In the realm of automotive maintenance and repair, having a comprehensive grasp of the various components that contribute to lifting systems is essential. These mechanisms are crucial for safely elevating vehicles, allowing for effective access to the undercarriage and facilitating various maintenance tasks. A detailed exploration of these elements can enhance both efficiency and safety in any workshop environment.

Every lifting device consists of a unique set of functionalities that work together harmoniously. By dissecting the structure and operation of these systems, one can identify how each individual piece contributes to the overall effectiveness of the equipment. This knowledge not only aids in troubleshooting but also promotes proper usage and maintenance, ensuring longevity and reliability.

Whether you’re a seasoned technician or an enthusiastic DIYer, familiarizing yourself with the intricacies of these lifting tools will significantly improve your hands-on experience. By gaining insight into how each segment functions, you empower yourself to undertake repairs with confidence, ultimately leading to a more productive and safer working atmosphere.

Understanding the Floor Jack Mechanism

This section delves into the inner workings of a lifting device commonly used for elevating heavy objects. By exploring its fundamental components and their functions, users can gain a clearer understanding of how it operates efficiently and safely.

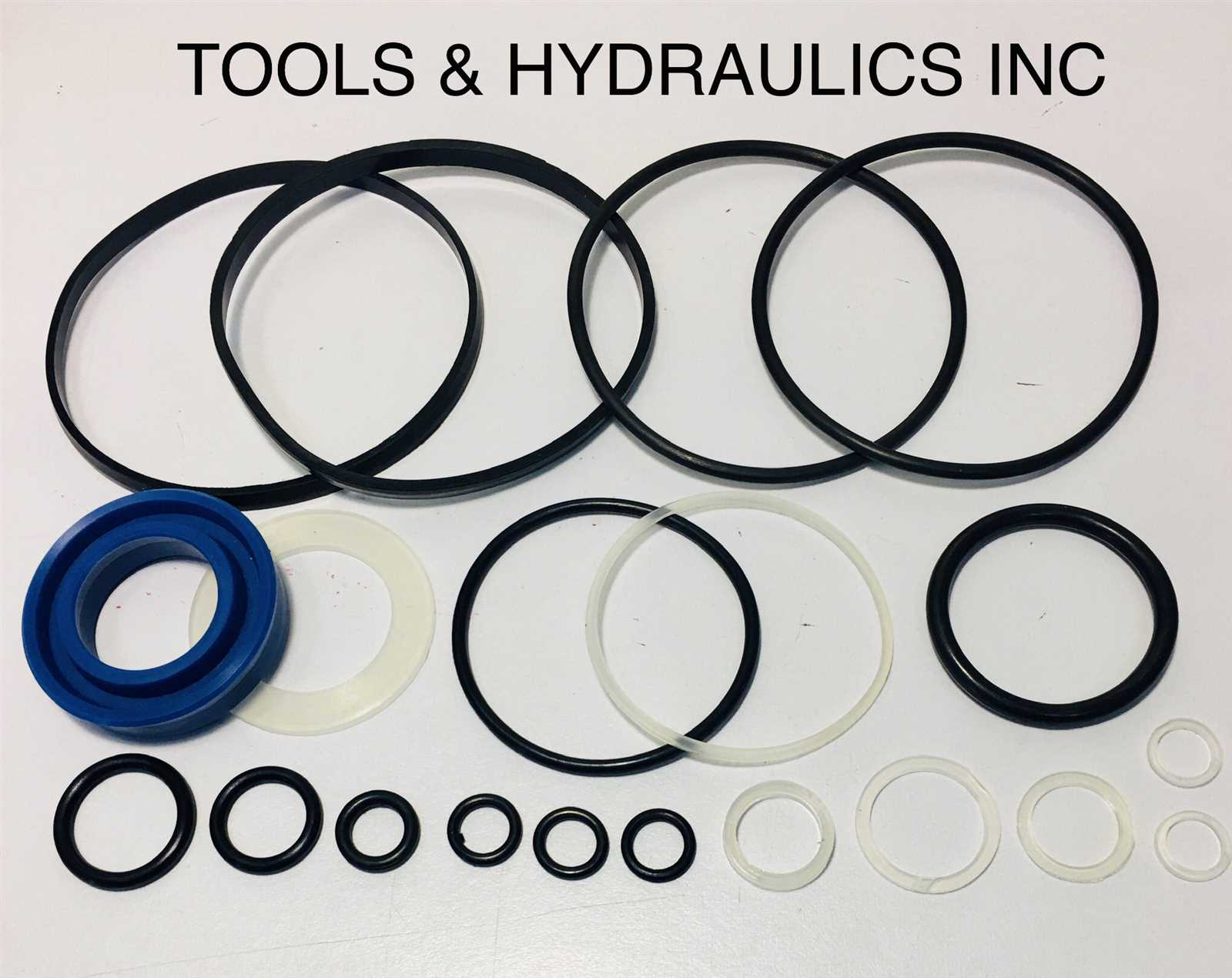

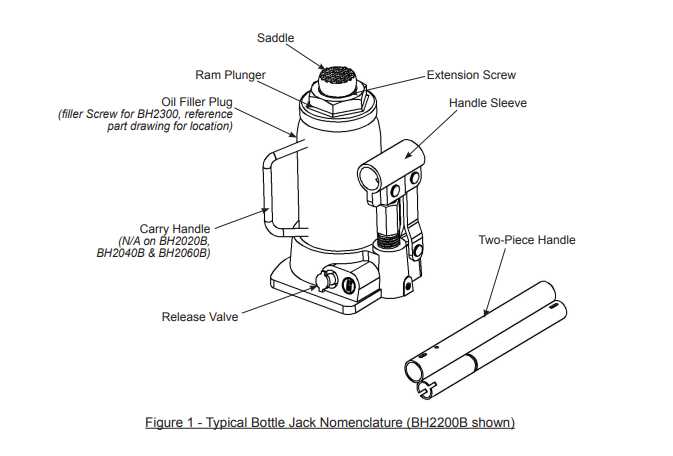

- Hydraulic System: This is the heart of the mechanism, utilizing fluid to create pressure that lifts the load.

- Piston and Cylinder: These elements work together to amplify force. When the piston is pushed down, it compresses the fluid, generating upward movement.

- Release Valve: This component controls the descent of the lifted object, allowing for gradual lowering by releasing pressure.

Each of these parts plays a crucial role in ensuring stability and safety during operation. Understanding their interaction is essential for proper usage and maintenance.

- Check the hydraulic fluid level regularly to ensure optimal performance.

- Inspect seals and gaskets for any signs of wear or leaks.

- Follow manufacturer guidelines for maintenance and operational procedures.

By familiarizing oneself with these key elements, users can not only improve their handling skills but also extend the lifespan of their lifting apparatus.

