In the world of gardening and land cultivation, the intricate machinery used to prepare the soil is essential for achieving optimal results. Each element within this equipment plays a crucial role in ensuring efficient operation and effective tilling. A comprehensive exploration of these components can enhance your knowledge and improve your gardening practices.

By delving into the various sections of the equipment, users can identify how each part interacts with others, contributing to the overall performance. Understanding these individual elements allows for better maintenance and troubleshooting, ultimately leading to a more successful gardening experience.

Moreover, recognizing the significance of each piece not only aids in repair and replacement but also empowers users to make informed decisions when purchasing or upgrading their tools. This foundational knowledge is key to mastering the ultimate art of soil preparation.

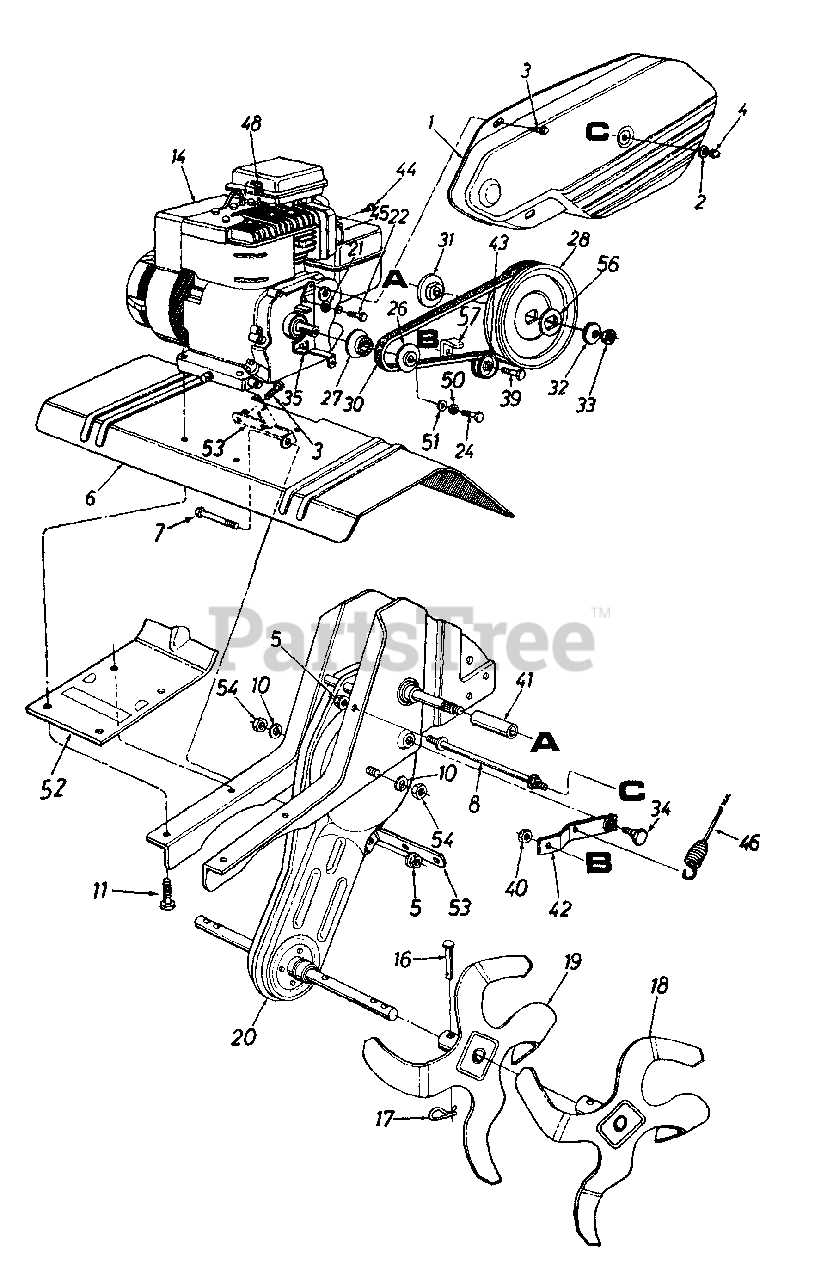

Understanding Rototiller Components

Familiarizing yourself with the elements of soil cultivation equipment can significantly enhance your gardening experience. Each component plays a crucial role in the overall functionality and efficiency of the machine. By grasping how these elements work together, you can ensure better maintenance and effective usage.

