Exploring the intricate assemblies of air compression units reveals essential insights into their functionality and maintenance. A clear visualization of these configurations allows users to effectively navigate through their mechanical structures, enhancing both comprehension and repair processes.

For enthusiasts and professionals alike, delving into the schematic representations of these machines can unveil the ultimate guide to troubleshooting and optimizing performance. Knowing how each element interconnects not only aids in repairs but also in preventing future issues.

Whether you are a seasoned technician or a curious learner, familiarizing yourself with these layouts is crucial for maximizing efficiency and longevity. This knowledge empowers users to address challenges with confidence and precision.

Understanding Ingersoll Rand SS5 Components

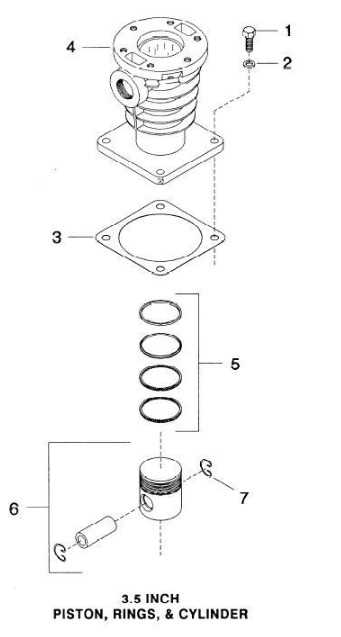

Grasping the various elements of a compressor unit is essential for effective operation and maintenance. Each component plays a pivotal role in ensuring the system functions smoothly and efficiently. Familiarity with these parts not only aids in troubleshooting but also enhances overall performance and longevity of the equipment.

Motor: The motor serves as the driving force, converting electrical energy into mechanical energy. Its efficiency directly impacts the compressor’s output and energy consumption.

Pump: This component is crucial for compressing air. It draws in ambient air and compresses it to a specific pressure, making it available for various applications.

Tank: The storage vessel holds compressed air for immediate use, providing a buffer that helps maintain consistent pressure during operation. The tank’s size affects the system’s capability and run time.

Regulator: This device controls the output pressure, ensuring that the air delivered meets the requirements of connected tools and equipment.

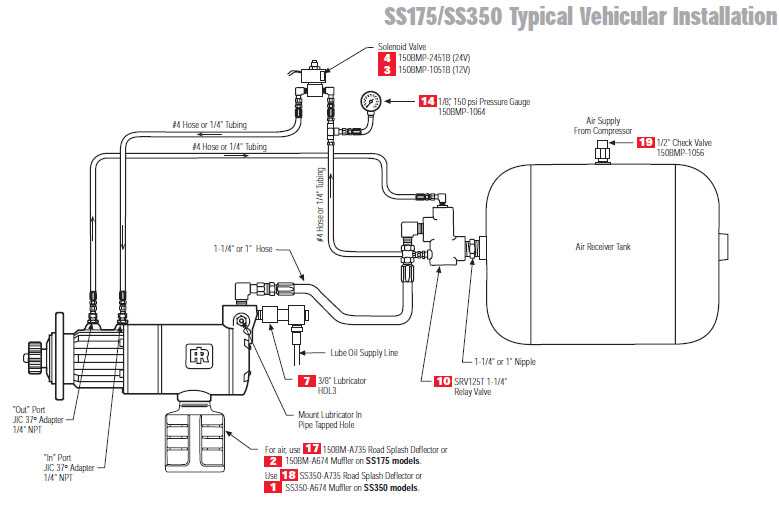

Valves: A series of valves manage the flow of air, directing it as needed and maintaining pressure within the system. Their proper functioning is essential for operational safety and efficiency.

Filters: Air quality is vital for performance. Filters remove contaminants from the intake air, protecting internal components and ensuring clean airflow.

Hoses and Fittings: These are the connectors that facilitate the transfer of compressed air to various tools and equipment, playing a key role in the overall system’s efficiency.

By comprehensively understanding these individual elements, users can optimize performance, ensure safety, and extend the lifespan of their compressor unit.

Key Features of the SS5 Air Compressor

The air compression unit is designed for optimal performance and reliability, catering to a variety of industrial and commercial applications. Its robust construction and innovative technology ensure that users can depend on it for consistent power and efficiency.

Durability: Constructed with high-quality materials, this compressor is built to withstand demanding environments. Its rugged design minimizes wear and tear, leading to a longer lifespan and reduced maintenance needs.

