The intricate system of a modern automobile involves numerous elements that work in harmony to ensure optimal performance and functionality. Each component plays a crucial role, and understanding their arrangement and interrelations can significantly enhance one’s knowledge of automotive mechanics. Whether you are a seasoned technician or a curious enthusiast, gaining insights into these structures can empower you to make informed decisions about maintenance and repairs.

In exploring this topic, we delve into the layout of these essential elements, providing a comprehensive overview of their specific functions and placements. By visualizing how each segment connects and interacts, you can better appreciate the complexity of automotive design. This understanding not only aids in troubleshooting but also enhances the overall driving experience by ensuring that every part operates seamlessly.

Furthermore, having a clear understanding of these mechanical components can facilitate better communication with service professionals. When you are equipped with the right knowledge, discussing issues or potential upgrades becomes much easier. In essence, familiarizing yourself with the underlying structure of your vehicle is a step towards mastering automotive care.

Understanding the Tc Encore Components

The Tc Encore model consists of various integral elements that contribute to its overall functionality and performance. Each component plays a crucial role in ensuring that the system operates efficiently and meets the desired standards. A clear comprehension of these elements is essential for users looking to optimize their experience and maintenance of the unit.

Key Elements of the Tc System

Among the critical features of this model are the structural and mechanical components that enable seamless interaction between different functionalities. These elements are designed to withstand operational stresses while providing the necessary support and stability. Understanding how each part interacts with others allows for improved troubleshooting and enhanced durability.

Maintenance and Upgrades

Regular upkeep and timely enhancements of these components are vital for sustaining peak performance. Users should familiarize themselves with the various functions and requirements of each element, ensuring that they can identify potential issues early. This proactive approach not only prolongs the lifespan of the system but also optimizes its overall efficiency.

Importance of Accurate Parts Diagrams

Precise representations of components play a crucial role in various fields, ensuring that tasks are performed efficiently and effectively. Clarity in these illustrations not only aids in identification but also fosters a deeper understanding of the entire assembly process.

Facilitating Maintenance and Repairs

Having reliable visuals simplifies troubleshooting and repair efforts. Technicians can quickly locate faulty elements, streamlining the process and reducing downtime. This ultimately leads to enhanced operational efficiency.

Enhancing Communication

Clear depictions bridge gaps between manufacturers and users, promoting better communication. When everyone has access to accurate visuals, it minimizes misunderstandings and enhances collaboration, resulting in improved outcomes.

Common Issues with Tc Encore Models

Various challenges may arise with specific vehicle models, impacting performance and user experience. Understanding these common pitfalls can assist owners in maintaining optimal functionality and prolonging the lifespan of their automobiles.

Frequent Mechanical Problems

- Engine performance issues

- Transmission difficulties

- Suspension malfunctions

Electrical and Technology Concerns

- Battery drainage

- Sensor failures

- Navigation system glitches

By addressing these typical issues proactively, owners can ensure a smoother driving experience and enhance vehicle reliability.

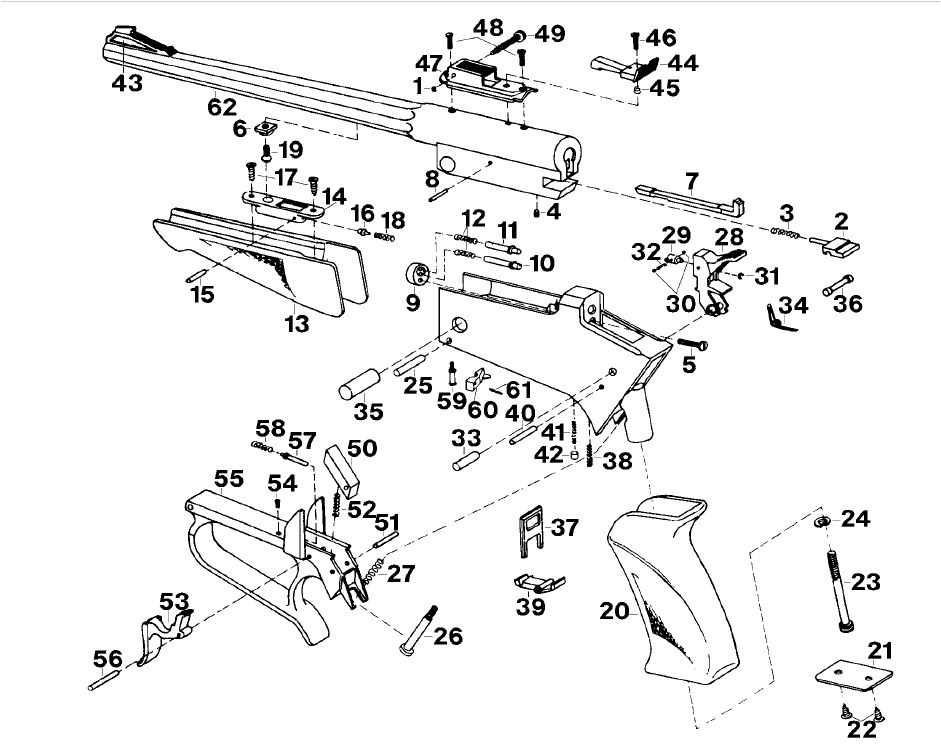

How to Read a Parts Diagram

Understanding a schematic representation can significantly enhance your ability to identify and manage components within a system. This section will guide you through the essentials of interpreting these visual tools effectively.

To begin, familiarize yourself with the key elements:

- Symbols: Each icon or mark corresponds to a specific item or function.

- Labels: These provide crucial information regarding the identification and specifications of each component.

