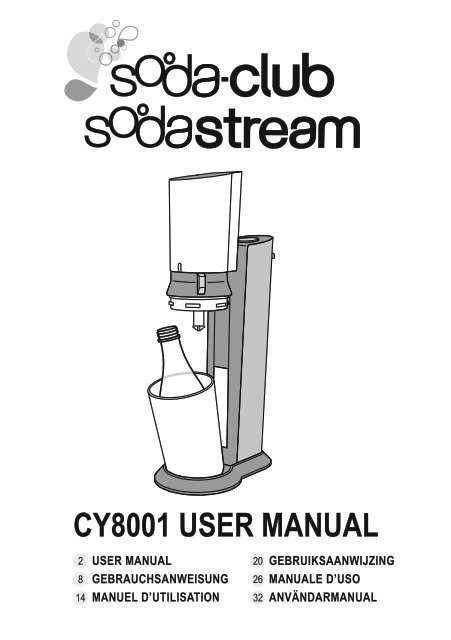

When it comes to creating refreshing fizzy beverages at home, having a solid grasp of the essential elements of your carbonation device can greatly enhance your experience. Each piece plays a crucial role in ensuring optimal performance and longevity, allowing you to enjoy sparkling drinks with ease. Understanding how these individual parts interact can also assist in troubleshooting common issues.

In this guide, we will explore the various components that make up these innovative machines. From the carbonation chamber to the gas cylinder, every element contributes to the functionality of the system. Recognizing their layout and connection will empower you to maintain and operate your device more effectively.

Whether you’re a newcomer to this world or a seasoned user looking to deepen your knowledge, familiarizing yourself with the intricate structure of your machine is a valuable step. Dive into the details and discover how each segment contributes to the delightful effervescence of your favorite beverages.

Understanding Sodastream Components

The carbonation process involves several essential elements that work together to create refreshing, fizzy beverages. A deeper insight into these components reveals how each part contributes to the overall functionality of the machine, ensuring a seamless user experience.

Main Elements of the System

Here are the key components involved in the carbonation process:

- Carbonation Cylinder: This is the heart of the system, responsible for infusing the liquid with carbon dioxide.

- Filling Mechanism: Facilitates the transfer of the beverage into the carbonation chamber.

- Carbonation Chamber: Where the magic happens, as the gas is dissolved into the liquid.

- Dispensing Tap: Allows the user to pour the finished drink easily.

- Pressure Regulator: Maintains the optimal pressure levels throughout the process.

Understanding Each Component’s Role

Each part plays a significant role in the overall operation:

- The carbonation cylinder is filled with high-pressure gas, which is crucial for creating carbonation.

- The filling mechanism ensures that the beverage is introduced without spills or leaks.

- In the carbonation chamber, the mixture undergoes a transformation as the gas penetrates the liquid.

- The dispensing tap provides a user-friendly way to enjoy the fizzy beverage without hassle.

- Lastly, the pressure regulator ensures consistent results, making each use as effective as the last.

Understanding these components can enhance your appreciation of the carbonation experience and ensure you get the best results every time you use your machine.

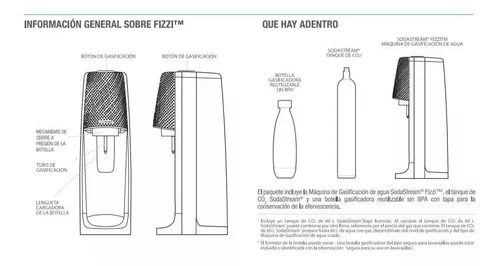

How to Identify Main Parts

Understanding the essential components of your carbonation system can enhance your experience and ensure optimal performance. Each element plays a crucial role in the process of creating fizzy beverages, and knowing them will help you troubleshoot or maintain your equipment effectively.

Key Components Overview

The system typically consists of a pressurized container, a carbonation mechanism, and a connector. Familiarizing yourself with these units will allow you to recognize any issues quickly and understand how they interact to produce your favorite drinks.