Powerful Output: With a significant horsepower rating, this model delivers an impressive air output, making it suitable for heavy-duty tasks. It effectively meets the needs of various pneumatic tools and equipment.

Ease of Use: The intuitive controls and straightforward setup make operation hassle-free. Users can quickly familiarize themselves with its functions, ensuring a smooth workflow.

Portability: Designed with mobility in mind, this unit features a compact design and convenient wheels. This allows for easy transportation between job sites or within a workspace.

Energy Efficiency: Engineered to optimize power consumption, this compressor helps reduce operational costs. Its efficient performance contributes to lower energy bills while maintaining high output levels.

Versatile Applications: This air compression solution is ideal for a wide range of uses, from automotive repair to construction projects. Its adaptability makes it a valuable asset in various settings.

Importance of Maintenance for SS5 Parts

Regular upkeep is crucial for ensuring the longevity and efficiency of any mechanical system. Neglecting this aspect can lead to performance issues and increased repair costs over time. By focusing on systematic care, operators can enhance reliability and minimize downtime.

Proper maintenance not only extends the lifespan of components but also optimizes overall functionality. This proactive approach helps identify potential problems before they escalate, allowing for timely interventions that save resources and ensure smooth operations.

| Benefit | Description |

|---|---|

| Increased Efficiency | Regular maintenance helps keep systems running at optimal performance levels. |

| Cost Savings | Preventive care reduces the likelihood of major repairs and associated costs. |

| Extended Lifespan | Consistent attention to components can significantly prolong their useful life. |

| Safety | Maintaining equipment reduces the risk of accidents and enhances workplace safety. |

Implementing a routine maintenance schedule is essential for maximizing performance and safeguarding investments. By prioritizing upkeep, users can enjoy the benefits of a well-functioning system for years to come.

Common Issues with Ingersoll Rand SS5

Air compressor systems can encounter a variety of challenges that impact their performance and efficiency. Understanding these common issues is essential for proper maintenance and troubleshooting, ensuring that the equipment operates smoothly and reliably.

- Pressure Problems: Inadequate pressure generation can stem from several factors, including worn-out components, leaks in the air system, or incorrect settings.

- Noise Levels: Excessive noise may indicate mechanical issues, such as loose parts or failing bearings, which require immediate attention to prevent further damage.

- Overheating: High operating temperatures can result from poor ventilation, blocked filters, or malfunctioning cooling systems, leading to reduced efficiency and lifespan.

- Start-up Difficulties: Issues during the initial start can arise from electrical problems, low oil levels, or faulty pressure switches, hindering the compressor’s functionality.

Regular maintenance and prompt attention to these common challenges can significantly enhance the reliability and longevity of the compressor system.

