The efficient functioning of agricultural machinery relies heavily on the intricate arrangement of its individual elements. Each component plays a crucial role in the overall performance, ensuring that the equipment meets the demands of modern farming practices. A thorough grasp of these elements can enhance maintenance strategies and extend the lifespan of the machinery.

For operators and technicians, visual representations of these components can be invaluable. Detailed schematics not only assist in identifying specific parts but also streamline repair processes, reducing downtime and improving productivity. Such illustrations serve as essential guides for anyone involved in the upkeep and operation of cutting tools.

Exploring the various segments of this machinery fosters a deeper appreciation for its engineering and design. Whether you are a seasoned professional or a novice, understanding these elements empowers you to make informed decisions regarding repairs and upgrades. This knowledge ultimately contributes to more efficient farming operations and better resource management.

Understanding Vermeer 7040 Components

The intricacies of agricultural machinery involve a myriad of elements that work in harmony to enhance efficiency. Familiarity with these components is essential for optimal performance and maintenance. A comprehensive understanding can significantly impact productivity and durability.

Key elements include the cutting system, drive mechanisms, and frame structure, each serving a distinct function. The cutting apparatus is crucial for achieving precise and effective results, while the drive system ensures power is transmitted smoothly. Additionally, the overall build quality influences resilience against the rigors of daily use.

Regular inspection and awareness of potential wear and tear on these components can prevent downtime. By delving into each part’s role, operators can make informed decisions regarding upkeep and upgrades, ultimately enhancing their machinery’s performance.

Key Features of the Disc Mower

Understanding the essential attributes of a cutting implement designed for agricultural use is crucial for maximizing its efficiency and effectiveness. These machines are engineered to enhance productivity while ensuring durability and ease of maintenance. Below are some of the standout characteristics that define these tools.

Efficiency and Performance

The design of these machines allows for rapid cutting, significantly reducing the time needed for forage preparation. The unique configuration of the blades ensures a clean cut, which is vital for the health of the plants and the quality of the harvested material.

Durability and Maintenance

Constructed from high-quality materials, these implements are built to withstand the rigors of heavy agricultural use. Regular maintenance is simplified through accessible components, ensuring that operators can keep the equipment in optimal condition with minimal effort.