Maintenance and Care

Functionality of Each Component

This section explores the roles and operations of various elements within the carbonation system, emphasizing how they work together to create refreshing beverages. Each component plays a crucial part in ensuring the efficiency and effectiveness of the carbonation process, contributing to a delightful user experience.

Key Components

- Carbonation Cylinder: This is the source of carbon dioxide, responsible for infusing the liquid with bubbles.

- Filling Mechanism: Facilitates the smooth introduction of gas into the liquid, controlling the pressure and ensuring optimal saturation.

- Sealing Lid: Prevents gas escape during the carbonation process, maintaining the desired pressure for effective carbonation.

- Bottle: Holds the liquid and provides a vessel for carbonation, designed to withstand the pressure created during the process.

Operational Synergy

Each part works in harmony to deliver a consistent carbonation experience. The cylinder releases gas through the filling mechanism, while the sealing lid keeps everything contained. The specially designed bottle accommodates the high-pressure environment, allowing for effective carbonation without leaks. Together, these elements ensure that every drink is fizzy and refreshing.

Common Issues with Sodastream Devices

Many users encounter various challenges when operating their carbonation systems. Understanding these common problems can help in troubleshooting and maintaining optimal performance. Below are some frequently reported issues and their potential solutions.

Carbonation Problems: One of the most prevalent issues is insufficient carbonation. This may result from an empty CO2 cylinder or a faulty nozzle. Ensuring the cylinder is properly connected and replacing it if necessary can often resolve this.

Leakage: Another common concern is the presence of leaks. These can occur at the connection points or within the device itself. Inspecting seals and connections for wear and tear, and tightening any loose components can help eliminate leaks.

Unresponsive Buttons: Users sometimes find that the control buttons do not respond. This may be due to a buildup of residue or moisture. Cleaning the interface gently with a soft cloth can restore functionality.

Inconsistent Fizz: Achieving the desired level of fizziness can be tricky. If the carbonation level fluctuates, it may be worth checking the machine’s settings and ensuring the bottle is securely locked in place before starting the process.

Overheating: Some devices may overheat during prolonged use. It’s advisable to allow the machine to cool down between uses to prevent potential damage and ensure longevity.

By recognizing these common issues and their remedies, users can enhance their experience and prolong the life of their carbonation system.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your carbonation device requires attention to detail and regular upkeep. By following simple yet effective maintenance practices, you can enhance performance and extend the life of your equipment, making your sparkling beverage experience consistently enjoyable.

Regular Cleaning

Keeping your equipment clean is essential for optimal operation. Residue build-up can lead to malfunctions and affect taste. Follow these steps for effective cleaning:

| Step | Description |

|---|---|

| 1 | Disconnect and empty the device. |

| 2 | Use a damp cloth to wipe the exterior. |

| 3 | Clean the carbonating cylinder area with a gentle brush. |

| 4 | Rinse all removable parts with warm water. |

Proper Storage

When not in use, store your device in a cool, dry place. Avoid direct sunlight and extreme temperatures, as these conditions can damage internal components. Ensuring that the equipment is stored properly will help maintain its integrity and performance.

Replacement Parts and Upgrades

Maintaining and enhancing your carbonation system is essential for optimal performance and longevity. Over time, certain components may wear out or become less efficient, prompting the need for replacements. Additionally, various upgrades can significantly improve functionality, offering a better user experience. This section explores options for replacements and enhancements to keep your device running smoothly.

