The functionality of a spray application system relies on various intricate elements working in harmony. Each component plays a crucial role in ensuring efficiency and precision during the operation, contributing to the overall effectiveness of the equipment. A thorough comprehension of these elements enhances the user’s ability to maintain and troubleshoot the apparatus effectively.

Familiarizing oneself with the different sections of the system allows for better decision-making when it comes to repairs or upgrades. Recognizing how each element interacts within the assembly provides valuable insights into the mechanics behind optimal performance. By delving into the specifics of these components, users can improve their understanding and elevate their skills in handling the apparatus.

Whether one is a novice or an experienced operator, gaining knowledge about the assembly can significantly impact the quality of results achieved. A well-informed user is better equipped to manage the intricacies of the system, ensuring longevity and reliability. This exploration serves as a guide to navigating the various elements that contribute to a successful spraying experience.

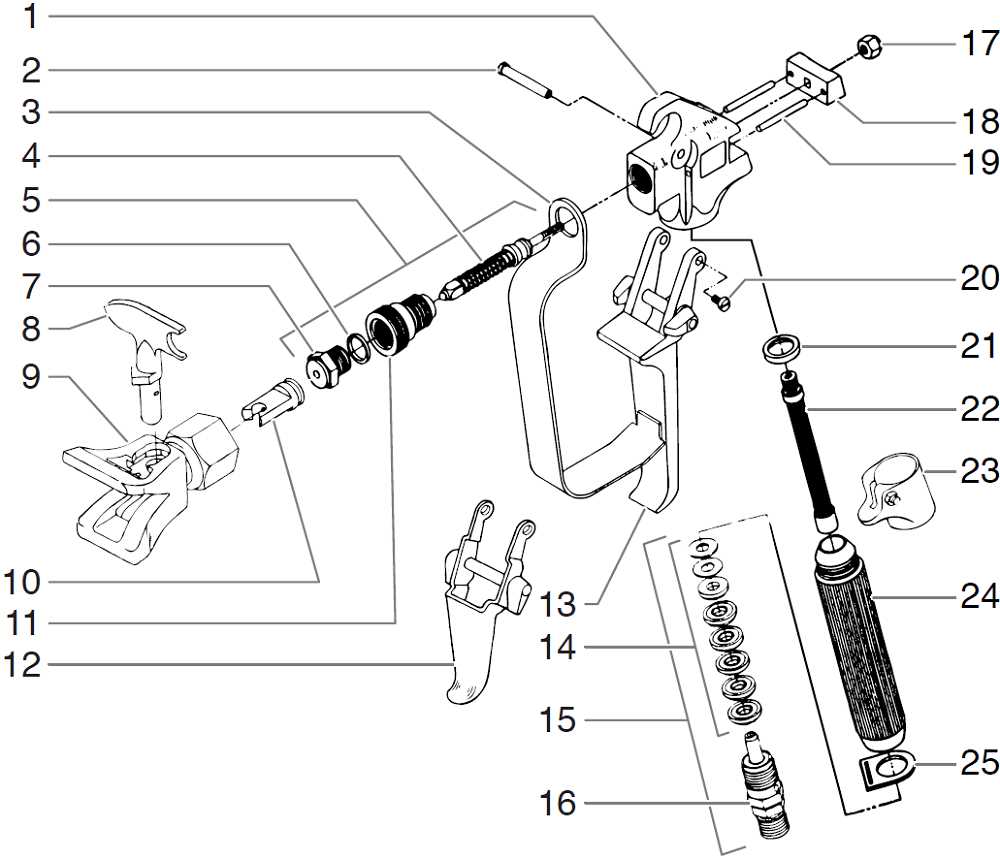

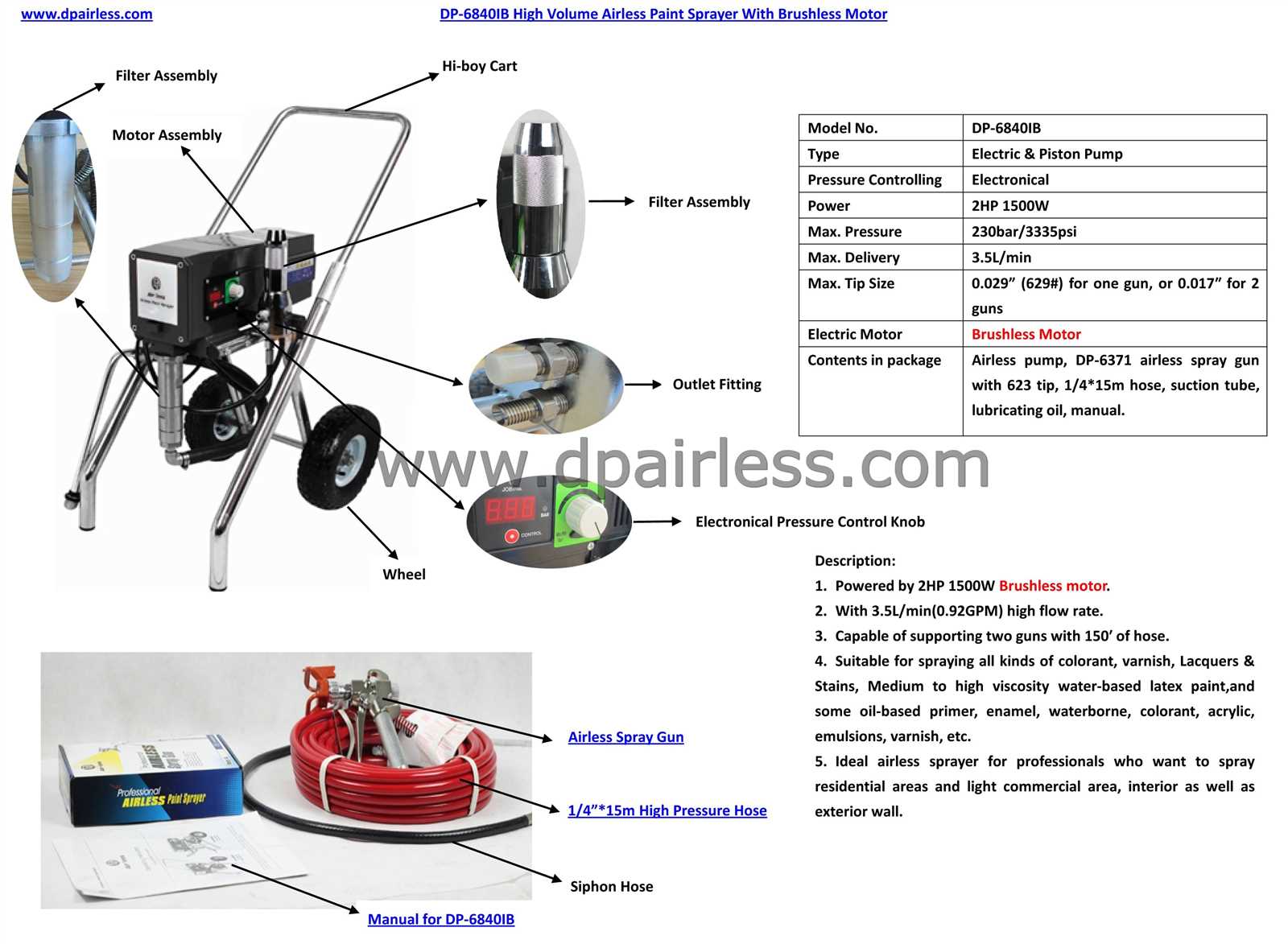

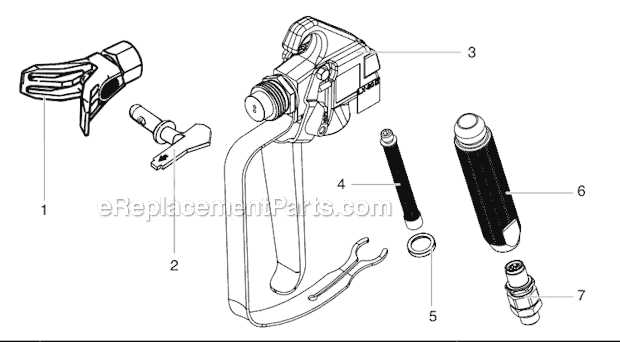

The visualization of a device’s components plays a crucial role in ensuring efficient operation and maintenance. This representation serves as a guide, helping users to identify and comprehend the various elements that constitute the machinery. By familiarizing oneself with these components, one can enhance their understanding of the overall functionality and improve troubleshooting processes.

Typically, this visual representation includes various sections that outline different functions:

- Assembly Overview: Provides a comprehensive view of the entire structure, highlighting the interconnections between components.

- Individual Components: Breaks down each element, detailing its specific purpose and function within the system.

- Maintenance Tips: Offers recommendations for upkeep and care, ensuring longevity and optimal performance.

Recognizing these features is essential for anyone looking to work effectively with the equipment. It empowers users to make informed decisions regarding repairs and enhancements, ultimately leading to more successful outcomes.

Common Issues with Sprayer Parts

When working with equipment designed for application tasks, users may encounter several common challenges related to the components involved. Understanding these issues is essential for maintaining optimal functionality and ensuring the longevity of the machine. Below are some frequent problems that operators may face along with their potential causes and solutions.

