In the realm of machinery and equipment, comprehending the intricate arrangements of individual elements is essential for optimal functionality and maintenance. Each unit consists of various sections that play pivotal roles in the overall performance, making it crucial for users to grasp how these components interconnect.

Accessing a visual representation of these arrangements can greatly enhance one’s ability to troubleshoot issues and perform repairs effectively. Such illustrations serve as invaluable tools, providing clear insights into how each part fits within the larger assembly, thereby facilitating a deeper understanding of the unit’s operations.

By exploring detailed visual guides, users can not only identify specific elements but also appreciate their contributions to the machinery’s efficiency. This knowledge empowers operators to engage more confidently with their equipment, ensuring longevity and reliability in performance.

Understanding the Ms194t Parts Diagram

Grasping the components of a mechanical assembly is essential for effective maintenance and troubleshooting. By visualizing the layout of individual elements, users can enhance their understanding of how everything functions together. This knowledge is crucial for anyone looking to perform repairs or optimizations efficiently.

The following table highlights key elements found within the assembly, providing a quick reference for their functions and relationships:

| Component Name | Description |

|---|---|

| Handle | Provides control and maneuverability. |

| Engine | Drives the overall functionality of the machine. |

| Fuel Tank | Holds the necessary fuel for operation. |

| Chain | Transfers power to the cutting mechanism. |

| Blade | Performs the primary cutting task. |

By delving into the specifics of each component, users can make informed decisions about maintenance and upgrades, ensuring optimal performance for their equipment.

Key Components of the Ms194t

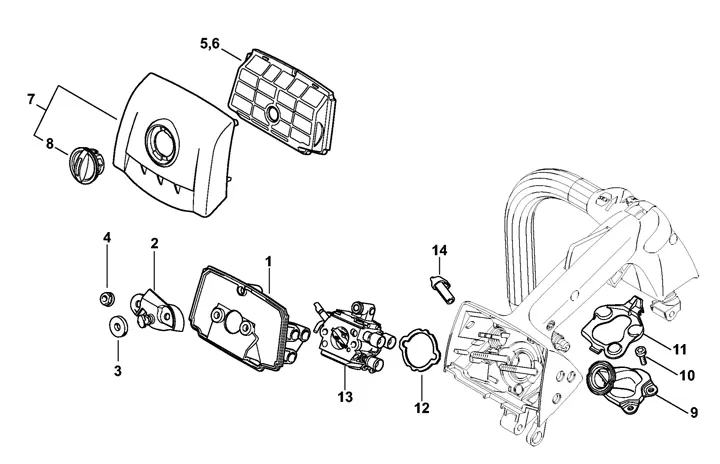

This section explores the essential elements that contribute to the functionality and efficiency of this particular model. Understanding these components is crucial for maintaining optimal performance and ensuring longevity.

Core Elements

Among the primary features are the engine assembly, fuel system, and ignition module. Each plays a vital role in the overall operation, impacting power output and reliability.

Supporting Mechanisms

Additionally, various supporting mechanisms such as the air filtration system and starter assembly enhance the machine’s efficiency and user experience.

| Component | Function |

|---|---|

| Engine Assembly | Generates power for operation |

| Fuel System | Delivers fuel to the engine |

| Ignition Module | Controls the spark for combustion |

| Air Filtration | Prevents debris from entering the engine |

| Starter Assembly | Facilitates initial engine ignition |

How to Read a Parts Diagram

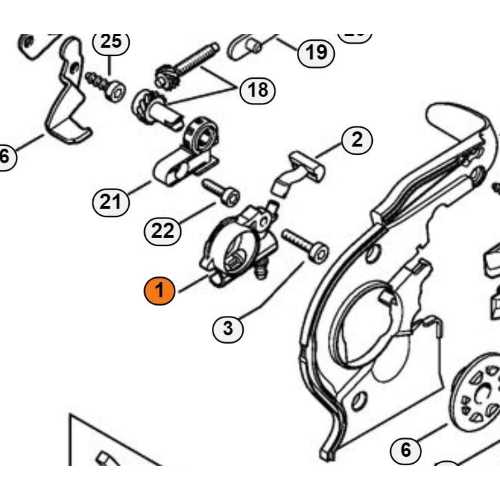

Understanding a schematic representation of components is crucial for effective maintenance and repair. These visual guides provide an organized layout of various elements, allowing users to identify and locate each piece easily. Mastering this skill enhances both troubleshooting and assembly processes.

Familiarizing Yourself with Symbols

Every illustration features unique symbols and notations that represent different components. Take the time to familiarize yourself with these icons, as they convey essential information about each part’s function and connectivity. Key identifiers are often highlighted, making it easier to spot critical elements in the overall layout.

Interpreting the Layout

Once you recognize the symbols, focus on the arrangement of components. The organization usually follows a logical sequence, which can help you understand how each element interacts within the entire system. Pay attention to lines and connections that indicate relationships between parts, as they are vital for proper assembly and troubleshooting.

Common Issues with Ms194t Parts

Many users encounter various challenges when dealing with components of their equipment. Understanding these common problems can lead to effective troubleshooting and maintenance strategies, ultimately enhancing performance and longevity.