| Feature | Description |

|---|---|

| Blade Design | Specialized blades for clean cuts and optimal plant health. |

| Speed | High operational speed for increased productivity. |

| Durability | Robust construction to endure tough conditions. |

| Maintenance | User-friendly access for easy upkeep and repairs. |

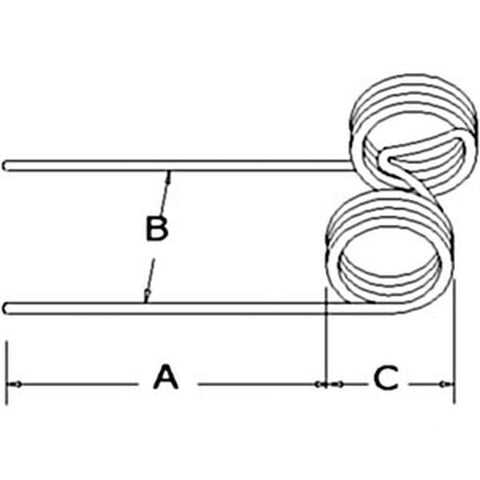

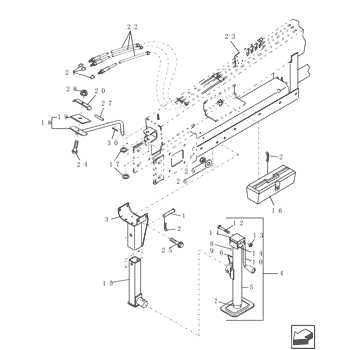

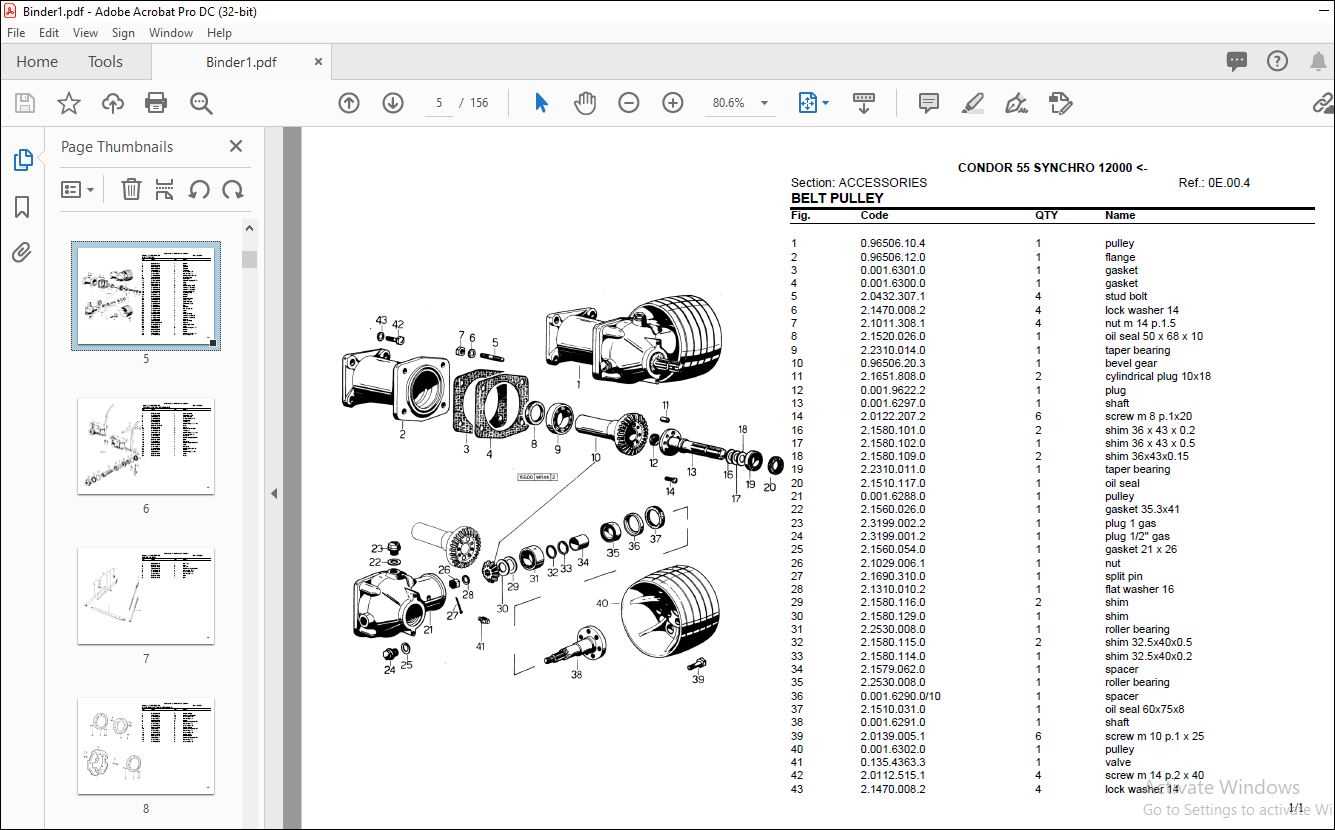

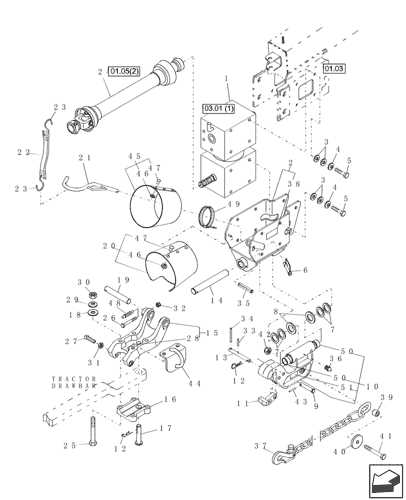

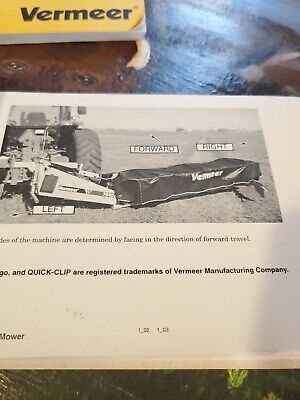

Parts Diagram Overview

This section provides a comprehensive look at the various components involved in the machine’s functionality. Understanding the layout and relationships between different elements is crucial for efficient maintenance and repair.

Each element plays a significant role in ensuring optimal performance. Familiarity with these components allows operators to identify issues quickly and streamline their troubleshooting process.

- Component Identification: Recognizing each piece helps in assessing its condition and functionality.

- Maintenance Planning: A clear view of the arrangement aids in planning regular checks and replacements.

- Repair Strategies: Knowing how parts fit together supports effective repair methods.

Overall, a well-understood assembly can lead to better operational efficiency and longevity of the equipment.

Common Issues with the 7040 Model

When operating advanced agricultural machinery, it’s essential to be aware of potential challenges that may arise. Understanding these common issues can help in maintaining optimal performance and extending the lifespan of the equipment. Below are some frequently encountered problems and their implications.

Hydraulic System Failures

One of the prevalent challenges involves the hydraulic system. Leaks and pressure drops can significantly affect functionality, leading to reduced efficiency. Regular checks for fluid levels and signs of wear can mitigate these risks.

Blade Dullness and Damage

Another common concern is the condition of the cutting components. Over time, blades may become dull or sustain damage, which directly impacts cutting performance. Routine inspections and timely replacements are vital to ensure consistent operation and high-quality results.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. A well-maintained machine not only performs better but also extends its operational life, reducing the need for costly replacements. Adopting a systematic maintenance routine can lead to significant benefits in performance and reliability.

