| Cutting Deck |

Responsible for the primary function of the mower, ensuring clean and even cuts across varied terrain. |

Understanding the Mower Deck Assembly

The mower deck is a critical component in any cutting machine, responsible for ensuring smooth and even grass trimming. It houses the blades and provides the necessary structure for efficient grass cutting. Proper understanding of how the deck functions helps in maintaining its performance and diagnosing potential issues that might arise during operation.

The assembly includes various interconnected elements that work together to deliver optimal results. The blades, spindles, and pulleys are some of the essential parts that make up this structure. Ensuring these components are aligned and in good condition guarantees that the machine will operate efficiently, providing clean and consistent cuts.

Regular maintenance of this system is crucial. Checking for wear, adjusting the height, and keeping the underside clean can prolong the life of the deck and improve the overall performance of the cutting equipment. Knowing how the assembly fits together will also assist in making necessary repairs or upgrades when needed.

Engine and Drive System Layout

The design of the engine and drive mechanisms in this model focuses on achieving optimal performance and reliability. By carefully organizing the components, the system ensures efficient power transfer, precise control, and long-term durability. This arrangement allows for smooth operation in various conditions, making it suitable for heavy-duty tasks. In this section, we will explore the core elements of the drive structure and how they interact to maintain steady movement and power flow.

Engine Configuration

The engine is the core of the vehicle’s functionality, designed to deliver consistent power output. It operates in sync with various

Exploring the Electrical System Connections

The intricate web of connections within the electrical system plays a vital role in ensuring that all components operate seamlessly. These connections are responsible for distributing power and signals throughout the machine, enabling various functions to work in harmony. Understanding the layout and purpose of each connection is essential for troubleshooting and maintaining the overall system’s health.

Power Distribution Pathways

The power pathways ensure that energy is delivered efficiently to critical components. This includes wiring responsible for connecting the power source to key systems such as the ignition, lights, and engine controls. Proper routing and secure connections are crucial for preventing electrical failures and ensuring reliable performance under various operating conditions.

Signal Transmission and Control

Apart from distributing power, the electrical system also manages signals that control different functionalities. These signals travel through various cables and connectors, linking sensors, switches, and actuators. Clear signal flow is essential for the system’s response to user inputs, whether it’s starting the engine or adjusting speed settings. Periodic inspections can

Hydraulic System Parts and Functionality

The hydraulic system is an essential component, allowing various mechanisms to function efficiently by transmitting power through fluid dynamics. It plays a critical role in enhancing performance and ensuring smooth operation across multiple systems. Understanding how this intricate system operates and the key elements involved is fundamental for proper maintenance and optimization.

Pumps are central to the system, creating the necessary pressure to drive the fluid through the circuit. Without a functioning pump, the hydraulic system would be ineffective in transmitting force to the working components.

Valves control the direction and flow of the hydraulic fluid, ensuring that power is distributed to the right areas at the correct time. These elements help manage the overall efficiency and safety of the system.

Cylinders convert the fluid pressure into mechanical force, enabling movement or lifting of heavy objects. They are often found in systems that require strong, precise control of linear motion.

