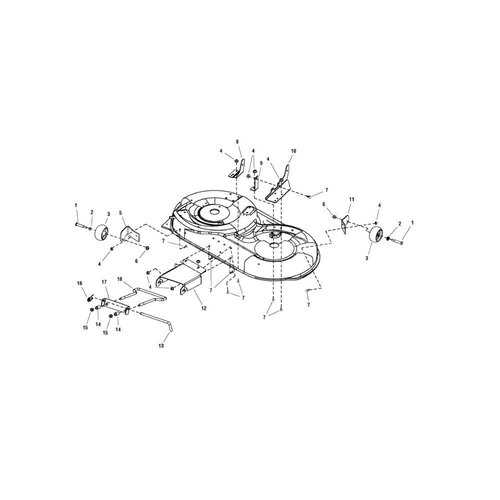

When maintaining outdoor machinery, comprehending the individual elements that contribute to its operation is crucial. A detailed visual representation can aid in identifying the various sections and their functions, ensuring efficient repairs and replacements. This knowledge not only enhances the longevity of the equipment but also improves overall performance.

Exploring the layout of these mechanisms reveals the intricate connections between each component. From the power source to the cutting apparatus, every piece plays a significant role in achieving optimal functionality. By familiarizing oneself with these parts, users can better navigate maintenance tasks, troubleshooting issues with confidence.

Furthermore, possessing an organized reference for these components simplifies the process of sourcing replacements or upgrades. With a clear understanding of how everything fits together, enthusiasts and professionals alike can ensure their machinery operates smoothly, allowing for effective lawn care and management.

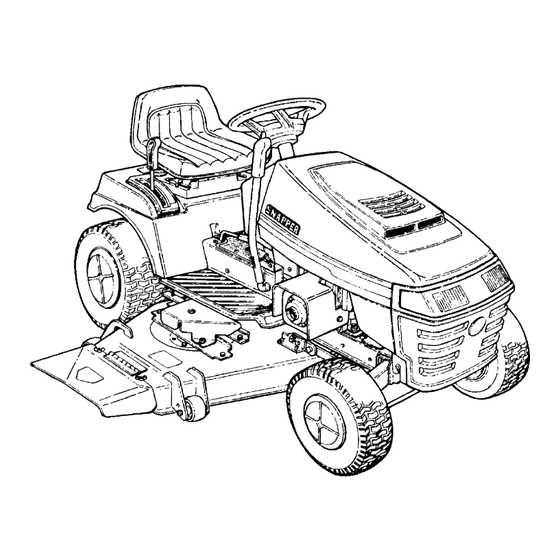

Understanding Snapper LT200 Components

Exploring the various elements that constitute a robust outdoor maintenance machine can enhance both efficiency and longevity. Each component plays a crucial role in ensuring optimal performance, offering users the ability to tackle various tasks with ease. A comprehensive knowledge of these individual parts allows for better maintenance practices and informed decisions when repairs or replacements are needed.

Key Elements of the Equipment

- Engine: The heart of the machinery, providing the necessary power for operation.

- Chassis: The framework that supports the entire structure, ensuring stability and durability.

- Transmission: Responsible for transferring power from the engine to the wheels, affecting speed and torque.

- Cutting Deck: Essential for grass trimming, designed to deliver a clean cut for a well-manicured lawn.

- Wheels: Provide mobility and control, crucial for maneuvering across various terrains.

Maintenance Considerations

- Regularly check the engine oil level and quality.

- Inspect the cutting blades for sharpness and damage.

- Clean the chassis and remove debris to prevent rust.

- Examine the tires for wear and ensure proper inflation.

- Service the transmission fluid according to the manufacturer’s recommendations.

By familiarizing oneself with these essential components and their maintenance needs, users can maximize the functionality and lifespan of their outdoor equipment.

