Understanding the individual elements that make up a well-known recreational vehicle can significantly enhance the maintenance and repair process. Each component plays a vital role in ensuring optimal performance, and familiarity with their arrangement and functions can save both time and resources. This section aims to provide a detailed overview of the essential features associated with this specific vehicle.

In any mechanical setup, clarity regarding the layout of each segment is crucial for effective troubleshooting and customization. Knowing how the various sections interconnect enables enthusiasts and technicians alike to approach repairs with confidence. This guide will shed light on the intricate details, highlighting how each element contributes to the overall functionality.

Whether you’re an experienced mechanic or a new owner seeking to deepen your knowledge, comprehending the structure of these components is fundamental. Through this exploration, you will gain insights that empower you to tackle any challenges that may arise in your journey with this remarkable vehicle.

Understanding the Pac Fab Challenger Parts

This section aims to provide insights into the various components of a specific aquatic equipment model. A comprehensive grasp of each element is essential for optimal performance and maintenance. By familiarizing oneself with these elements, users can ensure their device operates efficiently and lasts longer.

Key Components Overview

The machinery consists of several essential units, each contributing to its overall functionality. These units work in harmony to deliver a seamless experience. Understanding their roles enables users to diagnose issues effectively and perform necessary adjustments.

Maintenance and Upgrades

Regular upkeep and potential enhancements are crucial for sustaining the device’s performance. Knowing the various components assists in identifying which areas may require attention. Proper maintenance can significantly extend the lifespan and enhance the efficiency of the equipment.

Overview of Key Components

This section provides an insightful examination of essential elements that contribute to the overall functionality and performance of the system. Each component plays a vital role in ensuring that the entire mechanism operates seamlessly, providing reliability and efficiency in various applications.

Core Elements

The core elements encompass the primary structures and mechanisms that facilitate operation. These include the framework, which provides stability and support, as well as the various actuators that enable movement and control. Understanding the interaction between these components is crucial for optimal performance.

Auxiliary Features

In addition to the core elements, several auxiliary features enhance the system’s capabilities. Safety systems ensure secure operation by preventing potential failures, while monitoring devices offer real-time data on performance metrics. These features contribute significantly to the system’s reliability and user confidence.

Importance of Accurate Diagrams

Precise representations of components are essential for effective assembly, maintenance, and troubleshooting. These illustrations serve as invaluable tools for understanding the intricate relationships between various elements, ensuring that users can effectively manage and repair equipment. Clear visual aids help reduce errors, enhance efficiency, and ultimately contribute to the longevity of machinery.

Enhancing Understanding

When users have access to well-detailed visual representations, they can grasp the configuration and operation of the system more easily. This clarity enables individuals to identify specific components and comprehend their functions within the whole structure, fostering better problem-solving abilities and informed decision-making.

Minimizing Errors

Accurate representations play a critical role in minimizing mistakes during assembly or repairs. By following clear instructions and illustrations, individuals are less likely to misplace components or overlook essential connections. This reduction in errors not only saves time but also prevents potential damage to equipment, ensuring a smoother operational process.