One frequent issue is wear and tear, which can affect functionality over time. Components may become less efficient, leading to decreased performance and increased fuel consumption. Regular inspections can help identify these signs early.

Another concern is improper assembly or disassembly, which can cause misalignment or damage. Following manufacturer guidelines during maintenance is crucial to prevent these pitfalls.

Environmental factors also play a significant role. Exposure to harsh conditions can lead to corrosion and degradation, necessitating more frequent replacements. Proper care and storage can mitigate these effects.

Lastly, the availability of quality replacements is essential. Using substandard parts can result in further complications, making it vital to source reliable components to maintain optimal operation.

Replacement Parts: What You Need

When maintaining equipment, knowing what components require substitution is crucial for optimal functionality. Ensuring that you have access to the correct replacements can prevent unexpected downtime and enhance overall performance.

Identifying Essential Components

Begin by assessing the various elements that may need upgrading or replacement. Familiarity with the specifications of your device will help streamline the selection process, ensuring that you acquire the most suitable items for your needs.

Where to Source Quality Replacements

Quality matters when sourcing substitutes. Look for reputable suppliers that offer a wide range of options, along with detailed descriptions to aid your decision-making. Prioritize durability and compatibility to guarantee that your equipment runs smoothly for the long term.

Benefits of Using Original Parts

Utilizing authentic components in any machinery ensures optimal performance and longevity. These original pieces are specifically designed to fit seamlessly, enhancing the overall functionality of the equipment. By choosing genuine replacements, users can maintain the integrity of their systems, avoiding issues that might arise from using inferior alternatives.

One of the primary advantages is the assurance of quality. Original components undergo rigorous testing and adhere to strict manufacturing standards, which significantly reduces the risk of malfunction. This reliability translates into fewer breakdowns, saving both time and money in the long run.

Moreover, employing authentic elements often contributes to warranty preservation. Many manufacturers stipulate that only original components should be used; failing to do so can void warranties. Therefore, investing in genuine replacements not only protects the machinery but also safeguards the owner’s financial investment.

Lastly, using authentic parts fosters better resale value. Prospective buyers often look for well-maintained equipment, and the presence of original components can serve as a testament to proper care and attention. This consideration can be crucial for those looking to upgrade or sell their machinery in the future.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. Implementing a routine maintenance schedule can significantly enhance performance and lifespan, ultimately saving you time and resources in the long run.

Regular Inspections: Conduct frequent assessments to identify any wear or damage. Addressing issues early can prevent costly repairs and downtime.

Cleanliness: Keep your machinery clean to prevent the buildup of debris and contaminants. A clean environment promotes efficient operation.

Lubrication: Use appropriate lubricants for moving parts to reduce friction and wear. This simple step can drastically improve functionality.

Storage Conditions: Store equipment in a controlled environment to protect it from extreme temperatures and moisture, which can lead to deterioration.

Training: Ensure that all operators are well-trained in proper handling techniques to minimize the risk of damage during use.

Where to Find Parts Online

In today’s digital age, locating components for various machinery has become more convenient than ever. Whether you’re a seasoned technician or a casual DIY enthusiast, the internet offers a wealth of resources to help you source the necessary elements for your projects.

Online Marketplaces: Major platforms such as eBay and Amazon provide extensive listings of components from various sellers. These marketplaces allow users to compare prices and find both new and used items, often with customer reviews to guide your purchasing decision.

Specialized Retailers: Numerous websites specialize in specific types of equipment and their associated items. These retailers often carry a wider selection than general marketplaces and may offer expert advice, making them a valuable resource for precise needs.

Manufacturer Websites: Many manufacturers maintain online stores where you can purchase original components directly. This option ensures quality and compatibility, providing peace of mind when selecting what you need.

Forums and Online Communities: Engaging with online forums dedicated to your field can yield recommendations and insights from fellow enthusiasts and professionals. Members often share their experiences and can direct you to trustworthy vendors.

Social Media and Local Groups: Platforms like Facebook and Instagram have groups and pages where users buy, sell, or trade components. This grassroots approach can lead to finding rare items or making local connections for easier transactions.

By exploring these avenues, you can enhance your chances of successfully acquiring the necessary items for your projects, ensuring a smooth and efficient process.

Expert Recommendations for Ms194t Owners

Owning a high-performance tool requires not only understanding its functionality but also ensuring its longevity and optimal performance. Expert insights can greatly enhance your experience, providing essential tips for maintenance and usage. Implementing these strategies will help you maximize efficiency and extend the life of your equipment.

Regular Maintenance Practices

Routine inspections are crucial for identifying potential issues before they escalate. Pay close attention to wear and tear, particularly on components that undergo frequent use. Keeping your device clean and free from debris is essential; a clean machine operates more effectively and safely. Additionally, always refer to the manufacturer’s guidelines for specific maintenance schedules to ensure you’re performing the necessary checks.

Usage Tips for Enhanced Performance

To achieve the best results, familiarize yourself with the tool’s operational limits. Overworking the machine can lead to premature failure, so it’s wise to work within its designed capacities. Utilizing the correct accessories and attachments will also enhance functionality and improve the quality of your tasks. Lastly, storing your equipment in a dry, cool place will help prevent damage from moisture and extreme temperatures, ensuring it remains in peak condition.