For anyone involved in gardening or landscaping, the effectiveness of soil preparation tools can significantly impact the success of planting and cultivation. A thorough grasp of the machinery used for tilling and aerating soil is essential. Familiarizing oneself with the individual components and their functions enhances maintenance and repair efforts, ultimately prolonging the life of these valuable devices.

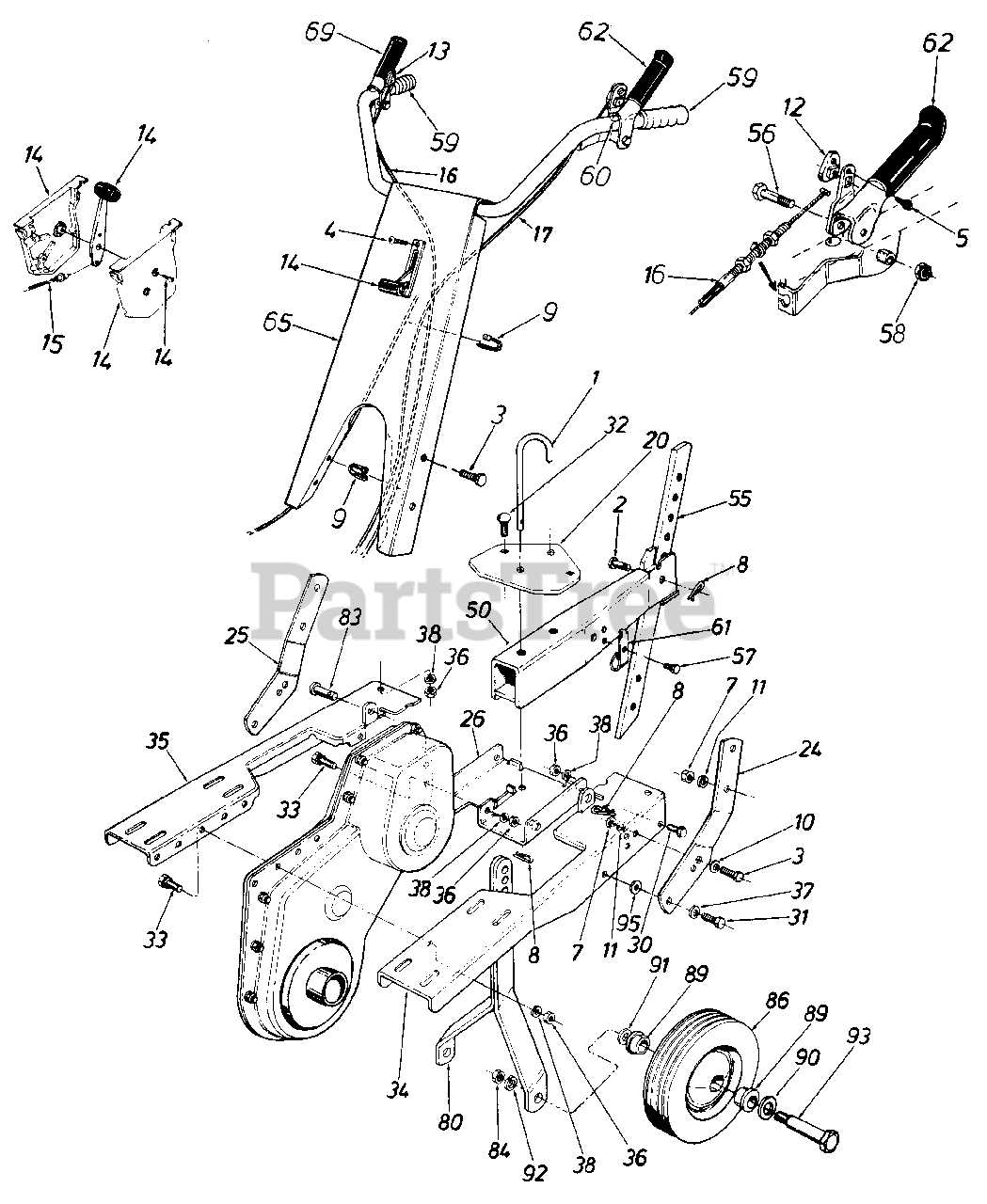

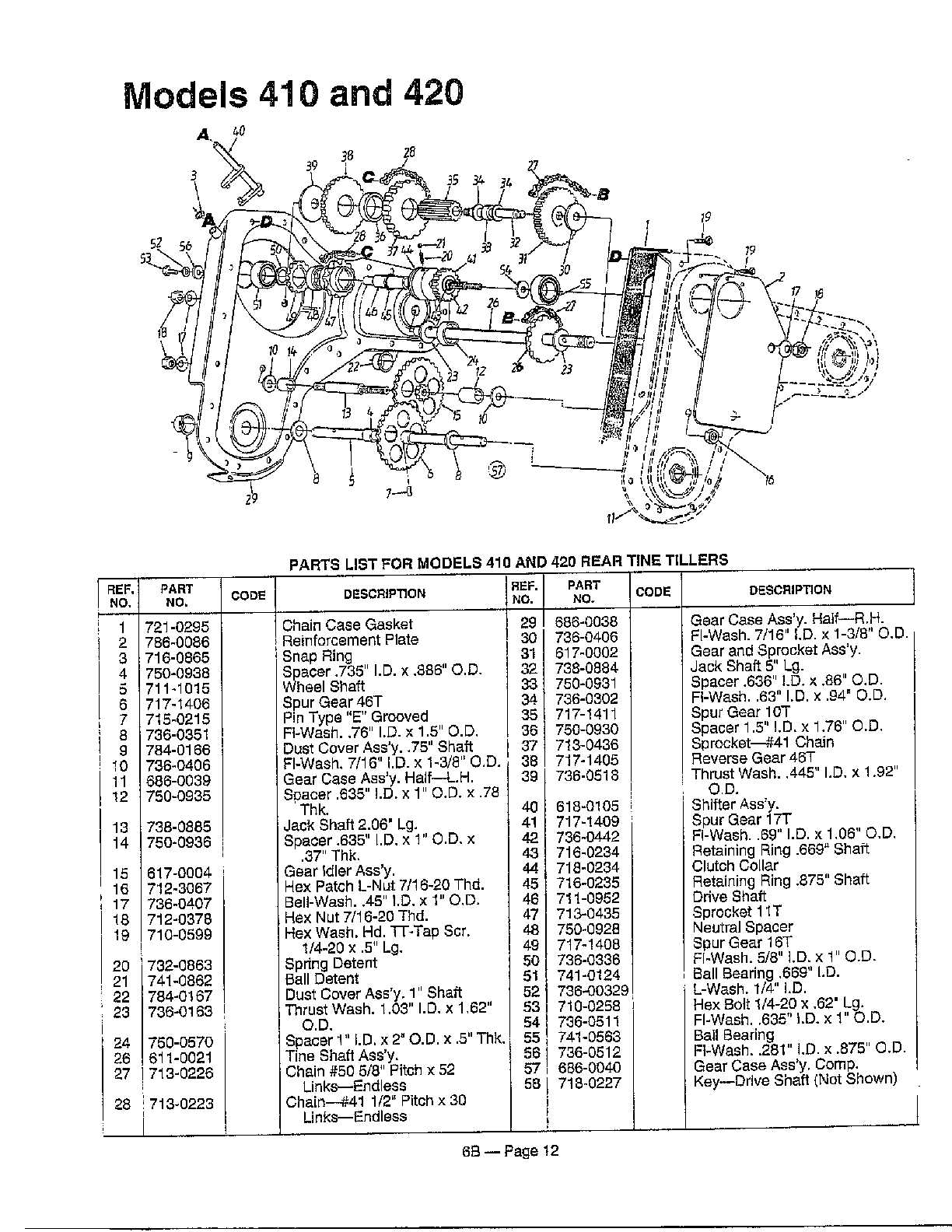