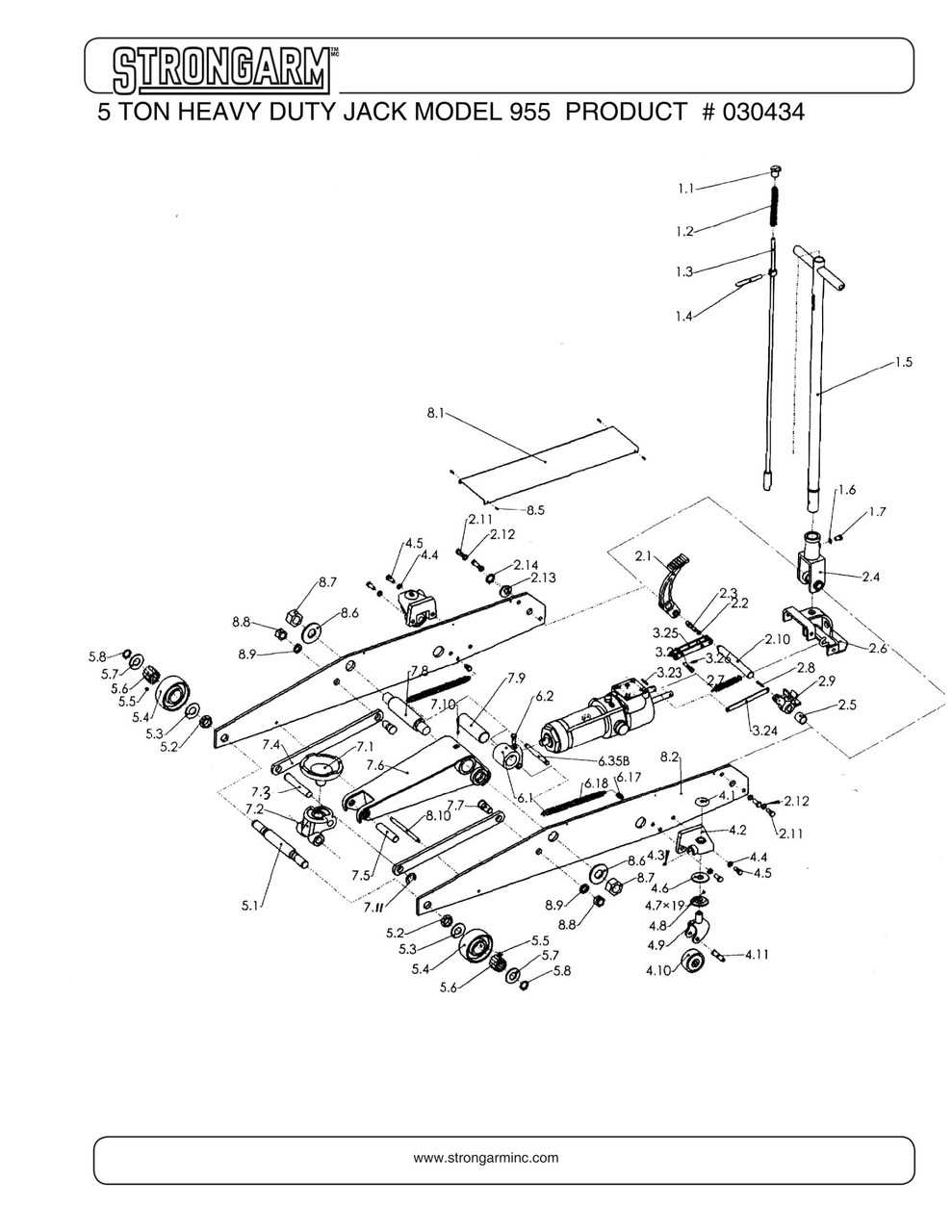

Main Components of a Floor Jack

Understanding the essential elements of a lifting device is crucial for effective usage and maintenance. Each component plays a vital role in the functionality and safety of the equipment, ensuring it can reliably elevate and support heavy loads.

Key Elements

Several fundamental components work in harmony to provide stability and strength. Familiarity with these elements enhances user confidence and operational efficiency.

| Component | Function |

|---|---|

| Base | Supports the entire structure and maintains stability. |

| Hydraulic Cylinder | Converts manual force into hydraulic pressure for lifting. |

| Handle | Allows for manual operation and control of the lifting mechanism. |

| Lift Arm | Transmits force from the hydraulic cylinder to the load. |

| Release Valve | Controls the lowering of the lifted object safely. |

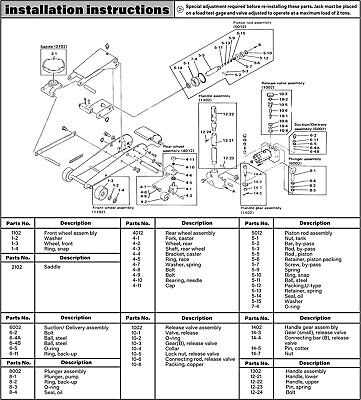

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. It allows individuals to identify each element and comprehend how they interact within the assembly. By mastering the art of interpreting these illustrations, one can streamline troubleshooting processes and ensure proper reassembly.

Key Elements of a Schematic

When examining a visual layout, several fundamental features stand out. Recognizing these components enhances the ability to navigate the illustration efficiently:

| Element | Description |

|---|---|

| Labels | Designations that indicate specific parts or assemblies, often accompanied by reference numbers. |

| Connections | Lines or arrows that demonstrate how parts are linked or interact with each other. |

| Legends | Explanatory notes that provide additional context or definitions for symbols used in the illustration. |

Tips for Effective Interpretation

To fully grasp the layout, consider the following strategies:

- Start with the legend to understand symbols and terms.

