The intricate design of vintage stitching devices offers a fascinating glimpse into the craftsmanship of the past. Each element plays a crucial role in the overall functionality, contributing to the machine’s performance and longevity. By exploring these components, one can appreciate the synergy that allows for smooth operation and reliable results.

To effectively maintain or restore such a device, it is essential to familiarize oneself with its various sections and mechanisms. Recognizing how these parts interconnect not only aids in troubleshooting but also enhances the overall user experience. A comprehensive overview of these essential components provides valuable insights for enthusiasts and hobbyists alike.

Whether you are an experienced seamstress or a newcomer to the world of stitching, understanding the layout of these machines can significantly enhance your proficiency. By delving into the specifics of each section, you’ll be equipped to make informed decisions regarding repairs, upgrades, and overall maintenance, ensuring that your beloved machine continues to serve you well for years to come.

Understanding the Singer Model 66

This section explores a classic sewing machine renowned for its functionality and design. It has captured the hearts of enthusiasts and crafters alike, making it an enduring favorite in the world of textile arts.

Key features include:

- Durable construction

- Variety of stitch options

- User-friendly operation

For those seeking to delve deeper into its mechanics, it’s beneficial to consider:

- Maintenance tips to ensure longevity

- Common issues and troubleshooting techniques

- Customizing for specific projects

Ultimately, understanding this machine enhances the sewing experience, allowing for creativity and precision in every project.

Overview of Sewing Machine Parts

Understanding the components of a stitching device is essential for effective use and maintenance. Each element plays a critical role in the machine’s functionality, contributing to the overall performance and efficiency of sewing tasks. Familiarity with these sections allows users to troubleshoot issues and enhance their crafting experience.

| Component | Description |

|---|---|

| Needle | A sharp metal instrument that penetrates fabric to create stitches. |

| Bobbin | A small spool that holds the lower thread, essential for forming stitches. |

| Feed Dogs | Teeth-like components that move the fabric forward during sewing. |

| Presser Foot | A component that holds the fabric in place while sewing. |

| Throat Plate | The flat surface that supports the fabric and has openings for the needle and feed dogs. |

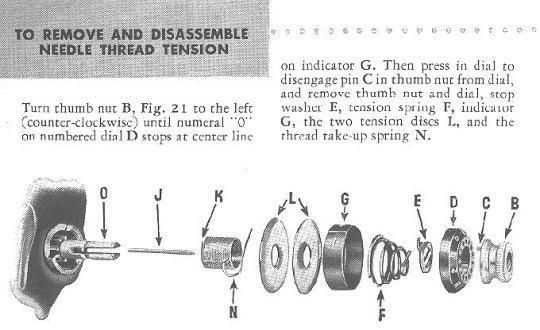

| Thread Tension Dial | A control that adjusts the tightness of the upper thread for optimal stitching. |

| Motor | The driving force that powers the machine, enabling it to operate smoothly. |

