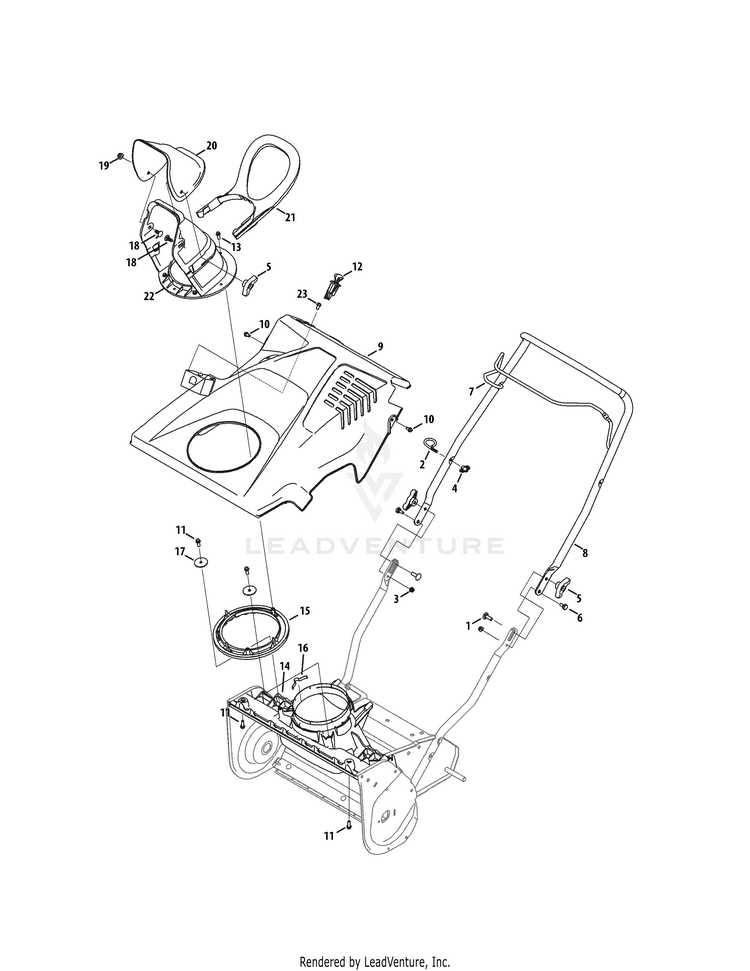

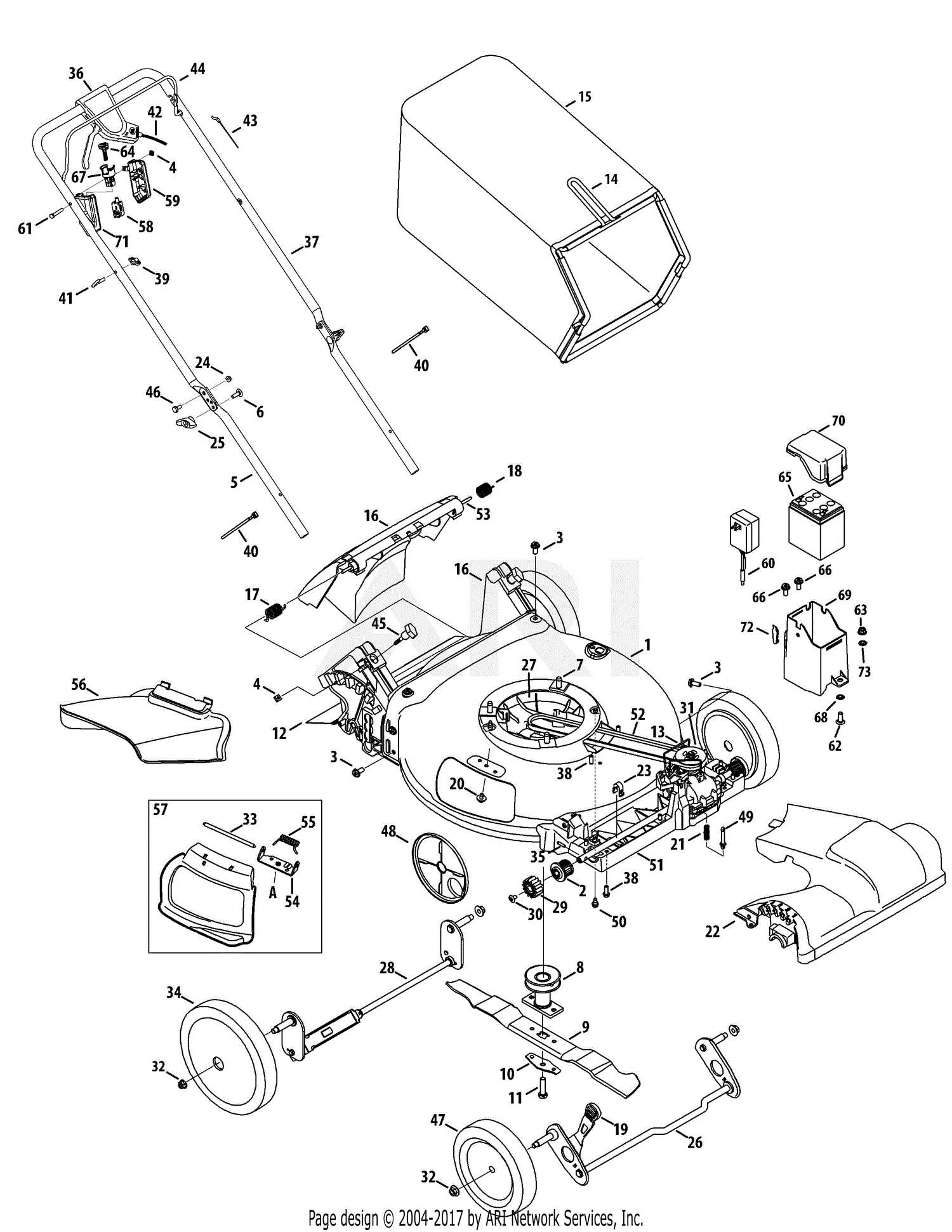

When it comes to maintaining and repairing various tools, having a clear visual representation of their internal structure is essential. Such illustrations help users quickly identify individual elements, ensuring efficient troubleshooting and replacement procedures. Whether you are a seasoned technician or a DIY enthusiast, a comprehensive layout can significantly simplify the repair process.

In this section, we will explore the significance of these visual guides, emphasizing their role in enhancing understanding and facilitating repairs. A well-organized layout allows users to pinpoint specific sections, making it easier to address issues effectively. By familiarizing oneself with the configuration, one can approach repairs with confidence and precision.

Moreover, grasping the arrangement of components not only aids in resolving current problems but also helps prevent future complications. Knowing how each element interacts can lead to better maintenance practices and prolong the life of your equipment. Join us as we delve into the intricacies of these helpful representations and empower your repair endeavors.

Understanding the components and their relationships within a device is crucial for effective maintenance and repairs. Visual representations help users identify specific elements, facilitating quicker troubleshooting and enhancing overall efficiency in handling machinery. Such illustrations serve as invaluable references, especially for individuals who may not be familiar with the technical aspects of the equipment.

Utilizing these visuals can significantly reduce the time spent searching for replacement components or comprehending assembly instructions. Additionally, they promote accuracy in reassembly, minimizing the risk of errors that could lead to further complications.

| Benefits | Description |

|---|---|

| Clarity | Provides a clear view of how each component fits together. |

| Efficiency | Speeds up the repair and maintenance process. |

| Accuracy | Reduces the likelihood of mistakes during reassembly. |

| Resource Management | Helps in identifying necessary replacements and their specifications. |

Common Issues and Solutions

Understanding frequent problems associated with outdoor power equipment can help users maintain optimal performance. Identifying these common challenges enables timely intervention, ensuring that the equipment remains in good working condition.

-

Engine Won’t Start:

This issue may arise due to fuel problems or battery failures. Check the fuel level and ensure it is fresh. If the battery is dead, consider recharging or replacing it.

