Exploring the detailed structure of a household appliance can greatly enhance its maintenance and functionality. When you gain a clear understanding of the different elements and how they interact, you are empowered to perform repairs, upgrades, or replacements with ease.

Visual representations play a key role in breaking down complex systems into manageable sections. By examining how individual components are arranged, it becomes easier to identify which parts might require attention during troubleshooting or routine maintenance. Whether it’s a worn-out component or a malfunctioning feature, having this knowledge makes a significant difference in achieving optimal performance.

Understanding the arrangement of internal elements also allows users to appreciate the design and engineering behind the product. It sheds light on the practical connections between parts, ensuring the device operates smoothly and efficiently. The more informed you are about the structure, the better your approach to managing any potential issues or improving its overall lifespan.

Overview of Shark NV70 Components

This section provides an in-depth look into the essential elements that come together to form the overall functionality of the device. Understanding the individual parts and their roles is key to grasping how the system operates efficiently. Each component plays a vital role in contributing to the device’s performance and ease of use.

Main Functional Units

- Motor Assembly: Powers the device and drives the performance of the suction system.

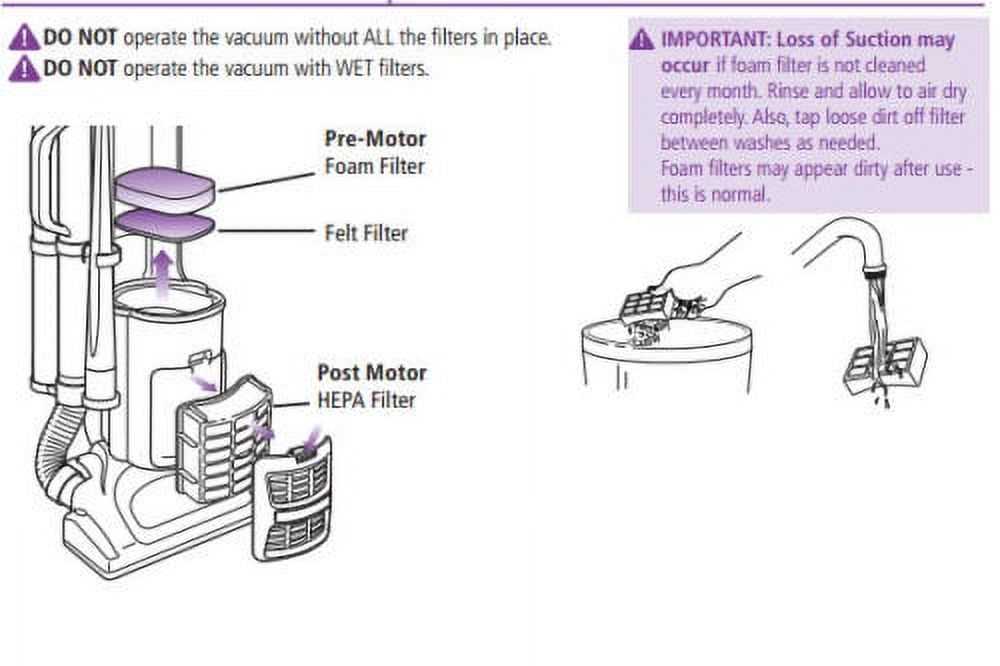

- Filter System: Helps in maintaining clean air by trapping fine particles and allergens.

- Brush Roll: Designed to agitate and lift debris from various floor surfaces.

Supportive Features

- Dustbin: Holds the collected dirt and debris, offering easy disposal when full.

- Hose: Flexible conduit used for reaching tight spaces or extended cleaning areas.

- Wheels: Provide smooth movement and navigation, enhancing maneuverability.

Understanding Key Parts of the Model

The functionality of any cleaning device relies heavily on the individual components that make up its structure. Each element serves a distinct purpose, contributing to the overall efficiency and performance of the machine. By exploring the key components, users can gain a better understanding of how these pieces work together seamlessly to ensure optimal results during use.

Among the essential parts, the motor system plays a crucial role in powering the device, providing the necessary suction force. The housing and filters, designed to contain and direct airflow, ensure that dust and debris are effectively trapped. Additional components such as brushes, belts, and hoses work in tandem to facilitate thorough cleaning across different surfaces. Understanding how these elements interact can help users make informed decisions about maintenance and troubleshooting.

How to Disassemble the Shark NV70

Disassembling this cleaning device is a straightforward process, but it requires a careful approach to avoid damaging any components. To begin, ensure that the appliance is unplugged and completely powered off. You’ll need to remove any detachable elements, such as the handle and attachments, to gain access to the internal parts. Below, we’ll outline the key steps and tools you will need for a successful disassembly.

Step 1: Detach External Components

The first step involves detaching any external components, including the handle, cleaning head, and hose. Carefully unscrew or unlock any clips that hold these parts in place. Use a small screwdriver to remove screws, being mindful of where each part is stored for reassembly.