Filters ensure that the fluid remains clean and free from

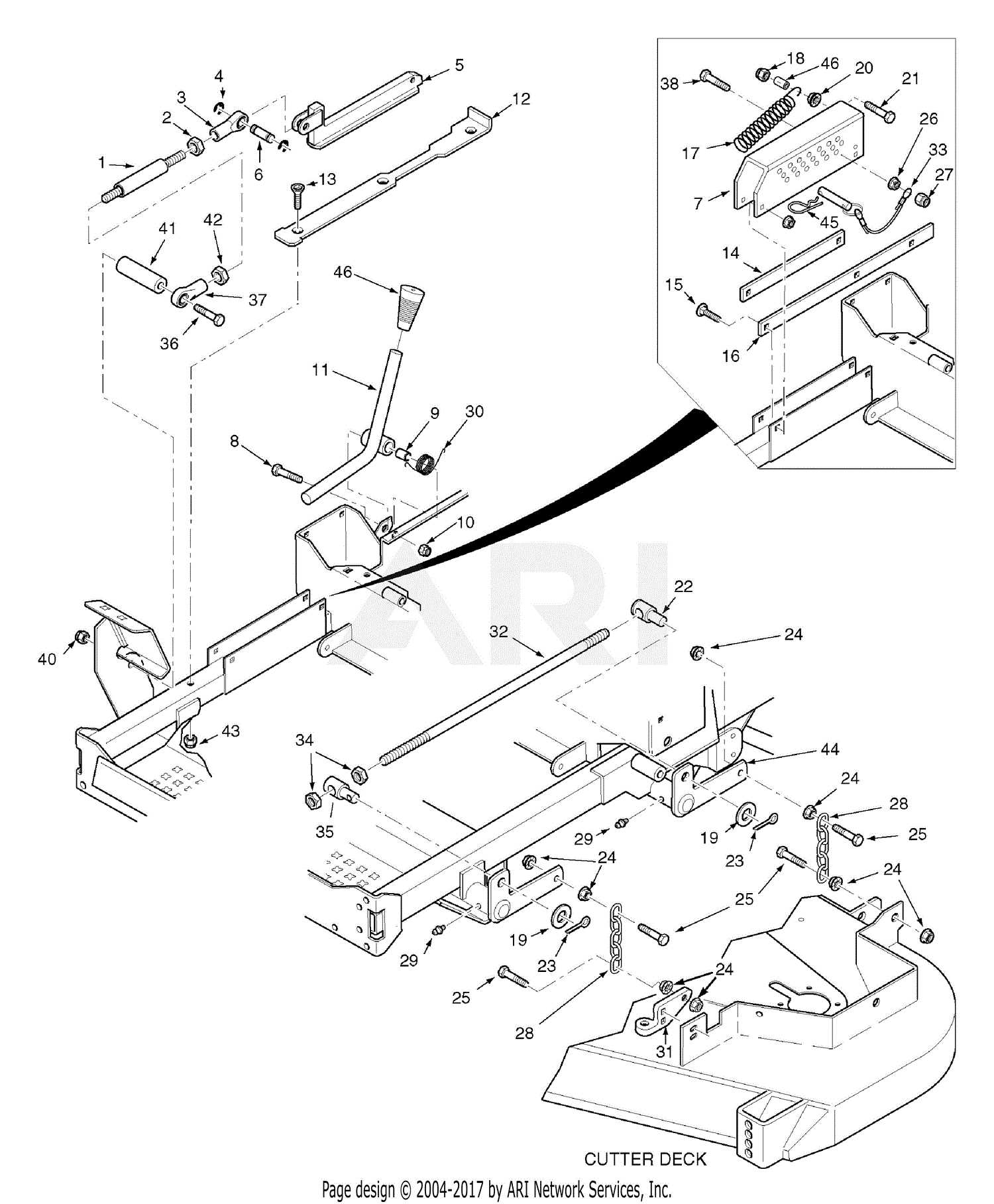

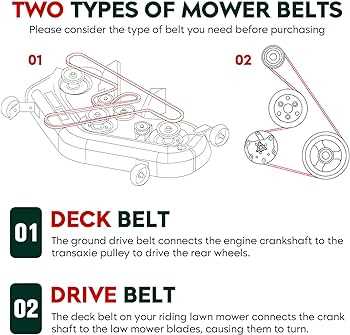

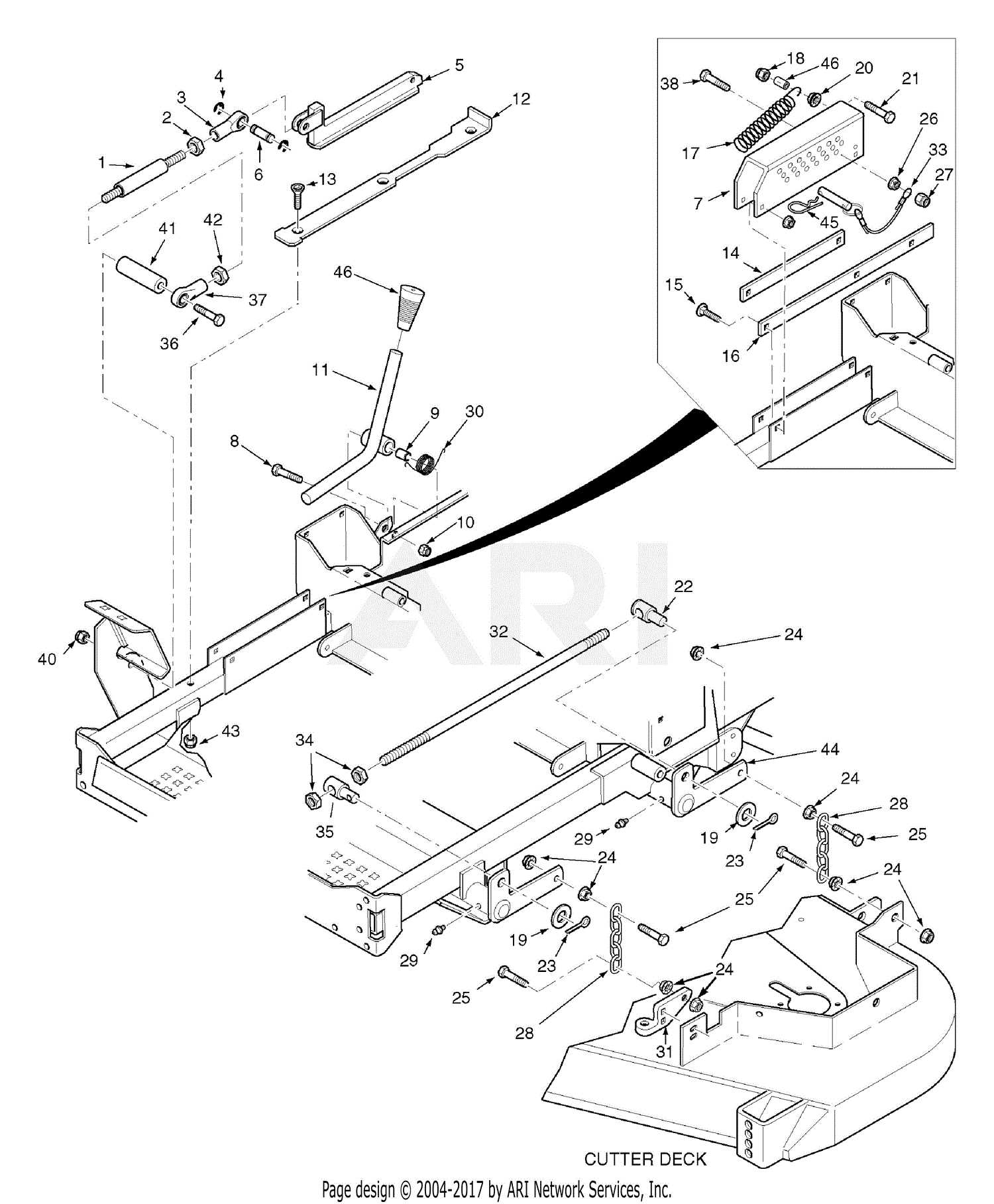

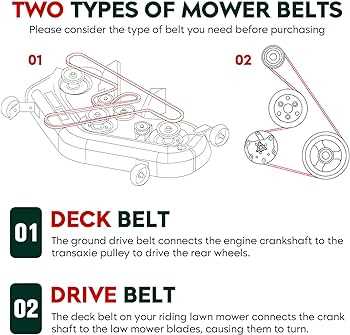

Blade and Belt Arrangement in the System

The configuration of cutting implements and drive mechanisms plays a crucial role in the overall functionality of lawn care equipment. This section delves into how the positioning and interaction between blades and belts contribute to efficient operation, ensuring optimal performance and longevity of the system.

Blade alignment is essential for achieving a clean cut. Proper positioning allows the blades to work harmoniously, providing an even trim across various terrains. The angle and height at which blades are set can significantly affect cutting efficiency, making it vital to maintain the correct specifications.

Belts serve as the vital link between the engine and the cutting implements. Their arrangement determines how power is transferred, impacting the responsiveness and speed of the blades. The correct tension and alignment of these belts are necessary to prevent slippage and ensure consistent operation under different load conditions.

Seat and Operator Controls Layout

The layout of the seating and control systems is crucial for ensuring operator comfort and efficient machine handling. A well-designed arrangement allows for easy access to all necessary functions, enhancing the overall user experience during operation. The intuitive positioning of controls contributes significantly to safety and performance, enabling users to focus on their tasks without unnecessary distractions.