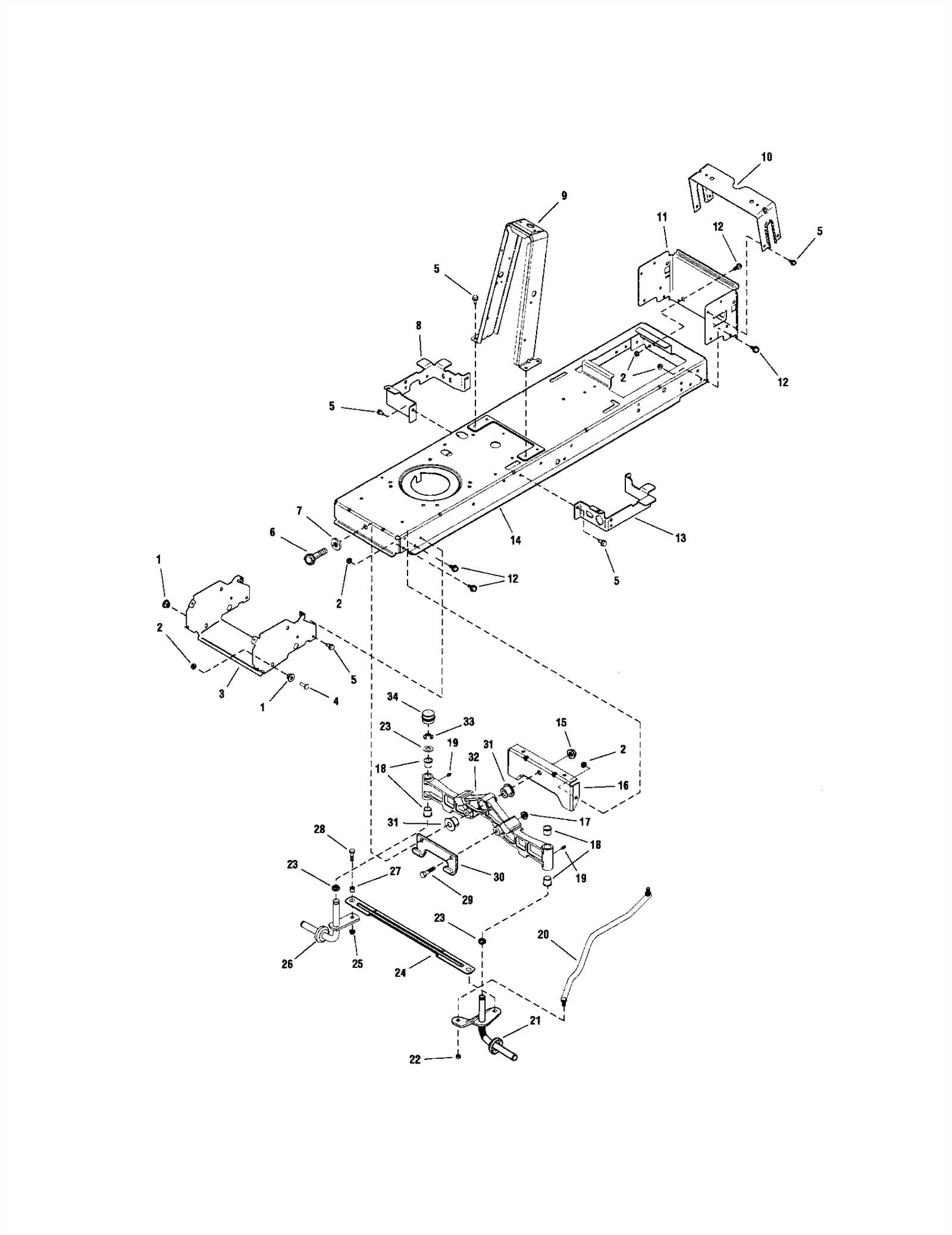

Importance of Parts Diagrams

Visual representations of components are essential for understanding the intricate workings of machinery. These illustrations provide a clear overview, helping users identify individual elements and their relationships within a system. By breaking down complex assemblies into manageable parts, users can effectively troubleshoot, maintain, and repair their equipment.

Moreover, such representations serve as valuable references for both novice and experienced users. They facilitate easier communication with technicians and suppliers, ensuring accurate identification of required elements. This can significantly reduce downtime and enhance the efficiency of repair processes.

| Benefits | Description |

|---|---|

| Clarity | Offers a simplified view of complex assemblies, making it easier to understand how components interact. |

| Identification | Aids in recognizing specific elements and their corresponding numbers or codes, essential for ordering replacements. |

| Efficiency | Streamlines the repair process by providing detailed information, reducing the likelihood of errors. |

| Communication | Enhances discussions with service professionals by allowing for precise references to specific components. |

Identifying Key Mechanisms

Understanding the essential components of a mechanical system is crucial for effective maintenance and repair. Each part plays a specific role, contributing to the overall functionality and performance. By analyzing these elements, one can ensure the longevity and efficiency of the equipment.

