In the realm of machinery and equipment, a clear visual representation of individual elements is essential for both assembly and maintenance. Such illustrations serve as a crucial guide for technicians and enthusiasts alike, simplifying the complex interactions within a system. By breaking down the various constituents, one can gain invaluable insights into functionality and design.

Comprehending these visual aids allows for a more profound grasp of how each segment contributes to the overall operation. This knowledge is not merely academic; it plays a vital role in troubleshooting and enhancing performance. When one delves into the specifics, the interdependencies among components become evident, revealing the ultimate synergy of engineering.

Whether you’re a seasoned professional or a curious novice, exploring these layouts can significantly enhance your understanding. Armed with this knowledge, you can navigate the intricacies of your machinery with confidence, ensuring optimal performance and longevity.

Understanding the Ry253ss Model

The intricate design and functionality of this specific model showcase the fusion of technology and engineering. Each component plays a vital role, contributing to the overall performance and reliability of the system. A comprehensive grasp of its elements enables users to maximize efficiency and enhance operational capabilities.

Familiarity with the various components facilitates not only maintenance but also troubleshooting. Recognizing how each part interacts within the broader assembly can significantly impact the longevity and effectiveness of the equipment. A thorough examination reveals the meticulous planning that underlies its creation.

Moreover, understanding this model’s layout allows users to identify potential upgrades or modifications. Knowledge of its structure empowers individuals to make informed decisions, ensuring that any changes will align with the intended performance goals. As a result, users can tailor the system to better suit their specific needs.

In essence, delving into the intricacies of this model provides a pathway to greater competence and assurance in its use. The clearer the understanding of its components and functions, the more proficiently one can engage with the technology at hand.

Key Components of the Ry253ss

Understanding the essential elements of a sophisticated system is crucial for optimizing its functionality and performance. Each component plays a vital role, contributing to the overall efficiency and reliability of the unit. This section delves into the primary parts that form the backbone of this advanced machinery.

1. Power Unit: This element serves as the heart of the mechanism, providing the necessary energy for operation. Its design ensures a steady supply, allowing the entire system to function smoothly.

2. Control Interface: The interface allows users to interact with the device, offering intuitive options for monitoring and adjusting settings. It enhances usability and enables precise management of functions.

3. Transmission System: Responsible for transferring energy between different components, this system is crucial for ensuring that power reaches the necessary areas efficiently. Its design minimizes losses and maximizes performance.

4. Safety Features: Integral to any advanced equipment, these mechanisms protect against malfunctions and ensure safe operation. They provide peace of mind, allowing users to operate the system with confidence.

5. Structural Framework: The foundation of the unit, this component provides stability and support for all other elements. Its robust construction is essential for maintaining the integrity of the system during operation.

Each of these critical elements works in harmony to create a cohesive and effective unit, emphasizing the importance of understanding their roles in achieving optimal performance.

How to Read the Parts Diagram

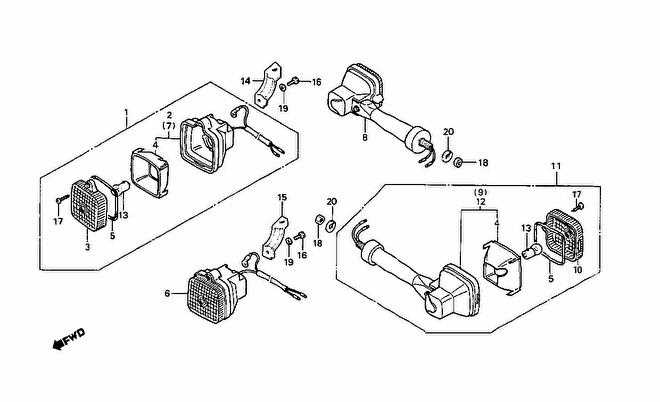

Understanding a technical illustration can greatly enhance your ability to navigate and maintain complex machinery. By familiarizing yourself with the components and their relationships, you can ensure efficient repairs and modifications. This section aims to simplify the process of interpreting these visual aids.

| Component | Description | Location |

|---|---|---|

| Element A | Main functional unit | Top-left corner |

| Element B | Support structure | Bottom-right corner |

| Element C | Connecting link | Center |

Pay attention to labels and numbers associated with each part, as they guide you in identifying specific items within the visual representation. Additionally, familiarizing yourself with common symbols can further ease your understanding and help you pinpoint the necessary elements swiftly.

