In the realm of industrial machinery, a comprehensive understanding of various elements is essential for efficient operation and maintenance. Each component plays a crucial role in ensuring that the system functions smoothly and safely. Familiarity with these elements not only enhances performance but also minimizes downtime.

For those involved in the handling of heavy loads, knowledge of the different sections involved in the lifting mechanism becomes paramount. Identifying and recognizing each segment’s function can lead to improved safety measures and operational efficiency. The intricate interplay between these components dictates the overall effectiveness of the equipment.

Moreover, grasping the layout and connection between various sections allows for better troubleshooting and repair strategies. Understanding the relationships among these elements empowers operators and technicians to delve deeper into the mechanics, ultimately contributing to a more productive working environment.

Understanding Hoist Mechanisms

In the realm of lifting equipment, various systems work together to facilitate the movement and elevation of heavy loads. These systems rely on intricate designs and components that interact seamlessly to ensure efficiency and safety during operation. Understanding these mechanisms is essential for anyone involved in the use or maintenance of lifting devices.

Components of Lifting Systems

The functionality of these mechanisms depends on several key elements, each playing a critical role in the overall performance. Below is a table summarizing the main components and their functions:

| Component | Function |

|---|---|

| Motor | Provides power to lift and lower loads. |

| Drum | Houses the cable or chain used for lifting. |

| Load Block | Connects the lifting mechanism to the load being moved. |

| Controls | Allows the operator to manage lifting and lowering functions. |

Operational Principles

The operation of these systems is based on fundamental principles of physics, such as force and mechanical advantage. By employing various techniques, these devices can lift significantly heavier weights than could be managed manually. Understanding the interplay of these principles is vital for ensuring safe and effective use in various applications.