Common Replacement Components

When it comes to replacements, several elements are frequently needed to ensure continued efficiency. Here are some key components to consider:

| Component | Description |

|---|---|

| Carbonation Cylinder | Essential for providing the gas needed to carbonate liquids. |

| Sealing Gasket | Ensures a tight seal to prevent leaks during the carbonation process. |

| Fountain Nozzle | Facilitates the dispensing of carbonated beverages, affecting flow rate. |

Enhancements for Better Performance

In addition to replacing worn parts, users may seek upgrades to enhance their carbonation experience. Some options include:

| Upgrade | Benefit |

|---|---|

| Advanced Nozzle | Improves gas dispersion for a finer bubble size, enhancing taste. |

| Reusable Carbonation Bottles | Eco-friendly option that reduces waste while maintaining beverage quality. |

| Customizable Flavors | Allows users to experiment with different flavors for personalized drinks. |

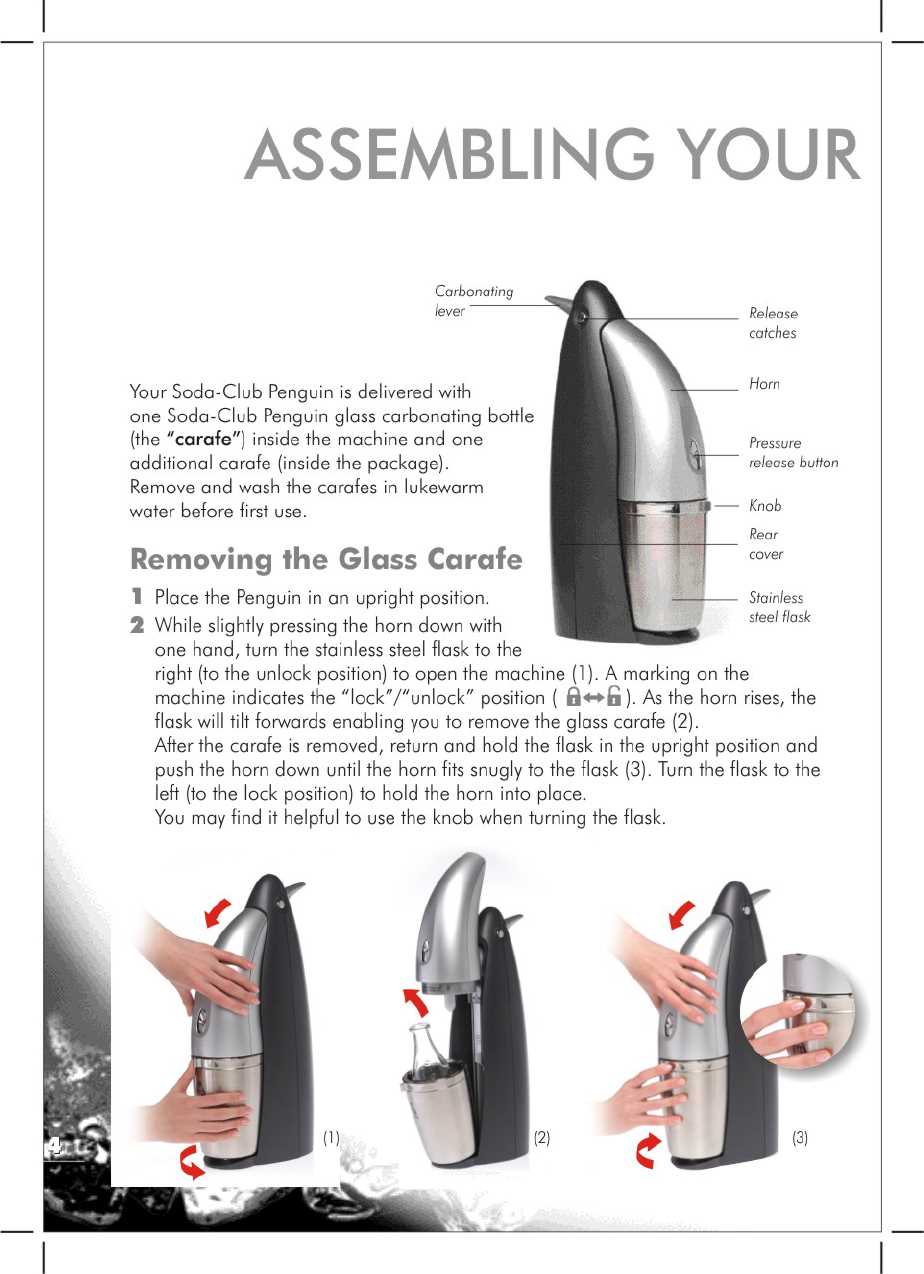

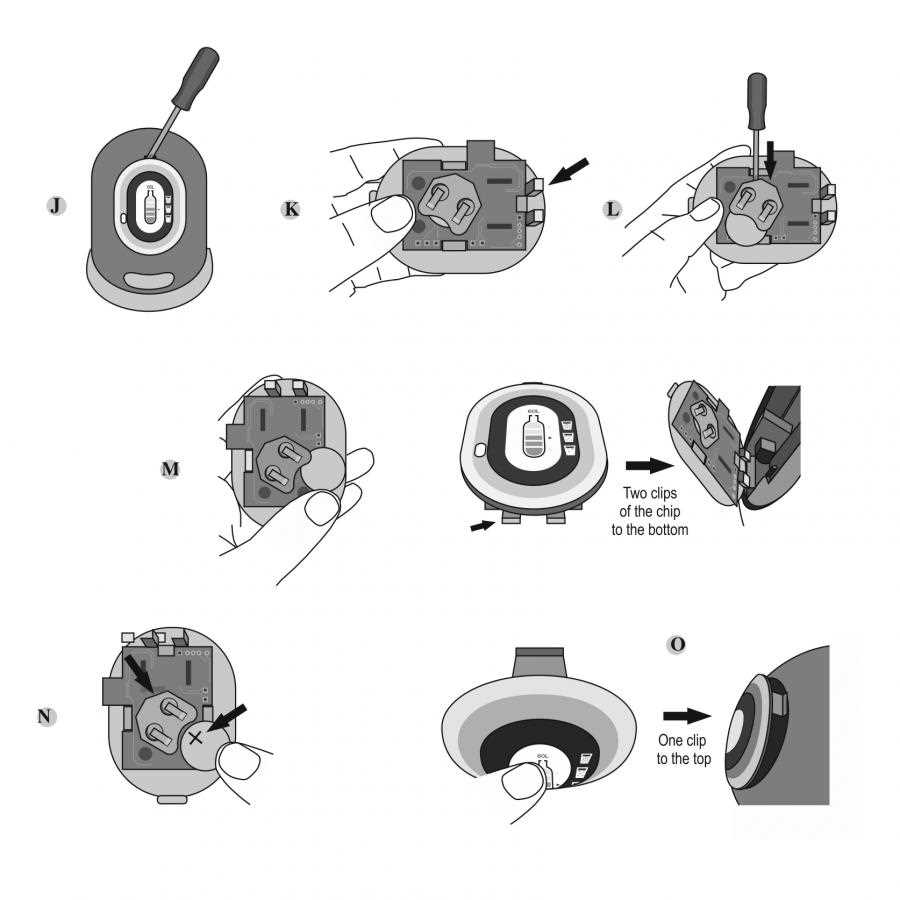

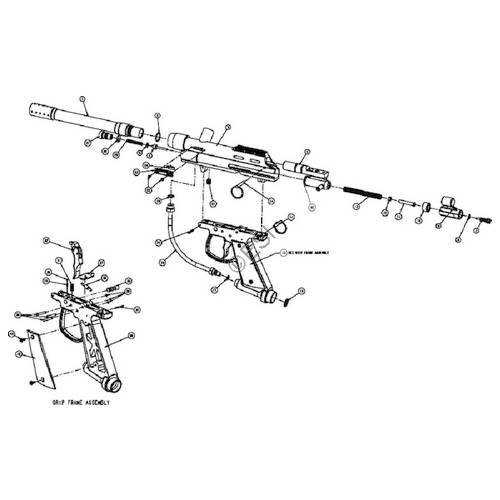

Visual Guide to Assembly

This section provides a comprehensive overview for assembling your carbonation device, ensuring a smooth and efficient setup process. With clear illustrations and concise instructions, you’ll be able to navigate the components effortlessly.

