Exploring the intricate design of handheld power tools reveals a wealth of information that can enhance their usability and maintenance. Each element plays a crucial role in ensuring efficiency and performance, making it essential for users to familiarize themselves with these components.

By examining a comprehensive visual representation, enthusiasts and professionals alike can identify the specific sections and mechanisms within their tools. This knowledge empowers users to troubleshoot issues effectively and extend the lifespan of their equipment.

Moreover, a deeper understanding of these intricate parts fosters an appreciation for the engineering that goes into crafting reliable tools. This insight not only aids in practical applications but also enriches the overall experience of working with such valuable equipment.

Understanding Rotozip Tool Components

To effectively utilize a specialized cutting tool, one must have a solid grasp of its essential elements and their functionalities. Familiarity with the components enhances both efficiency and safety during operation. This section delves into the various segments of this versatile device, illuminating their roles and importance.

Main Features

The core components of a cutting tool are designed to work in harmony, ensuring optimal performance. Understanding each part allows users to troubleshoot issues, maintain the tool, and achieve precise results. Here are the primary elements:

| Component | Description |

|---|---|

| Motor | Powers the device, driving the cutting mechanism at variable speeds for different materials. |

| Cutting Bit | Interchangeable element that determines the type of cut, available in various shapes and sizes. |

| Base Plate | Provides stability and support, aiding in precise cuts and ensuring user safety. |

| Switch | Controls the power supply to the motor, enabling quick activation and deactivation. |

| Ventilation System | Prevents overheating by allowing airflow around the motor during operation. |

Importance of Maintenance

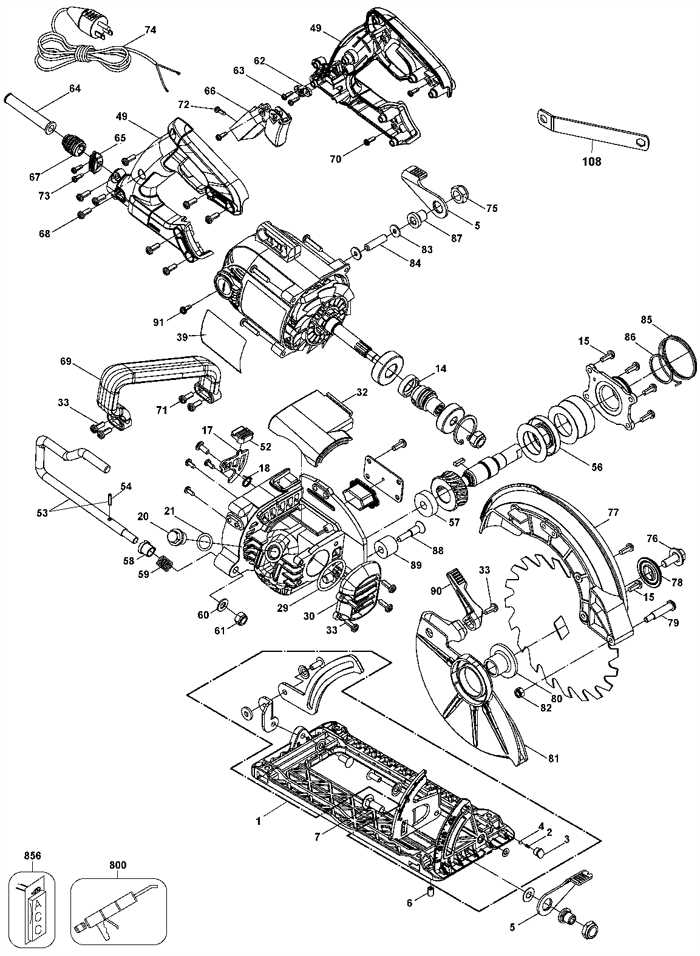

Importance of Parts Diagrams

Understanding the components of a tool is crucial for efficient maintenance and repair. Visual representations of these elements can significantly enhance the user’s ability to identify issues and perform necessary fixes. By breaking down a device into its individual parts, users can gain insights into its functionality and structure.

Benefits of Visual Guides

- Enhances comprehension of the tool’s construction.

- Facilitates quick identification of damaged or worn components.

- Supports efficient assembly and disassembly processes.

- Provides a reference for troubleshooting specific problems.

Applications in Maintenance

- Streamlines repair tasks by offering clear visual cues.

- Reduces the likelihood of errors during reassembly.

- Assists in inventory management by tracking missing or replaced items.

- Promotes a deeper understanding of operational principles.

In summary, visual aids play a pivotal role in enhancing the overall user experience by simplifying the complexities involved in the upkeep of tools.

Common Rotozip Parts Explained

Understanding the essential components of a cutting tool can significantly enhance its performance and longevity. Each element plays a crucial role in the functionality of the device, ensuring precision and efficiency in various applications. This section outlines the primary features that contribute to the effectiveness of these tools.

Key Components

- Motor: The powerhouse of the device, responsible for driving the cutting action.

- Collet: Holds the cutting bits securely in place, allowing for quick changes.

- Base Plate: Provides stability and control during operation, ensuring clean cuts.