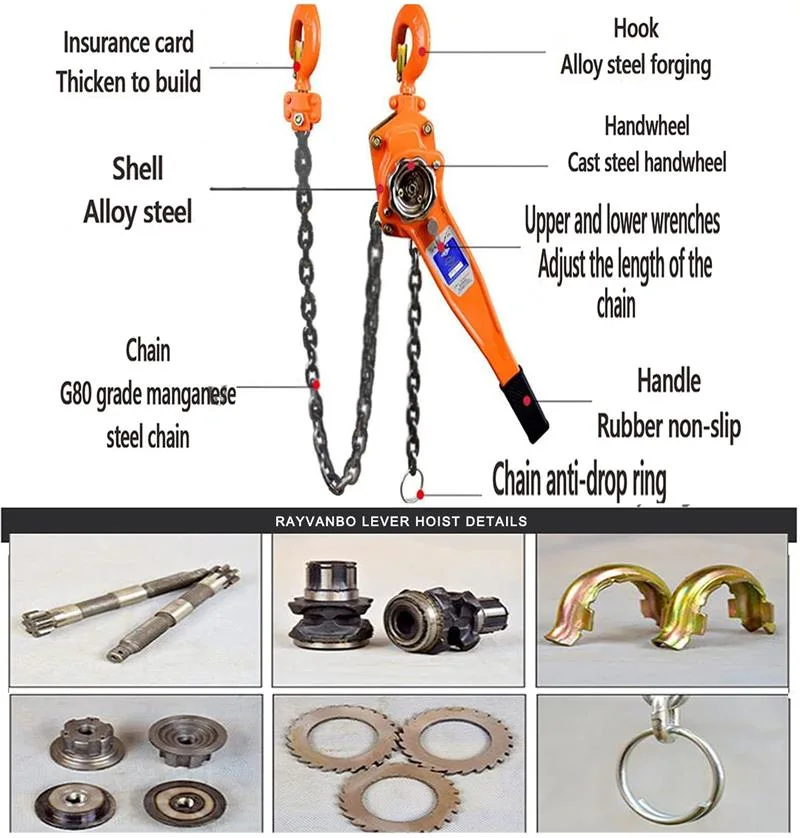

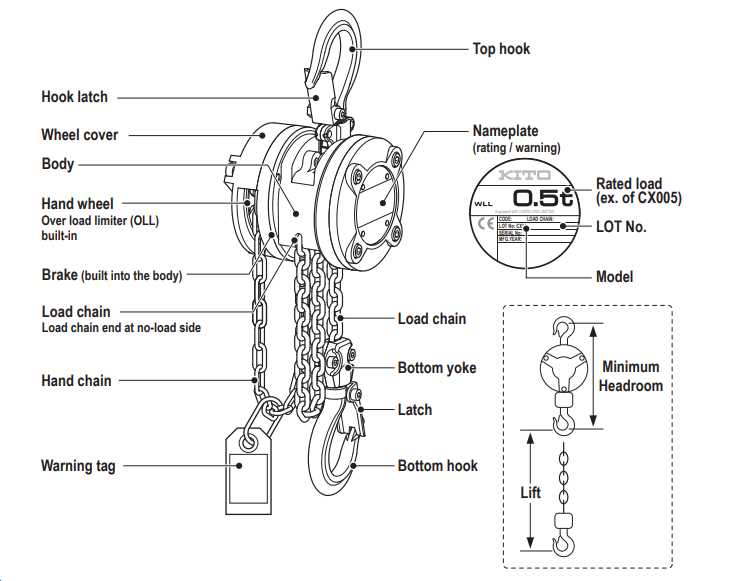

Components of a Hoist System

A lifting mechanism consists of various essential elements that work in unison to facilitate the movement of heavy loads. Each component plays a vital role in ensuring the efficiency, safety, and reliability of the entire system.

Main Elements

- Motor: The driving force behind the lifting process, converting electrical energy into mechanical motion.

- Drum: A cylindrical device around which the lifting cable is wound, crucial for managing the load’s ascent and descent.

- Chain or Cable: The medium through which the load is lifted, providing strength and flexibility.

- Control System: An interface that allows the operator to manage the lifting operation, ensuring precision and safety.

- Frame: The structural support that houses and protects all components, providing stability during operation.

Additional Components

- Brakes: Essential for stopping and holding the load in place, preventing accidental descents.

- Pulleys: Used to change the direction of the cable or chain, enhancing control and efficiency.

- Limit Switches: Safety devices that prevent over-travel by automatically stopping the mechanism at predetermined points.

- Load Sensors: Devices that monitor the weight being lifted, ensuring that the system operates within its safe limits.

Importance of Accurate Diagrams

Precise visual representations play a crucial role in the efficient operation and maintenance of machinery. They serve as essential tools for technicians and engineers, providing clarity and guidance in complex systems. The accuracy of these illustrations directly influences the ease of assembly, troubleshooting, and repair processes.

Enhanced Understanding

Clear visual guides help in breaking down intricate mechanisms, making it easier for individuals to comprehend the relationships between various components. This understanding is vital for effective training and skill development among workers, ensuring that everyone is on the same page regarding procedures and best practices.

Reduction of Errors

When illustrations are precise and detailed, the likelihood of mistakes diminishes significantly. Accurate visuals help prevent misinterpretations that could lead to improper assembly or maintenance, which in turn reduces the risk of equipment failure and enhances safety in the workplace.

| Benefits | Impact |

|---|---|

| Improved Clarity | Facilitates better understanding of complex systems |

| Training Aid | Enhances learning and skill development |

| Error Minimization | Reduces chances of mistakes during assembly |

| Increased Safety | Mitigates risks associated with equipment failure |

Common Types of Hoists Explained

In the realm of lifting equipment, various mechanisms serve to elevate and lower heavy loads efficiently and safely. Each type is designed with specific applications in mind, catering to different industries and lifting requirements. Understanding these mechanisms helps in selecting the right tool for the job.