- Connections: Lines or arrows indicate how different parts interact or relate to one another.

Follow these steps to enhance your comprehension:

- Start by identifying the legend or key that explains the symbols used.

- Trace each connection to see how components link together.

- Take note of any numerical codes or annotations that provide further detail.

By mastering these techniques, you will ultimately improve your ability to troubleshoot and maintain various systems effectively.

Locating Replacement Parts Efficiently

Finding suitable components for repairs can often be a daunting task, yet it is essential for maintaining the functionality of any machine. An organized approach can streamline this process, ensuring that you spend less time searching and more time restoring performance.

Utilizing Online Resources

Many websites specialize in providing detailed listings of components, often accompanied by specifications and compatibility information. Leveraging these platforms can save you significant time. Make use of search filters to narrow down options based on your needs. Additionally, customer reviews can offer valuable insights into the reliability and performance of various items.

Consulting with Professionals

Engaging with experts in the field can prove beneficial. They often possess extensive knowledge about suitable replacements and can recommend trustworthy suppliers. Moreover, they might have access to proprietary resources that are not widely available, enhancing your chances of finding the perfect fit.

In summary, adopting a systematic approach to sourcing replacements can greatly enhance your efficiency. Whether through online exploration or expert consultation, the right strategy can lead you to the components you need with minimal hassle.

Comparing Tc Encore to Other Models

When assessing the various offerings in a particular segment, it is essential to examine the distinctive features and functionalities that set each model apart. This analysis provides valuable insights into how different systems cater to the needs of their users, highlighting strengths and weaknesses across the board.

One prominent model distinguishes itself through its robust construction and superior performance metrics. While both systems may share similar aesthetic qualities, the underlying technology often varies significantly. The first system may offer advanced features that enhance usability, while the second might focus on efficiency and reliability.

Moreover, user feedback plays a crucial role in this comparison. Many individuals appreciate the intuitive interface of one model, which simplifies operation and minimizes the learning curve. In contrast, another system may provide a more customizable experience, appealing to those who prefer tailoring their devices to specific preferences.

In terms of maintenance and support, differences also emerge. Some models are celebrated for their accessibility to replacement components, ensuring that users can easily find what they need when repairs are necessary. Others, however, may require specialized knowledge or tools, complicating the maintenance process and potentially leading to increased downtime.

Ultimately, understanding these nuances allows potential buyers to make informed decisions based on their unique requirements and preferences. By evaluating each option’s capabilities, users can select the model that best aligns with their expectations and lifestyle.

Maintenance Tips for Longevity

Ensuring the extended lifespan of any equipment requires diligent care and attention. Regular maintenance not only enhances performance but also prevents unexpected breakdowns, ultimately saving time and resources. Implementing a structured routine can significantly contribute to the durability and efficiency of your machinery.

Regular Inspections

Conducting frequent evaluations is crucial in identifying potential issues before they escalate into major problems. Inspecting components for signs of wear or damage can help maintain optimal functionality. Pay close attention to critical areas, ensuring everything is operating smoothly and efficiently. Additionally, documenting these inspections can aid in tracking performance trends over time.

Proper Cleaning and Lubrication

Keeping machinery clean and well-lubricated is essential for its operation. Dust, dirt, and debris can lead to overheating and wear, while appropriate lubrication minimizes friction and enhances performance. Make it a habit to follow manufacturer guidelines for cleaning and lubrication schedules. This proactive approach can greatly extend the life of your equipment and maintain its reliability.

Expert Recommendations for Repairs

When it comes to maintaining and restoring your equipment, adhering to expert guidance can significantly enhance performance and longevity. Whether you’re dealing with mechanical issues or system malfunctions, following reliable suggestions is essential for achieving effective repairs.

Here are some key recommendations to consider when undertaking repairs:

- Assess the Issue Thoroughly: Begin by identifying the root cause of the malfunction. A comprehensive understanding of the problem is crucial for an effective solution.

- Use Quality Components: Opt for high-grade materials that meet or exceed original specifications. This choice can prevent future failures and ensure optimal functionality.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s instructions and recommendations when performing repairs. These guidelines often include important safety information and best practices.

- Keep a Clean Workspace: Maintain an organized and tidy repair area. A clean environment reduces the risk of contamination and ensures that tools and parts are easily accessible.

- Document the Process: Keep a detailed record of the repair steps taken, including any components replaced. This documentation can be invaluable for future reference and troubleshooting.

By following these expert recommendations, you can ensure that your repair efforts yield successful and lasting results. Taking the time to plan and execute repairs thoughtfully will ultimately enhance the reliability of your equipment.

Future Trends in Tc Encore Design

The evolution of design principles within the industry is set to undergo significant transformations in the coming years. As technology progresses, innovative methodologies will emerge, leading to enhanced efficiency and functionality. Stakeholders are increasingly focused on sustainability, user experience, and integration of advanced technologies.

Emphasis on Sustainability

One of the most critical trends will be the shift toward eco-friendly practices. Designers are likely to prioritize materials and processes that reduce environmental impact. This change not only appeals to environmentally conscious consumers but also aligns with global regulations aimed at sustainability.

Integration of Smart Technologies

The integration of smart technologies will redefine the interaction between users and their environments. By incorporating IoT devices and automation, designs will become more intuitive and responsive. This trend is expected to enhance usability and create a seamless experience for end-users.

| Trend | Description |

|---|---|

| Sustainability | Focus on eco-friendly materials and processes. |

| Smart Technology | Incorporation of IoT and automation for enhanced usability. |

| User-Centric Design | Prioritizing user experience and feedback in the design process. |

| Modular Systems | Developing flexible and adaptable solutions for diverse needs. |