Regular Inspections

Conducting periodic checks is essential for identifying potential issues before they escalate. Focus on key components such as bearings, blades, and belts. Look for signs of wear or damage and replace any parts that show significant deterioration. Keeping a maintenance log can help track inspections and repairs.

Lubrication and Cleaning

Proper lubrication of moving parts is vital for minimizing friction and preventing premature wear. Use the recommended lubricant for your machine, applying it according to the manufacturer’s guidelines. Additionally, regular cleaning helps remove debris and dirt that can impede performance. Pay special attention to areas that accumulate buildup, ensuring smooth operation.

Replacement Parts and Compatibility

Maintaining optimal performance in agricultural machinery is crucial for efficient operation. Understanding the availability of interchangeable components is essential for ensuring that equipment runs smoothly and reliably. This section will explore the significance of sourcing the right replacements and the compatibility factors to consider.

When looking for suitable components, it is important to consider the following aspects:

- Manufacturer Specifications: Always check the original manufacturer’s recommendations to ensure quality and performance.

- Compatibility with Existing Equipment: Verify that new components are designed to work seamlessly with your current machinery setup.

- Quality Standards: Opt for parts that meet or exceed industry standards to guarantee longevity and reliability.

To make informed decisions, consider the following sources for acquiring replacements:

- Authorized dealers that provide genuine components.

- Reputable aftermarket suppliers offering compatible alternatives.

- Local repair shops that might have access to both original and substitute options.

In conclusion, ensuring compatibility and quality when sourcing replacements not only enhances performance but also extends the lifespan of your equipment. Being proactive in this aspect will lead to better productivity and reduced downtime.

Assembly Instructions for Users

Proper assembly is crucial for the optimal performance of your equipment. Following these guidelines will help ensure that each component is correctly fitted, enhancing the overall efficiency and longevity of your machinery.

- Preparation:

- Gather all necessary tools and components.

- Read through the instructions thoroughly before starting.

- Choose a clean, spacious area to work.

- Assembly Steps:

- Begin by assembling the main frame. Ensure all connections are secure.

- Attach the cutting elements, making sure they are aligned properly.

- Install the drive components, checking for smooth movement.

- Connect any hydraulic or electrical systems as required.

- Final Checks:

- Inspect all bolts and screws for tightness.

- Verify that moving parts are functioning without obstruction.

- Conduct a visual inspection for any missing components.

Following these assembly instructions will help you achieve a reliable setup, ready for operation. Always consult the specific manual for additional details and safety information.

Where to Find Quality Parts

When it comes to maintaining your equipment, sourcing high-quality components is crucial for optimal performance and longevity. Many enthusiasts and professionals alike often find themselves seeking reliable suppliers that offer durable and efficient replacements for their machinery.

Local Dealers are a great starting point. They typically carry a wide range of items tailored to specific models and can provide expert advice on compatibility and installation. Building a relationship with your local distributor can also lead to exclusive offers and insights into new arrivals.

Online Retailers have become increasingly popular due to their convenience and extensive selection. Websites specializing in machinery often provide detailed descriptions, customer reviews, and competitive pricing, allowing you to make informed decisions without leaving your home.

Manufacturer Websites are another valuable resource. These platforms often list authorized retailers and sometimes offer direct purchasing options. By buying directly from the source, you can ensure the authenticity and quality of the components you need.

Second-Hand Markets can also be worth exploring. Platforms like auctions or dedicated marketplaces may have gently used items at a fraction of the cost. However, always verify the condition and reliability of the sellers to avoid potential pitfalls.

Investing time in researching these various sources can significantly enhance your chances of finding the right components to keep your equipment running smoothly.

Benefits of Using Genuine Components

Utilizing authentic components in your machinery ensures optimal performance and longevity. These original pieces are specifically designed to work seamlessly with your equipment, enhancing efficiency and reliability.

One of the primary advantages of choosing genuine components is quality assurance. Manufacturers meticulously engineer these parts, adhering to stringent standards that often surpass those of aftermarket alternatives. This leads to improved durability, reducing the likelihood of premature wear and the need for frequent replacements.

Additionally, using original components can significantly enhance operational safety. Genuine parts are tested for compatibility, minimizing the risks associated with poor fitting or substandard materials. This contributes to a safer working environment, protecting both the operator and the machinery.

Moreover, investing in authentic components can lead to cost savings in the long run. While the initial price may be higher, the reduction in maintenance costs and downtime often justifies the investment. Reliable parts decrease the chance of breakdowns, allowing for smoother operations and less disruption.

Lastly, maintaining your equipment with genuine components often ensures better resale value. Potential buyers are more inclined to purchase machinery that has been properly maintained with original parts, as this reflects a commitment to quality and care.