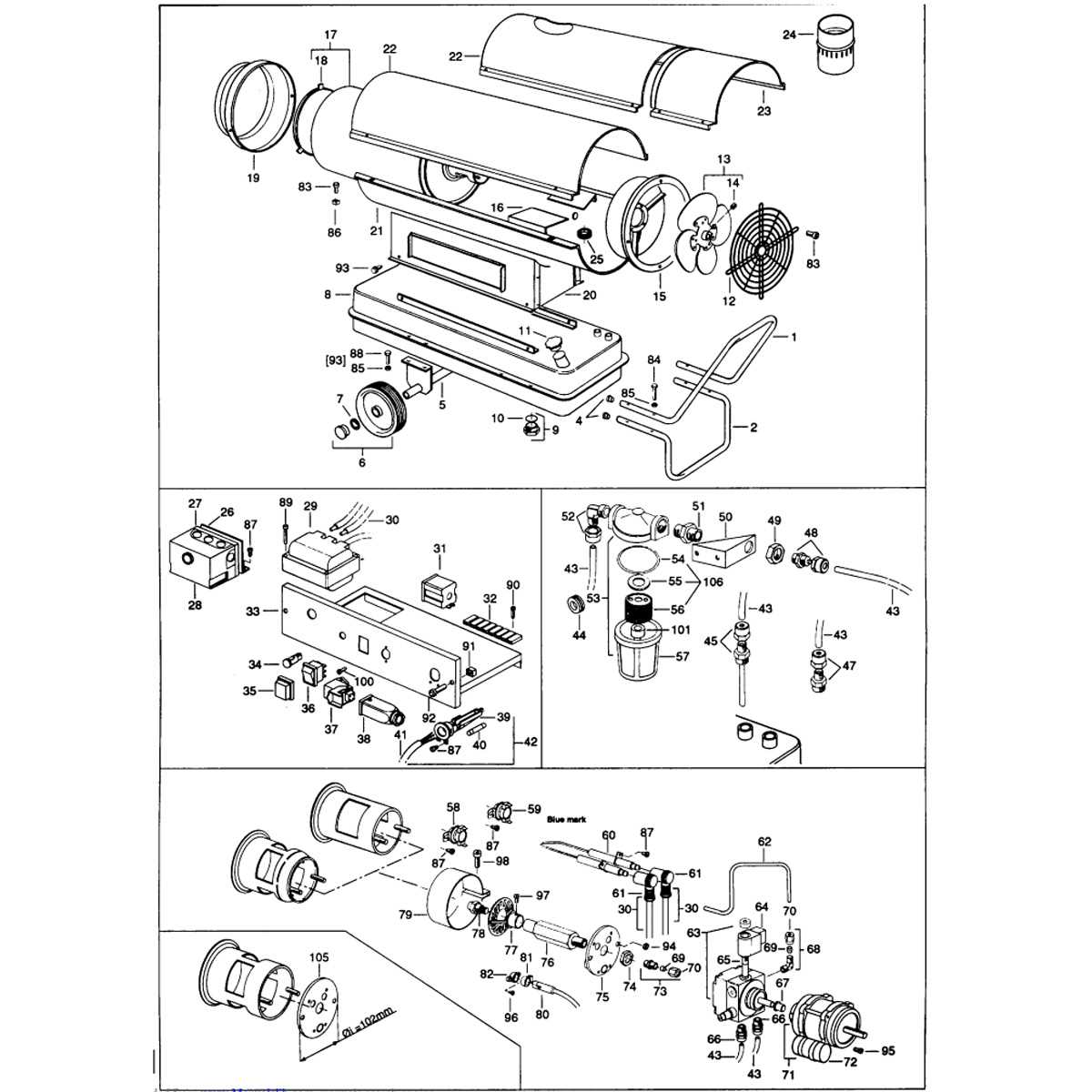

When dealing with portable climate control solutions, it’s essential to know how each component functions together. Whether you’re troubleshooting a malfunction or performing routine maintenance, having a clear overview of the system’s structure can be incredibly helpful. The arrangement of various elements plays a significant role in ensuring optimal performance and longevity of the device.

In this guide, we’ll explore the key features of these systems, detailing how different mechanisms interact to produce reliable warmth in challenging environments. From ignition systems to air intake, every part works in unison to create an efficient source of heat. Learning more about these components will equip you with the knowledge to maintain and repair your device with confidence.

By understanding the layout of essential elements, you’ll be better prepared to identify potential issues and keep your equipment in excellent condition for years to come. Let’s delve deeper into the specifics of each section and see how they contribute to overall functionality.

