In this section, we will explore the critical elements that make up a sophisticated air-powered system. These elements are designed to work in harmony, ensuring efficient functionality and longevity. Understanding how each component interacts can provide valuable insight into the system’s overall performance.

The mechanisms involved have been engineered for precision, durability, and user-friendly operation. Examining their arrangement and individual functions will offer a deeper comprehension of the system’s intricate design and how it maintains smooth and reliable operation over time.

This guide serves as a resource for those interested in enhancing their knowledge of the inner workings of such mechanisms. Whether you are performing maintenance or simply seeking to understand the technical details, this exploration will help you become more familiar with the core elements and their roles.

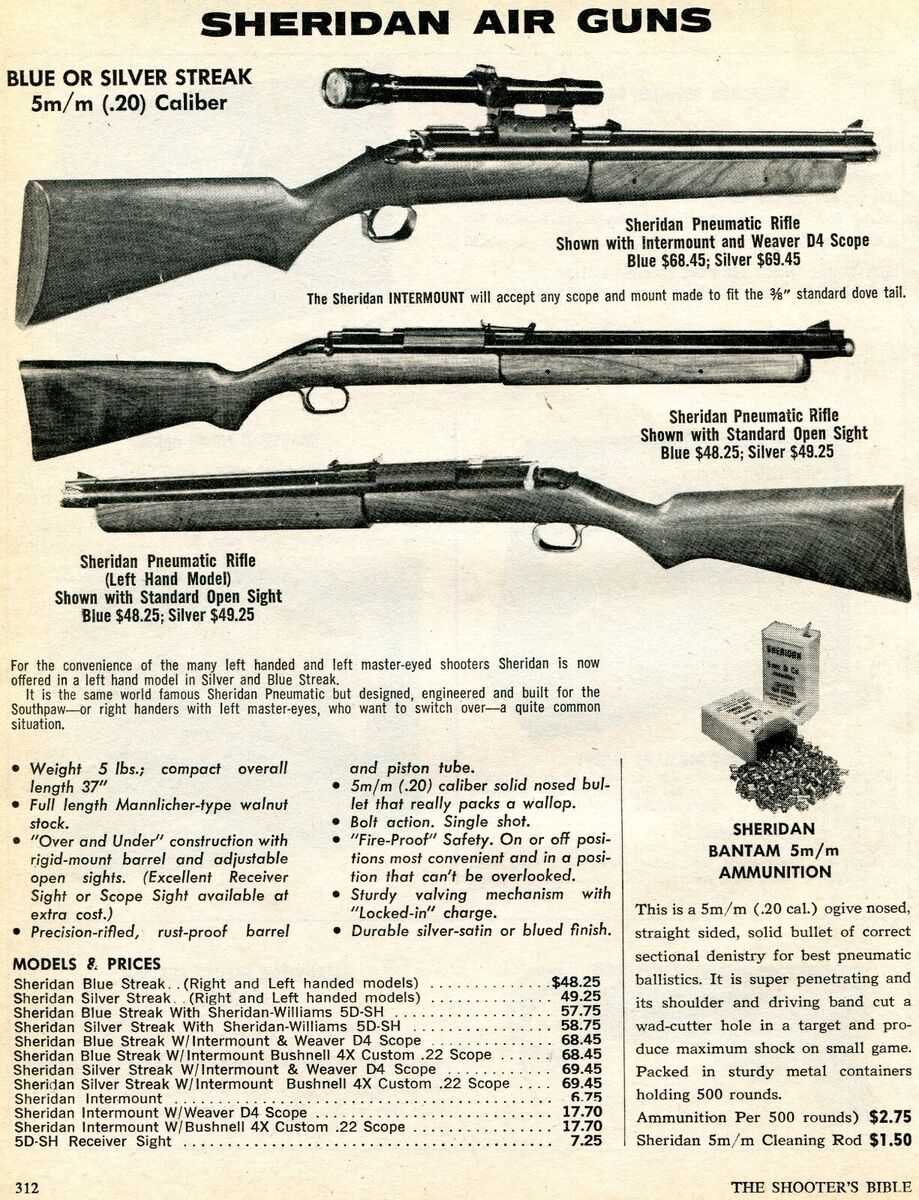

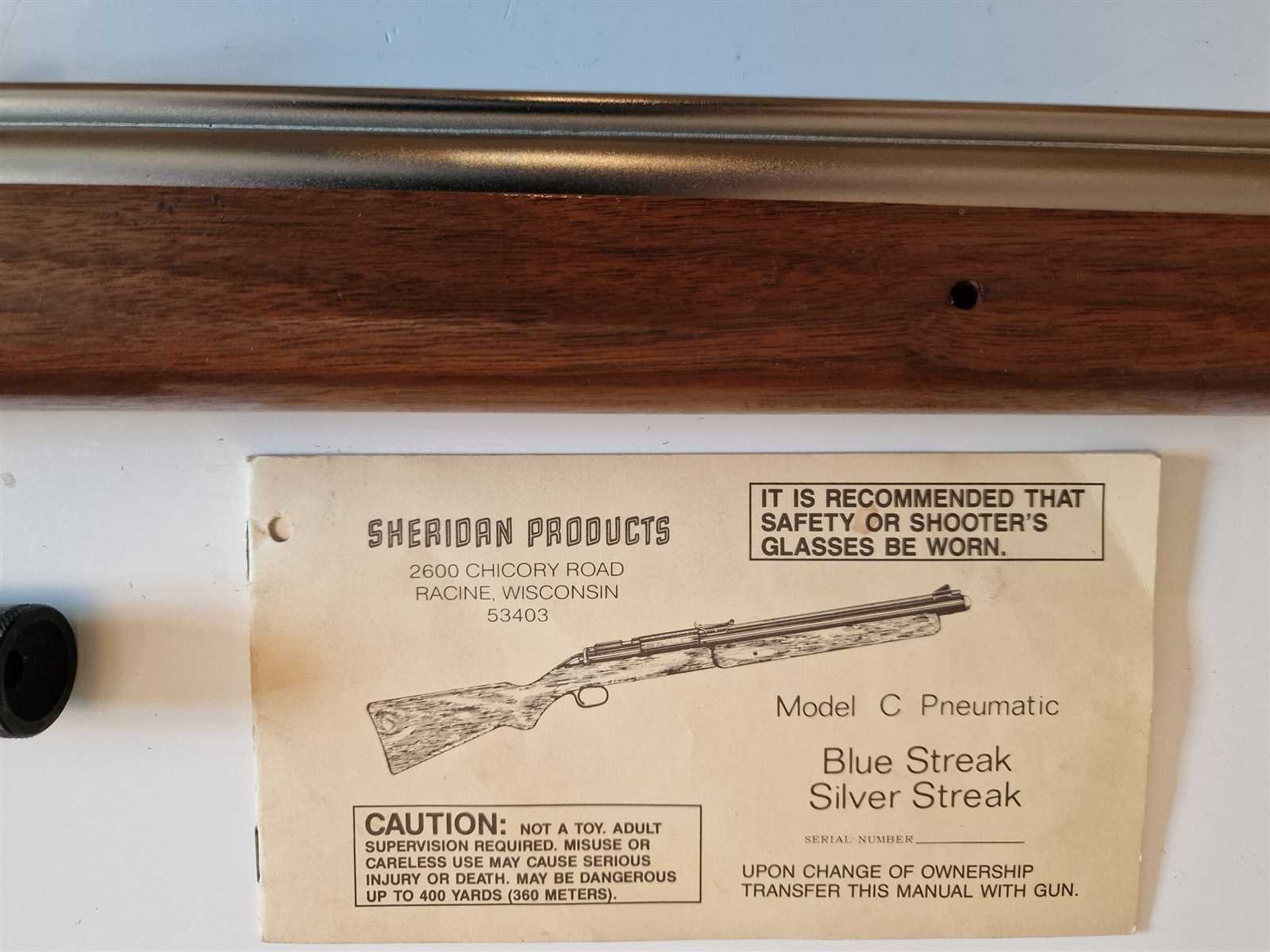

Sheridan Blue Streak Parts Overview

Understanding the internal elements and mechanisms of this pneumatic tool is essential for anyone seeking to maintain or upgrade it. Each component plays a specific role in ensuring proper operation and overall durability. Identifying the key segments of the device is crucial for efficient performance and long-term functionality.

Main Components

- Compression Chamber – This area is responsible for building and holding the necessary pressure for each discharge.

- Pump Mechanism – A critical element used to generate and store air pressure within the system.

- Barrel Assembly – Provides direction and accuracy for the expelled projectiles.

Additional Elements

- Trigger System – Controls the release of built-up pressure, ensuring safe and reliable operation.

- Seals and O-Rings – These prevent air leaks and help maintain efficient airflow.