- Switch: Controls the power supply, allowing for easy on/off operation.

- Ventilation System: Helps to dissipate heat, protecting the motor from overheating.

Cutting Accessories

- Cutting Bits: Various shapes and sizes available for different materials.

- Guide Wheels: Assist in maintaining straight cuts and enhance maneuverability.

- Dust Collection Attachments: Help keep the work area clean by minimizing debris.

Familiarity with these components not only aids in maintenance but also empowers users to select the appropriate accessories for specific tasks, leading to optimal results.

How to Read Diagrams Effectively

Understanding technical illustrations can greatly enhance your ability to assemble, repair, or analyze equipment. These visuals often convey complex information succinctly, allowing you to grasp the relationships between various components at a glance. By mastering the art of interpreting these visuals, you can save time and avoid frustration in your projects.

Familiarize Yourself with Symbols

Each visual representation typically includes a set of symbols that denote specific parts and functions. Take the time to learn these icons, as they are crucial for accurate interpretation. A legend or key is often provided to help you decipher the meanings, so be sure to reference it as needed.

Analyze the Layout

Examine how elements are arranged within the illustration. Pay attention to connections and orientations, as these details can indicate how components fit together. Understanding the flow of information or the sequence of assembly will empower you to work more efficiently and accurately.

Incorporating these strategies will enhance your ability to decode technical visuals, making your tasks more manageable and productive.

Maintenance Tips for Rotozip Tools

Regular upkeep is essential for ensuring the longevity and efficiency of your cutting instruments. Proper care not only enhances performance but also minimizes the risk of malfunctions. Here are some essential practices to keep your tools in top shape.

Cleaning and Lubrication

- After each use, remove debris and dust from the tool’s surface.

- Inspect the cutting accessories for wear and tear; replace if necessary.

- Apply a light lubricant to moving parts to prevent rust and ensure smooth operation.

Storage Recommendations

- Store the instrument in a dry place, away from extreme temperatures.

- Use a dedicated case to protect it from physical damage.

- Keep accessories organized and secure to avoid loss or damage.

By following these maintenance tips, you can enhance the performance and lifespan of your cutting tools, ensuring they remain reliable for all your projects.

Identifying Replacement Parts Easily

When it comes to maintaining your tools, recognizing the right components can make all the difference in ensuring optimal performance. Navigating through various options can be challenging, but understanding how to pinpoint what you need simplifies the process significantly.

Start by examining the tool itself. Look for any markings or labels that provide insight into the specific model and its specifications. Familiarizing yourself with the general layout and function of the device helps in identifying which elements may require attention.

Utilize online resources and communities. There are numerous platforms where enthusiasts and experts share their knowledge. Engaging with these resources can offer valuable information about the specific components and their functions, making it easier to identify what needs replacement.

Consult manuals or guides. Many manufacturers provide detailed documentation that outlines each component’s role within the device. Having access to this information is invaluable for recognizing what might be malfunctioning or worn out.

Visual aids can also be beneficial. Diagrams or charts that illustrate the tool’s assembly can assist in visually identifying parts. This method can be especially helpful when trying to match the correct replacement with what you have.

By combining these strategies, you can streamline the identification process and ensure your equipment remains in peak condition, enhancing its longevity and functionality.

Troubleshooting Common Issues

When working with power tools, encountering problems can be frustrating. Understanding the most frequent complications can help users quickly resolve them, ensuring efficient operation and safety. By identifying symptoms and applying straightforward solutions, one can maintain optimal performance.

Noise Issues: Excessive sound may indicate a need for lubrication or the presence of debris. Regular maintenance can prevent such disturbances and extend the life of the tool.

Overheating: If the equipment becomes too hot, it may be due to prolonged use or dull accessories. Allowing the tool to cool and checking the sharpness can mitigate this issue.

Inconsistent Power: Fluctuations in performance might stem from a faulty cord or connection. Inspecting these components for wear or damage is essential for reliable function.

Vibration Problems: Excessive shaking can result from imbalanced attachments. Ensuring all parts are secure and properly aligned can greatly reduce discomfort and enhance control.

By systematically addressing these common issues, users can delve into solutions that lead to the ultimate efficiency and safety in their projects.

Where to Find Parts Diagrams

Locating visual references for tool components can significantly enhance your understanding and maintenance of equipment. These illustrations serve as valuable guides, helping users identify various elements and their arrangement within the device. Whether you’re a DIY enthusiast or a professional, knowing where to access these resources is essential for effective repairs and upgrades.

One of the most reliable sources for such visuals is the manufacturer’s official website. They often provide detailed schematics that outline each element, along with part numbers for easy ordering. Additionally, user manuals frequently contain diagrams that can be downloaded in PDF format, offering a comprehensive overview of the tool’s structure.

Online marketplaces and specialized repair sites also host a wealth of information. Many of these platforms feature community forums where users share insights and links to helpful resources. Social media groups dedicated to tools and repairs can further connect you with individuals who may have already sourced the diagrams you need.

Lastly, local repair shops and tool rental centers might have printed resources or be able to guide you toward obtaining the necessary visuals. Engaging with professionals in your area can provide access to insights that might not be readily available online.