- Engine: The powerhouse that drives the entire unit, available in various sizes and types to suit different gardening needs.

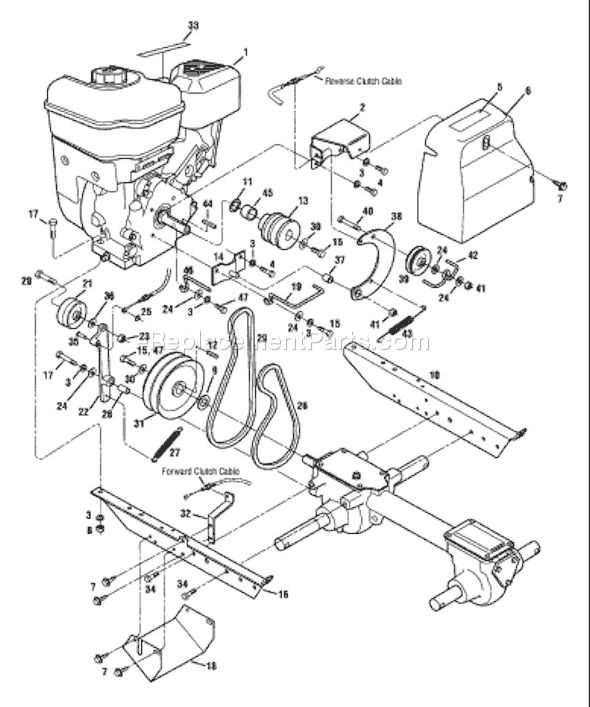

- Transmission: Transfers power from the engine to the tines, allowing for adjustable speed and torque based on soil conditions.

- Tines: The rotating blades that penetrate the earth, breaking up compacted soil and aiding in aeration.

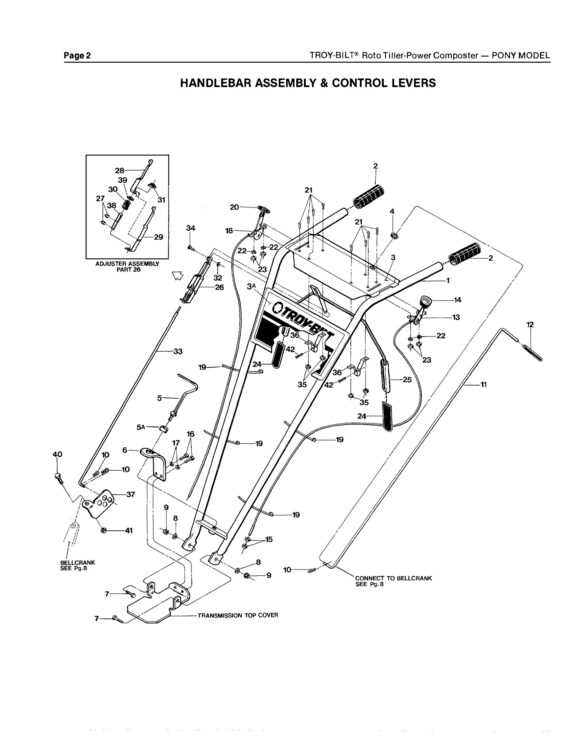

- Handlebars: Provide control and maneuverability, often adjustable for comfort during operation.

- Frame: The structure that supports all components, ensuring stability and durability during use.

- Wheels: Facilitate movement and transport of the equipment, often designed for various terrains.

- Clutch: Engages and disengages the tines from the engine, allowing for smooth operation and safety.

Understanding these fundamental elements can help you troubleshoot issues, perform regular maintenance, and optimize performance for your gardening tasks.