- Sight Adjustment – Allows for precise aiming by altering the position of the sight.

Exploring Key Components of the Air Rifle

The internal structure of an air-powered firearm is composed of several crucial elements that work together to ensure efficient operation. These parts are carefully designed to manage the flow of air, control the release of pressure, and deliver consistent firing performance. By examining the core components, we can better understand how the system functions as a whole.

Pressure Management System

The power behind this air-based rifle comes from its ability to compress and store air. At the heart of this system is a chamber that houses the compressed air, which is then released in controlled bursts to propel projectiles. This process is regulated by valves and seals that prevent air leakage and ensure accurate firing each time.

Trigger and Firing Mechanism

Another critical element is the trigger assembly, which interacts with the pressure system to release the stored energy. The trigger engages the firing mechanism, allowing the controlled release of air. Precision in the design of this mechanism ensures smooth

Breakdown of the Valve Assembly

The valve mechanism is a crucial component responsible for managing airflow within the system. Its role is to ensure smooth operation by regulating the pressure and direction of air movement, which ultimately affects performance. A thorough understanding of its structure is essential for effective maintenance and troubleshooting.

Key Elements of the Valve

The valve unit consists of several interconnected parts that work together to control air intake and release. These include the sealing mechanism, the regulating spring, and the air channel. Each of these components plays a specific role in ensuring the proper function of the entire unit.

Importance of Regular Inspection

