The process of understanding the internal configuration of cleaning devices involves familiarizing oneself with the individual components that make up the unit. This layout allows users to better comprehend how the different sections interact to ensure optimal performance. Each element plays a significant role in maintaining the efficiency and functionality of the machine.

For those looking to maintain or repair their equipment, knowing the positioning and connections between these sections is crucial. With this knowledge, it becomes easier to troubleshoot issues, replace worn-out elements, and ensure that the device operates at its full potential. Whether you’re dealing with an issue of power loss, suction strength, or general maintenance, understanding how each part fits together is the first step toward effective resolution.

Accurate identification of the internal components is vital when it comes to assembly and disassembly. Familiarity with the arrangement of the system helps streamline any repair efforts, saving both time and effort. Whether replacing filters or addressing motor issues, the detailed layout helps guide users through the process with confidence.

Essential Components of Shark NV352

Understanding the key elements that make up an advanced cleaning device is crucial for effective maintenance and optimal performance. These components work in unison to ensure efficiency in both suction power and ease of use. Each part plays a vital role in ensuring the smooth operation of the machine, and recognizing them helps in troubleshooting or replacing damaged items.

Main Unit and Motor Assembly

The heart of the device is its motor, which drives the suction mechanism and powers the vacuuming function. It is typically located within the main housing unit and works alongside a fan system to generate the airflow needed to lift dirt and debris. Regular maintenance ensures its longevity and uninterrupted performance.

- Motor assembly

- Airflow fan

- Power switch

Cleaning Head and Attachments

The cleaning head is designed for direct contact with surfaces, collecting dirt while providing flexibility to maneuver around obstacles. Different attachments can be swapped in depending on the surface or specific cleaning needs, ranging from upholstery tools to crevice attachments.

- Floor brush roll

- Upholstery tool

- Crevice tool

Each of these essential components ensures that the device can handle a variety of tasks, making it a versatile tool for cleaning around the home.

Understanding the Vacuum Motor Assembly

The motor unit in a cleaning device plays a critical role in maintaining powerful suction and efficient operation. It consists of several key components working together to ensure optimal performance. Understanding the layout and functionality of this assembly helps users recognize its importance in the overall system and address any maintenance or repair needs effectively.

This section focuses on the various parts that make up the motor assembly, including the motor itself, its housing, and associated electrical connections. Each component is designed to handle specific tasks such as air movement, filtration, and power supply regulation. Familiarity with these parts allows for better troubleshooting and proper care of the system.

Exploring the Dust Canister Design

The design of the debris collection compartment plays a pivotal role in the efficiency and ease of maintenance of a vacuum cleaner. This component is crucial for gathering dirt and dust during cleaning, ensuring that the system functions without interruption. A well-thought-out design helps in smooth operation, optimal dust storage, and easy disposal of collected debris.

Key Features of the Canister

- Transparent body for monitoring the fill level.

- Quick-release mechanism for hassle-free emptying.

- Durable construction to withstand regular handling.

- Compact shape for easy storage.

Improving Efficiency

- Advanced filtration systems integrated within the canister to trap fine particles.

- Design features that ensure minimal dust escape during disposal.

- Optimized airflow to prevent clogging and enhance suction power.

Key Brushes and Cleaning Tools

In any cleaning system, certain components are essential for maintaining optimal performance and efficiency. Brushes and specialized tools play a crucial role in ensuring that surfaces are thoroughly cleaned and that the machine remains in peak condition. These elements are designed to tackle various cleaning challenges, from removing debris to reaching difficult areas.

The right tools can significantly enhance the overall cleaning process, providing a deeper clean and extending the lifespan of the equipment. Below are the primary types of brushes and cleaning tools typically found in these systems:

- Brush Rollers: Ideal for agitating dirt and debris from carpets and floors, brush rollers are a fundamental part of many cleaning systems. They are designed to spin at high speeds to efficiently collect particles.

- Crevice Tools: These narrow, elongated tools are perfect for accessing tight corners, edges, and other hard-to-reach areas, ensuring no dirt is left behind.

- Upholstery Brushes: Soft bristles are used for gently cleaning furniture and delicate surfaces without causing damage. They are especially useful for picking up pet hair and fine dust.

- Hard Floor Brushes: These brushes are specifically designed for hard surfaces, ensuring an effective clean without scratching or damaging floors.

- Dusting Brushes: Soft, fine bristles make these tools ideal for dusting off surfaces such as baseboards, vents, and light fixtures, helping to remove fine particles without pushing them around.

