In the realm of outdoor equipment, the intricacies of mechanical assemblies play a vital role in enhancing efficiency and performance. Each element, whether large or small, contributes significantly to the overall functionality of the machine. A comprehensive grasp of these components enables users to maintain and optimize their equipment effectively.

For those delving into the mechanics of such machinery, visual representations serve as invaluable tools. They provide clarity and detail, allowing operators to identify specific sections and understand their interrelations. Ultimately, familiarizing oneself with these schematics ensures better upkeep and troubleshooting.

Moreover, recognizing the nuances of each component can lead to informed decisions regarding replacements and upgrades. Armed with this knowledge, users can prolong the lifespan of their machinery and enhance its operational capabilities, achieving the ultimate performance in wood processing tasks.

Understanding Swisher Log Splitter Components

The efficient operation of wood processing equipment relies heavily on its various elements. Each component plays a crucial role in ensuring that the machinery functions smoothly and effectively. Understanding these individual parts can greatly enhance the user’s ability to maintain and troubleshoot the system.

Power Source: The energy generator, whether electric or gas-powered, serves as the heart of the mechanism. It provides the necessary force to drive the entire operation.

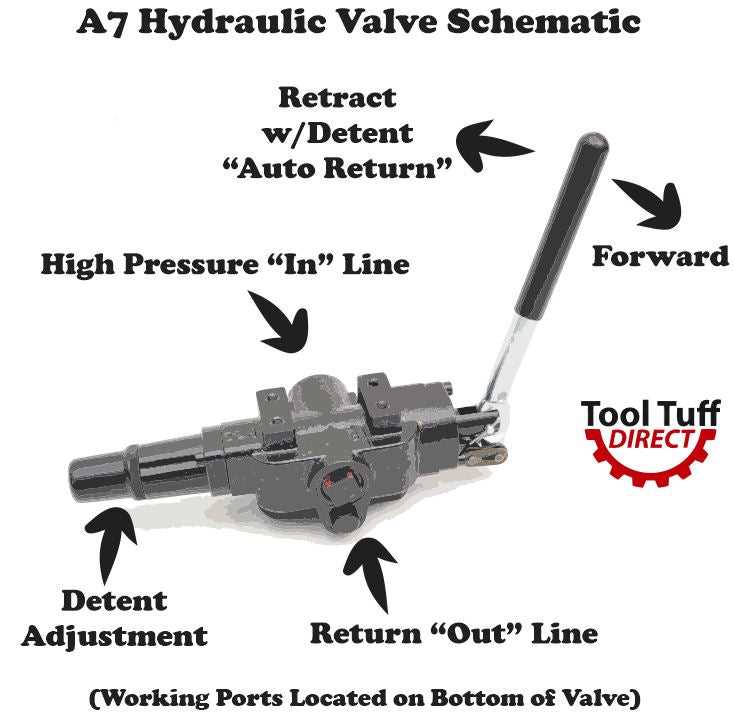

Hydraulic System: This system is vital for converting the power generated into the necessary force to perform cutting. It utilizes hydraulic fluid to transmit energy efficiently.

Frame: The structural foundation supports all components and ensures stability during operation. A robust design is essential for durability and performance.

Cutting Wedge: This sharpened element is designed to penetrate the wood and facilitate splitting. Its shape and material significantly influence efficiency.

Controls: User interfaces allow operators to manage the machine’s functions, enhancing safety and precision during use. Understanding the controls is essential for effective operation.

By delving into the individual components and their functions, users can gain insights that lead to improved performance and longevity of the equipment. Each part contributes to the ultimate efficiency of the wood processing process.

Importance of Parts Diagrams

Visual representations of components are essential for understanding complex machinery. They serve as a guide for users to identify individual elements and comprehend their functions within a system.

Enhancing Maintenance and Repair

Accurate visual aids streamline maintenance processes and troubleshooting. They provide the following benefits:

- Clear identification of each component

- Facilitation of timely repairs

- Reduction of errors during reassembly

Supporting Efficient Assembly

Using detailed visuals can greatly improve assembly efficiency. This includes:

- Minimizing assembly time

- Ensuring proper alignment of parts

- Enhancing overall safety during the assembly process

Common Issues with Log Splitters

When using machinery designed for cutting wood, several challenges may arise that can affect performance and efficiency. Identifying these problems early can prevent further complications and enhance longevity.

1. Hydraulic Problems: One frequent issue involves the hydraulic system, where leaks or low fluid levels can hinder operation. Regular checks and maintenance of the hydraulic fluid are essential to ensure optimal function.

2. Worn Blades: Over time, the cutting edge may become dull, resulting in inefficient performance. Regular sharpening or replacement is crucial for effective operation.

3. Engine Malfunctions: Mechanical failures can occur, often due to lack of maintenance. Ensuring regular oil changes and inspections can mitigate these risks.

4. Safety Features: If safety mechanisms fail, the risk of injury increases. Routine inspections of these components are necessary to maintain safe usage.

5. Stalling Issues: Machines may stall under excessive load. Understanding the maximum capacity and avoiding overload can help maintain smooth operation.