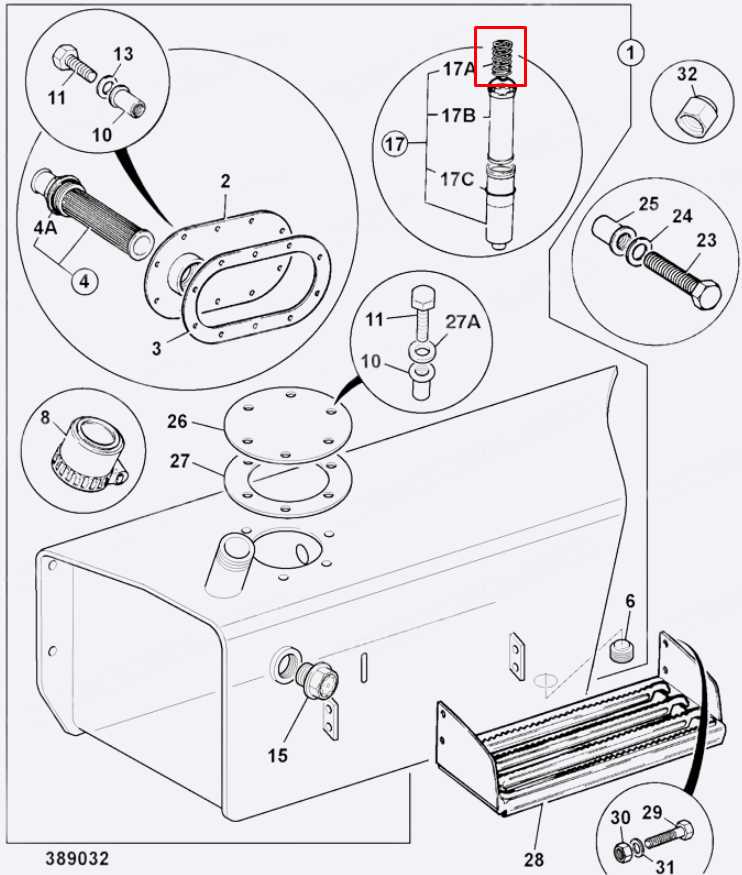

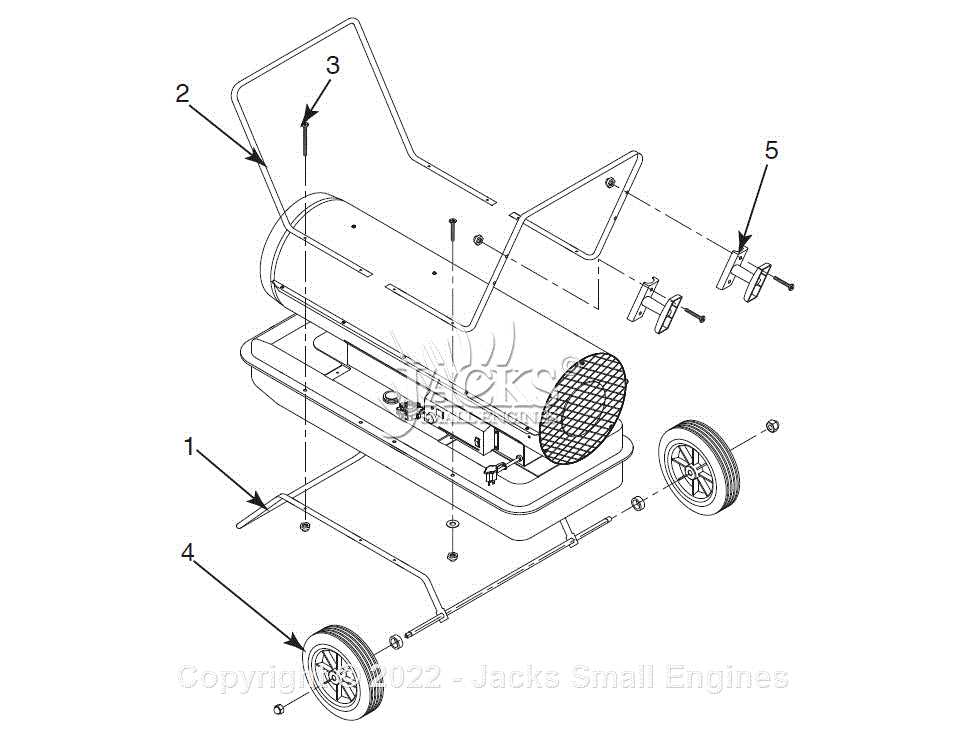

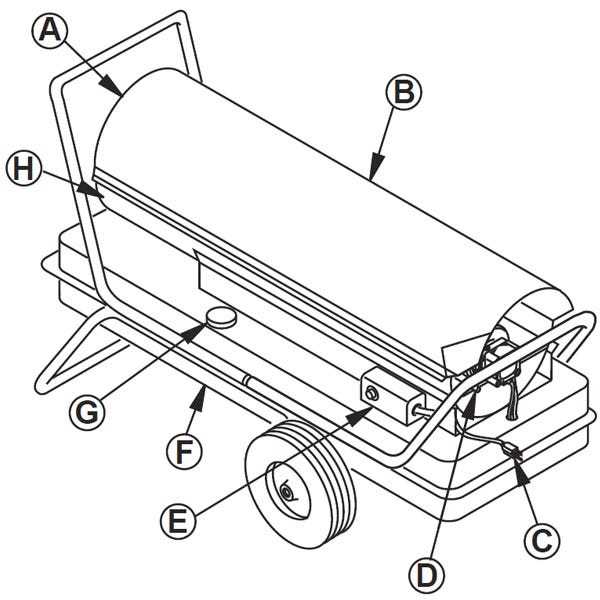

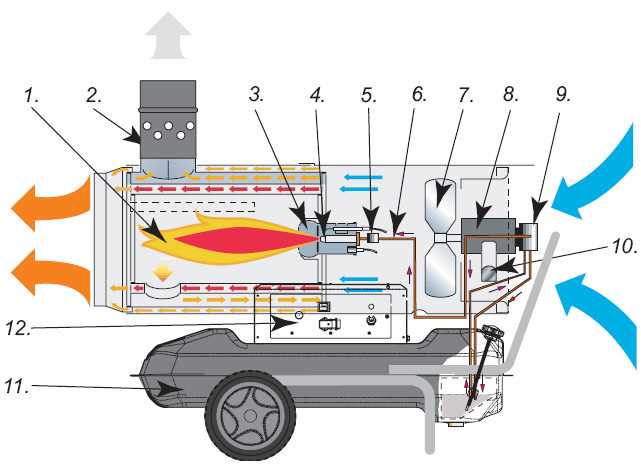

Understanding the Components of a Torpedo Heater

Effective operation of portable heating devices relies on several critical components that work together to generate and distribute warmth efficiently. Recognizing these elements and their functions can help maintain optimal performance and extend the lifespan of your equipment.

Main Elements of the System

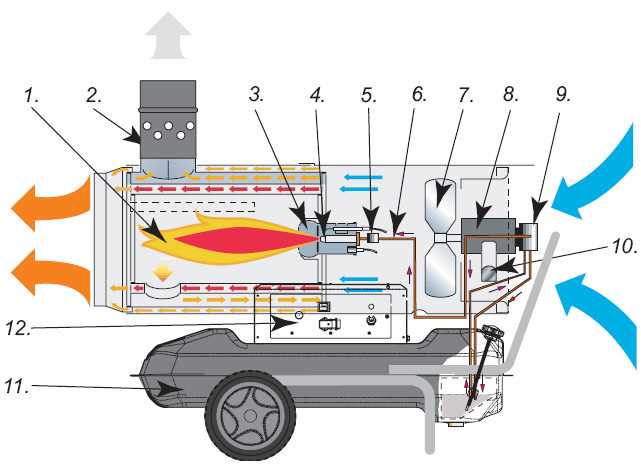

The central part responsible for ignition is the combustion chamber. It houses the process that transforms fuel into heat energy. Without proper airflow, this system would struggle to function. Therefore, air intake mechanisms are essential to maintain the right balance of oxygen, enabling efficient burning of fuel.

