In any lift system, the efficiency and functionality rely heavily on a well-organized assembly of components. Knowing how each element fits together is crucial for both maintenance and repair. This section explores the different mechanical and electrical elements that form the foundation of a reliable and durable system. By examining these aspects closely, you can gain a clearer understanding of how these machines operate and how their various elements work in harmony.

Whether you’re a technician or simply someone interested in the workings of lift mechanisms, it’s essential to become familiar with how each component interacts with others. From the hydraulic system to the electrical wiring, every piece plays a role in ensuring smooth and safe operation. This guide will walk you through the main structures, helping you to visualize and comprehend their functions in a straightforward manner.

Detailed knowledge of the components allows for easier troubleshooting and more effective repairs. As you continue, you will uncover the key areas that require attention for maintaining these systems in top working condition. Each section will break down the major elements, offering insight into their purpose and how they contribute to the overall performance.

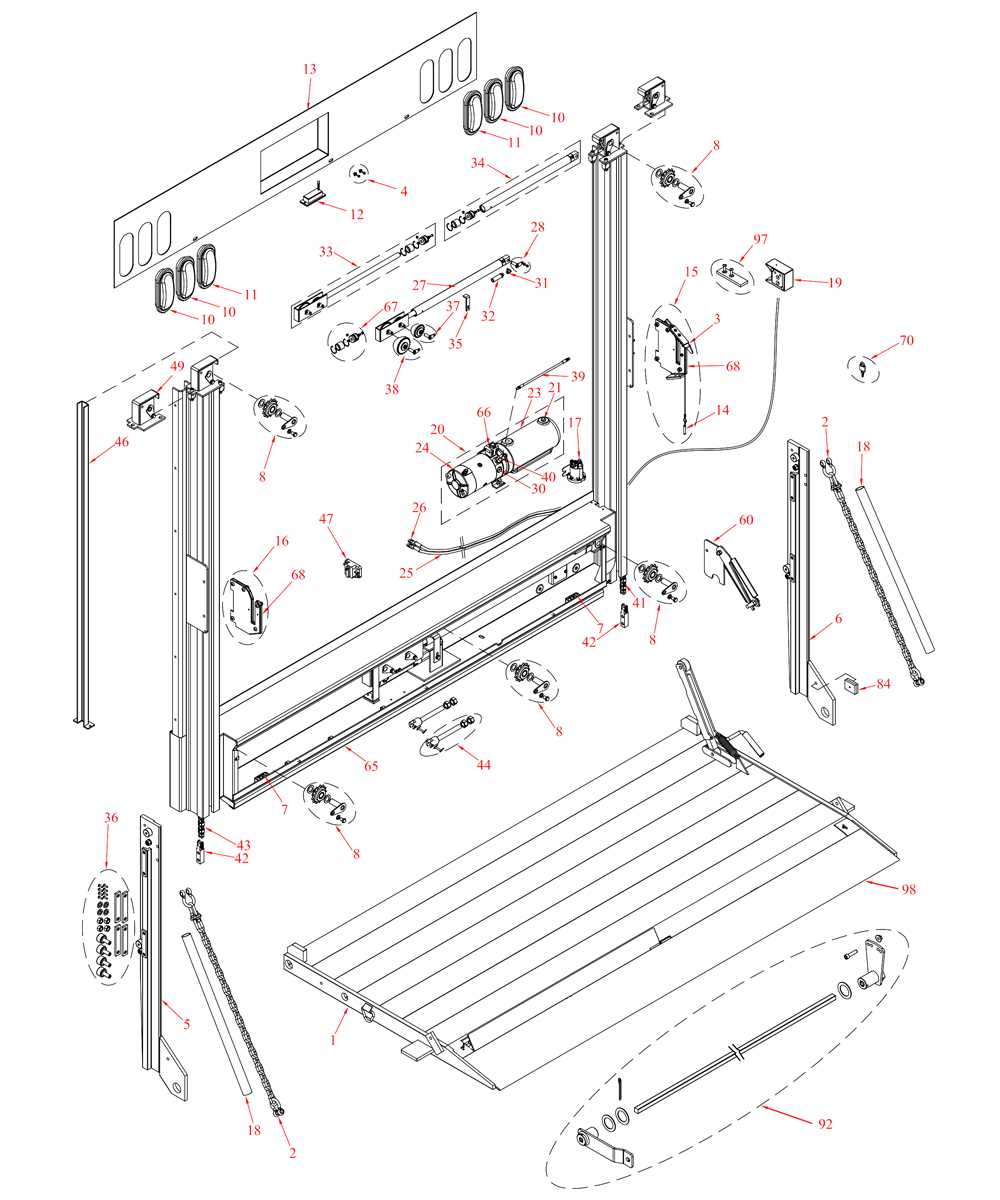

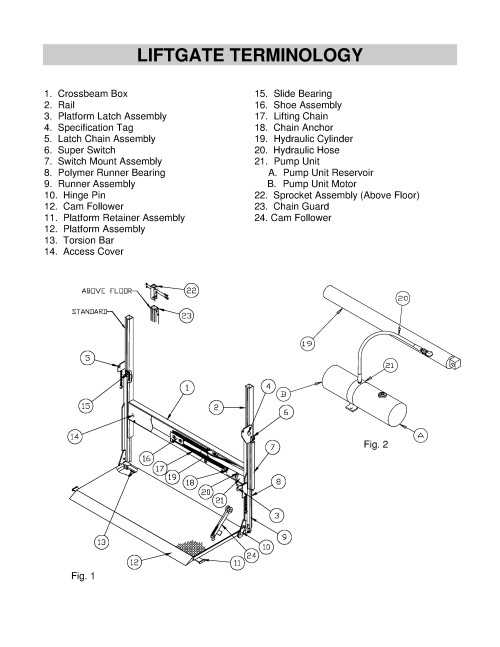

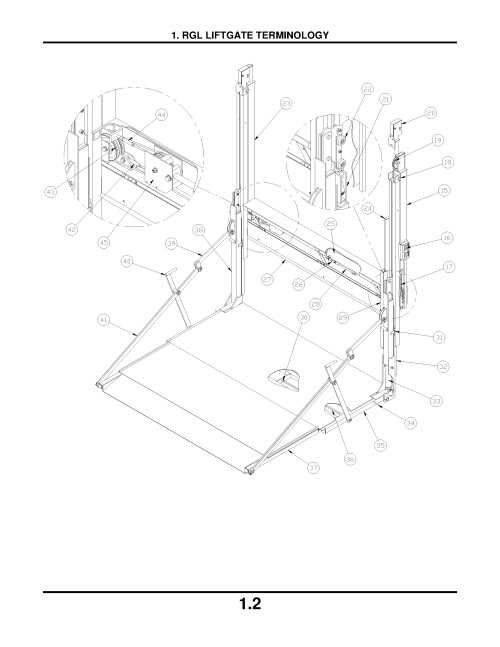

Understanding the Structure of Tommy Gate Components

When examining the composition of hydraulic lifting mechanisms, it’s essential to have a clear understanding of how different elements work together. By exploring each section and its role, you can ensure smoother operation and maintenance of the equipment.

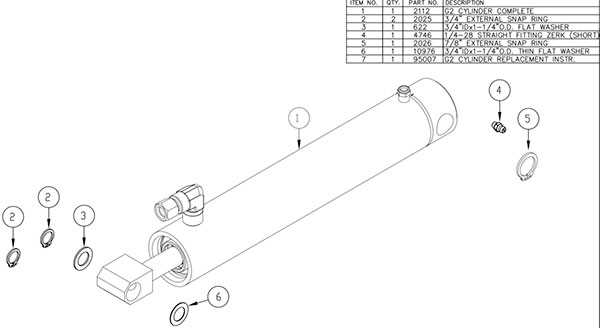

- Hydraulic Cylinder: This component is responsible for generating the lifting force by converting fluid pressure into motion.

- Control Valve: This mechanism regulates the flow of hydraulic fluid, allowing precise control over the lifting and lowering actions.