The primary mechanisms can be categorized based on their function and interaction within the system. Familiarizing oneself with these components not only aids in troubleshooting but also enhances the ability to perform upgrades or modifications when necessary.

| Component | Function |

|---|---|

| Engine | Generates power to drive the machinery. |

| Transmission | Transfers power from the engine to the wheels. |

| Control Panel | Allows the operator to manage settings and monitor performance. |

| Chassis | Provides structural support and houses key components. |

| Wheel Assembly | Facilitates movement and stability during operation. |

By recognizing and understanding these key mechanisms, users can effectively diagnose issues and implement solutions to maintain optimal performance in their equipment.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor machinery requires a dedicated approach to upkeep and care. Regular maintenance not only enhances performance but also prolongs the life of your equipment. By following a few essential guidelines, you can minimize wear and tear, preventing costly repairs and replacements.

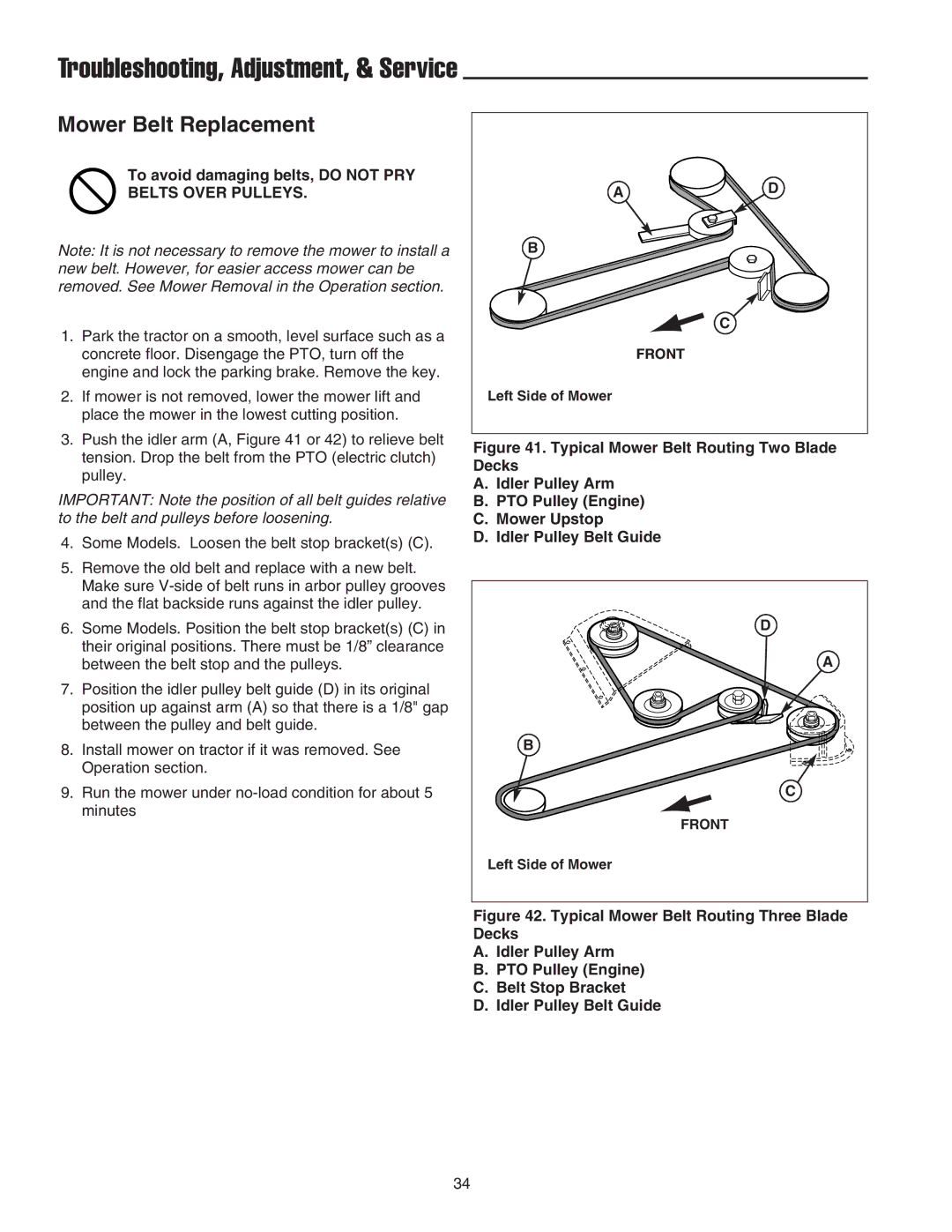

Regular Inspection

Frequent checks of your equipment can help identify potential issues before they escalate. Look for signs of wear, rust, or any loose components that may require attention. Implement a routine schedule to inspect belts, blades, and other critical elements, ensuring they are in optimal condition.