Fuel and Safety Mechanisms

To

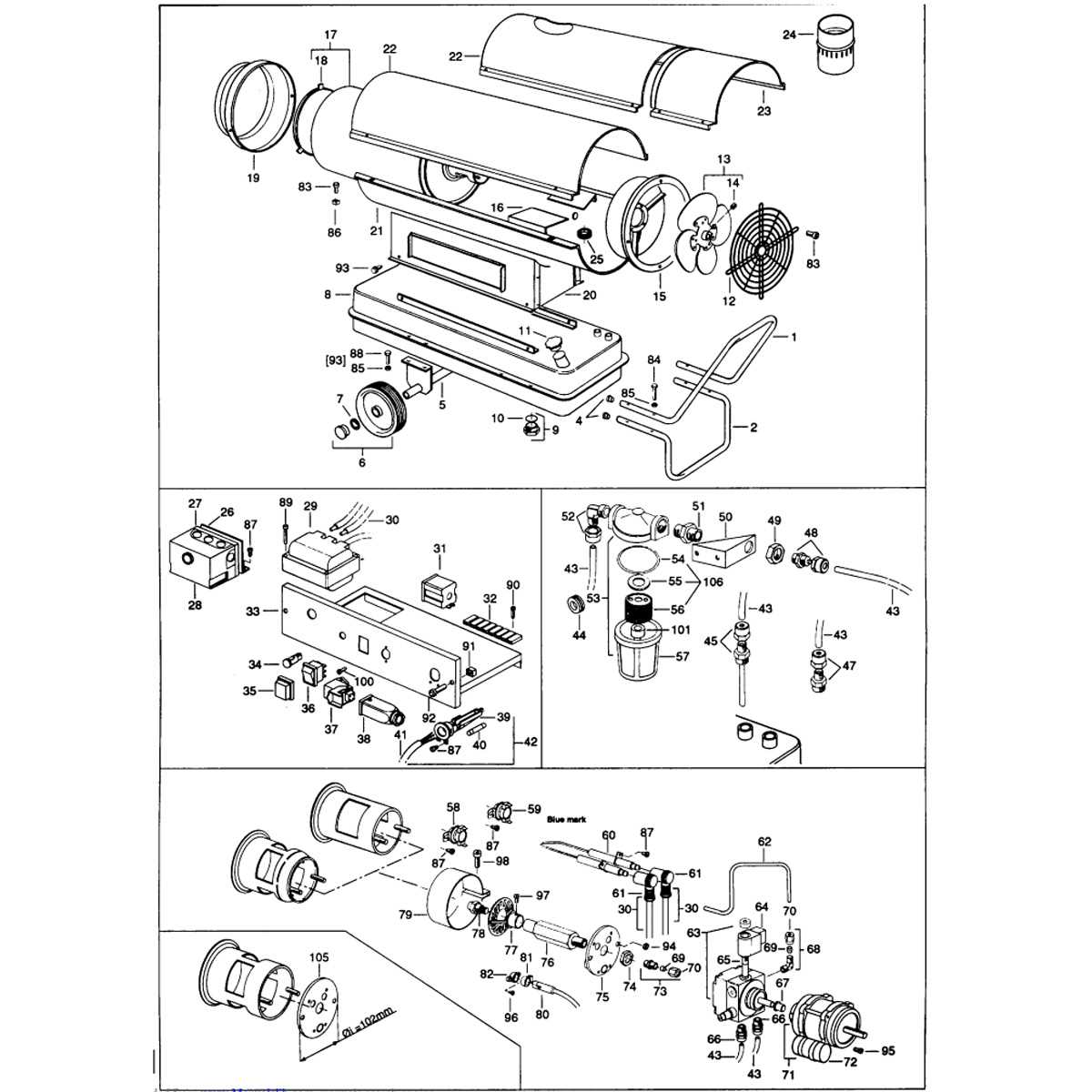

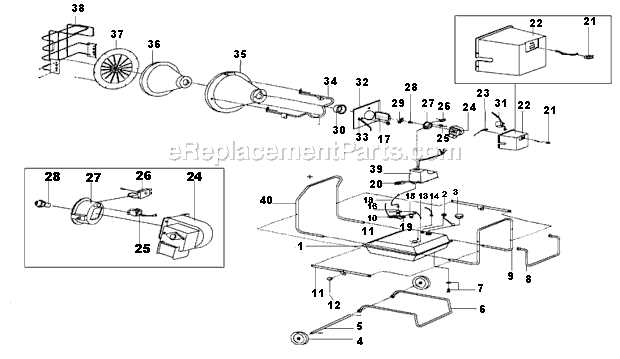

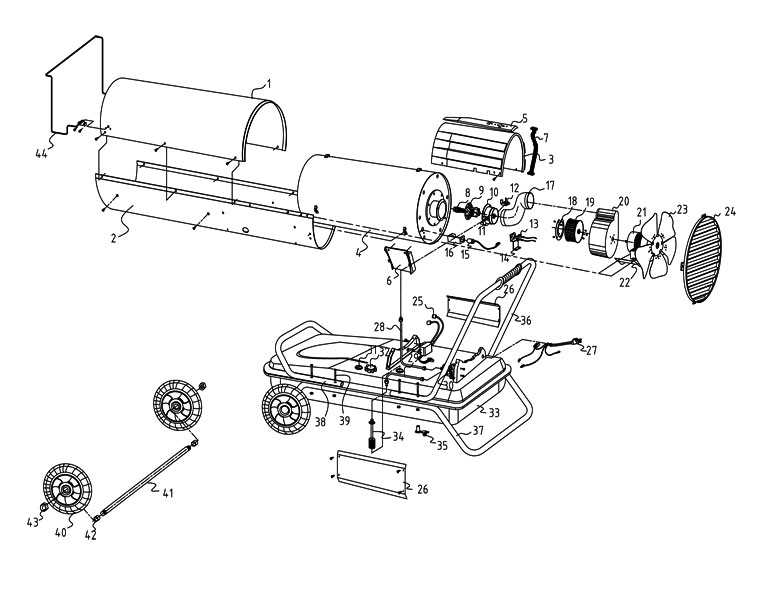

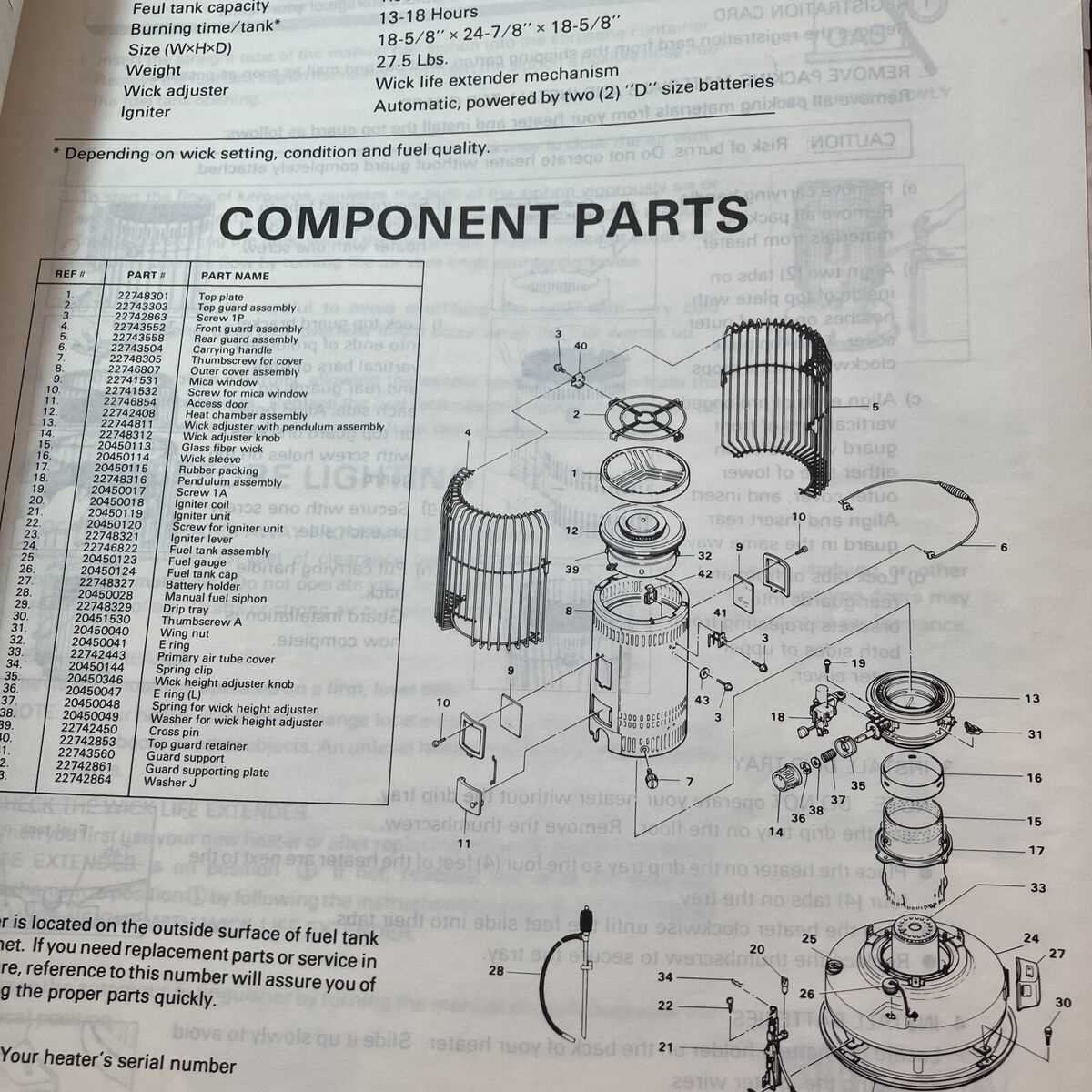

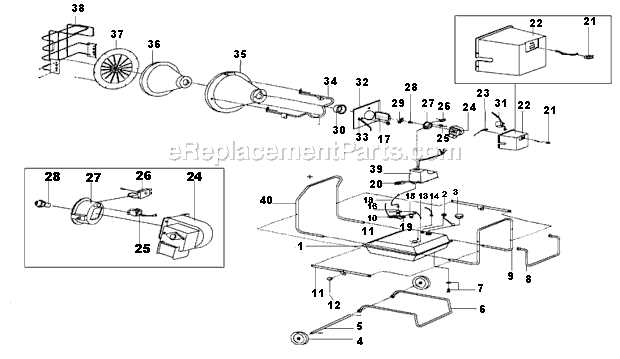

Key Internal Parts and Their Functions

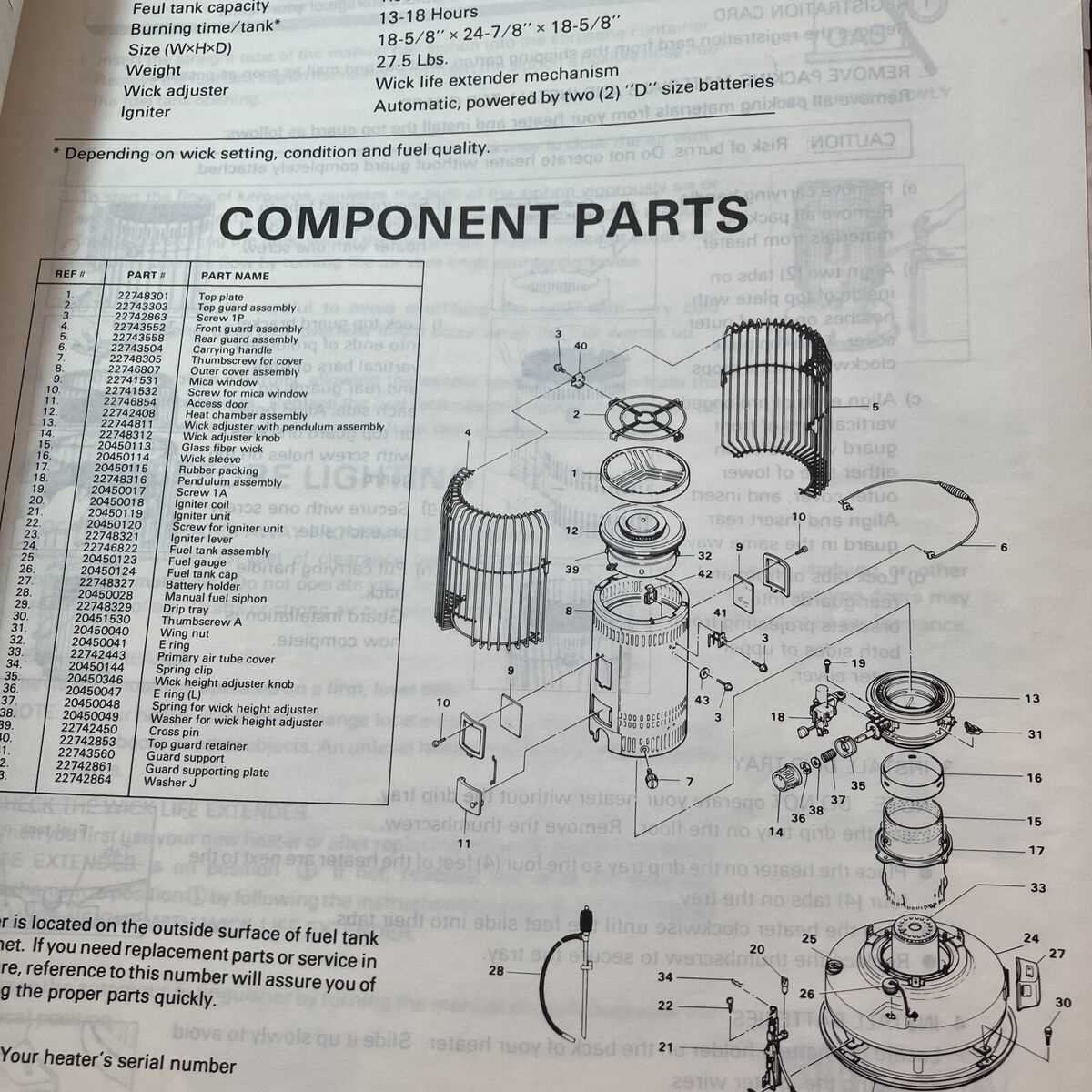

The inner workings of a portable heating device rely on several essential components, each playing a vital role in its operation. Understanding how these elements interact is crucial for both maintenance and troubleshooting. These mechanisms ensure the proper distribution of heat, fuel flow, and safe functioning of the equipment.

Ignition System: This component initiates the combustion process by creating the necessary spark or flame to ignite the fuel. Without this, the device cannot produce heat effectively.

Fuel Delivery Mechanism: A precise system that regulates the flow of fuel into the combustion chamber. It ensures the right amount of fuel is delivered for optimal performance and efficiency.

Combustion Chamber: The core of the heating process, where fuel and air mix and burn to generate heat. This area is designed to withstand high temperatures and maximize the energy produced from the fuel.

Blower or Fan: Responsible for circulating the heated air throughout the surrounding area. This element ensures that warm air is evenly distributed, enhancing the overall efficiency of

How to Identify a Malfunctioning Component

Detecting an issue with a mechanical or electrical system requires careful observation and an understanding of how the unit should operate when fully functional. By noting unusual behaviors and conducting simple tests, you can pinpoint which element might be causing the problem.

Signs of Potential Issues

The first step is to look for common warning signs, such as unexpected noises, irregular performance, or inconsistent power output. Any noticeable difference in operation could signal a fault in a specific element.

Testing for Malfunctions

To confirm whether a part is malfunctioning, you can carry out basic checks like inspecting for visible damage or measuring voltage with a multimeter. Use the table below to match typical symptoms with their potential causes.