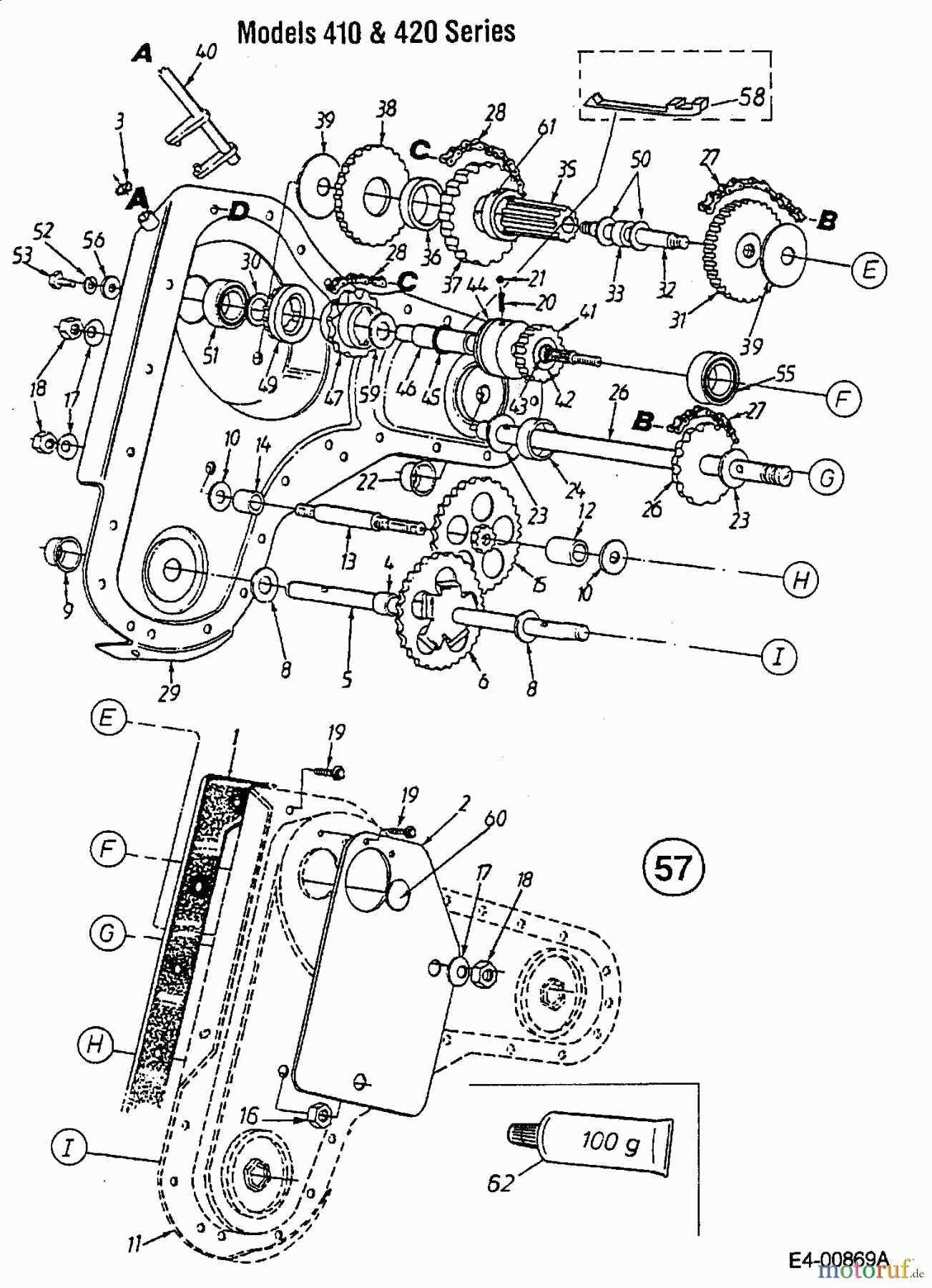

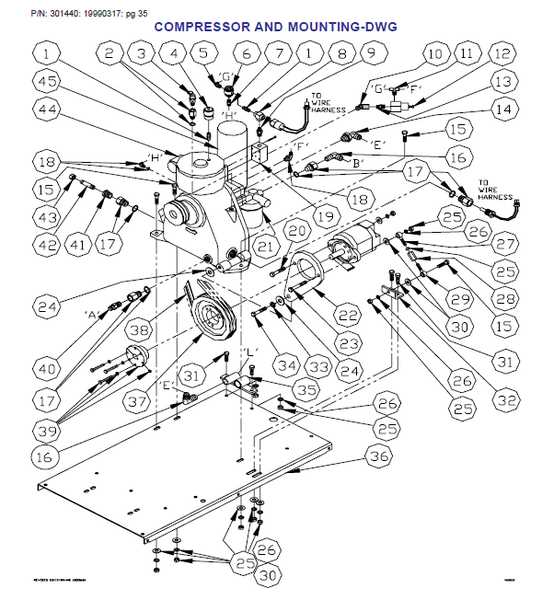

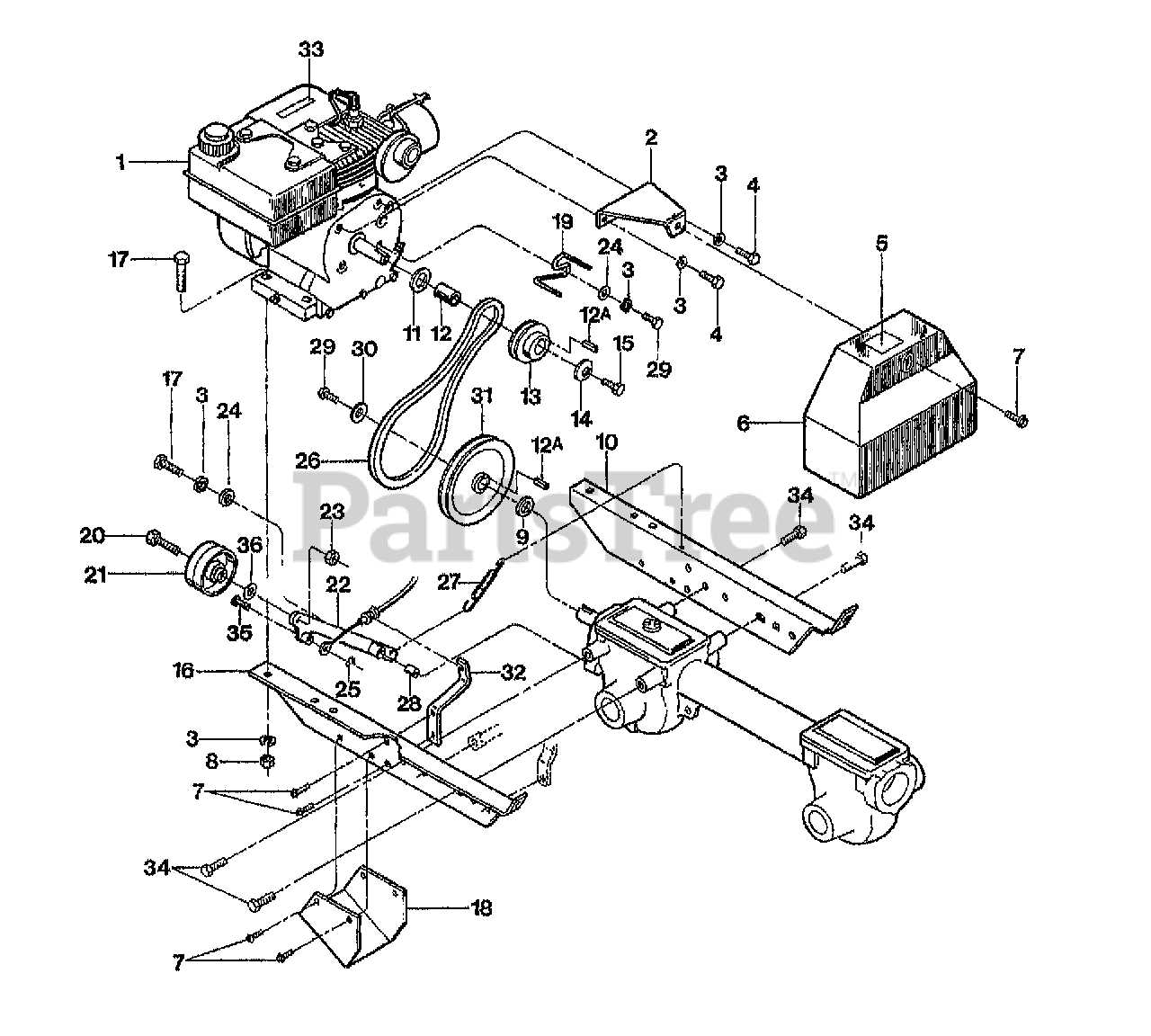

Visual aids, such as schematic representations, serve as vital resources for users seeking to comprehend the intricate relationships between various elements. These guides not only simplify the identification of each piece but also elucidate how they interact within the broader system. Such understanding can empower operators to tackle repairs with confidence, ensuring optimal performance and efficiency.