Proper maintenance of these tools is essential to maintain their effectiveness. Regular cleaning and replacing worn-out parts will ensure that the system continues to function efficiently for years to come.

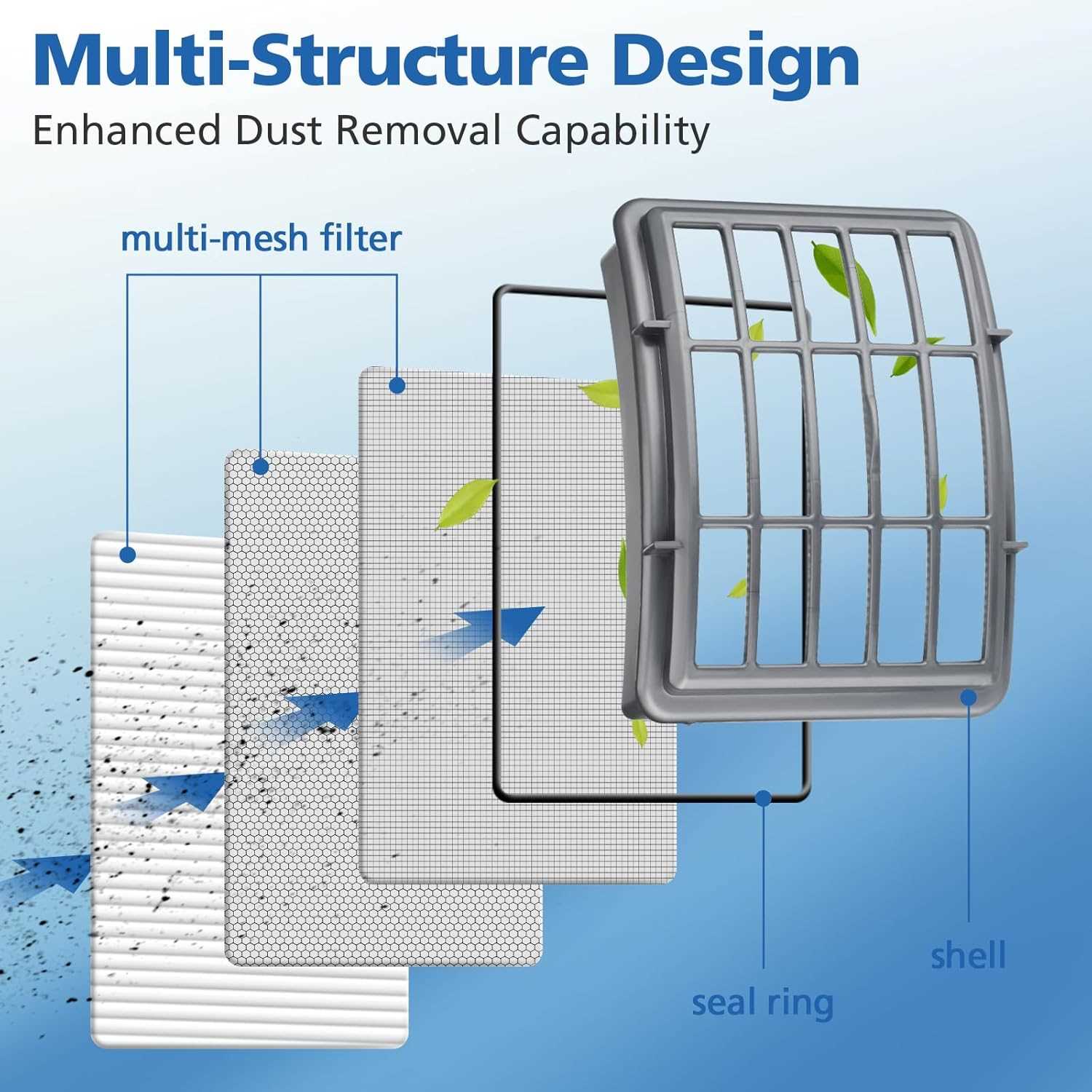

Filter Placement and Maintenance Tips

Proper placement and regular upkeep of the filtration system are essential to ensure optimal performance of your cleaning device. Keeping filters in their correct positions prevents blockages and ensures that the airflow remains uninterrupted, while proper maintenance extends their lifespan and maintains cleaning efficiency.