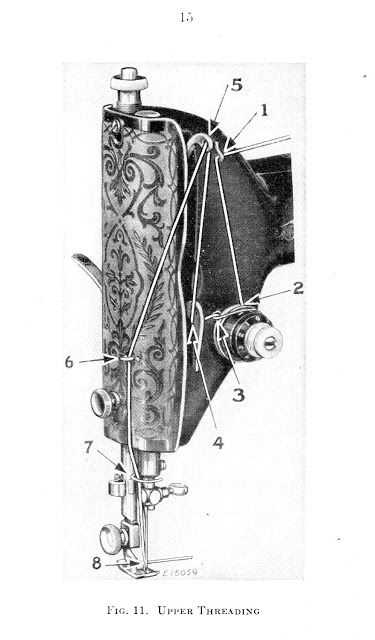

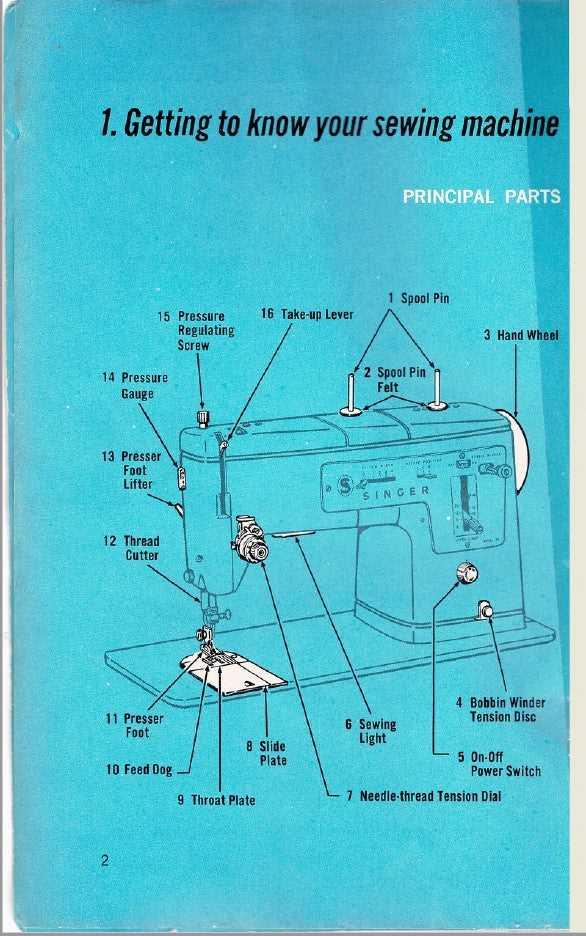

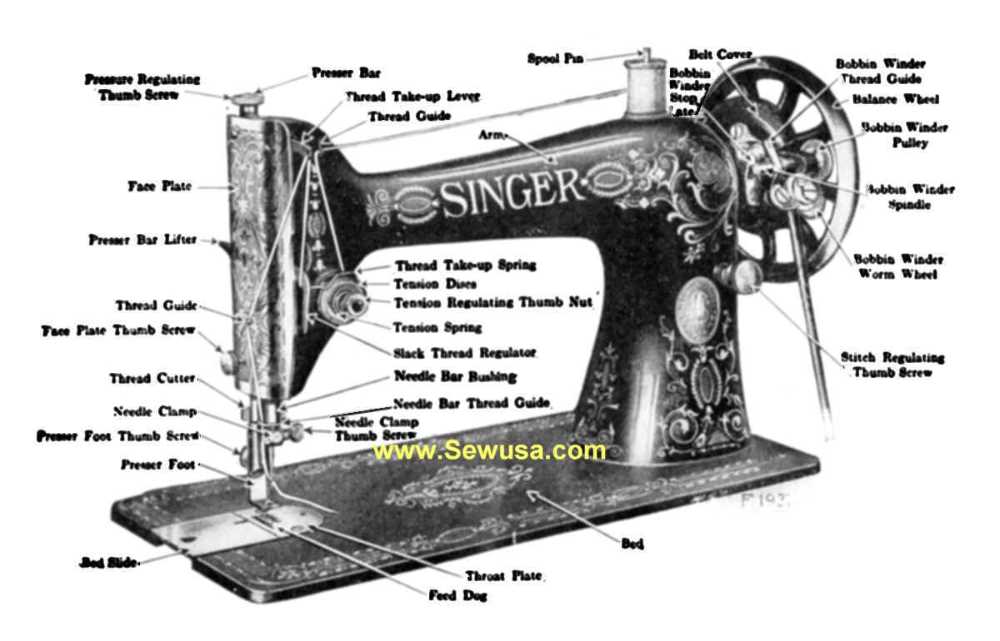

Importance of the Parts Diagram

Understanding the components of any mechanical device is crucial for effective maintenance and repair. A visual representation that outlines these individual elements serves as an essential tool for both beginners and experienced technicians. It simplifies the process of identifying each part, making it easier to troubleshoot issues and perform necessary replacements.

Facilitating Repairs

A clear illustration of the components enables users to navigate the complexities of assembly and disassembly with confidence. By knowing precisely where each piece fits, one can avoid common pitfalls that may arise during repairs. This visual aid reduces the likelihood of mistakes, ultimately saving time and resources.

Enhancing Understanding

Moreover, such a visual guide fosters a deeper understanding of how the machine operates. By seeing how different elements interact, users can develop insights into the functionality and mechanics behind the device. This knowledge not only aids in immediate repairs but also empowers users to optimize the performance of their equipment in the long run.

Common Issues with Model 66 Components

The intricate mechanisms of vintage sewing machines often face various challenges that can affect their performance and longevity. Understanding these common difficulties is essential for maintenance and repair, ensuring smooth operation and extending the life of the equipment.