Frequent Challenges

Many users report issues such as inconsistent fluid flow, clogging, and unexpected leaks. These problems can stem from various factors, including improper maintenance, wear and tear, or environmental conditions. Addressing these challenges promptly can prevent further damage and enhance performance.

Maintenance Tips

Regular upkeep is crucial in preventing common malfunctions. Here are some effective practices to consider:

| Issue | Cause | Solution |

|---|---|---|

| Inconsistent Flow | Clogged filters or hoses | Clean or replace filters; check hoses for blockages |

| Leakage | Worn seals or fittings | Inspect and replace seals; ensure fittings are secure |

| Excessive Wear | Poor lubrication | Apply appropriate lubricants regularly |

Maintenance Tips for Longevity

To ensure the enduring performance of your equipment, it is essential to adopt a regular maintenance routine. Proper care not only extends the lifespan of your tools but also enhances their efficiency and reliability. Here are some practical recommendations to keep in mind.

- Regular Cleaning: After each use, clean all components thoroughly to prevent residue buildup. Use appropriate solvents and brushes to reach intricate areas.

- Inspect for Wear: Frequently check all elements for signs of wear and tear. Replace any damaged or worn components promptly to avoid further issues.

- Lubrication: Apply lubricant to moving parts as recommended by the manufacturer. This helps reduce friction and prevents premature wear.

- Storage Conditions: Store your equipment in a dry and cool environment. Protect it from extreme temperatures and humidity to maintain optimal functionality.

- Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance instructions. Adhering to these guidelines ensures you are performing the correct procedures for upkeep.

By implementing these straightforward practices, you can significantly improve the longevity and performance of your machinery, ensuring it remains a reliable tool for all your tasks.

How to Replace Worn Parts

Maintaining equipment in optimal condition is essential for efficient operation and longevity. When components begin to wear out, timely replacement is crucial to prevent further damage and ensure smooth functionality. This section outlines the steps for identifying and replacing aged components effectively.

Follow these general steps for a successful replacement:

- Assess the Condition

- Regularly inspect all components for signs of wear, such as cracks or reduced performance.

- Identify specific areas that may require attention based on your observations.

- Ensure you have the appropriate tools for disassembly and reassembly, such as screwdrivers and pliers.

- Consider having replacement components on hand to minimize downtime.

- Carefully disassemble the unit, taking note of the arrangement of each component.

- Use a container to keep screws and small parts organized during this process.

- Remove the worn components gently, ensuring no additional damage occurs to surrounding parts.

- Install the new components, following the manufacturer’s specifications to ensure a proper fit.

- Once all replacements are made, reassemble the equipment in the reverse order of disassembly.

- Double-check that all screws and fasteners are securely tightened.

- After reassembly, conduct a thorough test to ensure everything operates smoothly.

- Monitor performance closely to confirm that the replacements were successful.

By following these steps, you can effectively maintain your equipment and extend its operational lifespan.

Upgrades and Accessories Available

Enhancing the efficiency and functionality of your equipment can significantly improve your overall experience. Various accessories and modifications are designed to elevate performance, extend capabilities, and provide greater ease of use. Whether you are a professional or a hobbyist, these additions can help you achieve superior results.

Essential Enhancements

Numerous upgrades are available to optimize your tool’s performance. High-capacity nozzles and specialized filters can facilitate more precise application and reduce the frequency of maintenance. Additionally, adjustable pressure settings allow for better control, ensuring that you can tailor the operation to meet specific project requirements.

Convenient Attachments

To further enhance usability, various attachments can be integrated into your setup. Extension poles enable access to hard-to-reach areas, while flexible hoses provide greater maneuverability. Storage solutions and carrying cases also ensure that your equipment remains organized and portable, making it easier to transport to job sites.

Resources for Further Learning

Exploring various educational materials can greatly enhance your understanding of equipment maintenance and operation. Numerous resources are available to help individuals gain insights into the components and functionality of machinery, enabling users to optimize performance and troubleshoot issues effectively.

- Online Courses: Websites like Coursera and Udemy offer courses focused on machinery operation and repair, providing in-depth knowledge and practical skills.

- Instructional Videos: YouTube hosts a wealth of tutorials demonstrating equipment usage, maintenance techniques, and repair strategies.

- Technical Manuals: Manufacturer websites often provide downloadable manuals detailing component functions, assembly instructions, and maintenance guidelines.

- Forums and Online Communities: Engaging with communities such as Reddit and specialized forums allows for the sharing of experiences, tips, and troubleshooting advice.

- Workshops and Seminars: Local technical schools and equipment suppliers frequently conduct hands-on workshops, providing opportunities to learn from professionals.

Utilizing these resources can empower users to deepen their knowledge and improve their proficiency with various devices, ensuring safer and more efficient operation.