- Trace connections between components to visualize relationships.

- Refer back to the schematic while working on disassembly or reassembly.

Common Floor Jack Issues and Solutions

In the world of lifting equipment, users often encounter various challenges that can hinder performance. Understanding these frequent problems and their remedies is essential for maintaining efficiency and safety. Below are some common complications along with suggested solutions to keep your apparatus in top shape.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Insufficient lifting | Low hydraulic fluid, leaks | Check fluid levels, repair leaks, and refill as needed. |

| Slow operation | Contaminated fluid, air in system | Replace fluid and bleed the system to remove air. |

| Unstable lifting | Improper placement, worn components | Ensure even placement and inspect for wear; replace as necessary. |

| Noise during operation | Loose parts, lack of lubrication | Tighten all connections and lubricate moving parts. |

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your lifting equipment requires regular care and attention. By following a few essential maintenance practices, you can significantly extend the lifespan of your apparatus and maintain its optimal functionality.

Regular Inspections

Conduct routine checks to identify any signs of wear or damage. Look for leaks, cracks, or rust that could compromise safety and efficiency. Regular assessments can help you catch potential issues early, preventing more significant problems down the line.

Lubrication and Cleaning

Keep all moving components well-lubricated to minimize friction and wear. Use appropriate lubricants recommended by the manufacturer. Additionally, clean the equipment after use to remove debris and contaminants, which can hinder performance and lead to premature wear.

Safety Precautions When Using a Jack

Ensuring safety during lifting operations is crucial to prevent accidents and injuries. Proper practices and precautions should always be followed to maintain a secure environment when elevating heavy loads.

Pre-Operation Checks

- Inspect the lifting equipment for any signs of damage or wear.

- Verify that the load capacity is appropriate for the items being lifted.

- Ensure the lifting surface is stable and level.

Operational Guidelines

- Always use the device on a flat, solid surface to prevent slipping.

- Never place any part of your body under the elevated load.

- Use appropriate supports or blocks to secure the load once elevated.

- Maintain a safe distance from the equipment while in operation.

- Ensure that bystanders are at a safe distance to avoid potential injuries.

Types of Floor Jacks Explained

This section explores various lifting devices commonly used in automotive settings, each tailored for specific tasks and environments. Understanding their unique characteristics can enhance efficiency and safety during operations.

- Hydraulic Models: These rely on fluid pressure to lift heavy loads with minimal effort.

- Pneumatic Variants: Utilizing compressed air, these tools offer rapid lifting capabilities ideal for professional workshops.

- Mechanical Options: Operated through manual mechanisms, they provide a more traditional approach to lifting.

- Portable Designs: Lightweight and compact, these are perfect for home users needing flexibility and convenience.

- Heavy-Duty Versions: Built to withstand extreme weight, these are essential for industrial applications.

Each type presents distinct advantages, making it vital to select the right one for your specific requirements.

Choosing the Right Jack for Your Needs

When it comes to lifting heavy objects, selecting the appropriate tool can significantly impact both safety and efficiency. Various models are designed for specific tasks, and understanding the nuances of each can help you make an informed choice. Whether you need it for professional use or personal projects, knowing the right type to use will ensure optimal performance.

Types of Lifting Devices

Several types of lifting tools are available, each suited for different applications. Here’s a brief overview of common options:

| Type | Best For | Capacity |

|---|---|---|

| Hydraulic Lifter | Heavy-duty lifting | Up to 10 tons |

| Scissor Lifter | Low-profile vehicles | Up to 3 tons |

| Portable Lifter | Home use | Up to 2 tons |

Considerations for Selection

Before making a decision, consider the weight of the objects you’ll be lifting, the frequency of use, and the space available for storage. Additionally, ensure that the selected tool meets safety standards and provides adequate support to prevent accidents. The right choice will enhance your lifting experience and ensure that tasks are completed smoothly and efficiently.