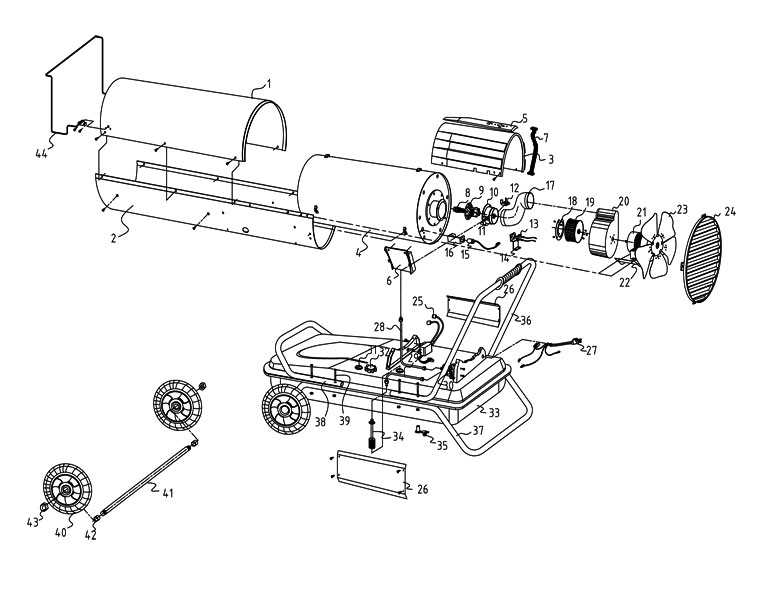

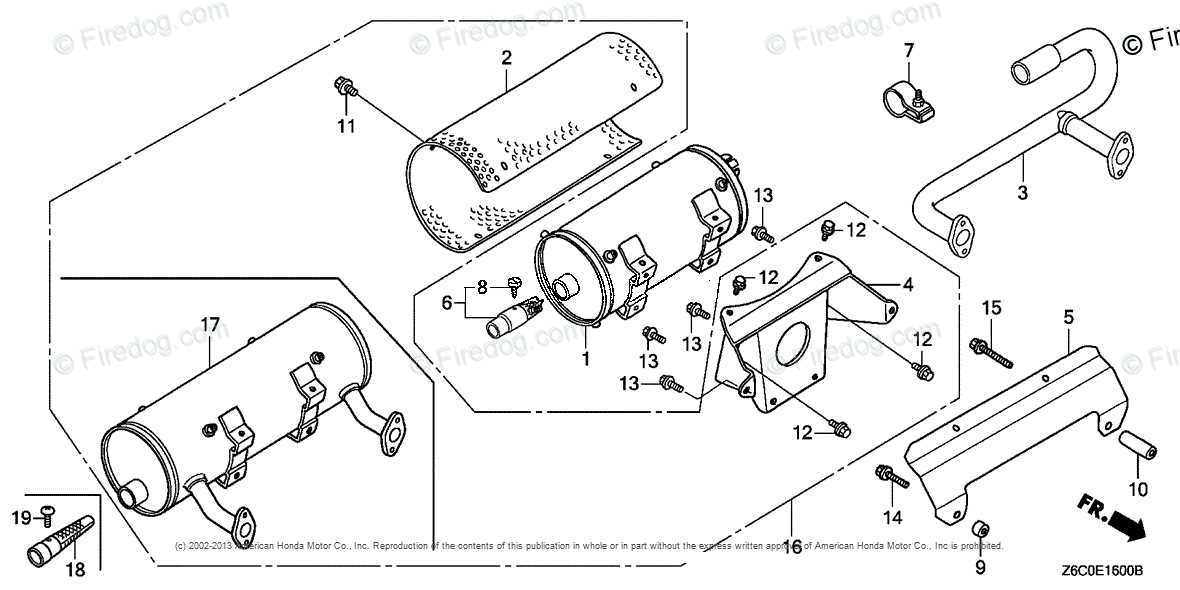

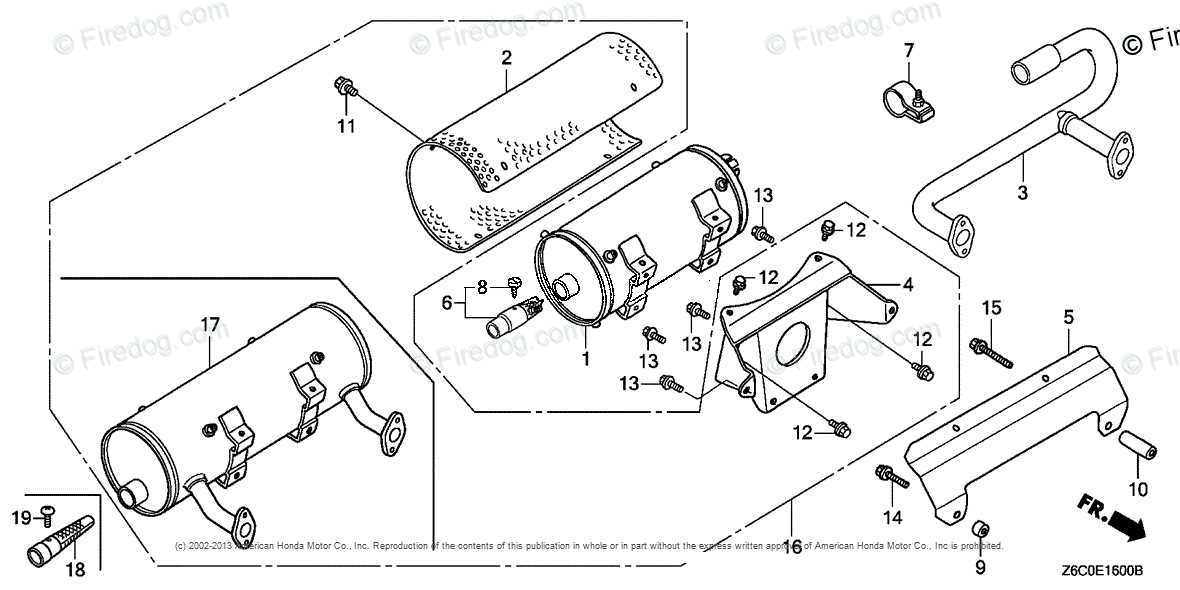

Replacing the Fuel System in a Heater

Maintaining optimal performance requires timely replacement of critical components involved in the fuel supply. Over time, these components may wear out or become clogged, affecting the efficiency and reliability of the equipment. Addressing fuel system issues promptly ensures that the unit operates smoothly and prevents potential malfunctions.

Identifying Fuel System Issues

Common signs of problems include difficulty in starting, uneven operation, or a drop in fuel efficiency. These indicators suggest that key parts in the system might be obstructed or deteriorating. A thorough inspection is recommended to determine the exact cause before proceeding with the replacement.

Steps to Replace Key Components

First, ensure the unit is completely powered down and disconnected from its energy source. Carefully remove the old filters, fuel lines, and any related connectors. It’s essential to clean any buildup in these areas to prevent future blockages. Once the old components are removed, replace them with new, compatible parts, making sure

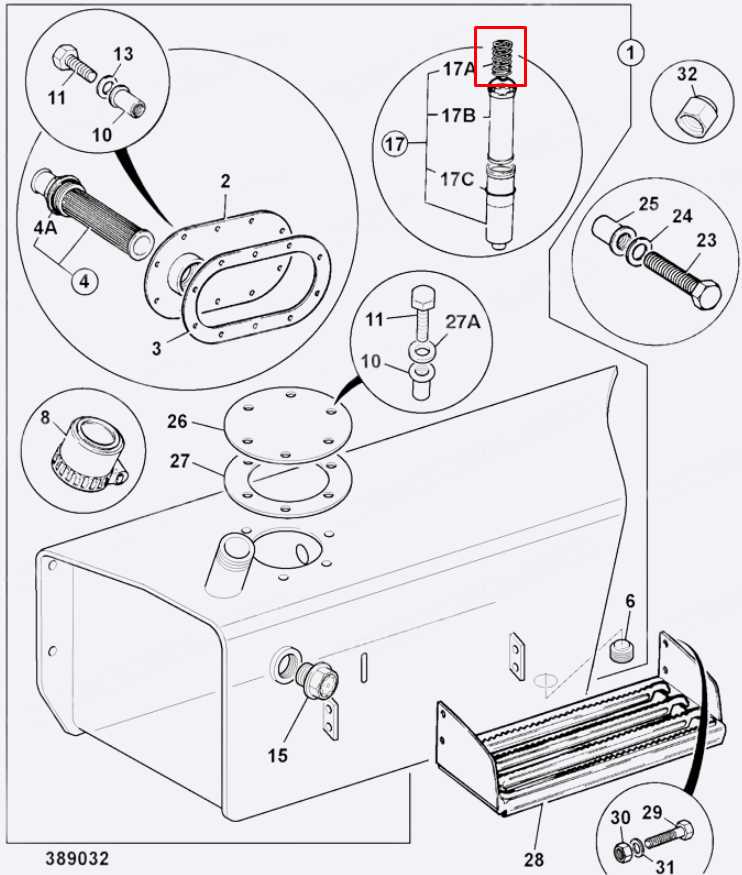

Maintaining Your Heater for Longevity

Regular upkeep is essential for ensuring the long-lasting performance of your equipment. Proper care not only enhances efficiency but also minimizes the need for repairs and extends its service life. Following a few key practices can significantly reduce wear and tear, helping to prevent potential issues before they arise.