Frequent Mechanical Problems

One major issue is the wear and tear of moving elements, which can lead to misalignment and operational inefficiencies. Lubrication is crucial; insufficient oiling may cause components to seize or grind, resulting in irreversible damage. Regular cleaning and timely maintenance can mitigate these risks.

Electrical and Tension Challenges

Electrical faults can arise, especially in machines with built-in motors. Overheating or faulty wiring may disrupt functionality. Additionally, tension discrepancies can result in uneven stitching, requiring careful adjustment of tension settings to achieve optimal results. Identifying and addressing these issues promptly is vital for maintaining performance.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your sewing machine operates smoothly and efficiently. A few simple practices can significantly enhance its longevity and performance, making your sewing experience more enjoyable and productive.

Routine Cleaning

Keeping your device clean is vital. Dust and lint can accumulate, affecting functionality. Follow these steps for effective cleaning:

- Unplug the machine before cleaning.

- Remove the needle and presser foot.

- Use a soft brush or cloth to clear away dust from the interior and exterior.

- Check and clean the bobbin case and feed dogs regularly.

Regular Oiling

Lubrication helps reduce friction and wear on moving parts. Adhere to these guidelines for optimal oiling:

- Refer to the user manual for specific oiling points.

- Use high-quality sewing machine oil.

- Apply a few drops to the designated areas, avoiding excess oil.

- Run the machine briefly to distribute the oil evenly.

Implementing these maintenance tips will contribute to the reliable operation of your sewing device, ensuring that you can continue creating beautiful projects with ease.

Where to Find Replacement Parts

Locating suitable components for your sewing machine can be a crucial step in ensuring its longevity and optimal performance. Whether you are restoring a vintage model or simply need a specific item for repairs, there are several avenues to explore.

Online Retailers

The internet offers a vast marketplace for acquiring various components. Numerous websites specialize in sewing equipment, providing a wide range of items. Be sure to check customer reviews and ratings to ensure reliability. Additionally, many forums and community groups can guide you to reputable online shops.

Local Shops and Repair Centers

Visiting local establishments that focus on sewing and crafting can also be beneficial. These stores often carry essential supplies and can help you identify the exact item you need. Furthermore, experienced technicians at repair centers can provide valuable insights and assistance in finding the right solution.

History and Evolution of the Model 66

The journey of this iconic sewing machine reflects the remarkable advancements in technology and design from the late 19th century. Initially developed to meet the demands of home sewing, its innovative features and robust construction quickly gained popularity among users. Over time, the machine has undergone significant transformations, integrating new functionalities while retaining the essence of its original charm.

Early Developments

The origins of this remarkable device can be traced back to the early innovations in sewing technology. At its inception, the focus was on improving efficiency and user-friendliness. The introduction of a foot-powered mechanism revolutionized the way garments were created, allowing seamstresses to work with greater speed and precision.

Technological Advancements

| Year | Key Features Introduced |

|---|---|

| 1851 | First sewing machine prototype |

| 1889 | Introduction of the foot pedal |

| 1920 | Decorative stitching options |

| 1950 | Electric motorization |

| 1970 | Computerized models emerge |

Tools Needed for Repairs

To successfully restore and maintain your sewing machine, having the right equipment is essential. A well-equipped toolkit not only simplifies the repair process but also enhances the overall efficiency of your work. Below is a list of necessary items that will aid in addressing common issues and performing routine maintenance tasks.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws in various components. |