Common Issues and Solutions

When working with complex machinery, various challenges can arise that affect performance and efficiency. Identifying these common problems and understanding their solutions can greatly enhance operational reliability and prolong the lifespan of the equipment.

Frequent Malfunctions

One of the most prevalent issues encountered is unexpected breakdowns, often caused by wear and tear. Regular maintenance checks can help mitigate this risk. Additionally, ensuring proper lubrication and replacing worn components can significantly reduce the likelihood of these malfunctions.

Performance Degradation

Another challenge is the gradual decline in functionality, which may stem from accumulated debris or misalignment. Cleaning the system and recalibrating settings can restore optimal performance. In cases where parts are damaged, timely replacement is essential to prevent further complications.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. Proper maintenance not only extends the lifespan of machinery but also enhances efficiency and safety. Here are some essential strategies to keep your device running smoothly for years to come.

Regular Inspections

- Conduct routine checks for any signs of wear or damage.

- Inspect components for loose connections or misalignments.

- Monitor fluid levels and replenish as necessary.

Cleaning and Lubrication

- Clean surfaces to prevent the buildup of dirt and grime.

- Apply lubricants to moving parts to reduce friction.

- Use appropriate cleaning agents to avoid damaging materials.

By following these guidelines, you can significantly enhance the reliability and longevity of your equipment, ensuring it remains in excellent condition for future use.

Where to Find Replacement Parts

Finding suitable components for your machinery can be a challenging task, but with the right resources, you can streamline the process. Various outlets offer an array of options, from online retailers to local stores, ensuring you have access to everything you need to keep your equipment running smoothly.

Online Resources

- Manufacturer’s Website: Always start with the official site, where you can find authentic items specifically designed for your model.

- E-commerce Platforms: Websites like Amazon or eBay provide a vast selection of options, often at competitive prices.

- Specialty Retailers: Look for shops that focus on machinery and tools; they often carry specialized components.

Local Options

- Authorized Dealers: Check with dealers who are certified by the manufacturer for reliable and compatible items.

- Local Hardware Stores: Many stores stock common components that might fit your needs.

- Salvage Yards: For budget-friendly solutions, consider visiting salvage or recycling centers that may have used parts in good condition.

Comparing with Similar Models

When evaluating machinery, understanding how different models stack up against one another is crucial. This analysis helps users identify which options best suit their specific needs. By examining features, specifications, and performance metrics, one can make a more informed decision when selecting equipment.

Feature Comparison

Different machines within the same category often have varying capabilities and attributes. This section highlights key features that set each model apart, allowing potential buyers to weigh the advantages and disadvantages effectively.

| Model | Power Output | Weight | Fuel Efficiency |

|---|---|---|---|

| Model A | 120 HP | 3000 lbs | 25 MPG |

| Model B | 110 HP | 2800 lbs | 28 MPG |

| Model C | 130 HP | 3200 lbs | 22 MPG |

Performance Metrics

Beyond features, performance is a critical factor in distinguishing among similar units. This section examines how each model performs under various conditions, such as speed, reliability, and maintenance requirements, giving prospective buyers insight into the long-term value of their investment.

User Experiences and Reviews

This section delves into the firsthand accounts and evaluations from individuals who have interacted with the subject matter. By examining their insights, we can gain a clearer understanding of the strengths and weaknesses inherent in the system. User feedback serves as a valuable resource, highlighting both satisfaction and areas for improvement.

Positive Feedback

Many users have expressed their appreciation for the efficiency and reliability of the system. One common theme is the seamless integration of components, which allows for a smooth operation without frequent interruptions. Enthusiasts particularly value the user-friendly interface, which simplifies navigation and enhances the overall experience.

Constructive Criticism

On the other hand, some reviews indicate areas where enhancements could be made. Several users noted that certain features could benefit from additional customization options. Others mentioned the need for improved documentation, as clearer guidelines would assist new users in maximizing the system’s potential. Addressing these concerns could lead to an even more satisfying user experience.