When it comes to maintaining outdoor machinery, having a clear understanding of its components is essential for optimal performance and longevity. This section delves into the intricate details of specific models, offering insights into how various elements function together. By familiarizing yourself with these aspects, you can ensure that your equipment remains in peak condition throughout its lifespan.

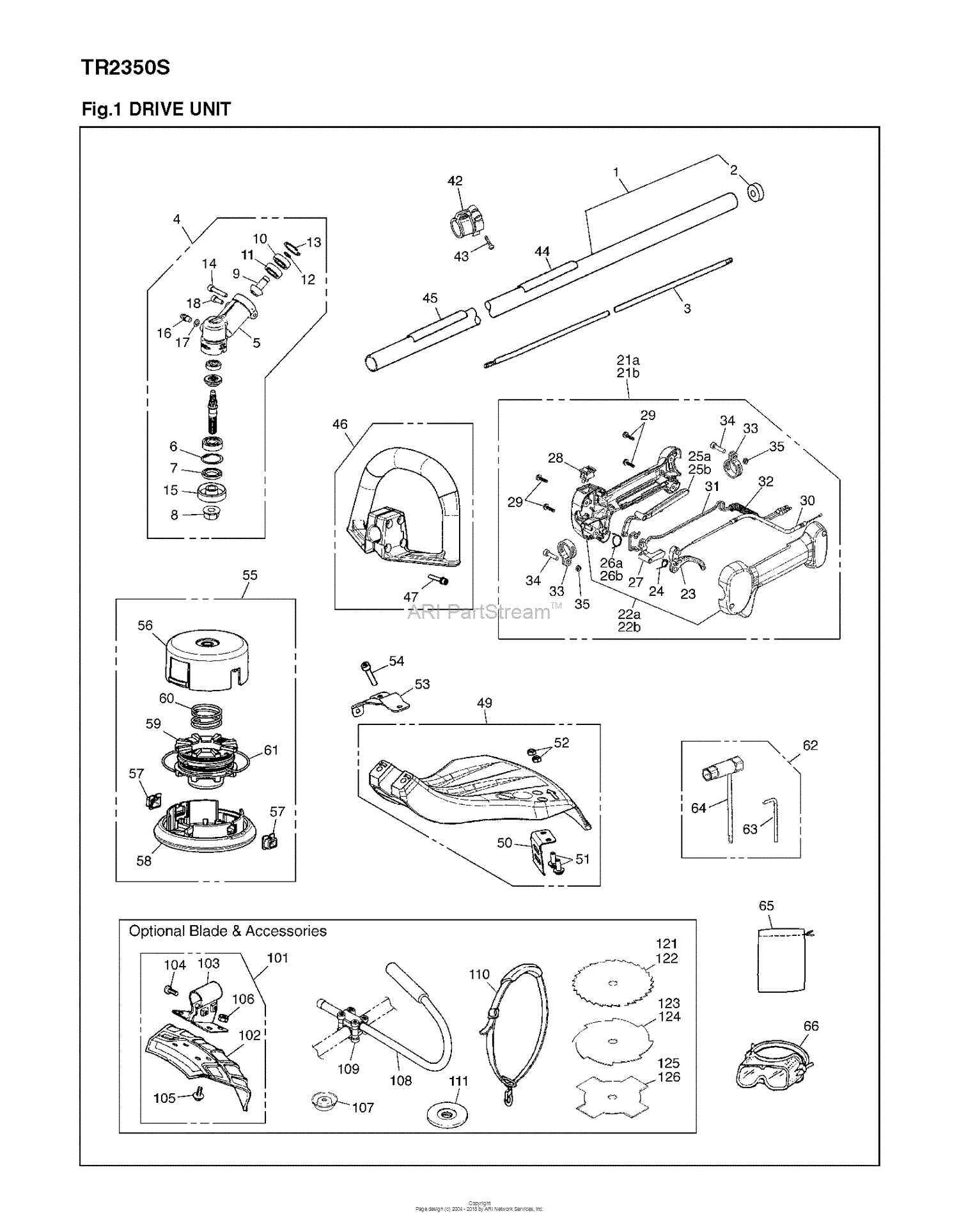

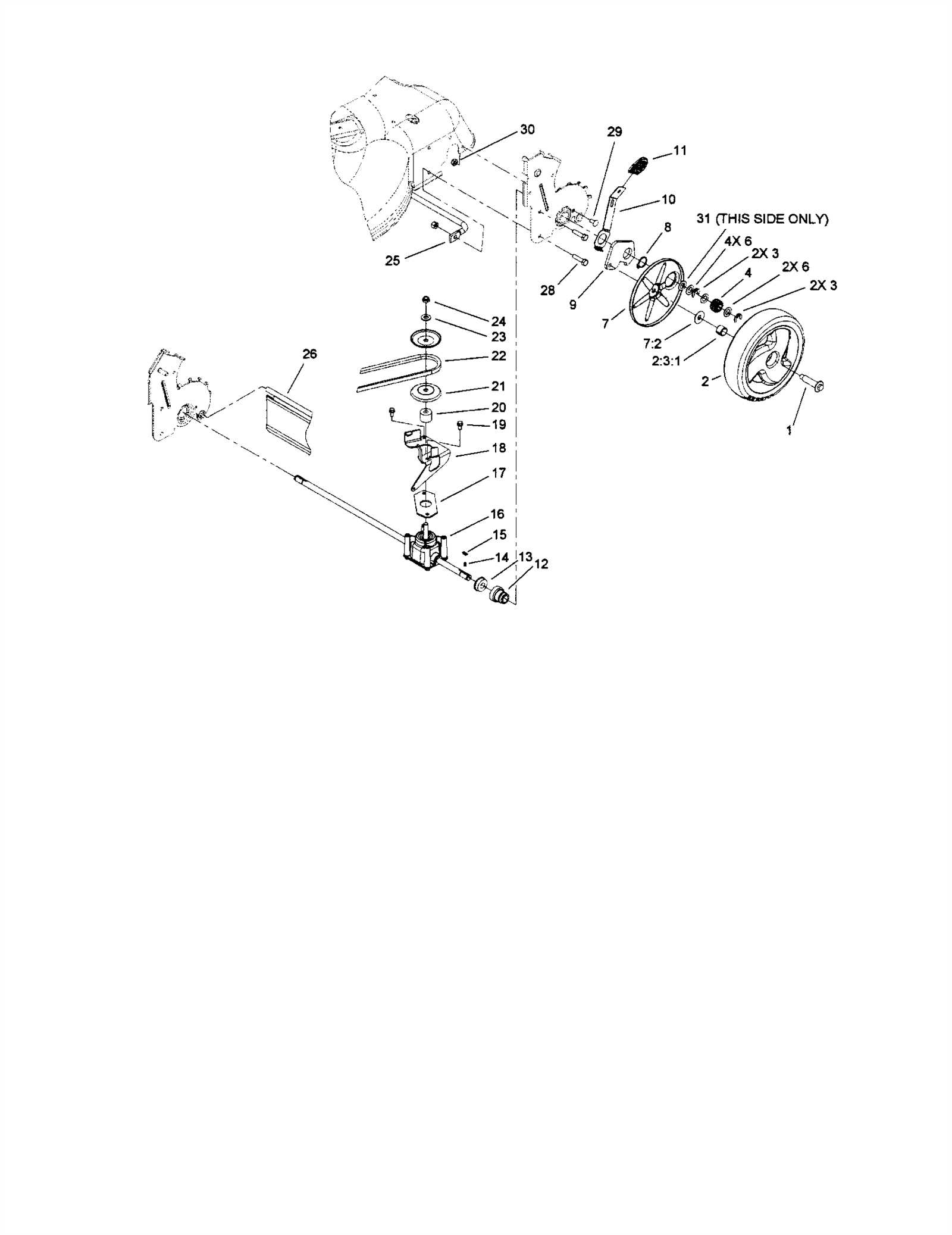

Visual representations play a crucial role in grasping the relationships between different elements of your machinery. They provide clarity and aid in identifying individual parts, making the maintenance process more intuitive. As we explore the layout and arrangement of these components, you’ll gain a deeper appreciation for the engineering behind your equipment.

Furthermore, understanding the configuration of each element can significantly enhance your troubleshooting skills. Whether you’re facing minor issues or preparing for comprehensive repairs, a thorough knowledge of the structure will empower you to take informed actions. This journey into the inner workings of your machinery not only simplifies maintenance but also fosters a stronger connection with your tools.