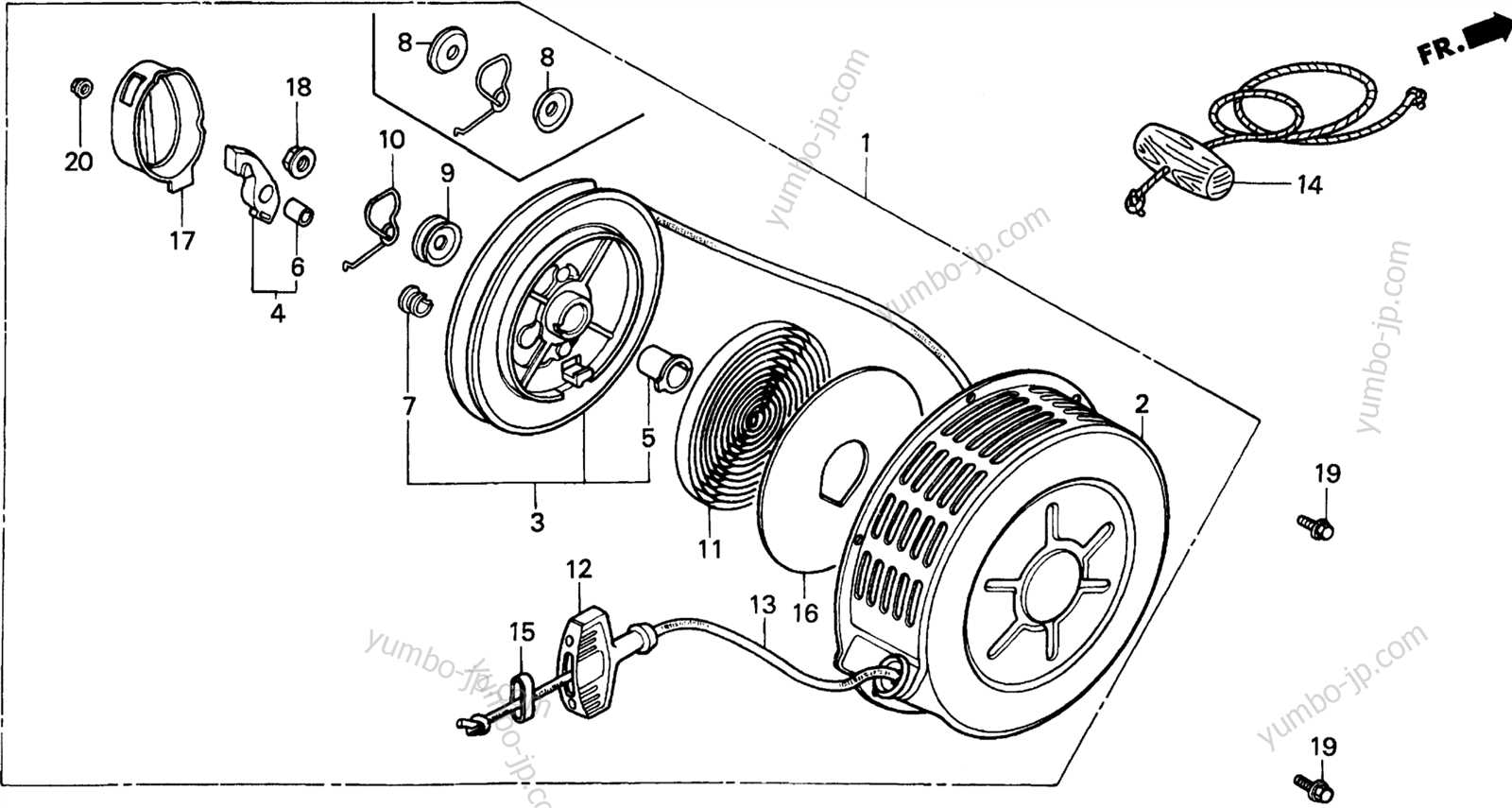

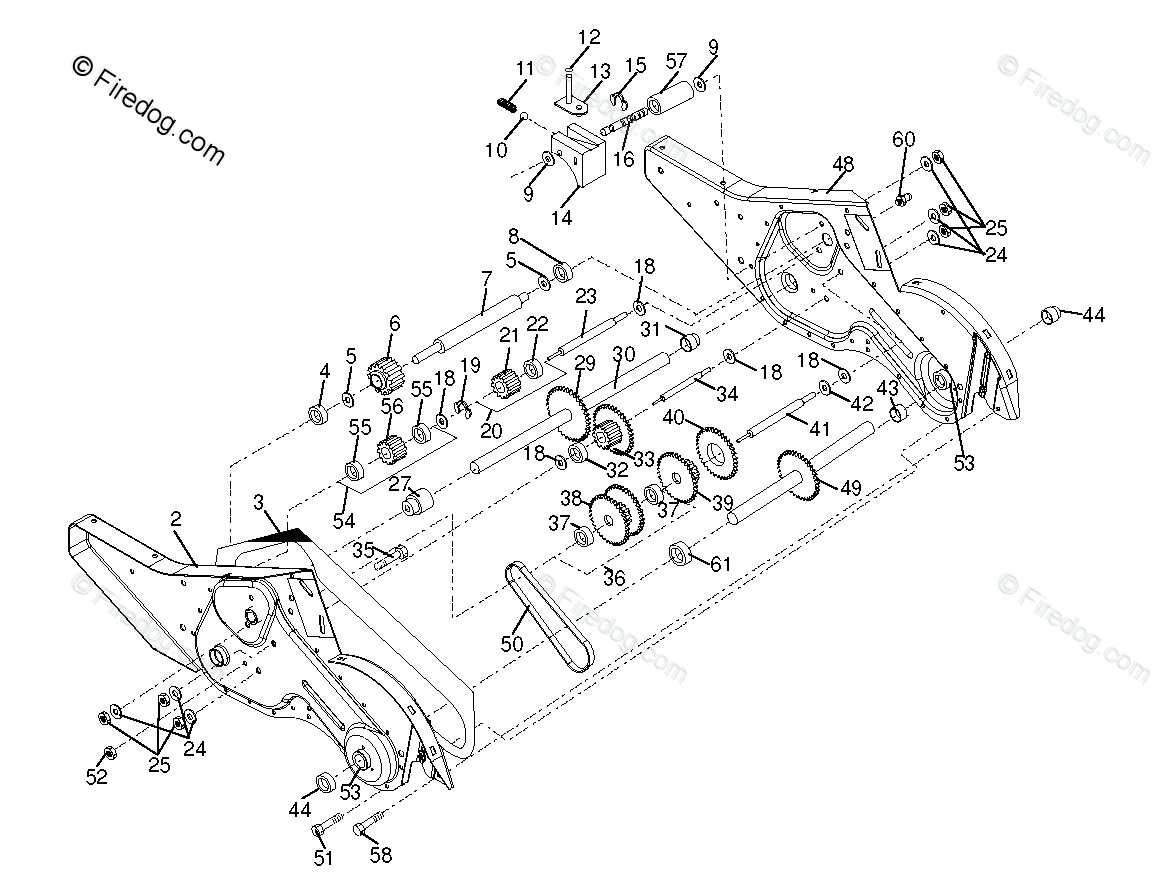

Importance of a Parts Diagram

Understanding the various components of a machine is crucial for effective maintenance and repair. A visual representation that outlines each element not only enhances comprehension but also streamlines the troubleshooting process. Such illustrations serve as a reference point, guiding users through the intricate web of machinery.

Facilitating Maintenance

Having a clear visual layout aids in regular upkeep by:

- Identifying specific elements that require attention.

- Allowing users to track wear and tear over time.

- Enabling efficient replacement of worn-out components.

Streamlining Repairs

When faced with malfunctions, a comprehensive visual guide can:

- Quickly pinpoint the source of the problem.

- Provide step-by-step instructions for disassembly and reassembly.

- Enhance communication between users and service professionals.

Common Rototiller Issues

Garden cultivators can face various challenges that hinder their performance and efficiency. Understanding these common problems is crucial for maintaining optimal function and ensuring a successful gardening experience.

Engine Problems

One prevalent issue is engine failure, which can manifest as difficulty starting or stalling during operation. Fuel quality often plays a significant role, as stale or contaminated gasoline can cause significant disruptions. Regular maintenance, including oil changes and air filter cleaning, is essential to avoid these issues.

Drive System Failures

Another common concern involves the drive system, where components may wear out over time. Issues such as slipping belts or damaged gears can lead to inadequate power transfer, affecting overall performance. Routine inspections and timely replacements of worn parts can prevent these complications.

How to Identify Damaged Parts

Recognizing worn or broken components is essential for maintaining optimal performance. Regular inspections can prevent larger issues and extend the life of your equipment. Understanding the common signs of damage will help you keep everything in top condition.