Proper Cleaning

Cleaning your machinery after each use is vital. Dirt and debris can accumulate, leading to operational inefficiencies. Make it a habit to remove grass clippings and other residues from all surfaces, particularly around the engine and undercarriage. This practice not only improves functionality but also prevents corrosion and damage.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check Oil Levels | Every 10 hours of use | Ensure oil is clean and at the correct level. |

| Sharpen Blades | Every 20 hours of use | Sharp blades provide a cleaner cut and reduce strain on the engine. |

| Inspect Fuel System | Before each use | Check for leaks and ensure fuel is fresh. |

| Clean Air Filter | Every season | A clean filter ensures optimal airflow to the engine. |

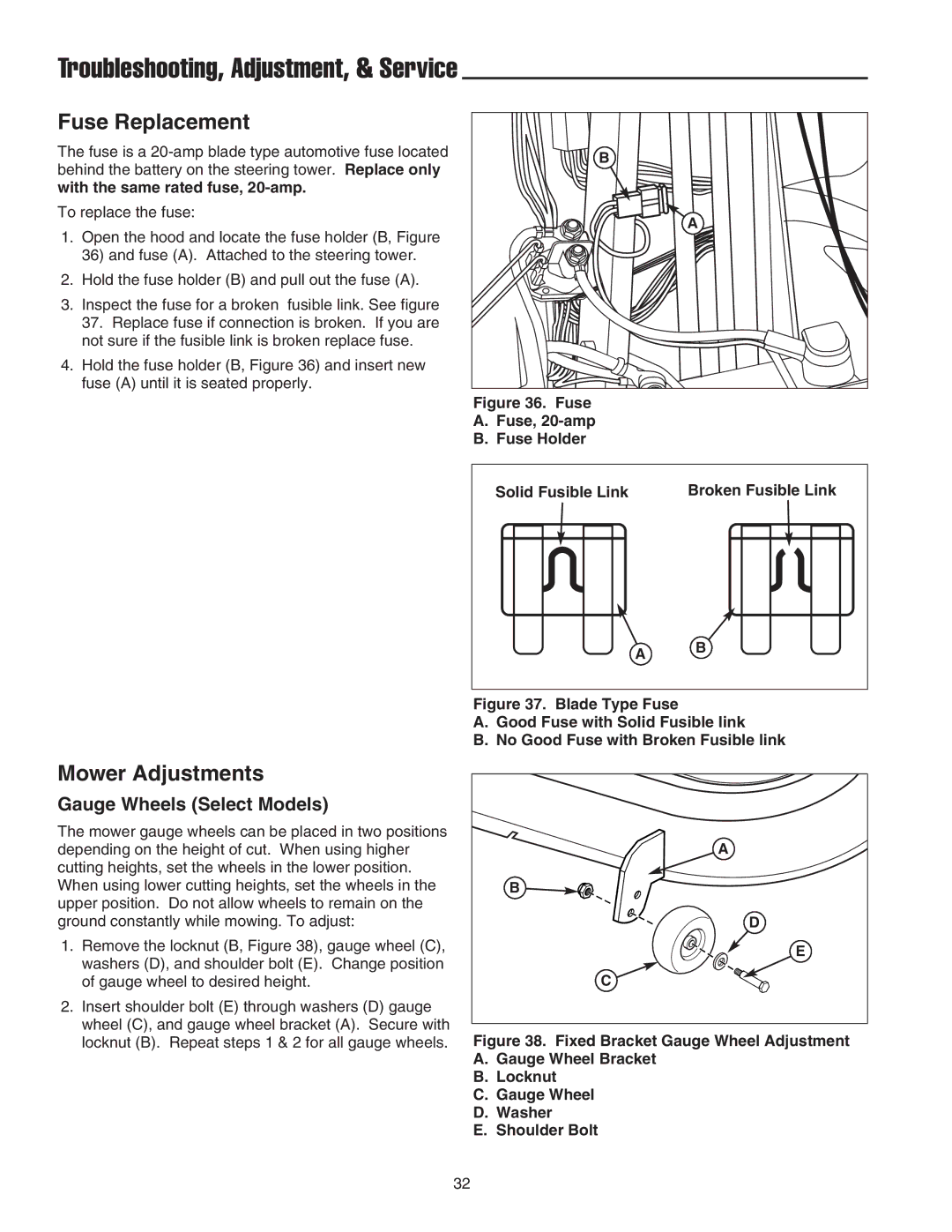