Manual Elevators are operated by human effort, often using a chain or rope. They are ideal for smaller loads and are commonly found in workshops or garages where power access may be limited.

Electric Lifters utilize electrical power to facilitate the movement of heavier items. These systems often incorporate advanced safety features and controls, making them suitable for industrial environments where efficiency is key.

Pneumatic Systems rely on compressed air to function, providing smooth and controlled lifting. They are frequently used in automotive repair shops and assembly lines due to their quick response times and versatility.

Hydraulic Lifters employ fluid pressure to generate lifting force. This type is known for its ability to handle substantial weights with minimal effort, making it essential in construction and heavy machinery applications.

Overhead Solutions involve track-mounted systems that can traverse along a designated path. These are particularly useful in warehouses and factories, allowing for efficient movement of goods without occupying floor space.

Each of these mechanisms plays a vital role in various sectors, enhancing productivity while ensuring safety during operations. Selecting the appropriate type depends on the specific lifting needs and operational conditions.

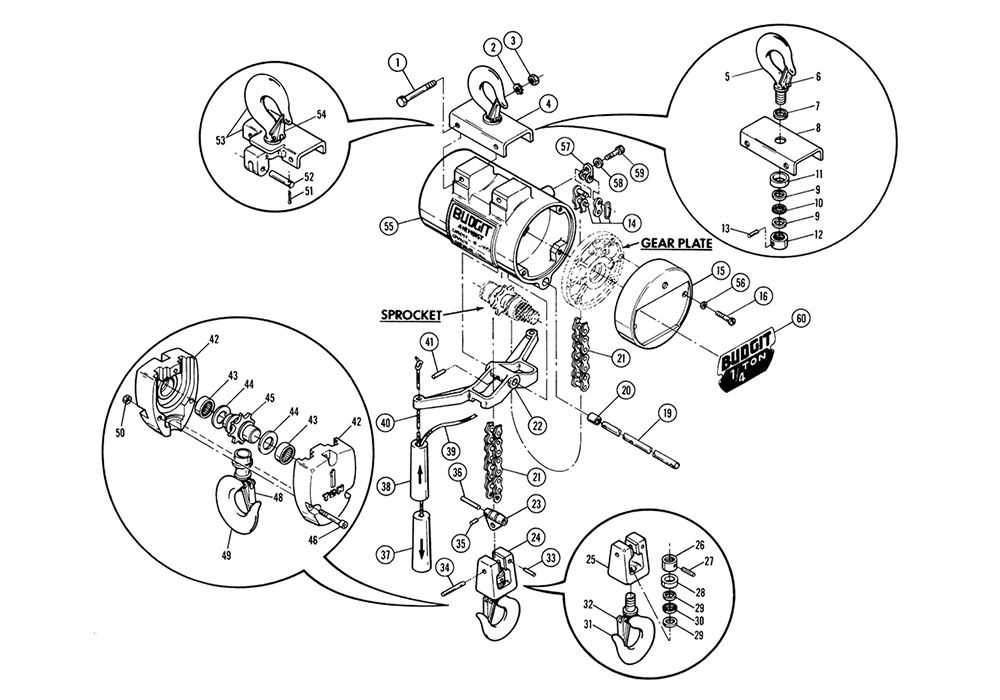

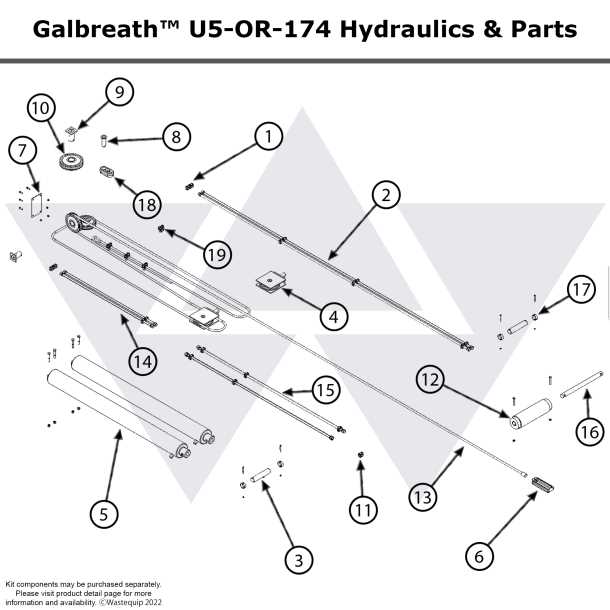

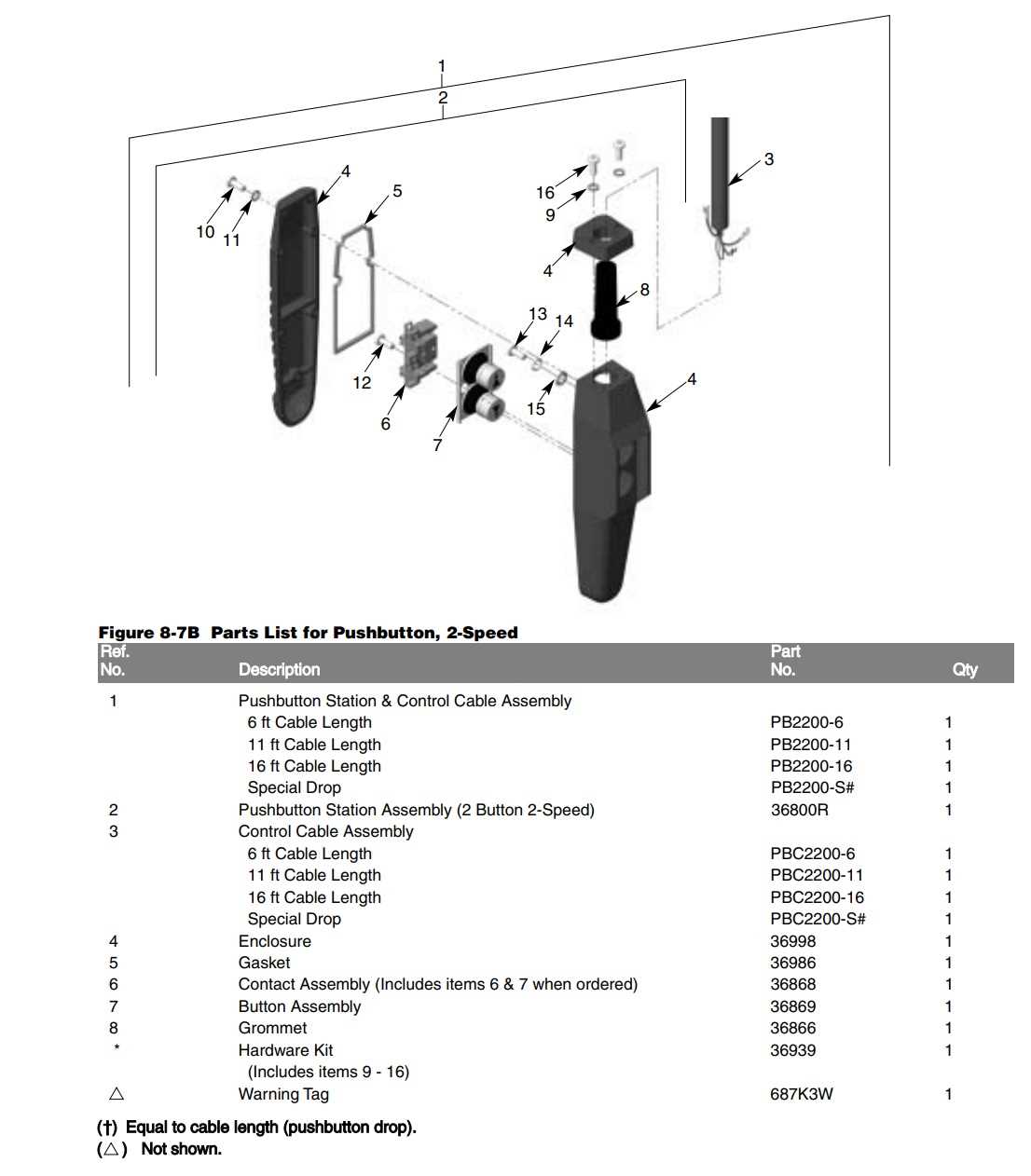

Identifying Parts in Diagrams

Understanding the components within technical illustrations is crucial for effective communication and application in various fields. Familiarity with these visuals enhances the ability to troubleshoot, assemble, or maintain equipment accurately.

When approaching these representations, it’s essential to adopt a systematic method for recognizing individual elements. Here are some strategies to aid in identification:

- Familiarize with Symbols: Each illustration uses specific symbols or shapes to represent various components. Learning these conventions is foundational.

- Reference Labels: Many visuals include labels that provide names or numbers for components. Always refer to these for precise identification.

- Understand Relationships: Analyzing how elements are interconnected can provide context that aids in recognizing their functions.

- Consult Documentation: Supplementary manuals or guides often contain detailed explanations that can clarify any ambiguities.

By applying these techniques, one can enhance comprehension and improve the efficiency of working with technical illustrations.

Maintenance Tips for Hoist Equipment

Regular upkeep of lifting equipment is crucial for ensuring safety and efficiency. Implementing a consistent maintenance routine can prevent unexpected failures and extend the lifespan of your machinery.

Routine Inspections

Conduct thorough checks on all components at scheduled intervals. Look for wear and tear, corrosion, and proper alignment. Early detection of issues can save time and resources in the long run.

Lubrication and Cleaning

Keep mechanisms well-lubricated to reduce friction and wear. Additionally, remove dirt and debris from moving parts. This practice not only enhances performance but also minimizes the risk of breakdowns.

Safety Considerations in Hoisting

Ensuring the well-being of personnel and the integrity of equipment during lifting operations is crucial. Awareness of potential hazards, adherence to regulations, and proper planning are essential components for maintaining a safe working environment. Implementing comprehensive safety measures can significantly reduce the risk of accidents and injuries.

Risk Assessment and Training

