In the realm of small machinery, grasping the intricacies of the various elements is essential for effective maintenance and repair. Each component plays a vital role in ensuring the smooth operation of the engine, contributing to its overall efficiency and longevity.

By exploring the relationships between these individual pieces, one can achieve a deeper appreciation for the mechanics involved. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions regarding upkeep and modifications.

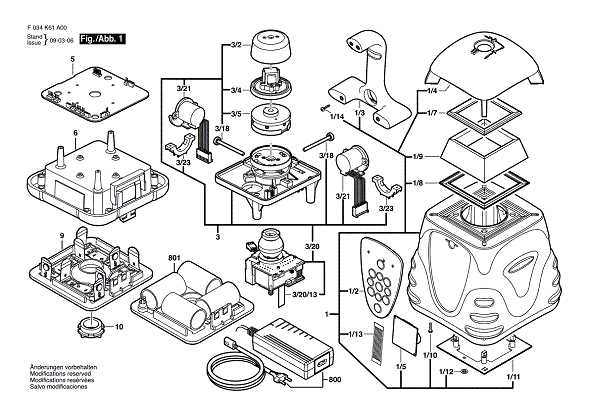

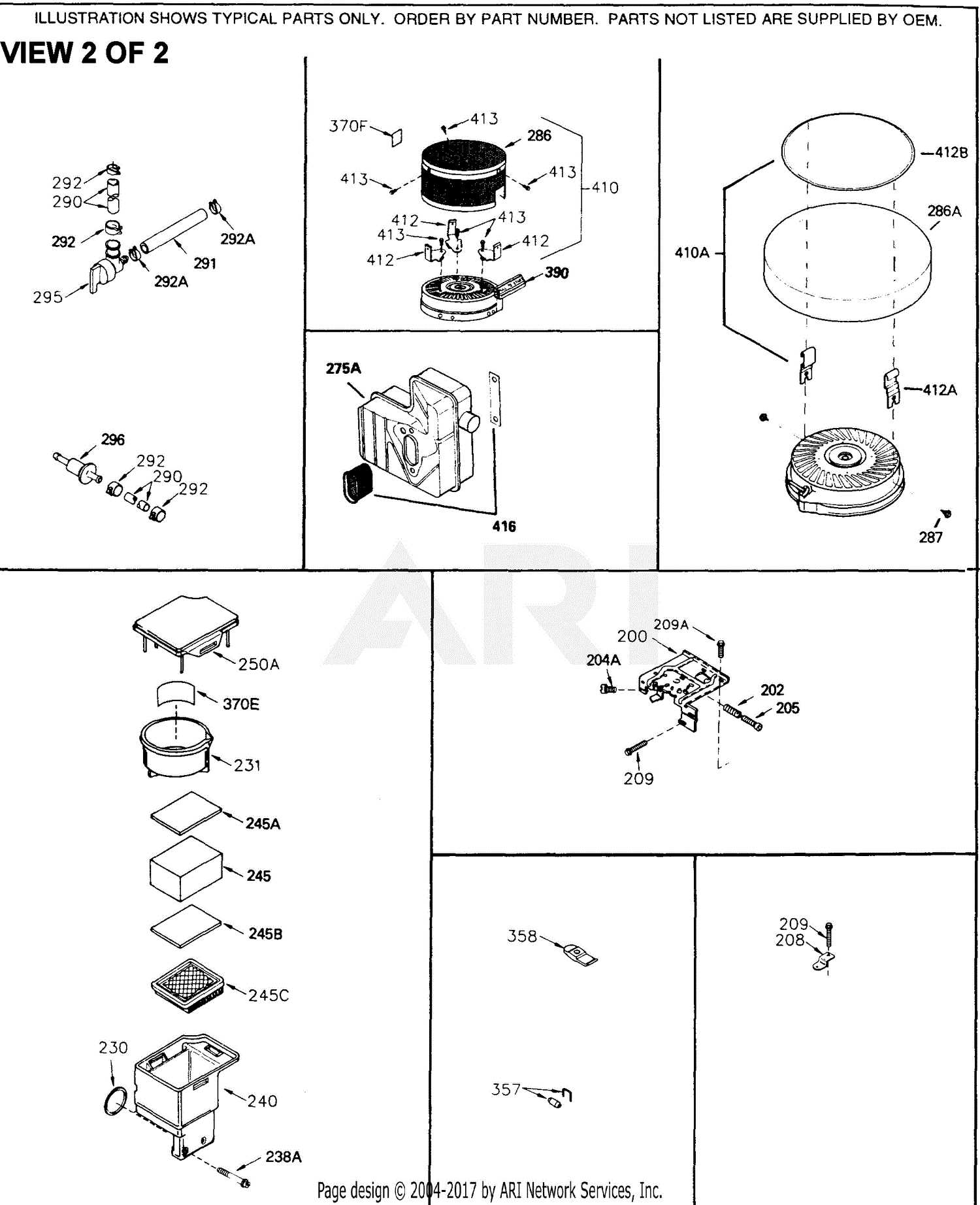

Ultimately, having access to a detailed representation of the assembly can significantly enhance the repair experience. A comprehensive overview allows both novice and seasoned users to navigate their equipment with confidence, ensuring optimal performance.

Understanding Tecumseh TC II Parts

When delving into the intricacies of small engine components, it is essential to familiarize oneself with the various elements that contribute to optimal performance. Each component plays a vital role in ensuring the smooth operation of the machinery, and understanding their functions can significantly enhance troubleshooting and maintenance efforts.

Familiarity with the individual elements allows for better assessment of any issues that may arise during operation. Identifying specific components helps users locate the source of malfunctions more efficiently, leading to quicker resolutions. This knowledge is invaluable for both novice and experienced users alike, as it empowers them to make informed decisions regarding repairs and replacements.

Moreover, comprehending the layout and connection of these elements facilitates easier assembly and disassembly, streamlining the maintenance process. Recognizing how each piece interacts within the larger system enhances overall reliability and longevity of the engine. In essence, gaining insight into these essential components equips users with the skills necessary to ensure their machinery operates at peak efficiency.

Overview of Tecumseh TC II Engine

The TC II engine series represents a significant development in small engine technology, designed to deliver reliable performance across a variety of applications. This compact powerhouse combines efficiency with ease of maintenance, making it a popular choice among enthusiasts and professionals alike.

Key Features

- Compact design suitable for various machinery

- Robust construction for enhanced durability

- Efficient fuel consumption for longer operation times

- Easy access for maintenance and repairs

Applications

This engine series is widely used in:

- Lawn care equipment

- Garden tools

- Small generators

- Various outdoor machinery

Its versatility makes it an excellent choice for both recreational and professional use, ensuring that users can rely on consistent performance in diverse conditions.