Begin by identifying the main elements of the system. Each piece plays a crucial role in the functionality and performance of the unit. Understanding their placements and connections will simplify the assembly and enhance your overall experience.

As you progress through the assembly steps, pay close attention to the orientation and alignment of each component. Proper positioning is vital to avoid common issues and ensure optimal performance. Use the visual references provided to guide you, making adjustments as necessary.

Lastly, take a moment to verify all connections are secure before operation. A well-assembled system not only performs better but also extends the longevity of your equipment. Enjoy the refreshing results of your handiwork!

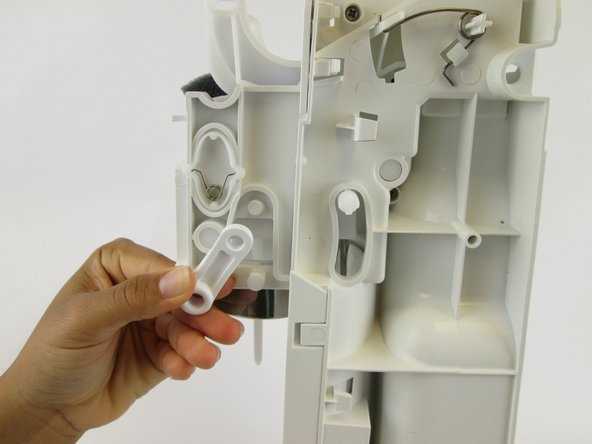

DIY Repairs for Common Problems

Addressing frequent issues with your carbonation system can save both time and money. By understanding the components and troubleshooting common malfunctions, you can restore functionality without needing professional assistance. This section outlines typical challenges and provides guidance on how to tackle them effectively.

| Issue | Possible Cause | Solution |

|---|---|---|

| Insufficient carbonation | Empty cylinder | Replace or refill the gas cylinder. |

| Leakage | Worn-out seals | Inspect and replace seals as needed. |

| No fizz | Faulty connector | Check and clean the connector; replace if damaged. |

| Unresponsive system | Power supply issues | Check the power source and ensure proper connections. |

Enhancing Your Soda-Making Experience

Creating your own sparkling beverages at home can be an enjoyable and rewarding activity. By optimizing your setup and using the right components, you can elevate the quality of your drinks and customize flavors to suit your preferences. This section will explore several ways to enhance the efficiency and enjoyment of your carbonated beverage-making process.

1. Experiment with Flavor Infusions: One of the most exciting aspects of crafting fizzy drinks is the ability to experiment with various flavorings. Consider using natural syrups, fresh fruits, or herbs to create unique combinations. Mixing different ingredients can lead to delightful discoveries and personalized recipes.

2. Optimize Carbonation Levels: Achieving the perfect fizziness is essential for a satisfying experience. Adjust the carbonation duration according to your taste. Whether you prefer a light effervescence or a robust fizz, finding the right balance will enhance the overall enjoyment of your homemade sodas.

3. Use Quality Ingredients: The foundation of any great beverage lies in its ingredients. Opt for high-quality syrups and additives, as well as fresh water. This attention to detail ensures that each sip is refreshing and flavorful, making your creations even more enjoyable.

4. Explore Creative Serving Ideas: Presentation matters when it comes to beverages. Experiment with different glassware, garnishes, and ice cubes to make your drinks visually appealing. A well-presented drink can enhance the overall experience and impress your guests.

5. Maintenance and Upgrades: Keeping your equipment in top condition is vital for consistent results. Regular maintenance ensures optimal performance. Additionally, consider upgrading components as needed to enhance functionality, which can lead to improved efficiency and enjoyment.

By embracing these tips, you can significantly enhance your fizzy beverage-making experience, creating delightful drinks that are tailored to your unique taste preferences.