Common Issues and Solutions

Understanding typical challenges associated with outdoor power equipment can greatly enhance maintenance efforts and extend the lifespan of the machinery. This section addresses prevalent problems users may encounter and offers practical solutions to ensure optimal performance.

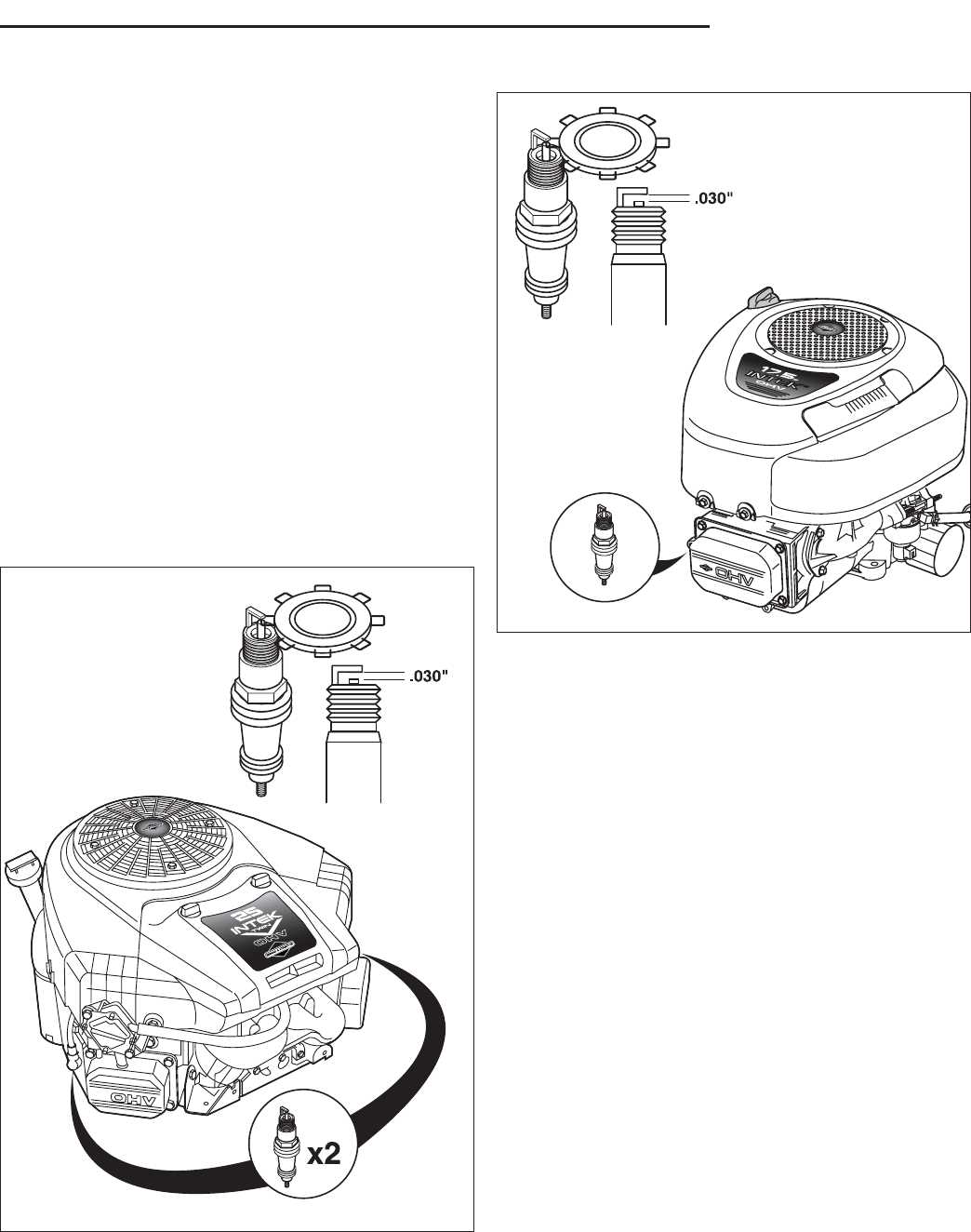

Engine Performance Issues

A frequent concern involves difficulties with the engine starting or running smoothly. These problems may stem from issues such as a clogged fuel filter, stale fuel, or a faulty spark plug. To resolve these issues, regularly check and replace the fuel filter, ensure fresh fuel is used, and inspect the spark plug for wear or damage. Cleaning or replacing the spark plug can significantly improve engine performance.