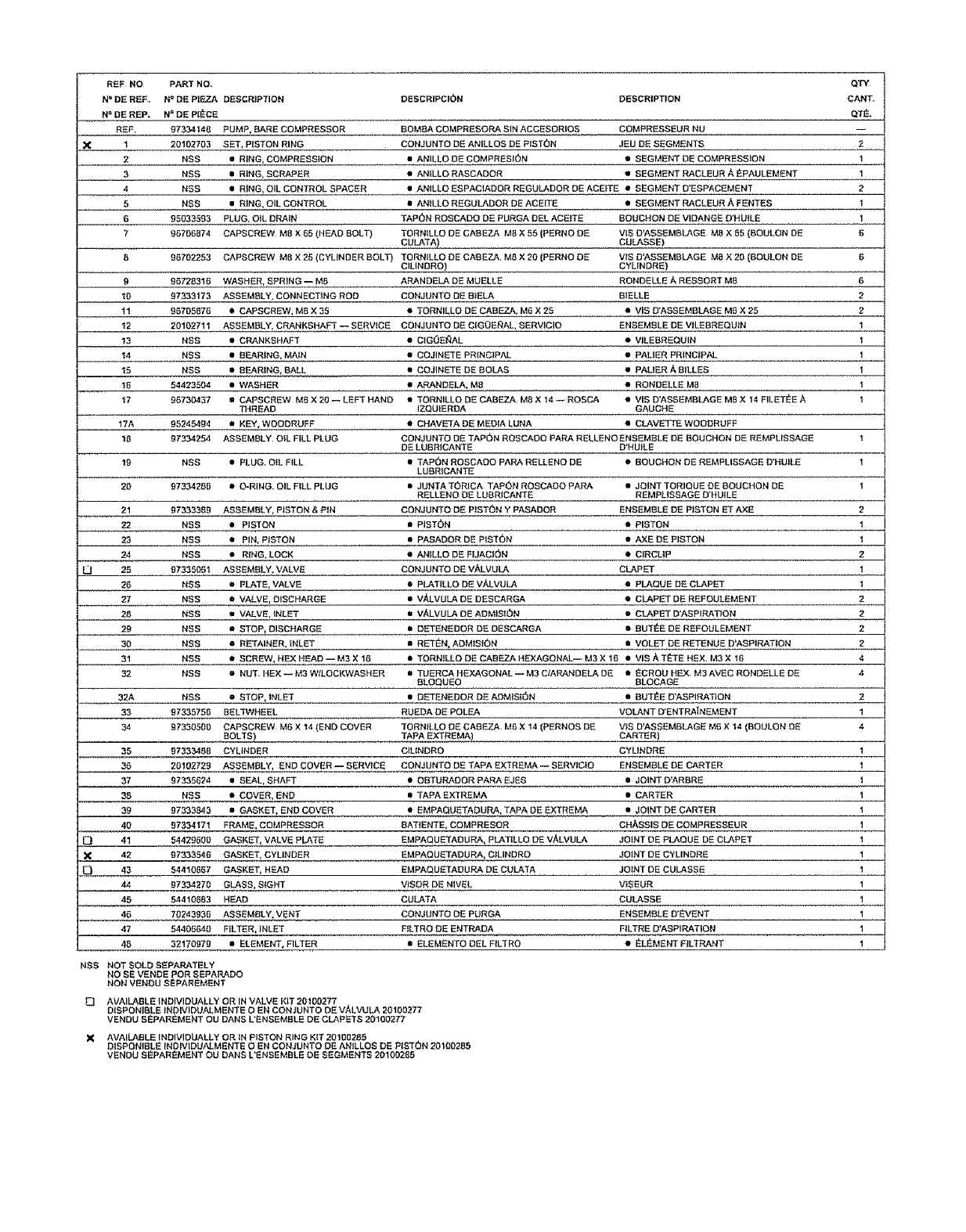

Finding Replacement Parts for SS5

Locating components for your air compressor can be essential for maintaining its efficiency and performance. Understanding where to find these elements and how to identify them will help ensure your machine operates smoothly for years to come.

Where to Look for Components

- Authorized Dealers

- Online Retailers

- Local Repair Shops

- Manufacturer’s Website

Identifying the Right Components

- Refer to the user manual for specific information on required items.

- Check the model number and serial number for accuracy.

- Consult online forums or communities for advice from other users.

- Consider OEM versus aftermarket options based on your needs.

By exploring these avenues and utilizing resources effectively, you can ensure that your equipment remains in optimal working condition.