Conducting thorough evaluations of potential risks associated with lifting activities is vital. Identifying hazards such as unstable loads, environmental factors, and equipment malfunctions allows for proactive measures to be taken. Additionally, providing training for operators and personnel involved in these operations ensures that they are equipped with the necessary skills and knowledge to handle situations effectively.

Equipment Inspection and Maintenance

Regular inspection and maintenance of lifting machinery play a pivotal role in safety. Establishing a routine check-up schedule helps identify wear and tear, ensuring that all components function correctly. This practice not only prolongs the life of the equipment but also enhances overall safety during operations, preventing potential failures that could lead to serious incidents.

Resources for Hoist Parts Diagrams

Accessing comprehensive resources is essential for understanding the components and assembly of lifting equipment. This section highlights various avenues to obtain visual aids that detail the intricacies of these systems, ensuring users can effectively identify and utilize each element for maintenance and repair.

Online Platforms

- Manufacturer Websites: Many brands provide downloadable resources and technical manuals that include visual representations of their equipment.

- Industry Forums: Participating in specialized forums can yield shared resources from experienced users, including schematics and troubleshooting tips.

- Technical Blogs: Numerous professionals document their insights and may share diagrams or links to helpful resources related to lifting equipment.

Print Resources

- Technical Manuals: These books often include detailed illustrations and can be sourced from libraries or purchased online.

- Trade Magazines: Industry publications frequently feature articles that discuss equipment, often including diagrams or reference materials.

- Workshops and Seminars: Attending events can provide hands-on resources, including printed guides that detail various components.