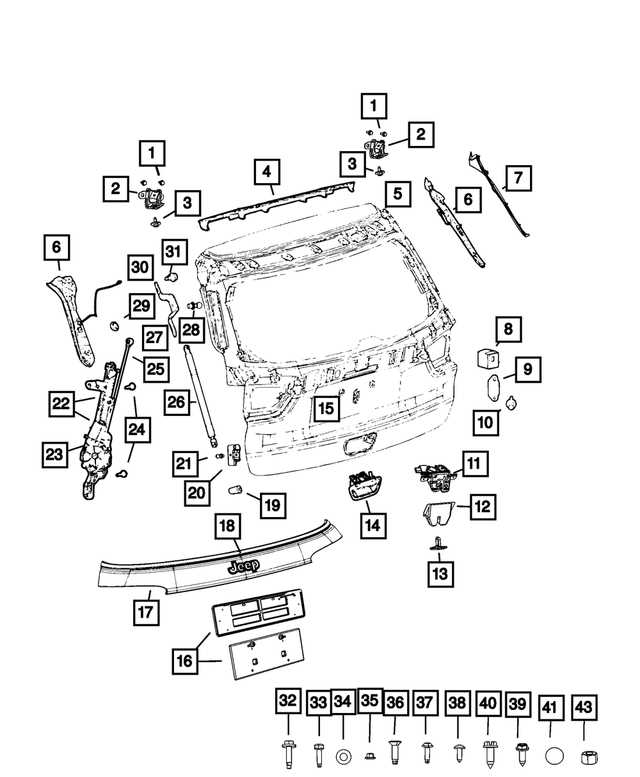

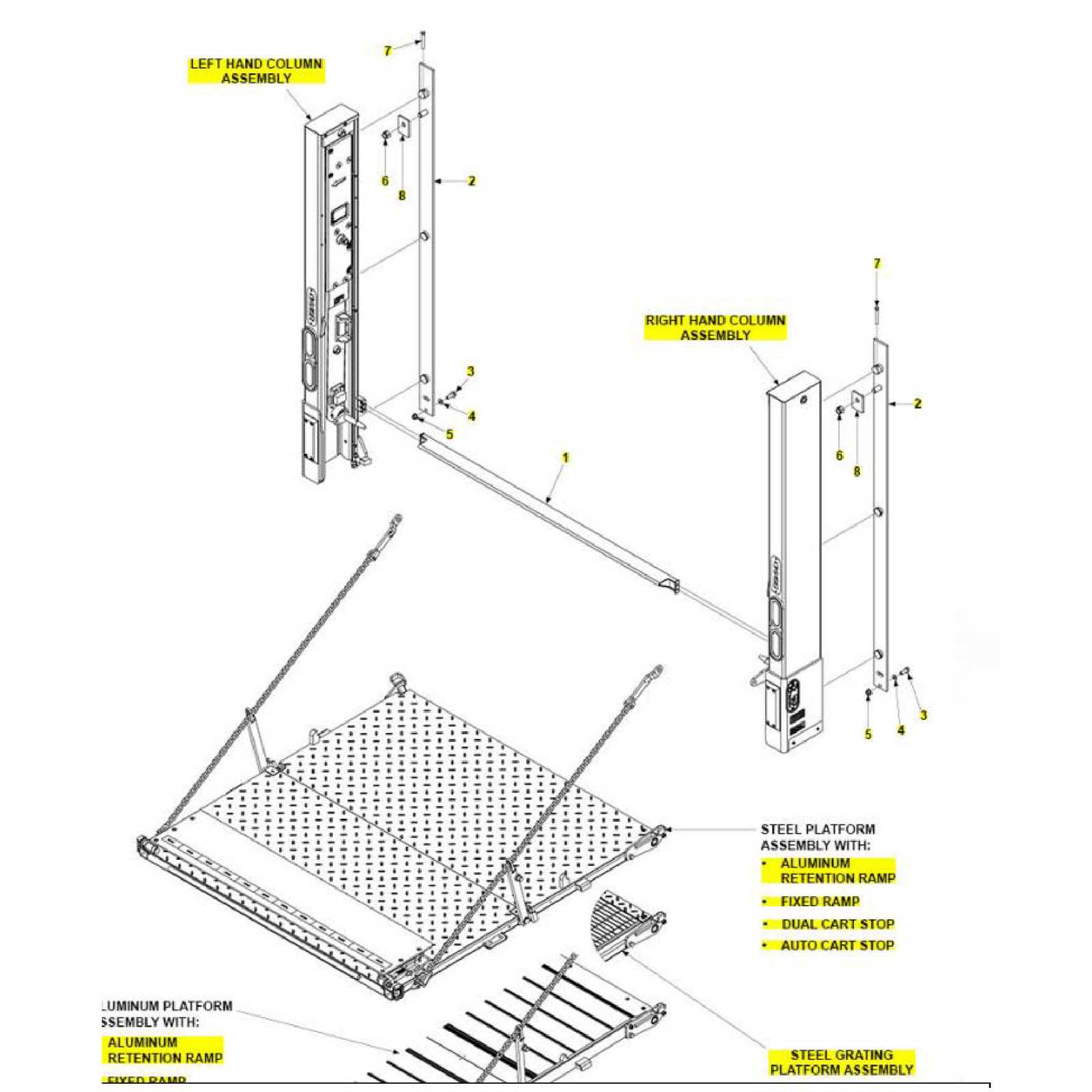

- Mounting Brackets: These secure the lift mechanism to the vehicle frame, ensuring stability and proper alignment during operation.

- Electrical Motor: The motor powers the hydraulic pump, ensuring that the necessary pressure is maintained to raise or lower the platform.

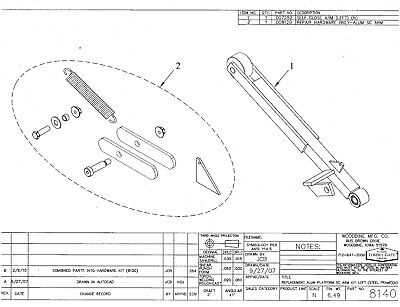

- Platform Linkage: This system of connecting arms and joints ensures the platform moves uniformly and remains stable during the lifting process.

Each of these key elements plays a crucial role in ensuring the overall functionality and reliability of the lifting system. Regular inspection and proper

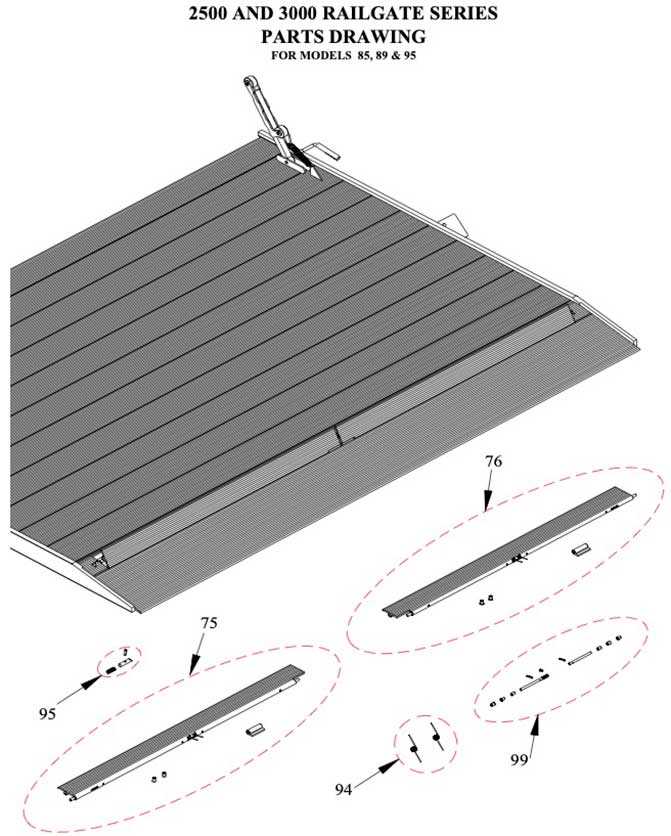

Main Components of a Tommy Liftgate

The lifting mechanism is made up of several key sections that work together to provide smooth and efficient cargo handling. Each section plays a vital role in ensuring the safe and reliable operation of the platform, allowing it to perform heavy-duty tasks with precision.

Hydraulic System: The core of the lifting functionality, this system uses hydraulic pressure to raise and lower the platform. It consists of a pump, cylinders, and hoses, all working together to ensure seamless motion.

Control Unit: This element allows the operator to easily manage the movement of the lift. It typically includes switches or buttons that engage the hydraulic system to move the platform up or down.

Platform: The surface where the cargo is loaded. It is designed to handle various types of loads, providing durability and stability during transport and operation.