Signs of Wear and Tear

Look for visible cracks, rust, or unusual wear on surfaces. Pay attention to any unusual noises during operation, which may indicate internal issues. Additionally, consider checking for loose fittings or excessive vibration.

Inspection Checklist

| Component | Signs of Damage |

|---|---|

| Blades | Chips, bends, or dull edges |

| Belts | Fraying or cracking |

| Engine | Leaking fluids or strange noises |

| Wheels | Uneven wear or wobbling |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your gardening equipment requires consistent care and attention. By following a few essential practices, you can enhance performance and reduce the need for repairs, ultimately saving time and money.

Regular Cleaning: After each use, it is crucial to clean the exterior and any components that come into contact with soil or debris. This prevents the buildup of grime that can lead to rust and malfunction.

Check Fluid Levels: Maintaining proper oil and fuel levels is vital for optimal operation. Regularly inspect and refill as needed, and consider changing the oil periodically to ensure the machinery runs smoothly.

Tighten Loose Fasteners: Vibrations during operation can cause nuts and bolts to loosen over time. Regularly check and tighten any loose fasteners to maintain stability and functionality.

Inspect Belts and Cables: Frayed or worn belts and cables can hinder performance and pose safety risks. Routine inspections will allow you to replace them before they fail completely.

Store Properly: When not in use, keep your equipment in a dry, sheltered location. This helps protect it from harsh weather conditions and prevents premature wear.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s manual for specific maintenance recommendations. Adhering to these guidelines can help you avoid issues and ensure your equipment remains in peak condition.

By incorporating these maintenance tips into your routine, you can maximize the efficiency and longevity of your gardening tools, allowing you to focus on enjoying your outdoor projects.

Replacement Parts: What You Need

Maintaining and repairing gardening equipment is essential for optimal performance and longevity. Understanding the necessary components ensures that your tools operate smoothly and efficiently, allowing you to tackle any project with confidence. This guide highlights crucial elements to consider when looking for replacements, ensuring your tasks are executed without a hitch.

Essential Components

Several key items play a vital role in the functionality of your gardening machinery. Below is a summary of important replacements to keep in mind:

| Component | Description |

|---|---|

| Blades | Critical for soil penetration and turning, these must remain sharp and intact. |

| Belt | Transmits power from the engine to the operational parts; a worn belt can affect performance. |

| Engine Filters | Prevent debris from entering the engine, ensuring it runs efficiently. |

Where to Find Quality Replacements

When seeking new components, consider authorized dealers, online retailers, or local hardware stores. Always verify compatibility with your equipment to achieve the best results.

Where to Find Parts Diagrams

Locating comprehensive visual guides for equipment components is essential for effective maintenance and repair. These resources can streamline the process of identifying and ordering necessary elements, ensuring your machinery remains in optimal condition.

Online Resources

- Manufacturer Websites: Most brands provide detailed illustrations on their official sites.

- Online Retailers: E-commerce platforms often feature visual references alongside product listings.

- Forums and Community Groups: Enthusiast communities frequently share valuable insights and resources.

Physical Resources

- User Manuals: Printed or downloadable guides often include useful images.

- Local Dealers: Authorized service centers can provide access to visual aids and expertise.

- Repair Shops: Professionals may have reference materials for common machinery.

DIY Repairs for Rototillers

Maintaining garden equipment is essential for ensuring optimal performance and longevity. Performing repairs on your machinery not only saves money but also provides a sense of accomplishment. Understanding how to troubleshoot and fix common issues can keep your tools running smoothly through the gardening season.

Common Issues and Solutions

Frequent problems include difficulty starting, reduced efficiency, and unusual noises. To address starting issues, check the fuel and spark plug conditions; replacing these components often resolves the problem. For machines that struggle with performance, inspect the tines and belts for wear and tear, as these parts can significantly impact functionality. Unusual sounds might indicate loose bolts or damaged gears, which can be tightened or replaced with relative ease.

Maintenance Tips

Regular upkeep is vital for preventing larger issues down the line. Clean the equipment after each use to remove debris that can cause rust or blockages. Additionally, changing the oil and inspecting filters at recommended intervals will enhance the machine’s efficiency. Keeping a maintenance log can help track when specific tasks are due, ensuring your garden tools are always in prime condition.