To help maintain optimal function, you should focus on these important maintenance steps:

| Task |

Frequency |

Purpose |

| Inspect all moving components |

Monthly |

Ensure smooth operation and detect early signs of damage |

| Clean fuel intake and exhaust |

Every 3 months |

Prevent blockages and maintain efficient airflow |

Replace

Common Issues with Ignition Systems

The ignition mechanism plays a crucial role in the functioning of various combustion appliances. Understanding the frequent problems that can arise in these systems is essential for maintaining optimal performance. Many users encounter challenges that can hinder efficiency, increase fuel consumption, or even lead to complete failure. Recognizing these issues early can save time and resources, ensuring a more reliable operation.

Inconsistent Spark Generation

One prevalent issue is inconsistent spark generation. This can occur due to a variety of factors, including worn-out components or improper adjustments. A weak or sporadic spark may fail to ignite the fuel effectively, leading to incomplete combustion. Regular inspection and maintenance of the ignition components can help mitigate this problem and enhance overall performance.

Faulty Connections and Wiring

Another common problem is related to faulty connections and wiring. Corrosion, loose connections, or damaged wires can interrupt the electrical flow necessary for ignition. These issues not only disrupt the ignition process but may also pose safety risks. Ensuring all connections are secure and regularly checking the wiring for signs of wear can help prevent these complications.

Thermostat and Safety Switch Mechanisms

The functionality of heating systems relies significantly on precise control mechanisms that regulate temperature and ensure safe operation. These devices are designed to monitor environmental conditions and make necessary adjustments to maintain optimal performance while preventing potential hazards. Understanding their roles is crucial for anyone involved in the maintenance or design of thermal appliances.

Temperature Regulation is primarily managed by a component that senses ambient conditions and communicates with the heating element. When the temperature deviates from a predetermined range, it activates or deactivates the energy flow. This process not only ensures comfort but also enhances efficiency by reducing unnecessary energy consumption.

Safety mechanisms play a pivotal role in safeguarding users and equipment. These devices are engineered to detect abnormal conditions, such as overheating or electrical faults. Upon identifying a potential risk, they promptly interrupt the power supply, preventing dangerous situations that could lead to fires or equipment failure. Regular inspection and testing of these features are vital to maintaining a secure environment.

In conclusion, the integration of regulation and protection systems is fundamental to the reliable operation of thermal appliances. Their effectiveness directly influences both user satisfaction and safety standards, underscoring the importance of understanding their mechanisms for optimal performance.