In the upcoming sections, we will delve into the specifics of these essential implements, offering insights into their construction and operation. By exploring the various components, users can better appreciate the engineering behind their gardening tools and make informed decisions regarding upkeep and enhancements.

Understanding Rototiller Components

Grasping the essential elements of gardening machinery is crucial for optimal performance and maintenance. Each component plays a significant role in the overall functionality, ensuring that the tool operates efficiently in various soil conditions. Familiarity with these elements not only enhances usability but also aids in troubleshooting and repairs.

Key components include:

- Engine: The heart of the machine, providing the necessary power for operation.

- Transmission: This system transmits power from the engine to the working parts, allowing for speed control and direction changes.

- Blades: These cutting tools are essential for breaking up the soil, allowing for aeration and nutrient penetration.

- Frame: The sturdy structure that houses all components, providing stability and support during use.

- Handlebars: The part that the operator grips, allowing for maneuverability and control.

- Wheels: These facilitate movement, making it easier to transport the machinery across various terrains.

Each of these components interacts harmoniously to achieve the desired results in soil preparation and cultivation. Understanding their functions and how they contribute to the overall effectiveness of the machinery can significantly improve gardening outcomes.

Importance of Accurate Parts Diagrams

Precise illustrations of components play a crucial role in the maintenance and repair of machinery. These visuals serve as essential guides for users, ensuring that every element is correctly identified and handled. Having a reliable reference not only simplifies the process of assembly and disassembly but also enhances overall efficiency and safety.

Benefits of Clear Visuals

- Improved Understanding: Clear images help users comprehend the relationships between different elements.

- Enhanced Efficiency: With a well-defined guide, time spent searching for the correct components is significantly reduced.

- Minimized Errors: Accurate visuals lower the chances of mistakes during repairs or replacements, ensuring optimal performance.

Impact on Maintenance

- Facilitates Quick Repairs: Knowing exactly what parts are needed allows for faster turnaround times.

- Encourages Regular Upkeep: Users are more likely to maintain their equipment when they can easily identify worn or damaged items.

- Supports DIY Enthusiasts: Hobbyists benefit greatly from accessible illustrations that empower them to take on projects confidently.

Identifying MTD Rototiller Parts

Understanding the various components of your gardening machine is crucial for effective maintenance and operation. Each element plays a vital role in ensuring optimal performance, and recognizing them can help you troubleshoot issues more efficiently.

To assist you in identifying the different components, here are some common categories you might encounter:

- Power Source: This includes the engine or motor that provides the necessary energy.

- Transmission System: Essential for transferring power from the engine to the rotating elements.

- Cutting Mechanism: The blades or tines responsible for breaking up the soil.

- Frame Structure: The chassis that houses all components and provides stability.

- Control Elements: Levers and switches that allow you to operate the machine.

- Wheels or Treads: These provide mobility and assist in maneuvering across various terrains.

By familiarizing yourself with these categories, you can better understand the assembly of your equipment and make informed decisions during repairs or replacements.

Consider consulting a user manual or reference guide to further explore the specific functions and arrangements of these components. This knowledge not only enhances your maintenance skills but also improves your overall gardening experience.

Common Issues with Tiller Parts

Understanding the typical challenges that arise with agricultural tools is crucial for maintaining their efficiency and longevity. Many users encounter specific malfunctions that can hinder performance, and recognizing these problems early can save time and money in repairs.

Frequent Challenges

- Engine Difficulties: Issues such as starting problems or stalling can stem from various sources, including fuel quality and ignition components.

- Transmission Failures: Difficulty in engaging gears or unusual noises can indicate wear or damage in the drive mechanism.

- Wear on Tines: The cutting blades can become dull or bent over time, reducing effectiveness in soil aeration.

- Overheating: Continuous operation without adequate breaks may lead to overheating, affecting overall performance.

Maintenance Tips

- Regularly check and change the oil to ensure smooth engine function.

- Inspect fuel filters and lines for blockages or leaks.

- Sharpen or replace tines as needed to maintain cutting efficiency.

- Keep the machine clean to prevent dirt buildup that can cause overheating.

How to Replace Tiller Components

Maintaining your gardening equipment is essential for optimal performance and longevity. When certain elements become worn or damaged, timely replacement can make a significant difference in efficiency. This guide outlines the steps to effectively swap out components, ensuring your machine runs smoothly and effectively.