Understanding the Redmax GZ23N Model

This section delves into the intricacies of a particular outdoor power tool, focusing on its components and their functionalities. By exploring the structure and operation of this model, users can gain valuable insights into its efficient use and maintenance. A comprehensive understanding of the machine not only enhances performance but also prolongs its lifespan.

The following table outlines key elements of the tool, providing a clearer picture of its assembly and the role each part plays in overall operation:

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for generating power. |

| Fuel Tank | Stores the fuel necessary for engine operation. |

| Air Filter | Prevents debris from entering the engine, ensuring optimal performance. |

| Throttle Control | Regulates engine speed and power output based on user input. |

| Cutting Head | Equipped with a trimmer line or blade for effective cutting. |

| Handle | Provides user control and stability during operation. |

By familiarizing oneself with these essential components, operators can effectively troubleshoot and maintain the tool, ensuring reliable performance in various outdoor tasks.

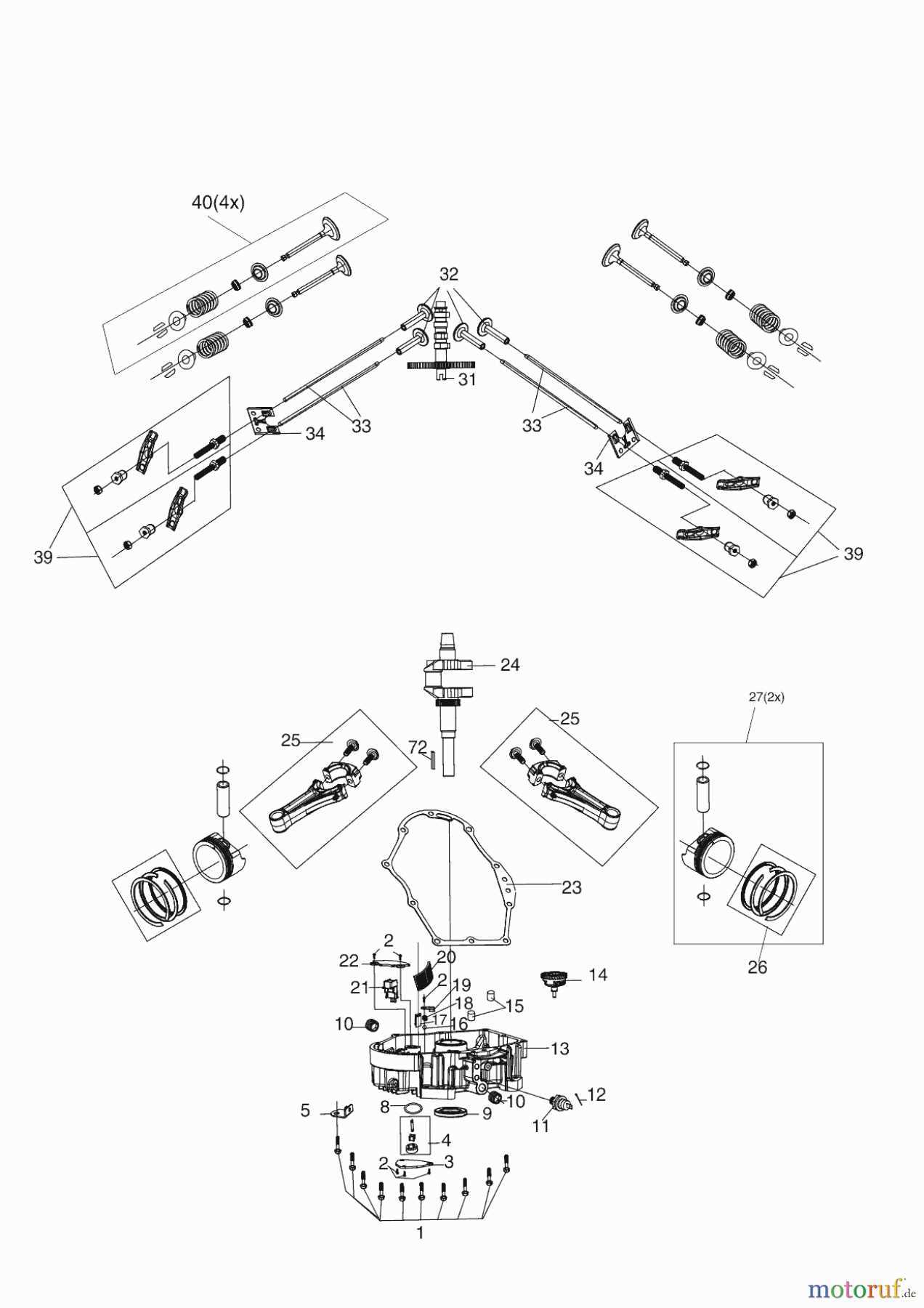

Essential Components of the GZ23N

The efficient operation of any machinery relies heavily on its fundamental elements. Each component plays a crucial role in ensuring smooth functionality and optimal performance. Understanding these vital parts helps in maintenance, troubleshooting, and enhancing the overall user experience.

Main Elements

Among the key components are the engine, which serves as the powerhouse, generating the necessary energy for operation. The fuel system, including filters and lines, ensures that the engine receives clean fuel, enhancing efficiency. Additionally, the ignition system is pivotal for starting the engine reliably, while the cooling system prevents overheating during extended use.

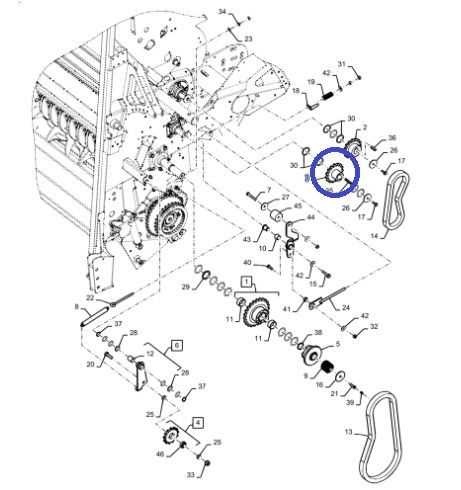

Supporting Structures

Supporting elements like the frame provide stability and durability, allowing for effective handling and maneuverability. The drive mechanism, responsible for transferring power to the operational parts, is equally important. Lastly, control handles and safety features are essential for user comfort and protection during operation, ensuring a seamless and safe experience.

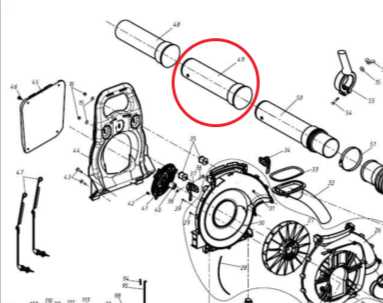