Seating Position

The operator’s seat is strategically positioned to provide optimal visibility and accessibility to all critical areas of the machine. Key features include:

- Adjustable Seat: Allows users to customize the height and angle for maximum comfort.

- Armrests: Support operator arms, reducing fatigue during prolonged use.

- Seat Suspension: Absorbs shocks and vibrations, enhancing comfort on uneven terrain.

Control Arrangement

The control layout is designed to promote intuitive handling and swift responses. Important components include:

- Throttle Control: Positioned for easy reach, allowing for precise speed adjustments.

- Brake Pedals: Located strategically to facilitate quick stopping when necessary.

- Steering Controls: Ergonomically designed for comfortable grip and maneuverability.

- Dashboard Indicators: Clearly visible displays for monitoring machine status and diagnostics.

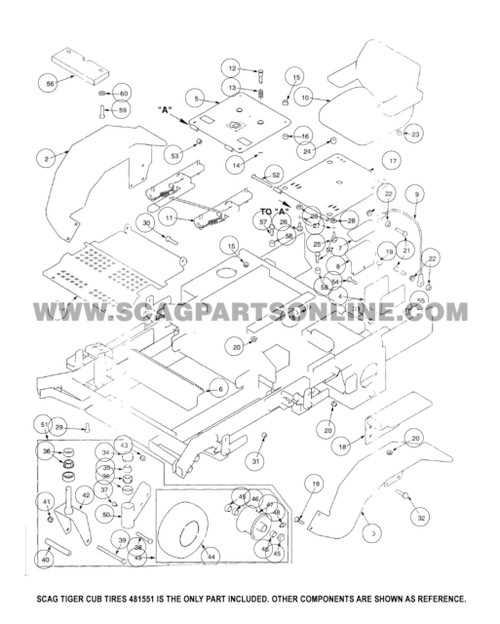

Steering and Wheel Assembly Breakdown

The steering and wheel assembly is a crucial component that facilitates the maneuverability and control of the equipment. Understanding the intricacies of this assembly is essential for maintenance and troubleshooting. It comprises various elements that work together to provide a smooth driving experience and precise handling.

Key Components of the Steering Assembly

This assembly typically includes the steering wheel, shaft, and a series of linkages that connect to the wheels. The steering wheel serves as the primary interface for the operator, allowing for directional control. The shaft transmits the motion from the steering wheel to the linkage system, translating the operator’s input into movement.

Wheel Assembly Features

The wheel assembly consists of the wheels, tires, and bearings that support the weight of the equipment and enable smooth movement. Tires are designed to provide traction and stability on various surfaces, while bearings reduce friction, ensuring that the wheels rotate freely. Regular inspection of these components is vital to maintain optimal performance and safety.

Fuel System and Maintenance Access Points

The fuel system plays a crucial role in the performance and reliability of outdoor power equipment. Understanding the layout and accessibility of various components can significantly enhance maintenance efficiency and ensure optimal functionality. Proper care and timely servicing of the fuel system are essential for preventing potential issues and prolonging the life of the machinery.

Key Components of the Fuel System

- Fuel Tank: The primary reservoir for storing fuel, typically located at the rear of the unit for easy access.

- Fuel Lines: Flexible tubing connecting the fuel tank to the engine, facilitating the flow of fuel.

- Fuel Filter: A critical component that removes impurities from the fuel before it reaches the engine.

- Fuel Pump: An electric or mechanical device that moves fuel from the tank to the engine under pressure.

- Carburetor: Responsible for mixing fuel with air in the correct ratio for combustion.

Access Points for Maintenance

Regular maintenance of the fuel system is vital to ensure reliable operation. Below are some key access points to consider:

- Fuel Tank Cap: Located at the top of the fuel tank, allowing for easy refueling and inspection of fuel levels.

- Fuel Filter Housing: Accessible for filter replacement, which should be done periodically to maintain fuel quality.

- Fuel Line Connections: Regular checks for leaks and secure connections are essential for safety and efficiency.

- Carburetor Access Panel: Provides direct access for cleaning and adjustments to ensure proper fuel-air mixture.

- Drain Plug: Located at the bottom of the fuel tank, allowing for complete fuel evacuation during storage or repairs.

By familiarizing oneself with the fuel system’s components and maintenance access points, operators can ensure efficient performance and longevity of their equipment.