Over time, the valve system can experience wear and tear, which may result in decreased efficiency or even malfunction. Regular inspection and timely replacement of worn components, such as seals and springs, can significantly extend the life of the assembly and ensure optimal performance.

Understanding the Pump Mechanism Function

The pump system plays a crucial role in ensuring the efficient operation of pneumatic devices. Its primary task is to create the necessary pressure to propel projectiles, allowing for consistent and reliable performance. By understanding how this mechanism works, users can ensure proper maintenance and troubleshooting when necessary.

Main Components of the Pump System

- Lever: Responsible for initiating the compression process by moving air into the chamber.

- Piston: Compresses the air in the chamber, generating pressure.

- Valve: Regulates the flow of air, ensuring the correct amount enters the chamber.

How the Pump Mechanism Works

- The user operates the lever to move air into the compression chamber.

- As the piston moves, it compresses the air, building up pressure.

- The valve then controls the release of this air, which is used to propel the projectile.

Detailed Look at the Trigger System

The mechanism responsible for initiating action in this pneumatic device is crucial for its overall performance. It directly influences how efficiently the tool responds to the operator’s input, ensuring smooth and precise operation. Understanding the components and their interactions within this system is essential for optimizing performance and troubleshooting any potential issues.

- Trigger Lever: This key component is responsible for transferring the force applied by the user to the internal mechanism.

- Seer: A vital element that holds the mechanism in place until enough pressure is applied to release it, initiating the firing process.