By addressing these common challenges, users can enhance the performance and safety of their wood processing equipment.

Maintenance Tips for Swisher Equipment

Ensuring the longevity and efficiency of outdoor machinery requires regular attention and care. Following a systematic maintenance routine not only enhances performance but also minimizes the risk of unexpected breakdowns. Here are some essential tips to keep your equipment in optimal condition.

Regular Inspection

- Check for loose bolts and connections.

- Inspect hoses and belts for wear or damage.

- Examine the cutting components for sharpness and alignment.

Cleaning Procedures

- Remove debris and buildup from surfaces after each use.

- Clean air filters regularly to ensure proper airflow.

- Use a suitable lubricant on moving parts to reduce friction.

By following these practices, you can ensure that your outdoor equipment remains reliable and efficient for years to come.

Identifying Worn-Out Parts

Recognizing components that have deteriorated is crucial for maintaining optimal performance of your machinery. Proper inspection can prevent further damage and ensure efficient operation. Key indicators often include unusual noises, decreased efficiency, and visible wear. Understanding these signs can help you take timely action.

| Indicator | Description |

|---|---|

| Unusual Noises | Grinding or rattling sounds may suggest that parts are failing or misaligned. |

| Decreased Efficiency | A noticeable drop in performance can indicate that components are not functioning as intended. |

| Visible Wear | Cracks, chips, or significant discoloration often point to excessive use or damage. |

Ordering Replacement Parts Online

Finding the right components for your machinery has never been easier, thanks to the convenience of online shopping. With a few clicks, you can access a wide range of options and have your essential items delivered straight to your doorstep. Understanding the process can save you time and ensure you get exactly what you need.

Steps to Follow

- Identify the specific components required for your equipment.

- Research reliable online retailers that specialize in these items.

- Utilize part numbers or descriptions for accurate searching.

- Compare prices and check customer reviews for quality assurance.

- Place your order and keep track of shipping details.

Tips for Successful Ordering

- Double-check compatibility with your machine model.

- Look for warranties or guarantees on the products.

- Be aware of return policies in case of errors.

- Consider bulk purchasing for future needs, if applicable.

DIY Repairs: Tools Needed

Undertaking maintenance or repair tasks at home can be rewarding and cost-effective. Having the right tools is essential to ensure the job is done efficiently and safely. This section outlines the necessary instruments that will help you tackle common repair projects with confidence.

Essential Tools for Repairs

- Wrenches: A variety of sizes will accommodate different fasteners.

- Screwdrivers: Both flathead and Phillips types are necessary for various screws.

- Hammer: Useful for driving nails or adjusting components.

- Pliers: Ideal for gripping and manipulating small objects.

- Measuring Tape: Ensures accuracy in measurements for cuts and fittings.

- Utility Knife: Versatile for cutting materials cleanly.

Safety Equipment

- Safety Glasses: Protect your eyes from debris.

- Gloves: Provide grip and protect your hands from sharp edges.

- Ear Protection: Useful when working with loud machinery.

By gathering these essential and safety tools, you’ll be well-prepared to handle most repair tasks effectively and safely.

Swisher Warranty and Support Options

Understanding the coverage and assistance available for your equipment is essential for ensuring long-term satisfaction and functionality. This section provides an overview of the guarantees and support services offered to customers, aimed at enhancing the ownership experience.

The warranty typically covers various components and provides peace of mind against manufacturing defects. It’s crucial to be aware of the terms to maximize the benefits.

- Coverage Duration: Most warranties span several years, varying based on the type of product.

- Components Covered: Key parts are often included, while some exclusions may apply.

- Transferability: Warranties may be transferable if the equipment is sold to a new owner.

In addition to warranty coverage, customer support plays a vital role in addressing inquiries and resolving issues.

- Contact Methods: Support can be accessed through phone, email, or online chat.

- Resources Available: Documentation, FAQs, and troubleshooting guides are commonly provided to assist users.

- Service Centers: Authorized locations may offer repairs and maintenance services.

For optimal support, it’s advisable to register your equipment promptly after purchase, ensuring you receive updates and notifications regarding service and warranty claims.

Enhancing Performance with Upgrades

Improving efficiency and functionality in machinery can significantly enhance overall productivity. By implementing targeted modifications, users can experience greater output, reduced operational time, and increased longevity of their equipment. Below are several avenues to consider when aiming to elevate performance.

- Power Enhancements:

- Upgrading the engine for higher horsepower can lead to faster operation.

- Incorporating a more efficient fuel system improves energy consumption.

- Hydraulic System Improvements:

- Replacing older pumps with high-performance alternatives boosts speed and force.

- Utilizing better hoses and fittings can minimize leaks and increase flow efficiency.

- Durability Additions:

- Using reinforced materials for key components enhances resistance to wear and tear.

- Coating surfaces with protective layers can extend the lifespan of machinery.

- Safety Features:

- Integrating advanced safety mechanisms reduces the risk of accidents.

- Implementing ergonomic designs ensures user comfort and minimizes fatigue.

By exploring these potential upgrades, operators can tailor their equipment to better meet specific needs and challenges, ensuring a more efficient and safer working environment.