-

Inconsistent Power:

Uneven power output can be linked to clogged filters or worn-out spark plugs. Regularly inspect and clean the air filter, and replace spark plugs as necessary to maintain steady performance.

-

Excessive Vibration:

Vibrations may indicate loose components or unbalanced parts. Tighten all screws and bolts, and check for any signs of wear on blades or other moving parts.

-

Overheating:

Overheating can occur due to inadequate lubrication or blocked cooling vents. Ensure that the equipment is properly lubricated and that all vents are clear of debris to prevent overheating.

Identifying Replacement Parts

Understanding how to locate and identify components necessary for maintenance is essential for ensuring the optimal performance of your equipment. Each element plays a crucial role in the overall functionality, and recognizing when a part requires replacement can prevent further issues and enhance durability.

Common Signs of Wear and Tear

Frequent indicators that a component needs attention include unusual noises, decreased efficiency, or visible damage. Regular inspection can help you catch these signs early, allowing you to address problems before they escalate. Being proactive in monitoring your equipment can save time and resources in the long run.

Where to Find Information

Consulting user manuals or manufacturer websites can provide detailed descriptions and specifications for various elements. Additionally, engaging with online forums and communities can yield valuable insights from experienced users who have navigated similar issues. Utilizing these resources can greatly assist in pinpointing the right replacements for your specific needs.

Maintenance Tips for RM2510

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns and costly repairs. Here are some valuable suggestions to keep your device in excellent condition.

Firstly, always refer to the manufacturer’s guidelines for maintenance schedules and recommended practices. Regularly check the components for wear and tear, ensuring that everything is functioning smoothly. Cleaning the exterior and interior parts after each use will help prevent dirt buildup, which can impair performance.

Additionally, lubricating moving parts as specified can reduce friction and extend the lifespan of the machinery. Keep an eye on the air filters, as clogged filters can hinder airflow and engine efficiency. Replacing them periodically is crucial for maintaining peak functionality.

Lastly, store the equipment in a dry and secure location when not in use. This practice helps protect against environmental damage and ensures that your device is ready for action whenever you need it.

Where to Find Diagrams

Locating detailed illustrations for equipment components can greatly enhance the repair and maintenance process. Various resources are available online and offline, catering to different needs and preferences. These resources often provide visual guides that simplify the understanding of each part’s functionality and arrangement.

Online Resources: Websites dedicated to machinery or DIY repairs frequently feature comprehensive images and manuals. These platforms may include user forums where individuals share their insights and tips. Searching through manufacturer websites can also yield valuable documentation that includes clear representations of parts.

Printed Manuals: Many retailers offer hard copies of guides alongside the equipment itself. These printed resources often contain annotated visuals that facilitate the identification of specific elements. Additionally, local libraries may house collections of repair manuals, providing an accessible alternative for those seeking information.

Community Support: Engaging with local repair shops or hobbyist groups can be beneficial. Members of these communities often possess personal collections of diagrams and may offer assistance in finding the information you need. Networking with others who share similar interests can lead to valuable exchanges of knowledge and resources.