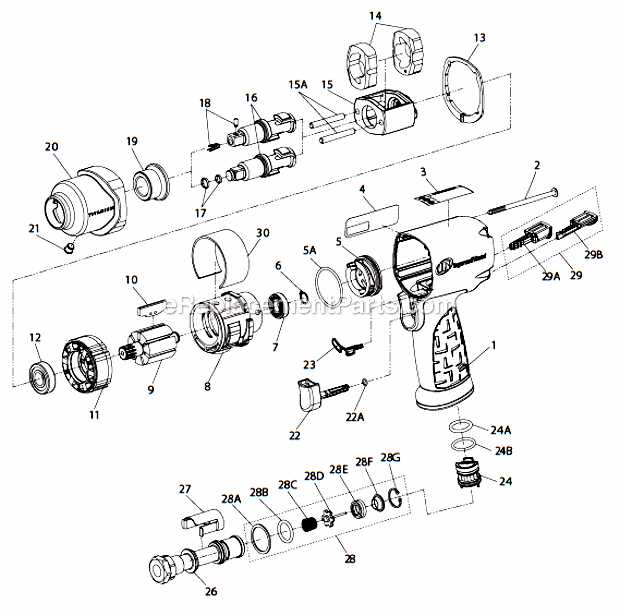

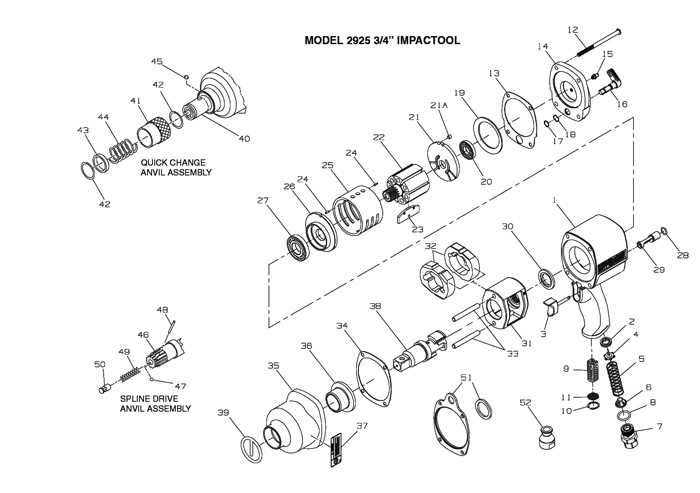

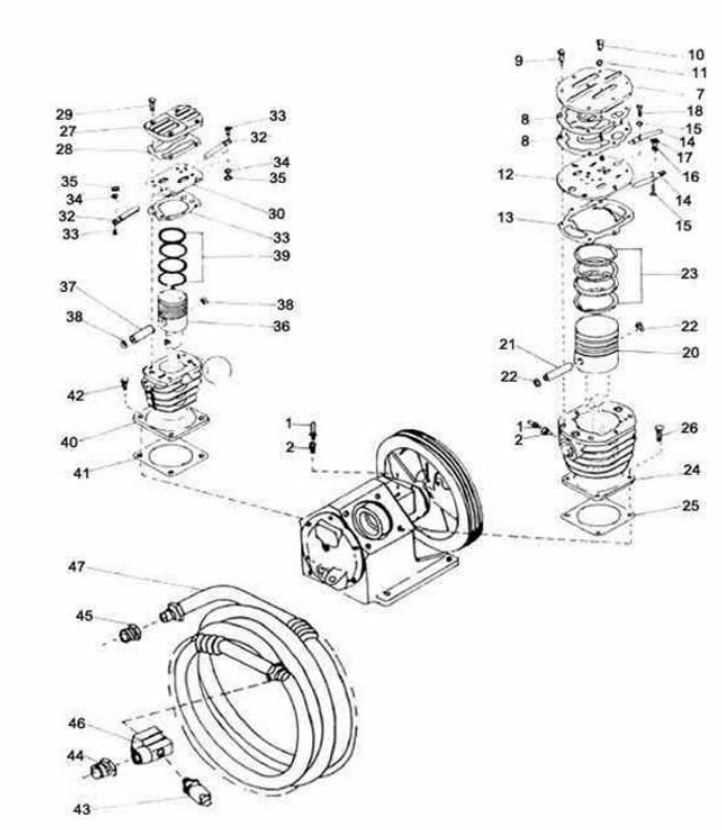

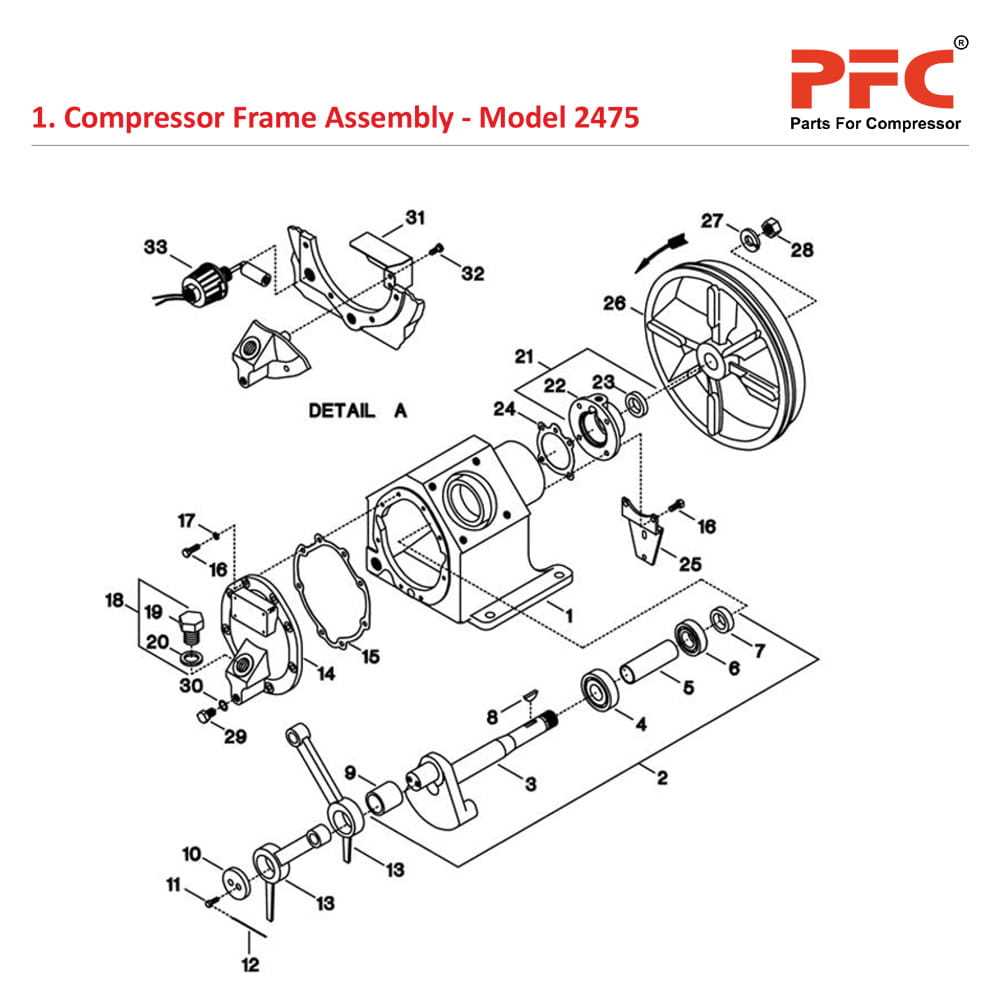

How to Read SS5 Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visual aids provide detailed representations of components, aiding users in identifying and assembling parts accurately.

Key Elements of the Illustrations

- Labels: Clearly indicate each component’s name and function.

- Numbers: Often correspond to a list of components, helping to track parts efficiently.

- Lines: Show connections or relationships between different elements.

Steps to Interpret the Illustrations

- Start by familiarizing yourself with the overall layout.

- Identify and match labeled components to their respective numbers.

- Note the connections to understand how parts interact.

- Refer to any accompanying documentation for additional context.

Upgrading Components of Your SS5

Enhancing the functionality and efficiency of your air compressor can significantly improve performance and longevity. By focusing on key elements, you can ensure that your equipment operates at its ultimate potential. This section explores essential upgrades that can elevate your machine’s capabilities.

Identifying Key Areas for Improvement

Start by assessing the most critical components that may require enhancement. Look for parts that show signs of wear or may not meet your operational demands. Upgrading the motor, for example, can lead to improved power output, while a new pressure switch can enhance safety and control.

Choosing Quality Upgrades

When selecting new components, prioritize quality over cost. Durability and performance should guide your choices. Research reputable manufacturers and consider reviews to find parts that ensure optimal compatibility and reliability, ultimately leading to a more efficient system.

Safety Tips for Using SS5 Compressors