Before starting, gather the necessary tools, including wrenches, screwdrivers, and replacement components. Ensure the machine is turned off and disconnected from any power source to prioritize safety. Begin by consulting the user manual for specific instructions regarding the assembly and disassembly of parts.

To replace a worn element, locate the component in question and remove any screws or bolts securing it in place. Carefully detach it from the main assembly, taking note of how it is positioned for easier reinstallation of the new part. Once removed, align the new component accurately and secure it with the appropriate fasteners. Double-check all connections to ensure they are tight and secure before proceeding.

After replacing the necessary components, reconnect the power source and conduct a test run. Listen for any unusual sounds and monitor the equipment’s performance. Regular checks and timely replacements will help maintain your machine in excellent condition, making your gardening tasks more efficient.

Maintenance Tips for Rototillers

Proper upkeep of gardening machinery is essential for optimal performance and longevity. Regular maintenance not only ensures efficiency but also helps prevent costly repairs in the future. By following a few simple guidelines, users can keep their equipment in top shape, ready for any landscaping challenge.

First, always inspect the blades for wear and tear. Dull or damaged blades can hinder performance and lead to uneven soil preparation. Sharpen or replace them as needed to maintain cutting efficiency.

Next, check the fuel and oil levels regularly. Using fresh fuel and clean oil contributes significantly to the engine’s performance. Replace the oil according to the manufacturer’s recommendations to avoid buildup of impurities.

Additionally, ensure that all air filters are clean. Clogged filters restrict airflow, impacting engine efficiency. Clean or replace them periodically to promote optimal combustion and reduce emissions.

Don’t forget about the belts and cables. Regularly inspect these components for fraying or signs of wear. Proper tensioning and timely replacement can prevent breakdowns during operation.

Lastly, store the machinery in a dry place and protect it from the elements. Covering the equipment when not in use will help prevent rust and deterioration, extending its lifespan significantly.

Finding MTD Parts Online

Locating components for your outdoor equipment can be a straightforward process if you know where to look. The internet offers a vast array of resources, making it easier to identify and acquire the specific items you need. Whether you’re seeking replacement elements or enhancements, understanding how to navigate online platforms is essential.

Begin by exploring dedicated websites that specialize in outdoor machinery. These platforms often have extensive catalogs that categorize products by brand and type, simplifying the search. Utilize search functions and filters to narrow down your options based on model numbers or descriptions.

In addition to official manufacturer sites, consider third-party retailers that stock various brands. They frequently offer competitive prices and customer reviews that can guide your decision-making process. Always verify the credibility of the seller to ensure a satisfactory purchase.

Forums and online communities can also be invaluable resources. Engaging with other enthusiasts can provide insights on where to find quality components and tips on maintenance. Sharing experiences can lead you to trustworthy suppliers and helpful recommendations.

Lastly, don’t overlook the benefits of local stores and repair shops that may have an online presence. Many small businesses have adapted to digital commerce, allowing you to check their inventory from the comfort of your home. This approach supports local economies while still providing the parts you need.

Comparing Different Rototiller Models

When selecting a garden cultivation machine, it’s essential to evaluate various models to find the one that best suits your needs. Different options vary in power, size, and features, making it crucial to understand how each model performs in different conditions. This comparison will highlight key aspects such as functionality, ease of use, and durability.

One critical factor to consider is the engine power. Machines with higher horsepower tend to handle tougher soil and larger areas more effectively. However, lighter models are easier to maneuver, making them suitable for smaller gardens. It’s important to balance power and usability based on the size of the space you intend to cultivate.

Another significant aspect is the width of the working area. Wider models can cover more ground in less time, but they may be harder to handle in tight spaces. Conversely, narrower machines excel in precision and control, allowing for detailed work around plants and landscaping features.

Additionally, ease of maintenance should not be overlooked. Some designs incorporate user-friendly features that simplify upkeep, while others may require more frequent service. Choosing a machine that aligns with your maintenance preferences can save you time and effort in the long run.

Finally, consider the available attachments and accessories. Some machines offer versatility with various tools for different tasks, enhancing their functionality throughout the gardening season. A model that supports a range of add-ons can be a valuable investment for any gardening enthusiast.