Deck and Blade Malfunctions

Another common issue is related to the cutting deck and blades. Users often notice uneven cutting or excessive vibrations. These symptoms can indicate dull blades, which should be sharpened or replaced. Additionally, inspecting the deck for debris buildup is essential. Regular cleaning and maintenance can prevent these malfunctions, ensuring a clean and even cut.

Ordering Replacement Parts Effectively

When maintaining equipment, ensuring the correct components are sourced is essential for optimal performance. Whether addressing wear and tear or upgrading functionalities, effective procurement strategies can save time and resources.

To streamline the ordering process, consider the following guidelines:

- Identify the Exact Components Needed:

- Review the manual or schematics to determine the specific items required.

- Make a list of part numbers and descriptions for easy reference.

- Research Reliable Suppliers:

- Look for vendors with a solid reputation for quality and service.

- Check customer reviews and ratings to gauge reliability.

- Compare Prices:

- Gather quotes from multiple suppliers to ensure competitive pricing.

- Be mindful of shipping costs and delivery times.

- Verify Compatibility:

- Ensure the components match the specifications of the equipment.

- Double-check compatibility with existing systems to avoid unnecessary returns.

- Place Orders Promptly:

- Order the components as soon as they are identified to avoid delays in repairs.

- Keep track of order confirmations and shipping notifications.

By following these strategies, you can ensure a more efficient ordering experience, ultimately leading to better upkeep of your machinery.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance and repair tasks is crucial for both personal safety and the longevity of the equipment. Proper precautions not only protect the individual performing the work but also minimize the risk of damage to the machinery involved.

Before beginning any repair, it is essential to wear appropriate protective gear, such as gloves, goggles, and sturdy footwear. These items help prevent injuries from sharp edges or flying debris. Additionally, working in a well-ventilated area is vital to avoid inhaling harmful fumes or dust particles generated during the repair process.

Always disconnect the power source prior to performing any maintenance to eliminate the risk of accidental start-up. Utilizing the correct tools for the job can also significantly reduce the chances of accidents. It is advisable to read the equipment’s manual thoroughly to understand specific safety guidelines and recommended practices.

Lastly, keeping the workspace organized and free of clutter will help prevent trips and falls, ensuring a safer environment while working. By adhering to these safety measures, individuals can effectively minimize hazards and create a more secure atmosphere during repair activities.

Upgrading Components for Better Performance

Enhancing the functionality of your machine can lead to significant improvements in efficiency and longevity. By focusing on key elements, you can achieve a more responsive and powerful experience. Upgrading specific components can help optimize the overall operation, making tasks smoother and less time-consuming.