Utilizing air compression equipment can significantly enhance productivity in various tasks, but it also requires careful attention to safety practices. Ensuring proper usage and maintenance not only extends the lifespan of the machinery but also protects users from potential hazards. Adhering to essential safety guidelines is crucial for a smooth operation.

Regular Maintenance Checks

Conducting routine inspections is vital. Regularly check for any signs of wear and tear, leaks, or irregular noises. Keep the area around the compressor clean to prevent accidents caused by clutter. Ensure that all connections are secure and that the equipment is free from any obstructions.

Proper Usage Protocols

Before starting, always review the operating manual to familiarize yourself with specific functions and safety measures. Wear appropriate personal protective equipment such as goggles and ear protection. Ensure the compressor is placed on a stable surface to avoid tipping, and never exceed the recommended pressure limits during operation.

Comparing SS5 with Other Models

This section explores the differences and similarities between a specific compressor model and its counterparts. By examining performance, efficiency, and application suitability, users can make informed choices based on their needs.

Performance Metrics

When analyzing the output capabilities, this model often stands out due to its robust pressure levels and air delivery rates. In contrast, other variants may offer lower performance but excel in energy efficiency, making them ideal for prolonged use.

Application Suitability

The versatility of this compressor allows it to be utilized in various settings, from workshops to industrial environments. However, some alternative models may be specifically designed for niche applications, providing tailored features that enhance functionality for particular tasks.