How to Interpret Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visual guides provide a clear representation of components, helping users identify and locate each item within a system. Mastering the art of reading these visuals can streamline the process of assembly or troubleshooting.

Here are key elements to focus on when analyzing these illustrations:

- Labels: Look for clearly marked identifiers that denote each piece. These are often accompanied by numbers or letters that correspond to a list.

- Groupings: Observe how components are clustered together. This often indicates their functional relationships or assembly order.

- Connections: Pay attention to lines or arrows that suggest how elements interact or fit together. This helps in visualizing the assembly process.

When reviewing these visuals, consider the following steps to enhance your understanding:

- Familiarize Yourself: Take time to study the layout and key features before diving into specifics.

- Cross-Reference: Use the accompanying list to match visual elements with their descriptions or part numbers.

- Practice: Regularly engaging with different representations will improve your ability to quickly identify components.

By applying these strategies, you can effectively navigate and utilize technical illustrations, leading to more efficient maintenance and repair tasks.

Common Issues with Redmax Equipment

Equipment used for landscaping and maintenance often encounters various challenges that can affect performance and longevity. Understanding these common issues can help users troubleshoot effectively and maintain optimal operation.

- Fuel System Problems:

- Clogs in fuel lines

- Contaminated fuel

- Fuel filter blockage

- Starting Difficulties:

- Weak spark plug

- Battery issues in electric models

- Choke malfunctions

- Mechanical Failures:

- Worn-out bearings

- Loose components

- Misalignment of moving parts

- Overheating:

- Insufficient lubrication

- Blocked air intake

- Faulty cooling systems

- Performance Issues:

- Loss of power

- Excessive vibration

- Poor cutting efficiency

By being aware of these potential issues, operators can take proactive measures to ensure their equipment remains in top condition, ultimately enhancing productivity and reducing downtime.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires regular upkeep and attention to detail. By following a few essential practices, you can significantly enhance performance and reliability over time.