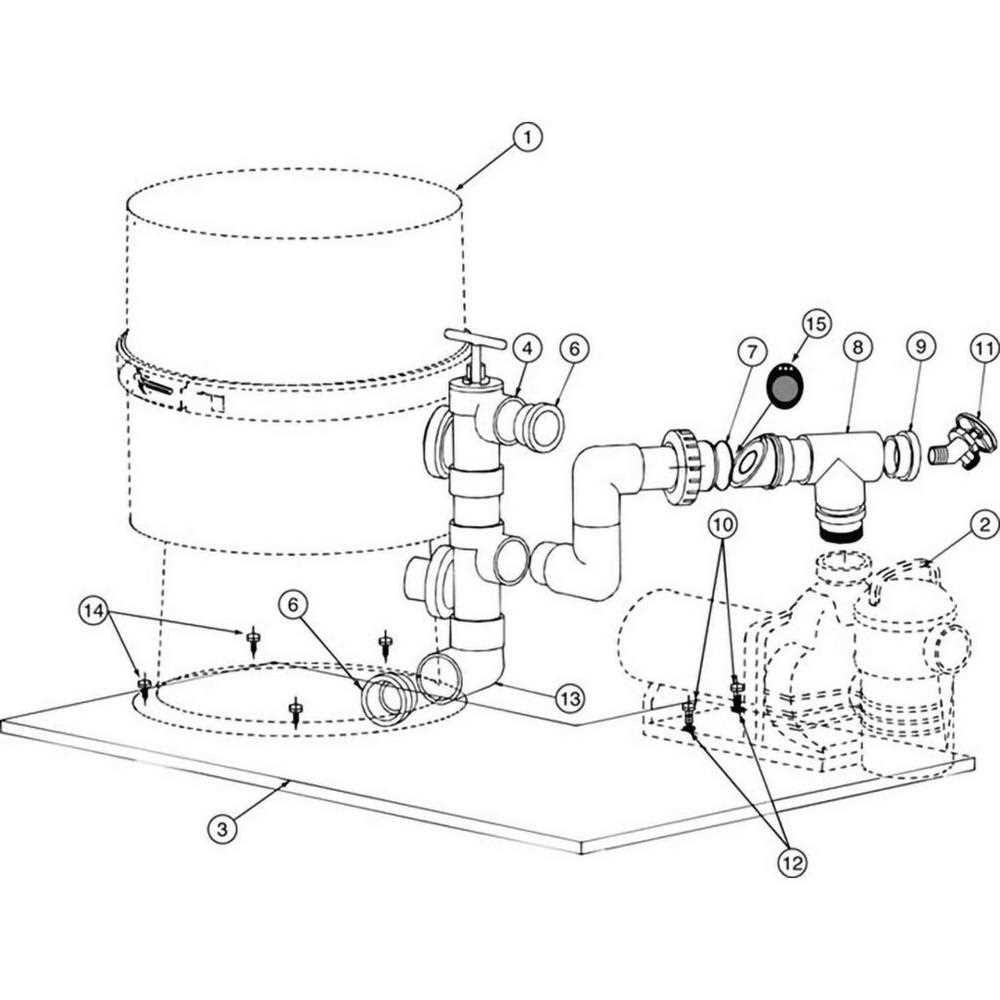

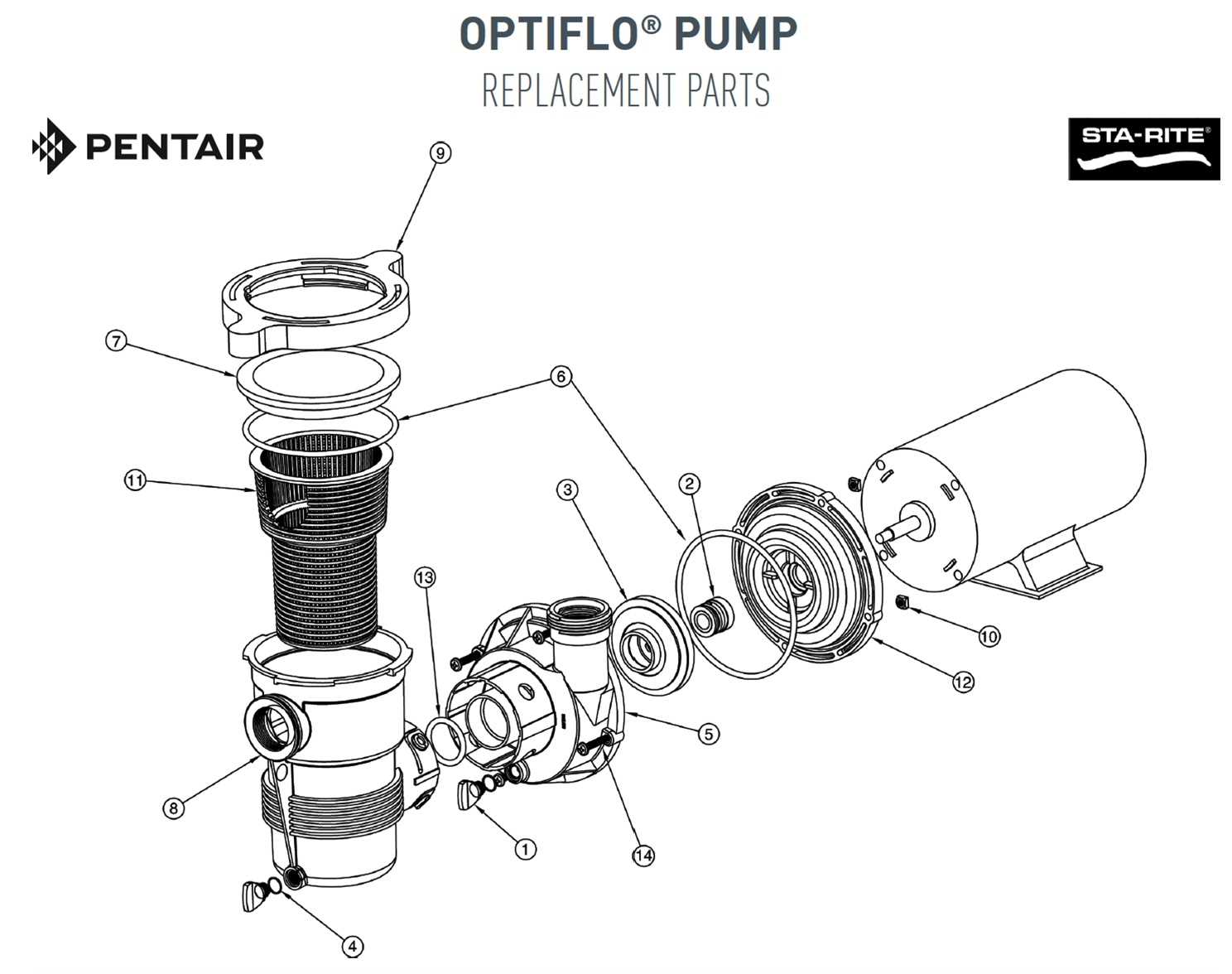

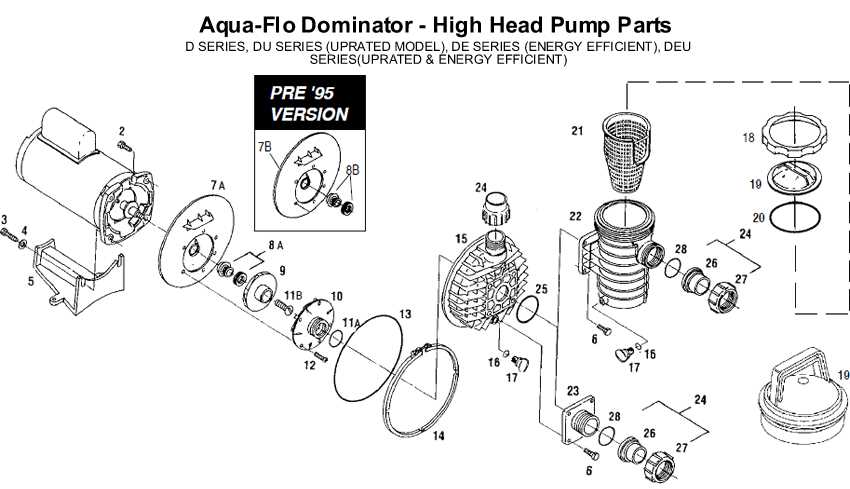

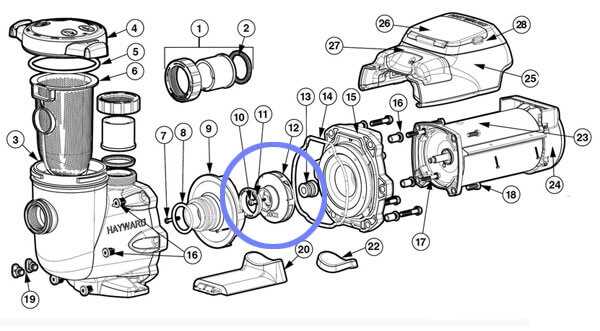

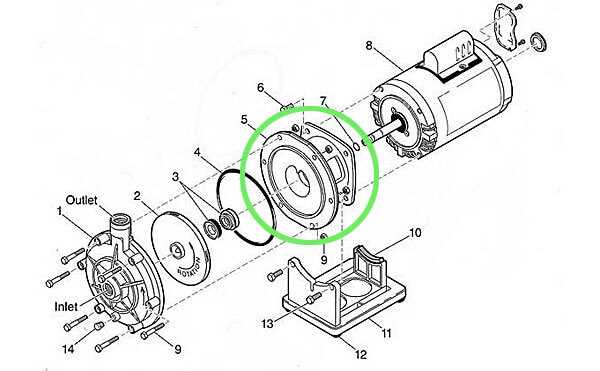

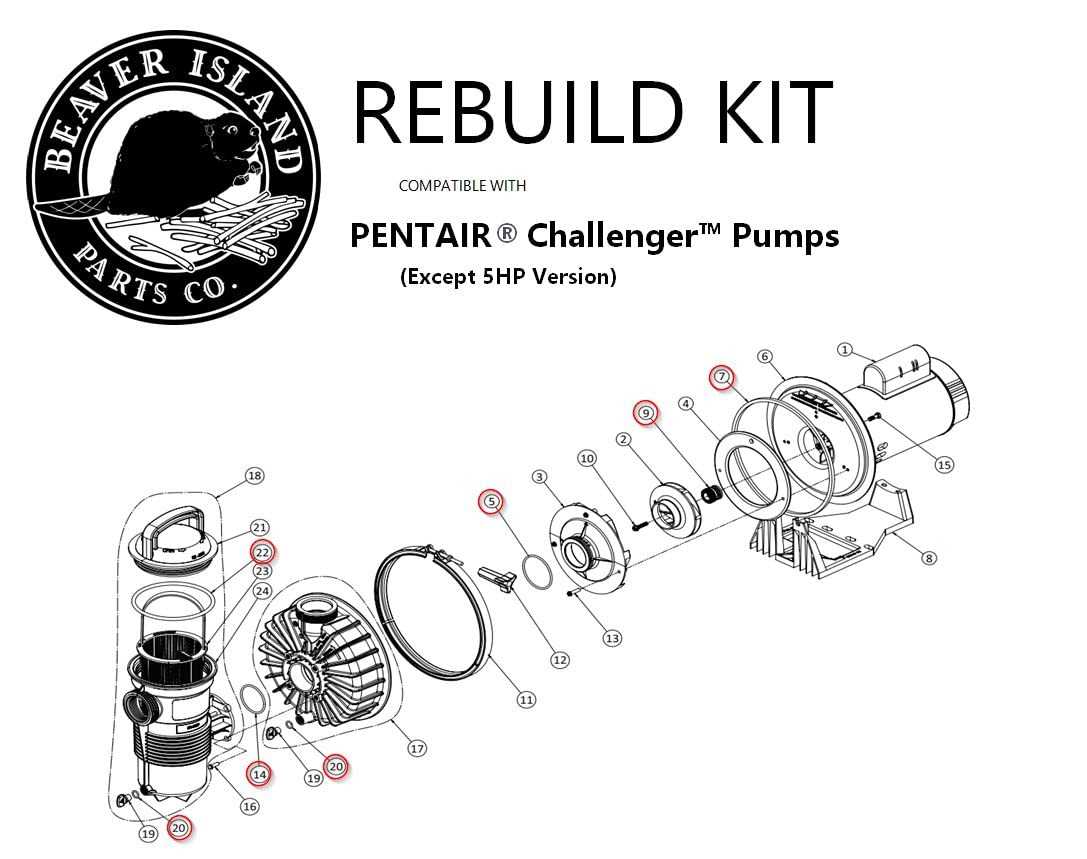

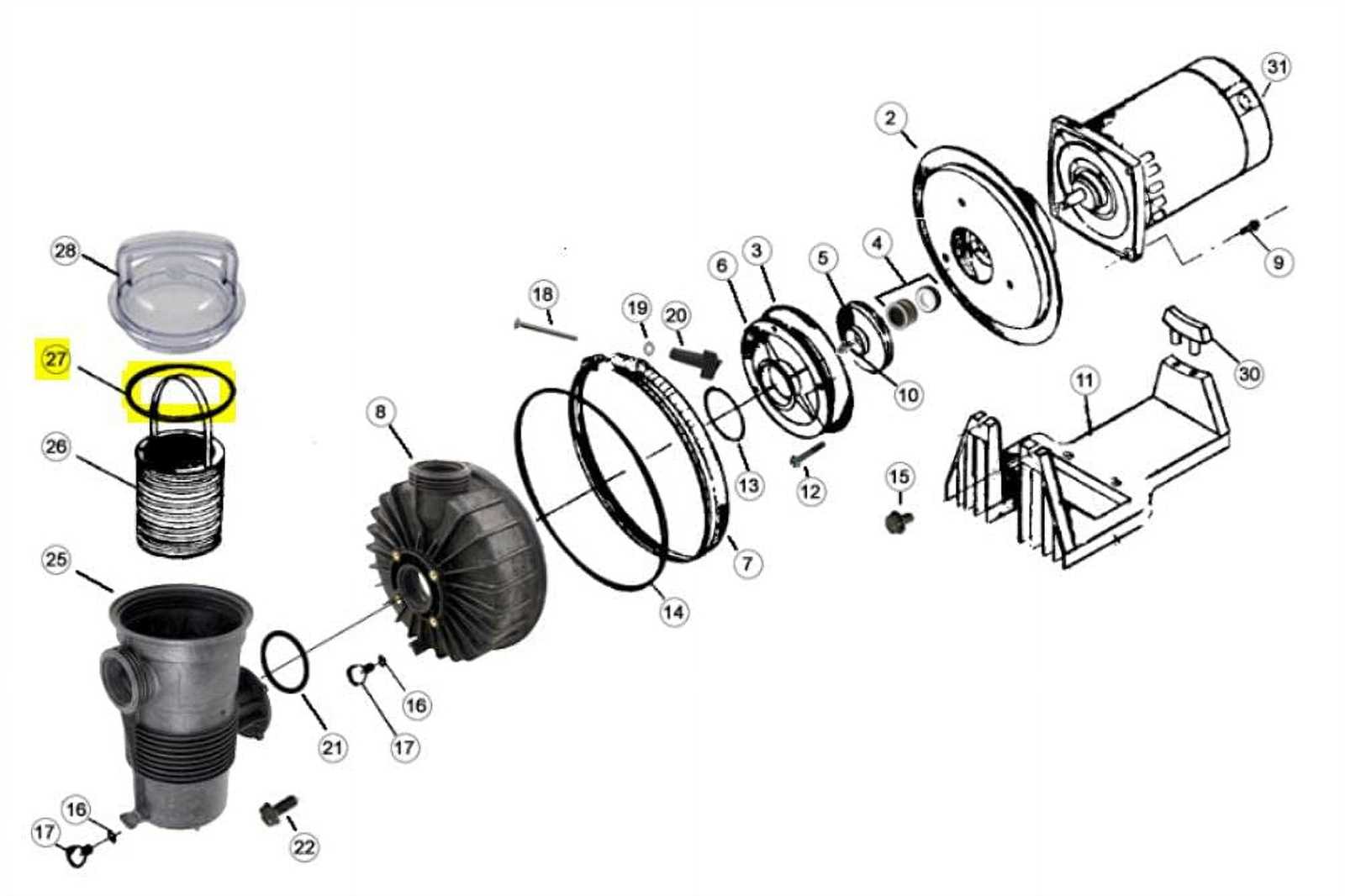

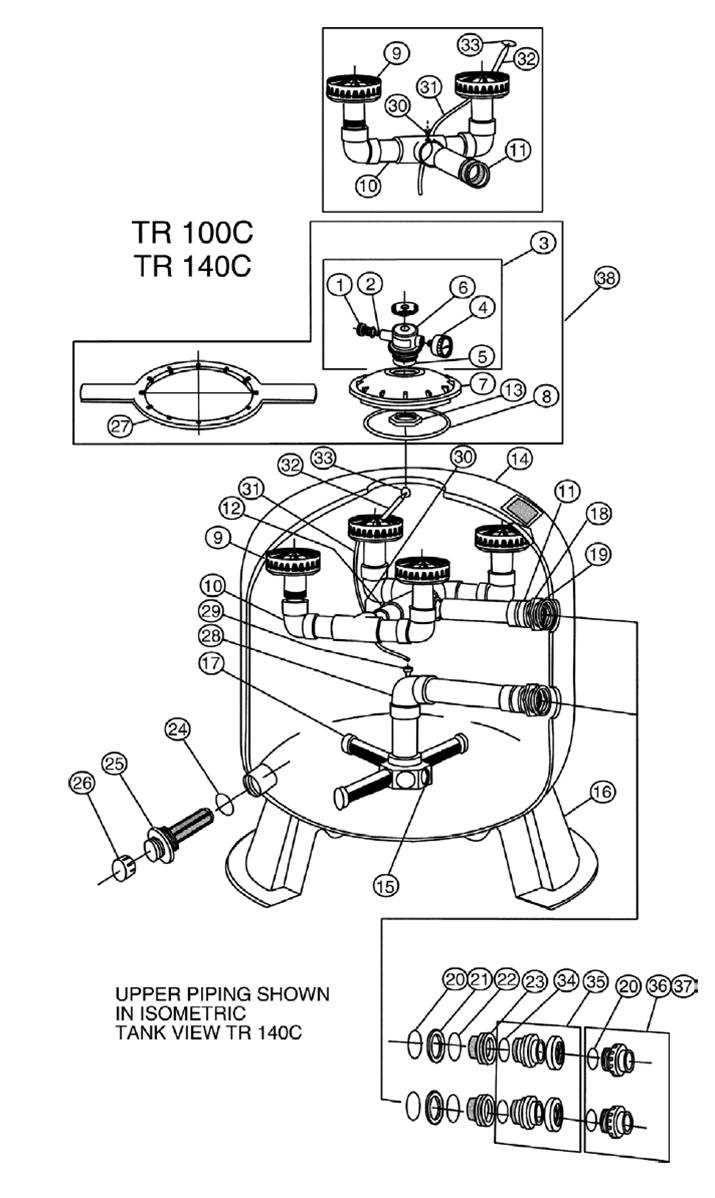

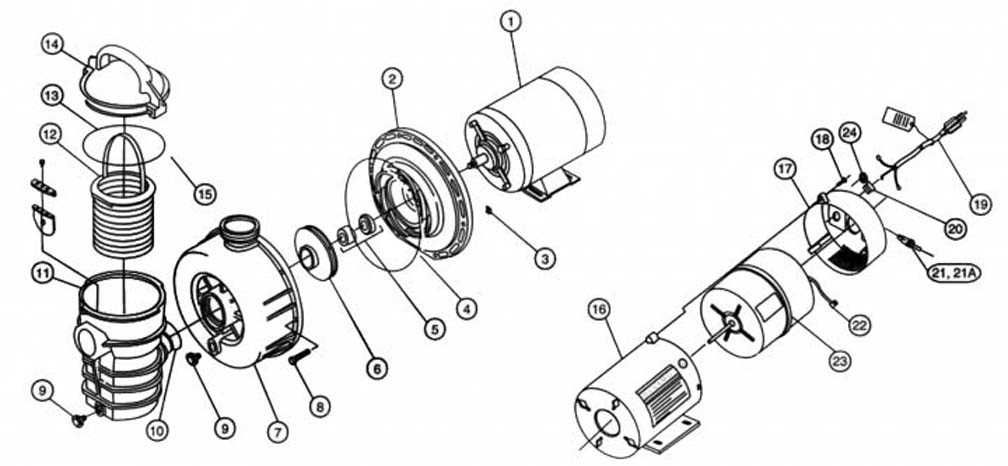

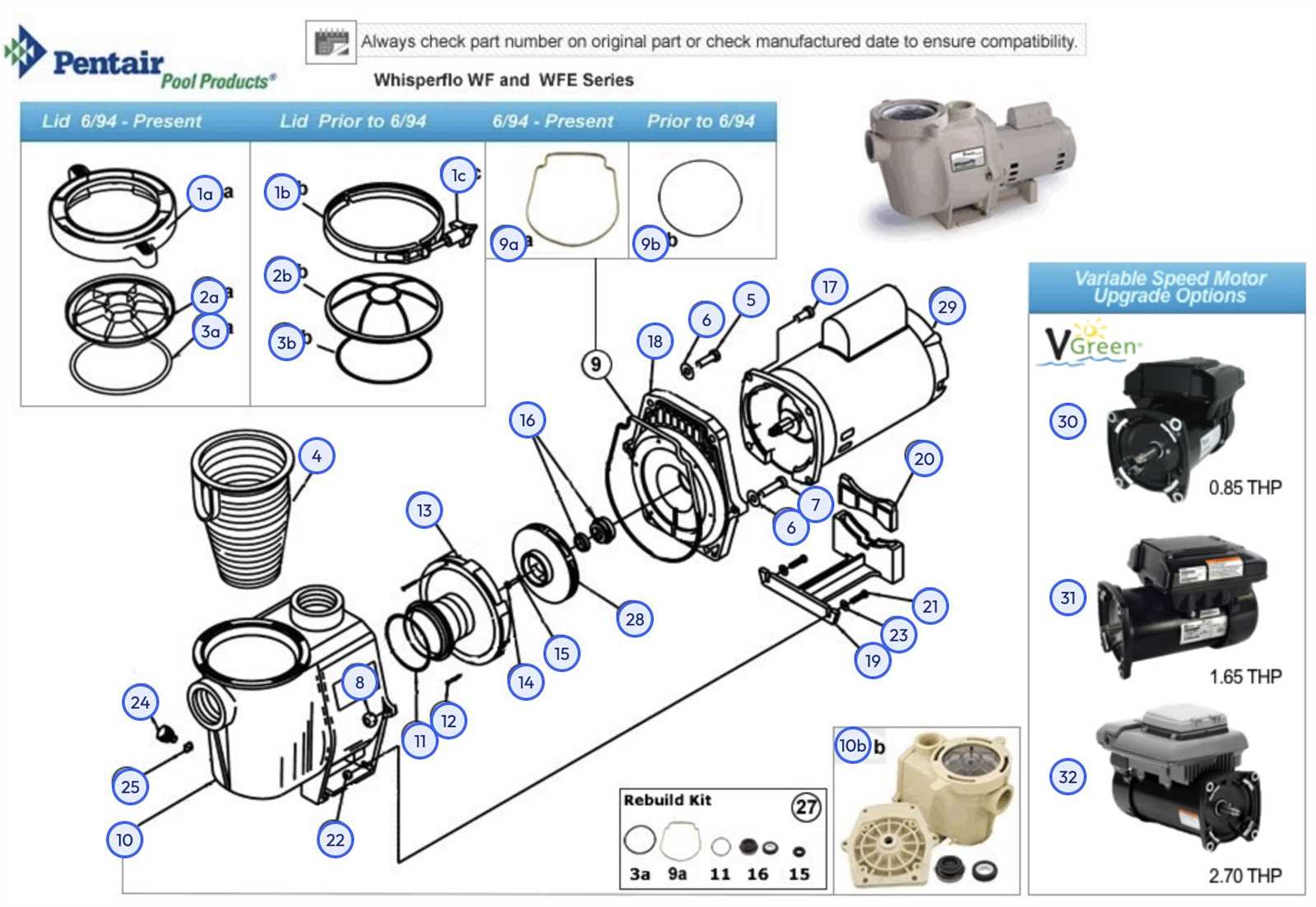

How to Read Parts Diagrams

Understanding how to interpret technical drawings is crucial for maintaining or repairing equipment. These schematics visually represent the various elements that make up a machine, helping users identify the correct components for replacement or assembly.