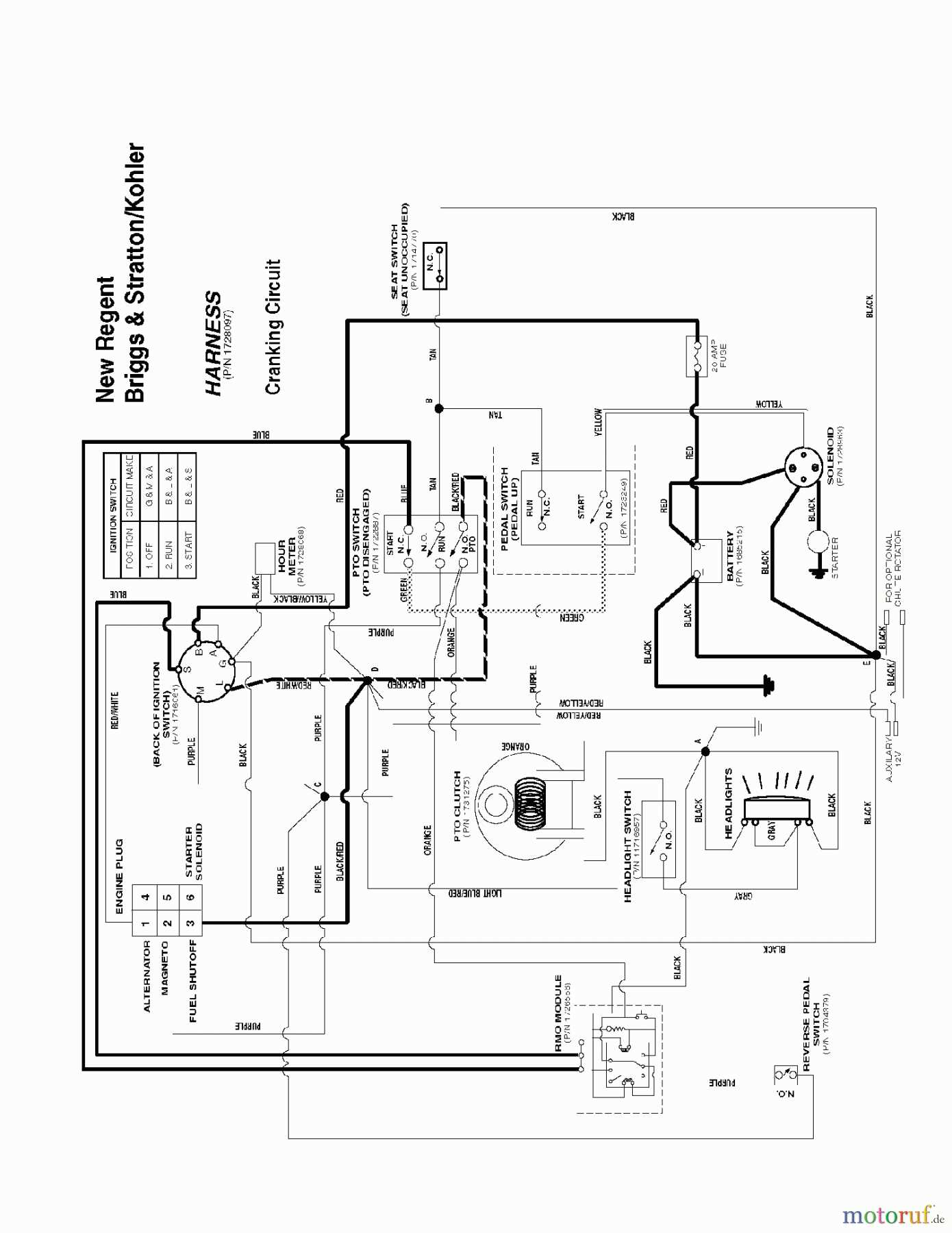

Identifying critical areas for enhancement is the first step. Look for parts that may have become outdated or are underperforming. This could include the engine, transmission, or even electrical systems. Each of these components plays a vital role in the overall performance, and replacing them with higher-quality alternatives can yield impressive results.

Additionally, considering aftermarket solutions may provide the edge needed for improved functionality. Aftermarket options often offer enhanced specifications, allowing for greater durability and efficiency. However, it’s essential to research compatibility and installation requirements to ensure seamless integration with existing systems.

Finally, regular maintenance of upgraded components is crucial for sustaining their performance over time. Implementing a routine check-up schedule and using quality materials for replacements will contribute to a more reliable and efficient operation.

Resources for Further Information

This section provides valuable avenues for obtaining additional knowledge and insights related to maintenance and components of various equipment. Whether you are looking for guides, manuals, or community forums, these resources can significantly enhance your understanding and facilitate informed decisions.

Manufacturer Websites: Official websites often contain detailed manuals, troubleshooting guides, and specifications. These platforms serve as primary sources for the latest updates and product information.

Online Forums and Communities: Engaging with communities of enthusiasts and professionals can yield practical advice and shared experiences. These forums are great for asking specific questions and learning from others’ insights.

YouTube Tutorials: Visual learning through video tutorials can be particularly helpful. Many creators offer step-by-step guides on maintenance and repairs, making complex processes easier to understand.

Local Workshops and Classes: Participating in hands-on workshops can provide practical knowledge and skills. These settings often allow for direct interaction with experienced professionals.

Books and Publications: There are numerous books dedicated to equipment maintenance and repair. These resources can provide in-depth knowledge and are often written by industry experts.