- Springs: Various tension springs are used to reset the system and maintain the necessary force to hold the internal components in position.

- Safety Lock: A critical safety feature, this ensures that the tool cannot be activated accidentally, preventing unintended operation.

By examining these elements individually and understanding their functions within the larger system, users can better maintain and optimize the device for long-term reliability and precise operation.

The Role of the Bolt Action Assembly

The bolt-action mechanism plays a critical role in ensuring smooth operation and precise performance in many mechanical systems. This assembly, known for its reliability, governs the controlled movement of key components, enabling the system to function as intended. Through a series of interconnected parts, it helps in managing the overall sequence of operations.

Ensuring Seamless Motion

One of the main functions of the bolt-action assembly is to facilitate seamless movement between different stages of the mechanical cycle. Its design allows for consistent force application, minimizing friction and ensuring that the system operates with precision. The assembly is engineered to handle repeated actions without compromising its efficiency.

Providing Structural Stability

Beyond motion control, the bolt-action mechanism contributes significantly to the overall stability of the system. By maintaining proper alignment of the moving components, it reduces wear and tear and enhances the durability of the entire setup. This structural stability is essential for maintaining optimal performance over extended use.

Examining the Barrel and Sights

The function and performance of any air rifle depend heavily on the quality and design of its essential components. One of the most critical parts is the long tube that directs the projectile, and the aiming devices which help ensure accuracy. Understanding how these elements interact can greatly enhance both precision and reliability.

The Barrel’s Role in Accuracy

The primary function of the elongated tube is to guide the projectile, ensuring it travels in a straight, controlled path. The internal structure of the tube is vital for maintaining velocity and stability during discharge. Over time, proper maintenance is required to preserve this key feature’s effectiveness.

Features of the Sights

- Front and rear alignment: These components work together to provide a clear line of sight for the shooter, crucial for accuracy.

- Adjustability: A good aiming device allows for fine-tuning

Maintaining the Stock and Metal Frame

Proper care of the structural components is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances functionality but also prevents potential issues that may arise from wear and tear. By focusing on key areas, users can significantly improve the reliability of their equipment.

Here are some important maintenance practices to consider:

- Cleaning: Regularly remove dirt, dust, and debris from both the stock and metal surfaces. Use a soft cloth and appropriate cleaning solutions to avoid damage.

- Inspection: Periodically examine for signs of wear, rust, or structural damage. Early detection can prevent more serious issues later.

- Lubrication: Apply suitable lubricants to moving parts and joints to ensure smooth operation. Follow manufacturer recommendations for the best results.

- Storage: When not in use, store the equipment in a cool, dry place to prevent moisture buildup and corrosion. Consider using protective covers or cases.

By adhering to these maintenance practices, users can maintain the integrity of their equipment, ensuring it remains in excellent condition for years to come.

Common Issues with Sheridan Blue Streak

When dealing with this type of airgun, enthusiasts often encounter several challenges that can affect performance and reliability. Recognizing these common problems is essential for effective maintenance and ensuring optimal functionality.

- Air Leaks: One of the most frequent issues is the presence of air leaks, which can lead to a decrease in power and accuracy. These leaks may originate from seals or connections.

- Inconsistent Velocity: Variations in projectile speed can affect accuracy. This inconsistency might be due to problems with the compression chamber or the firing mechanism.

- Trigger Malfunction: A poorly functioning trigger can hinder performance, resulting in unpredictable firing. Regular adjustments may be necessary to maintain smooth operation.

- Poor Accuracy: Issues related to accuracy can stem from various factors, including barrel wear or improper alignment. Cleaning and regular inspections can help mitigate this problem.

- Scope Alignment: When using optics, misalignment can lead to frustrating shooting experiences. Ensuring that the scope is correctly mounted and aligned is crucial for effective target acquisition.

By being aware of these typical concerns, users can take proactive steps to maintain their airgun, enhancing longevity and overall enjoyment.