Common Issues with Tecumseh Engines

Engines of this type are widely used in various applications, from lawn care to small machinery. While they are generally reliable, users may encounter several frequent problems that can affect performance and longevity. Understanding these issues can help in troubleshooting and maintaining optimal functionality.

Fuel System Troubles

One of the primary concerns often involves the fuel delivery mechanism. Clogs in the fuel lines or a dirty carburetor can lead to inadequate fuel flow, causing the engine to run poorly or not start at all. Regular maintenance, including cleaning the fuel filter and ensuring the carburetor is free of debris, can mitigate these issues. Using fresh fuel and keeping the tank clean are also crucial steps.

Electrical Component Failures

Electrical problems can arise, particularly with the ignition system. Common symptoms include difficulty starting or a complete failure to start. Issues may stem from a faulty spark plug, damaged wiring, or a malfunctioning ignition coil. Regular inspection of these components and timely replacements can prevent more severe complications. Ensuring proper connections and maintaining the battery can further enhance reliability.

How to Access Parts Diagram

To effectively locate the visual representation of component assemblies for your equipment, understanding the procedure to access this essential resource is paramount. The process involves navigating through a structured documentation system that illustrates the intricate details of every part’s configuration.

Locating the Visual Reference

Begin by identifying the pathway leading to the visual reference that depicts the detailed breakdown of the machinery’s internal components. This visual representation serves as a crucial aid in understanding the intricate layout and interconnections among the various elements.

Once you have pinpointed the access point, delve into the structured documentation system. Here, each component’s specific location and function are elucidated, facilitating a comprehensive grasp of the machinery’s operational framework.

Utilize this resource to enhance your understanding of the equipment’s configuration, aiding in efficient troubleshooting and targeted maintenance. The visual aid provided through this documentation ensures clarity and precision in identifying and replacing components when necessary.

Identifying Key Components of TC II

Understanding the essential elements of a machinery model is crucial for efficient maintenance and operation. By familiarizing oneself with the primary components, users can ensure optimal performance and troubleshoot issues effectively. This section delves into the significant parts that constitute the TC II, offering insights into their functions and importance.

