances the performance of your equipment but also ensures a more effective and safer approach to managing winter weather challenges.

Expert Resources for Snow Plow Repair

When it comes to maintaining and fixing your winter equipment, having access to reliable resources is crucial. Whether you’re a seasoned technician or a DIY enthusiast, knowing where to find quality information can save you time and money. This section outlines various expert resources that can assist you in troubleshooting and repairing your machinery effectively.

Online Communities and Forums

Engaging with online communities can provide invaluable insights and firsthand experiences. Many enthusiasts and professionals share their knowledge, tips, and tricks, making these platforms a treasure trove of information. Popular forums often feature discussions on common issues, solutions, and recommendations for reliable service providers.

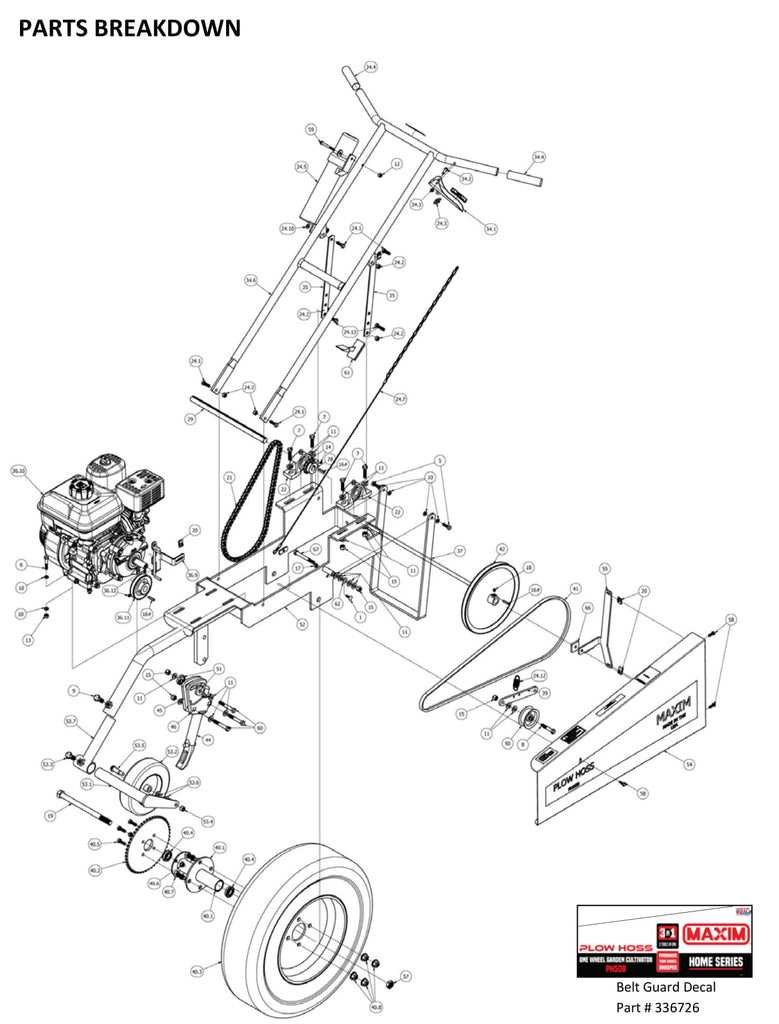

Technical Manuals and Guides

Accessing comprehensive manuals and guides is essential for understanding the intricacies of your equipment. These documents usually include schematics, maintenance schedules, and troubleshooting steps. Manufacturers and dedicated repair sites often offer downloadable versions for convenience.

| Resource Type | Description | Access Link |

|---|---|---|

| Online Forums | Community-driven discussions on repairs and maintenance. | Visit Forum |

| Manufacturer Manuals | Official documentation with technical specifications. | Download Manuals |

| Video Tutorials | Step-by-step guides available on video platforms. | Watch Tutorials |