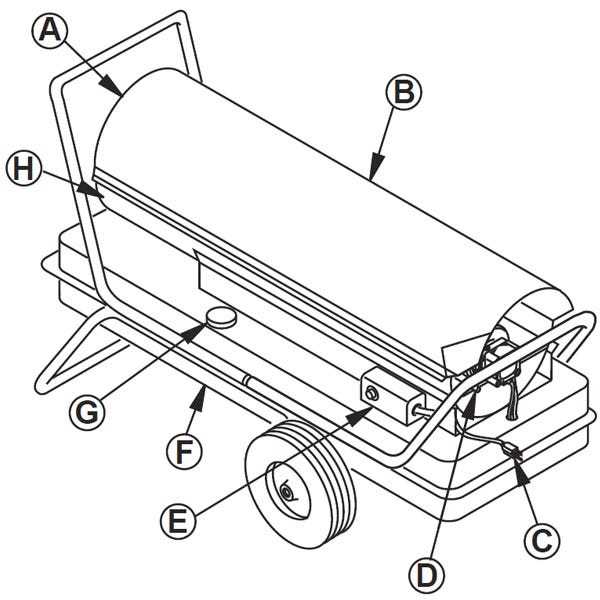

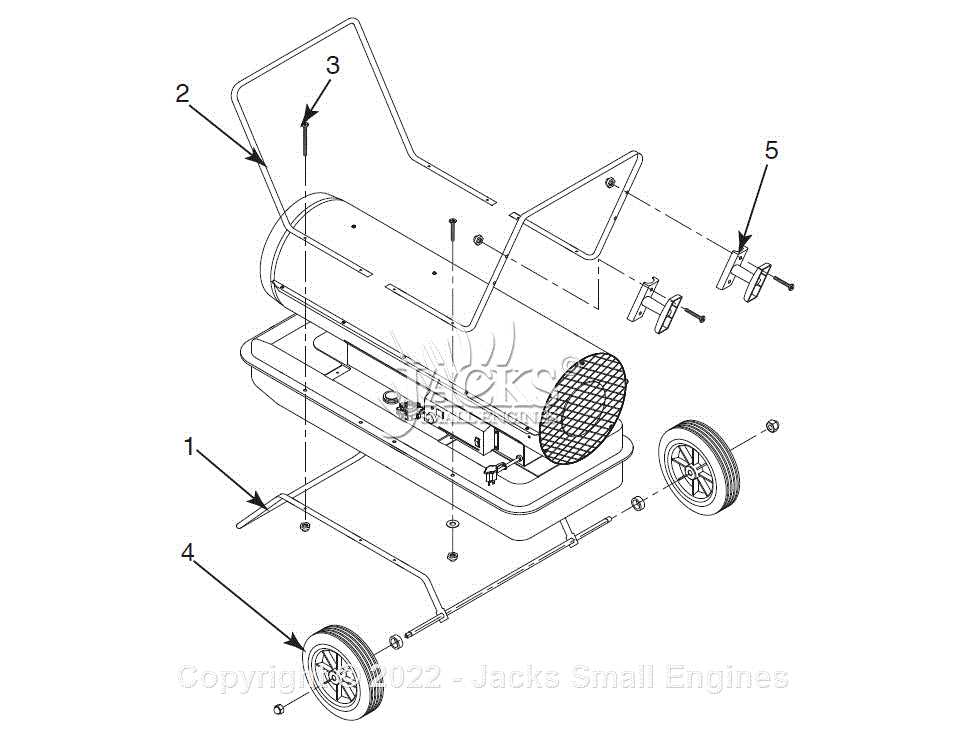

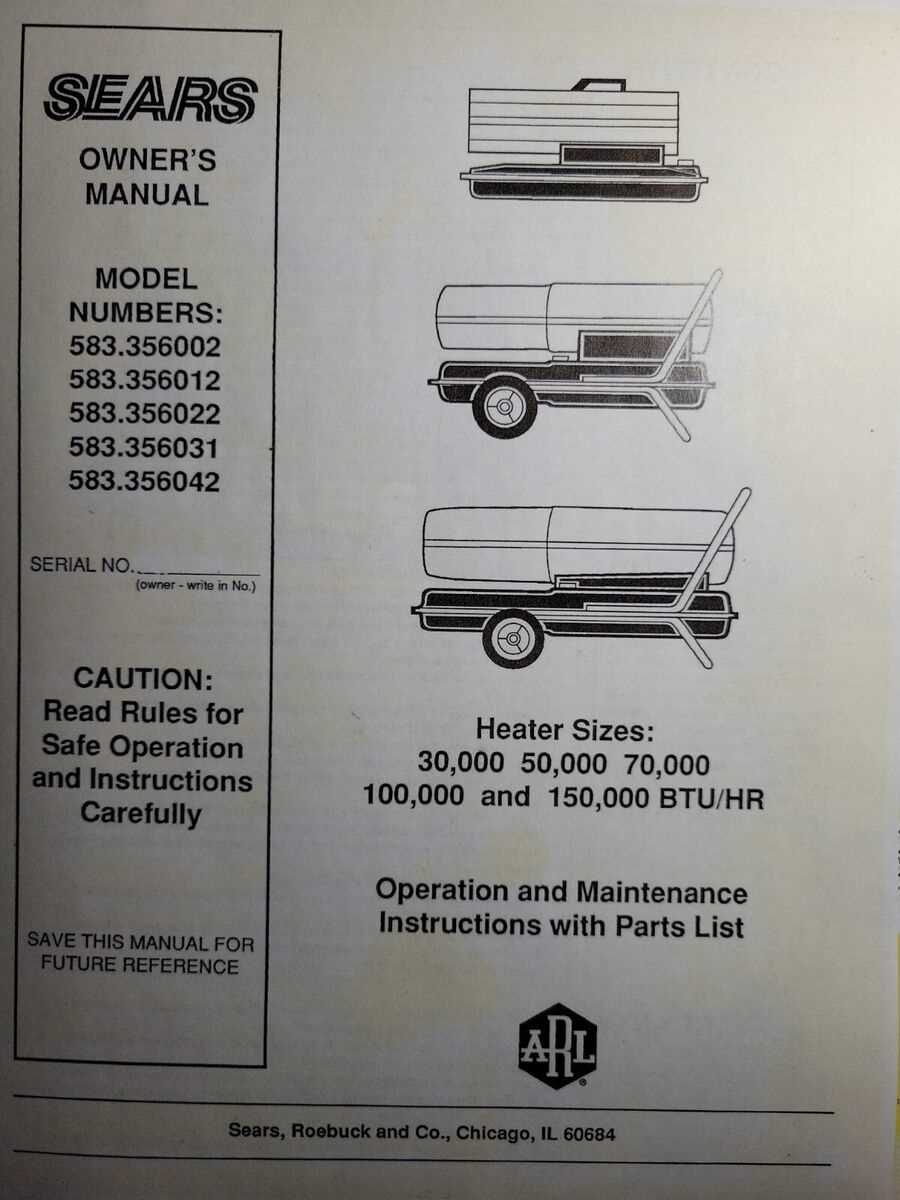

Differences Between Various Torpedo Heater Models

When it comes to portable heating solutions, a wide range of options is available on the market, each designed to meet specific needs and preferences. Understanding the nuances between different models can greatly enhance the selection process for consumers, ensuring they choose a unit that aligns with their requirements. Key factors such as fuel type, heat output, efficiency, and portability play significant roles in distinguishing one option from another.

Fuel Types and Efficiency

One of the most notable differences among these devices lies in the types of fuel they utilize. Some models operate on kerosene, while others may use diesel or propane. Each fuel type offers distinct advantages regarding efficiency, cost, and environmental impact. For instance, kerosene models are often favored for their affordability and ease of use, while propane variants may provide cleaner combustion and reduced emissions.

Heat Output and Portability

Heat output is another critical factor that varies among different designs. Units can range from lower BTU outputs suitable for small spaces to high-capacity versions designed for larger areas or industrial applications. Additionally, portability features differ, with some models designed for easy transport, including wheels and lightweight constructions, while others are more stationary. Understanding these aspects can help users select the best option for their intended application.

Essential Tools for Heater Repair and Maintenance

Maintaining and repairing heating systems requires a specific set of instruments to ensure efficiency and longevity. Having the right tools on hand not only simplifies the process but also enhances safety and effectiveness during service. From basic handheld devices to specialized equipment, each plays a vital role in addressing issues and performing regular upkeep.

Basic Hand Tools

The foundation of any repair job lies in basic hand tools. Essential items include screwdrivers, pliers, wrenches, and adjustable spanners. These tools are indispensable for tightening, loosening, or replacing components with precision. A sturdy utility knife is also beneficial for cutting insulation or other materials.

Diagnostic Equipment

In addition to hand tools, diagnostic equipment is crucial for identifying issues within the system. A multimeter allows for measuring voltage and current, providing insights into electrical problems. Infrared thermometers can help assess temperature variations, indicating potential malfunctions. Having access to these tools enables technicians to efficiently troubleshoot and resolve issues, ensuring optimal performance.

|

|