| Needle Nose Pliers | Useful for gripping and manipulating small parts. |

| Seam Ripper | For removing stitches and correcting mistakes. |

| Oil Can | For lubricating moving parts to ensure smooth operation. |

| Cleaning Brush | To remove lint and dust from internal mechanisms. |

| Measuring Tape | For taking precise measurements during adjustments. |

| Replacement Needles | To ensure optimal stitching performance and quality. |

| Fabric Scissors | Essential for cutting fabric cleanly and accurately. |

Resources for Learning More

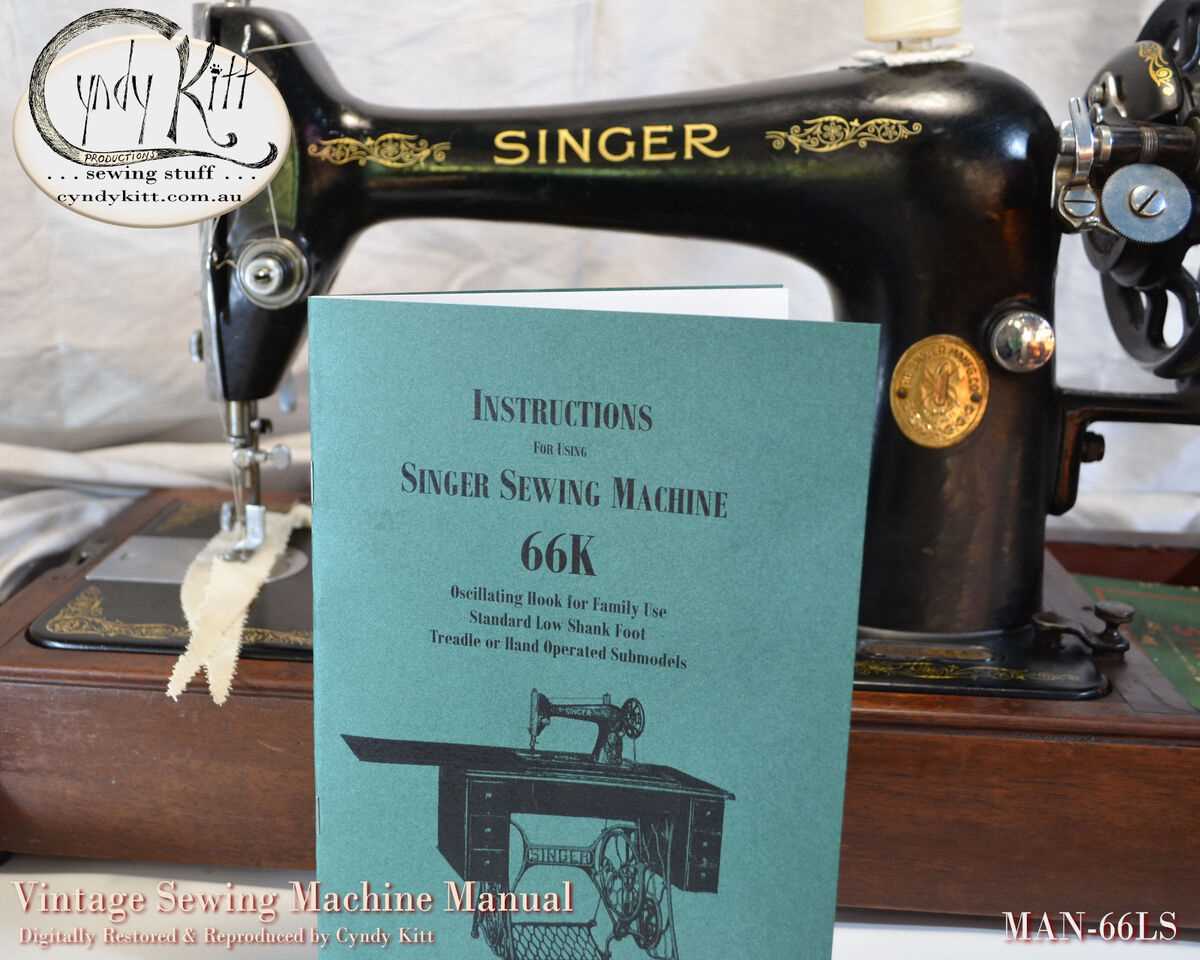

For those eager to deepen their understanding of vintage sewing machines, a wealth of information is readily available. Exploring various resources can enhance knowledge about the intricate workings and maintenance of these beloved devices. From online communities to specialized literature, each avenue offers unique insights and practical guidance.

Online Communities and Forums

Joining online forums dedicated to sewing enthusiasts can be particularly beneficial. Engaging with fellow hobbyists allows for the exchange of tips, troubleshooting advice, and restoration techniques. Websites like Reddit and specialized sewing forums host discussions that can illuminate common challenges and innovative solutions.

Books and Manuals

Books written by experts in the field serve as excellent references. They often include detailed illustrations and comprehensive explanations of machine mechanics. Additionally, obtaining original user manuals can provide invaluable information about operation and care. Consider visiting local libraries or searching online bookstores for both new and vintage texts.

Incorporating these resources into your learning journey will undoubtedly enhance your appreciation and skill with these classic sewing machines.