Here are some tips to help you maintain the filters effectively:

| Task | Recommendation |

|---|---|

| Filter Installation | Ensure that filters are placed securely in their designated slots. Improper placement can lead to reduced suction power. |

| Cleaning Frequency | Clean filters regularly, ideally every 1-2 months, depending on usage. Washing helps prevent dirt buildup and maintains air circulation. |

| Drying Filters | Allow filters to dry completely before reinserting them to prevent mold or odor development. |

| Replacement | Replace filters when they show signs of wear, such as tears or persistent odors, to keep the machine functioning at its best. |

Internal Wiring and Electrical Connections

The intricate design of household appliances includes a network of wires and electrical components that ensure efficient operation. These connections are essential for powering the device, enabling its various functions. A well-organized wiring setup ensures safety, reliability, and longevity, preventing short circuits or power malfunctions. Understanding these internal components is key to troubleshooting and repairs.

Typically, the wiring layout consists of power cables, connectors, and switches that interact with motors, sensors, and other electrical elements. Each component is carefully connected to form a functional system, with the wiring paths organized to minimize the risk of interference or damage.

| Component | Function | Connection Type |

|---|---|---|

| Power Cord | Supplies electrical power to the system | Direct connection to the power supply |

| Motor Wires | Power the motor for movement | Direct connection to motor terminals |

| Switches | Control the activation of different functions | Connected to power and control circuits |

| Sensors | Monitor the device’s performance | Integrated with control system wiring |

| Connectors | Link various components | Secure and insulated connections |

How to Replace the Hose and Attachments

Replacing the flexible tube and associated components is a simple process that can restore the full functionality of your cleaning tool. Over time, these parts may wear out or become damaged, requiring you to replace them. This section will guide you through the necessary steps to ensure proper installation and secure connection of these components.

Step 1: First, disconnect the device from the power source and lay it flat to access the tube. Carefully examine the current hose to check for any signs of damage or blockages that might require its removal.

Step 2: To remove the old tube, locate the attachment points on both ends. Release any locking mechanisms or clips that may be securing the hose. Gently pull the hose away from its connection points.

Step 3: Once the old hose is removed, attach the new one by aligning the connectors properly. Ensure that the attachment points are secure and that the hose is not twisted or kinked.

Step 4: Next, replace any additional components, such as brushes or nozzles. Secure them in place by snapping or twisting them into their designated positions.

Tip: Always verify the tightness of each connection after installation to prevent any leaks or malfunction during use.

Assembly and Disassembly for Troubleshooting

Proper assembly and disassembly are essential steps when addressing common issues in mechanical devices. A structured approach to these processes ensures that each component is inspected, cleaned, or replaced as needed, contributing to the effective repair and maintenance of the system. Understanding the order in which parts should be handled and recognizing their connections is crucial for troubleshooting various malfunctions.

Step-by-Step Breakdown

When beginning the disassembly, start by identifying the main sections of the device. Carefully remove the outer casing or covers, ensuring that no parts are damaged during the process. Once exposed, inspect the internal components for wear or debris that could cause performance issues. Reassembling involves reversing this process, ensuring each piece fits securely, and no parts are left loose or misaligned.

Key Considerations for Effective Troubleshooting

While disassembling, take note of any broken, worn, or out-of-place components that may be contributing to the issue. Use appropriate tools to avoid damaging sensitive areas. During reassembly, double-check that all connections are secure and that no parts are left unattached. This step ensures the device operates as intended after repairs.

Upgrades and Customization Options

Enhancing your cleaning device can significantly improve performance and adapt it to specific needs. Whether you’re looking for increased efficiency, added versatility, or personalized aesthetics, there are various ways to modify and upgrade key components. These modifications range from functional to cosmetic adjustments, allowing users to tailor their equipment for better results.

There are several popular enhancement choices that can help maximize the utility of the device. Upgrades in filtration systems, suction power, and additional attachments provide practical improvements, while design modifications focus on comfort and usability.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Filter Enhancements | Upgrading to high-performance filters for better dust retention and allergen control. | Improved air quality and a cleaner environment. |

| Suction Power Boost | Reinforcing suction capacity for tackling more stubborn dirt and larger debris. | Increased cleaning efficiency, especially for carpets and thick fabrics. |

| Additional Attachments | Adding specialized tools such as crevice tools or upholstery brushes. | Enhanced versatility for various surfaces and cleaning tasks. |

| Ergonomic Handles | Switching to more comfortable, adjustable handles for better maneuverability. | Improved ease of use, reducing strain during extended cleaning sessions. |