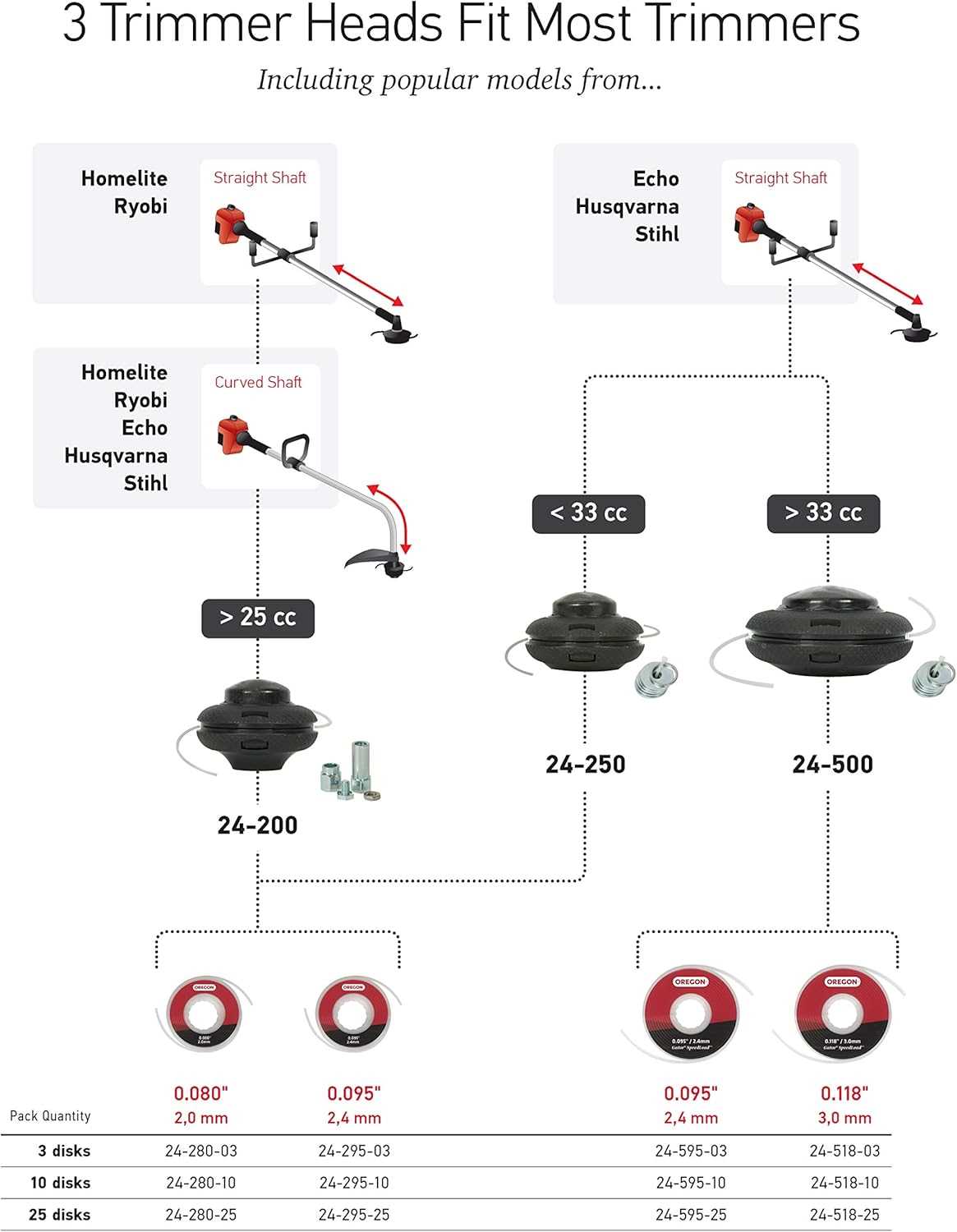

Upgrades and Accessories Available

When it comes to enhancing your equipment, there is a wide range of modifications and attachments that can significantly improve performance and functionality. Investing in quality upgrades can lead to a more efficient and enjoyable experience while using your device.

Performance Enhancements

Several enhancements can boost the capabilities of your equipment:

- Improved cutting blades for cleaner and more precise operations.

- High-capacity fuel tanks for extended run times.

- Enhanced engines for increased power and efficiency.

Useful Accessories

In addition to performance upgrades, various accessories can enhance usability:

- Protective covers to ensure durability and longevity.

- Storage bags for easy transport and organization.

- Custom attachments tailored for specific tasks and requirements.

Customer Reviews and Feedback

This section highlights the insights and opinions of users regarding their experiences with the product. Feedback from customers serves as a valuable resource for potential buyers, offering a glimpse into the reliability and performance of the item in everyday use.

Positive Aspects

- Many users appreciate the efficiency and ease of use, noting that it effectively meets their expectations.

- Customers frequently commend its durable construction, which enhances longevity and performance over time.

- Several reviewers highlight the effective customer support provided, making the purchase experience smoother.

Areas for Improvement

- Some users have reported minor issues with specific components, suggesting a need for better quality control.

- A few reviews mention the absence of certain features that could enhance functionality and user experience.

- There are suggestions for clearer assembly instructions to assist new users in setting up the product.