Lift Arms: These components connect the platform to the hydraulic system and provide the structural support needed to move the platform. They are crucial for maintaining balance and controlling the ascent and descent.

Safety Features: Multiple safeguards are built into the system, including overload protection and locking mechanisms, to ensure secure and safe operation during heavy lifting.

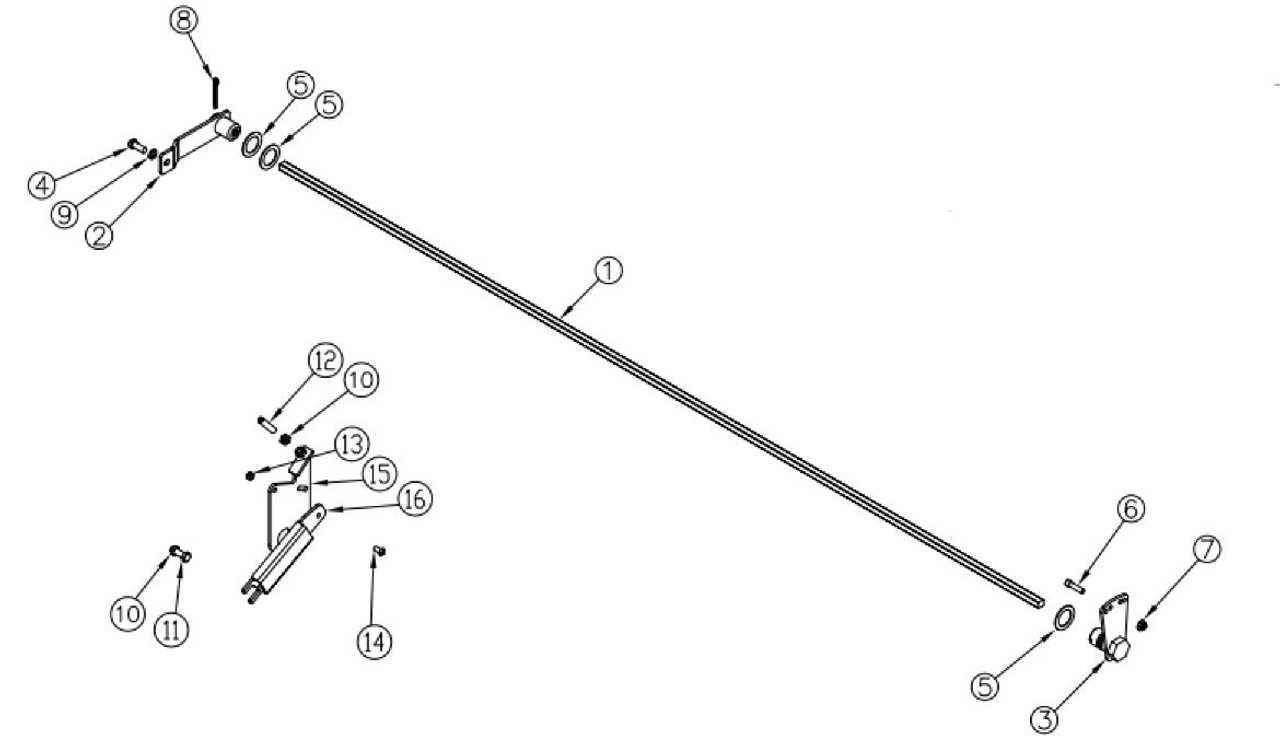

Exploring Key Mechanical Parts

In this section, we will take a closer look at the essential components that contribute to the overall functionality of the lifting system. These elements work together to ensure smooth operation and reliable performance under various conditions. Understanding the role of each component helps in maintaining optimal efficiency and addressing potential wear and tear issues effectively.

Hydraulic Cylinders play a critical role in providing the force needed for vertical motion. By converting fluid power into mechanical action, they ensure the seamless lifting and lowering of loads.

Control Levers allow the operator to manage the system’s movements. Their precise design ensures smooth and responsive handling, giving the user full control over the lifting process.

Support Arms offer stability and balance to the system during operation. These sturdy components help distribute weight evenly, preventing unnecessary strain on other elements.

Bearings and hinges facilitate smooth motion by reducing friction between moving parts. They play a vital role in ensuring that the system operates without excessive wear, enhancing durability.