Identify Key Sections

Most illustrations are organized into clear sections, each representing a specific area of the equipment. Start by locating the area you need to focus on, such as the motor or filtration system. Each part within that section will usually be labeled with a number or code.

- Look for labels or symbols that correspond to specific items.

- Check the reference table accompanying the drawing for detailed descriptions.

Understand Numbering Systems

The numbers on the diagram typically refer to an itemized list, where each number corresponds to a particular component. Cross-reference these numbers with the list to find the correct names and specifications of each part.

- Locate the number on the illustration.

- Find the corresponding entry in the table or list.

- Read the specifications or details provided to confirm the correct piece.

By learning to read these visuals efficiently, you can quickly identify what you need to keep your equipment running smoothly.

Common Issues with Parts Identification

When working with complex equipment, accurately identifying components can be challenging due to variations in models, slight design changes, or unclear visual references. Misidentification often leads to improper maintenance or repair, which can result in further complications. It is important to understand the key distinctions between different elements to ensure smooth operation and longevity of the system.

Frequent Causes of Confusion

Several factors contribute to difficulties in recognizing specific elements. These can include outdated documentation, wear and tear that alters the appearance, or subtle design changes that are not immediately obvious. Additionally, similarities between certain components may cause further confusion, especially for those unfamiliar with the intricate details of the system.

Visual vs. Functional Differences

Distinguishing between components by appearance alone can be misleading. It is important to consider not only how they look but also their function within the system. In many cases, two elements might appear similar but serve entirely different purposes, leading to errors in replacement or maintenance.

| Issue | Cause | Recommended Action | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Misidentification | Outdated or unclear documentation |

| Source Type | Benefits | Considerations |

|---|---|---|

| Authorized Suppliers | Genuine components, expert support | Higher prices, limited availability |

| Online Marketplaces | Wide variety, competitive prices | Risk of counterfeit, need

Customer Support and Resources

For any inquiries regarding product maintenance, operation, or troubleshooting, customers have access to a wide range of support options and materials. Whether you’re looking for step-by-step guides, common issues, or advanced setup assistance, dedicated help is available to ensure smooth operation.

All resources are designed to provide comprehensive assistance, ensuring users have all the necessary tools to maximize efficiency and maintain functionality. |