1. Regular Cleaning: Keeping the machinery free from dirt and debris is crucial. Regularly wipe down surfaces and remove any buildup that could affect functionality.

2. Lubrication: Proper lubrication is vital for moving parts. Use the recommended oils or greases to reduce friction and wear, ensuring smoother operation.

3. Inspection: Periodic checks for wear and tear are essential. Look for signs of damage or loose components, and address issues promptly to avoid more significant problems later.

4. Filter Maintenance: If applicable, clean or replace filters regularly. Clogged filters can hinder performance and lead to overheating, so maintaining airflow is key.

5. Fuel Quality: Always use high-quality fuel and store it properly. Contaminated or old fuel can cause starting issues and reduce efficiency.

6. Seasonal Care: Prepare your equipment for seasonal changes. In colder months, ensure that any necessary winterization steps are taken to prevent damage from freezing temperatures.

By incorporating these maintenance tips into your routine, you can ensure that your equipment remains reliable and efficient for years to come.

Finding Replacement Parts Easily

Locating suitable components for your equipment can streamline repairs and enhance performance. Understanding where to search and how to identify the right items is essential for efficient maintenance.

Begin by consulting the user manual, which often includes crucial information about compatible elements. Online retailers and specialized websites frequently provide comprehensive inventories, making it easier to locate necessary components.

Additionally, joining forums or communities related to your equipment can offer valuable insights and recommendations from experienced users. Sharing knowledge with others can lead to discovering rare or hard-to-find items.

Lastly, consider local dealers or service centers, as they might have stock on hand and can assist in finding the exact replacements you need. Efficient sourcing can save both time and money in the long run.

Comparing Redmax with Competitors

In the world of outdoor power equipment, numerous brands vie for consumer attention by offering unique features and performance capabilities. This section delves into the strengths and weaknesses of one prominent manufacturer compared to its rivals, highlighting aspects such as durability, efficiency, and user satisfaction.

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Durability | High | Medium | High |

| Fuel Efficiency | Good | Excellent | Average |

| Weight | Light | Heavy | Medium |

| User Satisfaction | 85% | 78% | 90% |

By examining these factors, consumers can make informed decisions based on their specific needs and preferences, ensuring they choose equipment that best aligns with their expectations for performance and reliability.

Expert Reviews of the GZ23N

When it comes to evaluating high-performance tools in the landscaping sector, expert opinions provide invaluable insights. These assessments often focus on durability, efficiency, and overall user satisfaction. Understanding the strengths and weaknesses of a particular model can guide potential buyers in making informed decisions.

Performance is frequently highlighted as a key aspect in reviews. Experts note that this model delivers exceptional power, making it suitable for various tasks, from heavy-duty trimming to precise edging. The engine’s responsiveness and reliability under load are often praised, ensuring that users can complete their work effectively without frequent interruptions.

Another important factor discussed is ergonomics. Many reviewers emphasize the comfort of the handle design and the overall weight distribution. A well-balanced tool reduces fatigue during prolonged use, which is essential for professionals and enthusiasts alike. This ergonomic consideration enhances productivity and contributes to a better overall experience.

Additionally, maintenance is a recurring theme in expert evaluations. Many reviewers appreciate the ease with which routine upkeep can be performed, noting that straightforward maintenance procedures contribute to the longevity of the equipment. This aspect is particularly significant for those who rely on their tools daily, as it minimizes downtime.

In summary, expert reviews highlight performance, ergonomics, and maintenance as critical factors when assessing this particular model. These insights can help prospective buyers understand what to expect and ensure they select a tool that meets their specific needs.

Resources for Further Research

For those looking to deepen their understanding of equipment maintenance and repair, a variety of valuable resources are available. Exploring these materials can enhance knowledge and provide essential insights into best practices and troubleshooting techniques.

Online Forums and Communities

Engaging with online forums dedicated to machinery enthusiasts offers a wealth of shared experiences and solutions. These platforms enable users to ask questions, share advice, and learn from others who have faced similar challenges.

Technical Manuals and Guides

Accessing comprehensive manuals and user guides is crucial for mastering operational intricacies. These documents often contain detailed instructions, specifications, and maintenance tips that can significantly improve proficiency and efficiency.