Step 2: Access Internal Parts

Once the external components are removed, you’ll have a clearer view of the internal mechanisms. At this stage, it’s important to unscrew any additional fasteners securing the internal sections. Take your time to identify all the screws, and keep track of them as you go.

| Component | Tool Required |

|---|---|

| Handle | Small screwdriver |

| Cleaning head | Phillips screwdriver |

| Internal fasteners | Flathead screwdriver |

Step-by-Step Breakdown Process

In this section, we will guide you through a detailed, systematic procedure to disassemble and analyze the various components of the cleaning device. This process ensures that each part is thoroughly examined and understood, providing clarity for maintenance or repair tasks.

- Preparation: Begin by gathering all necessary tools. Ensure that the workspace is clean and well-lit for optimal visibility.

- Disengage Power Sources: Disconnect the power supply to avoid any potential accidents or electrical hazards.

- Remove External Covers: Carefully detach any outer casings or panels that may be securing internal components.

- Identify and Extract Components: Identify key elements such as motors, filters, and other vital parts. Proceed to remove each part in a logical sequence, noting any screws or fasteners.

- Label and Store: As you remove parts, label them to ensure easy reassembly. Store each component separately to avoid mixing or misplacing them.

- Inspect and Clean: Once all parts are removed, inspect them for wear, damage, or dirt. Clean any parts that require it to maintain efficiency.

Following these steps carefully will not only help in maintaining the device’s longevity but also assist in diagnosing any issues effectively.

Common Shark NV70 Issues

When using a vacuum cleaner, there are a few recurring problems that users may encounter over time. These issues can affect performance and overall efficiency, requiring attention to specific components to ensure smooth operation. Understanding these common difficulties can help in troubleshooting and maintaining the device for optimal results.

Power Loss is one of the most frequent issues. This could result from a malfunction in the electrical connection, such as a damaged cord or faulty switch. It’s essential to inspect these parts regularly to avoid interruptions during cleaning.

Reduced Suction is another concern. Often caused by blockages in the hose or filters, this can greatly diminish cleaning effectiveness. Regular cleaning of these components can prevent clogging and help maintain proper airflow.

Noisy Operation may also occur, which could be indicative of a loose part or an issue with the motor. If the noise becomes louder than usual, inspecting the internal workings might be necessary to identify and fix the source.

Lastly, Brush Roll Problems often arise when hair or debris gets tangled around the roller, hindering its movement. Regular removal of tangled material can help restore full functionality.

Diagnosing Frequent Part Failures

Understanding the root cause of recurring malfunctions in components is key to ensuring long-lasting performance and minimizing downtime. It’s essential to assess each element of the system to identify patterns that may indicate frequent wear or failure. Regular monitoring and proactive maintenance can prevent unexpected issues and extend the lifespan of your device.

Signs of Common Failures: Some components tend to show signs of degradation more quickly than others. Pay attention to any unusual noises, decreased efficiency, or changes in overall performance. These are often early indicators that a failure is imminent.

Preventive Measures: To avoid frequent breakdowns, ensure that you are performing routine inspections and addressing minor issues before they escalate. This may include cleaning or replacing smaller parts before they cause larger problems. A proactive approach can help maintain efficiency and reduce the risk of failure over time.

Reassembling the Shark NV70

When putting the device back together, it is essential to follow the correct order of steps to ensure optimal performance. Proper reassembly will extend the lifespan and maintain the efficiency of the vacuum cleaner.

- First, gather all the disassembled components and check for any signs of wear or damage.

- Ensure the filters are clean and dry before reinserting them into their respective slots.

- Reconnect the primary body pieces, making sure all latches and fastenings click into place securely.

- Reinstall the hose, ensuring it is firmly attached at both ends to prevent air leaks.

- Lastly, check that the brush roll is spinning freely before sealing the lower casing.

By following these steps, you ensure that your cleaning device is reassembled correctly and ready for use.

Tips for Proper Reassembly

When putting a device back together, careful attention to detail is essential to ensure it functions as intended. It’s important to follow the process methodically, keeping track of every component and how it fits into the overall mechanism. The reassembly stage is just as critical as disassembly, and even the smallest oversight can affect performance.

Organize Your Workspace

Before starting, organize your workspace to have a clear view of all the elements. Arrange components by size or function, ensuring everything is easily accessible. This step helps prevent misplacement or confusion during reassembly.

Use the Right Tools

Make sure you have the correct tools for the task. Using the wrong instrument can damage delicate pieces, while the right one ensures everything is tightened and secured properly.

Maintaining Your Shark NV70

Regular care of your cleaning device is essential to ensure long-lasting performance. By taking simple steps to keep your appliance in good working condition, you can avoid common issues and maintain its efficiency. Proper attention to both internal and external components will prolong its usability.

Key Maintenance Areas

Focusing on specific areas of the device is critical for preventing malfunctions. This includes cleaning filters, checking brush rolls, and inspecting hoses for clogs or wear. Each part plays a crucial role in the overall function of the appliance.

Maintenance Schedule

Following a consistent maintenance schedule can help prevent unexpected breakdowns. Below is a simple guide to routine checks:

| Task | Frequency |

|---|---|

| Filter Cleaning |