By recognizing the function of these core components, it’s possible to extend the lifespan of the system and ensure consistent, reliable performance over time.

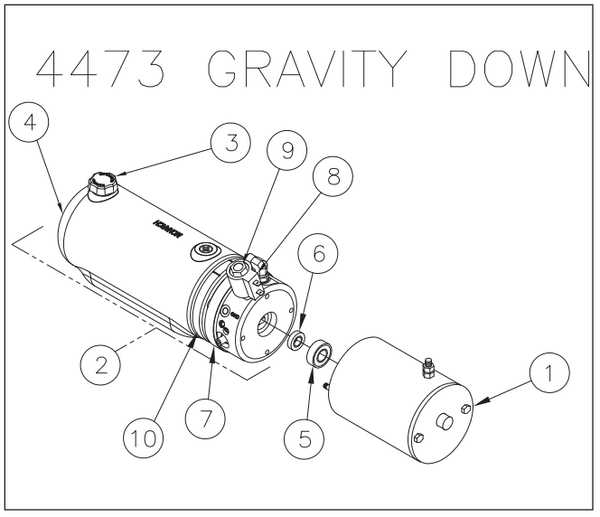

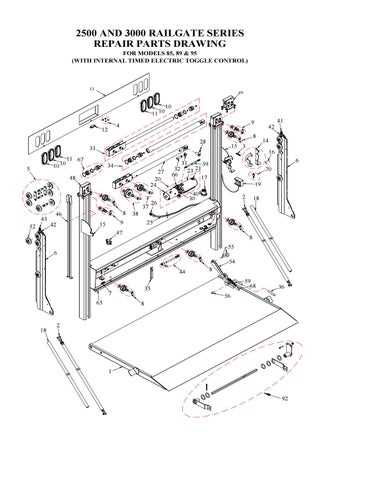

Hydraulic System Breakdown in Liftgates

The hydraulic mechanism in modern lift mechanisms plays a crucial role in ensuring smooth and reliable operation. It is designed to provide the necessary force for lifting and lowering, making it an essential component in heavy-duty loading systems. This section provides a detailed overview of how this system functions and highlights its core elements, explaining how each part contributes to overall efficiency.

| Component | Function | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pump | Responsible for creating the pressure that moves the hydraulic fluid through the system. | ||||||||||||||||||||||||||

| Hydraulic Fluid | Transmits power and lubricates the moving parts within the system. | ||||||||||||||||||||||||||

| Cylinders | Convert the hydraulic fluid’s pressure into mechanical force, enabling the platform’s movement. | ||||||||||||||||||||||||||

| Control Valve | Regulates the flow of hydraulic fluid, allowing for controlled operation of the lift. | ||||||||||||||||||||||||||

Hoses and Fittings

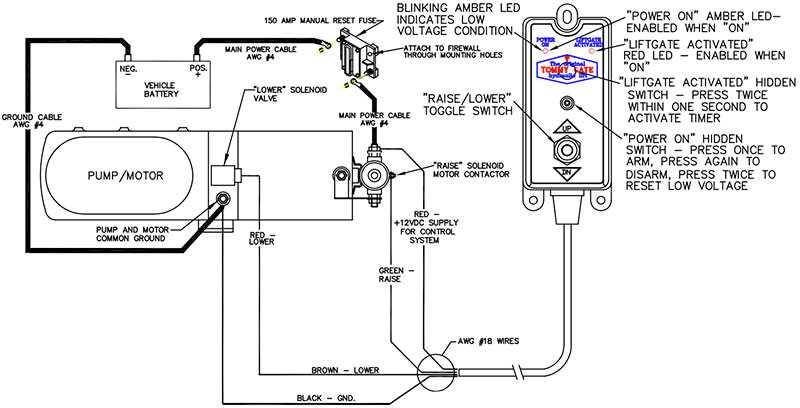

Electrical Wiring and Connections Overview

The section provides a comprehensive understanding of the overall layout of electrical components and their associated interconnections. The focus is on highlighting the key elements required to ensure a safe and functional electrical system, emphasizing the pathways and control mechanisms that guide electrical flow. Proper arrangement of wiring and secure connections are vital for the system’s performance, minimizing the risk of faults or malfunctions. Ensuring compatibility between wiring, connectors, and related components is crucial for maintaining optimal functionality.

|