Main Elements Overview

The following list highlights the core components commonly found in the TC II model:

- Engine Assembly

- Fuel System

- Ignition System

- Cylinder Head

- Crankshaft

- Air Intake

- Exhaust System

Functionality of Each Component

Each of these key elements plays a vital role in the overall functionality:

- Engine Assembly: The heart of the machinery, responsible for converting fuel into mechanical energy.

- Fuel System: Manages the supply and mixture of fuel, ensuring efficient combustion.

- Ignition System: Initiates combustion through spark generation, critical for engine starting and operation.

- Cylinder Head: Houses valves and spark plugs, facilitating airflow and combustion processes.

- Crankshaft: Transforms linear motion from pistons into rotational motion, powering various mechanisms.

- Air Intake: Supplies air for the combustion process, essential for engine efficiency.

- Exhaust System: Channels exhaust gases away from the engine, maintaining optimal pressure and performance.

Replacement Parts for Tecumseh Engines

In this section, we explore the essential components necessary to maintain and repair engines manufactured by a renowned company. We delve into the intricacies of the internal mechanisms that power machinery, focusing on the elements crucial for optimal performance and longevity. Our examination encompasses a detailed analysis of the components responsible for fuel delivery, combustion, and mechanical motion. These items are vital for ensuring the seamless operation of your machinery, enhancing reliability and efficiency.

Key Components

- Fuel Delivery System Elements

- Mechanical Motion Components

- Combustion System Parts

We further discuss the significance of sourcing high-quality replacements to uphold the performance standards set by the manufacturer. Understanding the role each part plays in the overall functionality empowers users to make informed decisions when selecting replacements. By highlighting the importance of compatibility and durability, we assist in maintaining the integrity of your equipment, optimizing its lifespan and operational effectiveness.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life and optimal performance of any machinery. Regular attention not only enhances efficiency but also reduces the likelihood of costly repairs. Following a few straightforward practices can significantly impact the durability of your equipment.

Regular Inspections: Conduct frequent checks to identify any signs of wear or damage. Early detection of issues can prevent more severe problems from developing.

Cleanliness is Key: Keep the exterior and interior free of debris and dirt. A clean environment promotes better airflow and prevents overheating, which can lead to breakdowns.

Oil Changes: Change lubricants according to the manufacturer’s recommendations. Clean oil is crucial for reducing friction and ensuring smooth operation.

Storage Conditions: Store machinery in a dry, sheltered area to protect it from moisture and extreme temperatures. This practice helps avoid rust and corrosion.

Follow the Manual: Always adhere to the guidelines provided in the user manual. Understanding specific maintenance requirements tailored to your equipment will maximize its lifespan.

By incorporating these maintenance strategies, you can ensure that your machinery operates efficiently and serves you well for many years.

Resources for Tecumseh Parts Availability

Finding essential components for outdoor equipment can be a challenge, but numerous avenues exist to simplify this process. Various online platforms, local retailers, and specialized suppliers provide access to a wide range of items necessary for maintenance and repairs. Understanding where to look can significantly enhance your search efficiency.

| Resource Type | Description |

|---|---|

| Online Retailers | Websites dedicated to equipment supplies often offer extensive inventories and user-friendly navigation. |

| Local Dealers | Physical stores frequently carry a selection of items and can provide expert assistance and advice. |

| Specialized Suppliers | Vendors focusing on outdoor machinery often have hard-to-find components and knowledgeable staff. |

| Community Forums | Online communities can be valuable for sharing experiences and recommendations for sourcing components. |

DIY Repair Techniques for TC II

Maintaining your equipment can be a rewarding endeavor, offering both satisfaction and cost savings. Understanding essential repair techniques can empower you to tackle common issues effectively. This section will explore practical approaches to enhance the longevity and performance of your machinery.

| Technique | Description |

|---|---|

| Routine Maintenance | Regularly check and clean components to prevent buildup and ensure smooth operation. |

| Component Replacement | Identify worn parts and replace them with compatible alternatives to restore functionality. |

| Sealing Leaks | Use sealants or gaskets to fix any leaks and maintain optimal performance. |

| Fuel System Care | Keep fuel lines clean and replace filters as needed to ensure proper fuel flow. |

| Electrical Checks | Inspect wiring and connections for damage and corrosion to prevent electrical failures. |